When it comes to maintaining the performance and longevity of your marine engine, understanding its intricate workings is crucial. This section delves into the key aspects of servicing, troubleshooting, and optimizing a popular two-stroke outboard model, ensuring you have the knowledge to keep it in peak condition.

In this guide, you will discover comprehensive instructions on various procedures, from routine inspections to more advanced diagnostic techniques. Whether you are a seasoned technician or a passionate enthusiast, this resource aims to equip you with the necessary skills to address common challenges and enhance your engine’s efficiency.

Furthermore, the emphasis is placed on practical tips and detailed descriptions that can simplify complex tasks. By following this structured approach, you will not only gain confidence in handling maintenance tasks but also foster a deeper appreciation for the engineering marvels that power your aquatic adventures.

Overview of Johnson 60 VRO Engine

This section provides an insightful look into a well-regarded marine power unit known for its reliability and performance on the water. This engine has become a popular choice among boating enthusiasts, thanks to its innovative design and ease of use. Understanding its features and specifications is essential for anyone looking to maintain or enhance their aquatic experience.

| Feature | Description |

|---|---|

| Cylinders | Two-stroke, in-line configuration for optimal power delivery. |

| Horsepower | 60 HP, providing ample thrust for various watercraft. |

| Fuel System | Advanced fuel mixing technology for efficient combustion. |

| Weight | Approximately 160 lbs, balancing power with manageable handling. |

| Cooling System | Water-cooled, ensuring optimal operating temperatures during use. |

Overall, this engine exemplifies a harmonious blend of technology and engineering, making it a standout option for both casual and competitive boating. Understanding its components can greatly enhance the user experience, ensuring longevity and performance on the water.

Common Issues with Johnson 60 VRO

When operating marine engines, certain problems frequently arise that can impact performance and reliability. Understanding these common challenges can help in diagnosing issues promptly and effectively.

- Fuel Delivery Problems:

- Clogged filters leading to reduced flow.

- Faulty pumps causing inconsistent supply.

- Overheating:

- Insufficient coolant circulation due to blockages.

- Worn-out thermostats affecting temperature regulation.

- Electrical Failures:

- Corroded connections interrupting power flow.

- Defective ignition components resulting in misfires.

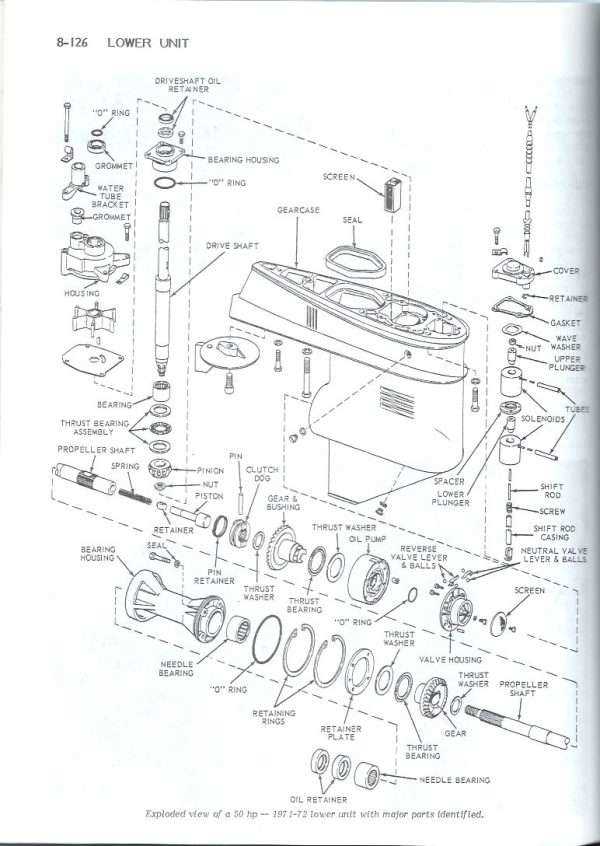

- Gearbox Issues:

- Worn gears causing slipping or rough operation.

- Insufficient lubrication leading to excessive wear.

By addressing these issues early, users can ensure smoother operation and extend the lifespan of their equipment.

Importance of a Repair Manual

Having access to a comprehensive guide is essential for anyone looking to maintain or troubleshoot their machinery. Such resources provide detailed instructions, ensuring that users can address issues efficiently and safely. The clarity and organization of these guides greatly enhance the user experience, leading to better outcomes in maintenance and restoration tasks.

Detailed Instructions are vital for understanding complex systems. These documents break down intricate processes into manageable steps, reducing the likelihood of errors. Users can follow clear guidelines, which fosters confidence in performing repairs or routine checks.

Safety Considerations cannot be overstated. A well-structured guide outlines necessary precautions, helping to prevent accidents. Knowledge of proper procedures protects both the individual and the equipment, contributing to a safer working environment.

Furthermore, time efficiency is a significant advantage. When users have a reliable reference, they can quickly identify problems and apply solutions, minimizing downtime. This is particularly important in professional settings where time directly correlates with productivity and cost.

In summary, the availability of an informative guide is crucial for effective maintenance and troubleshooting. It empowers users with the knowledge they need, enhances safety, and improves efficiency, making it an invaluable resource for any operator.

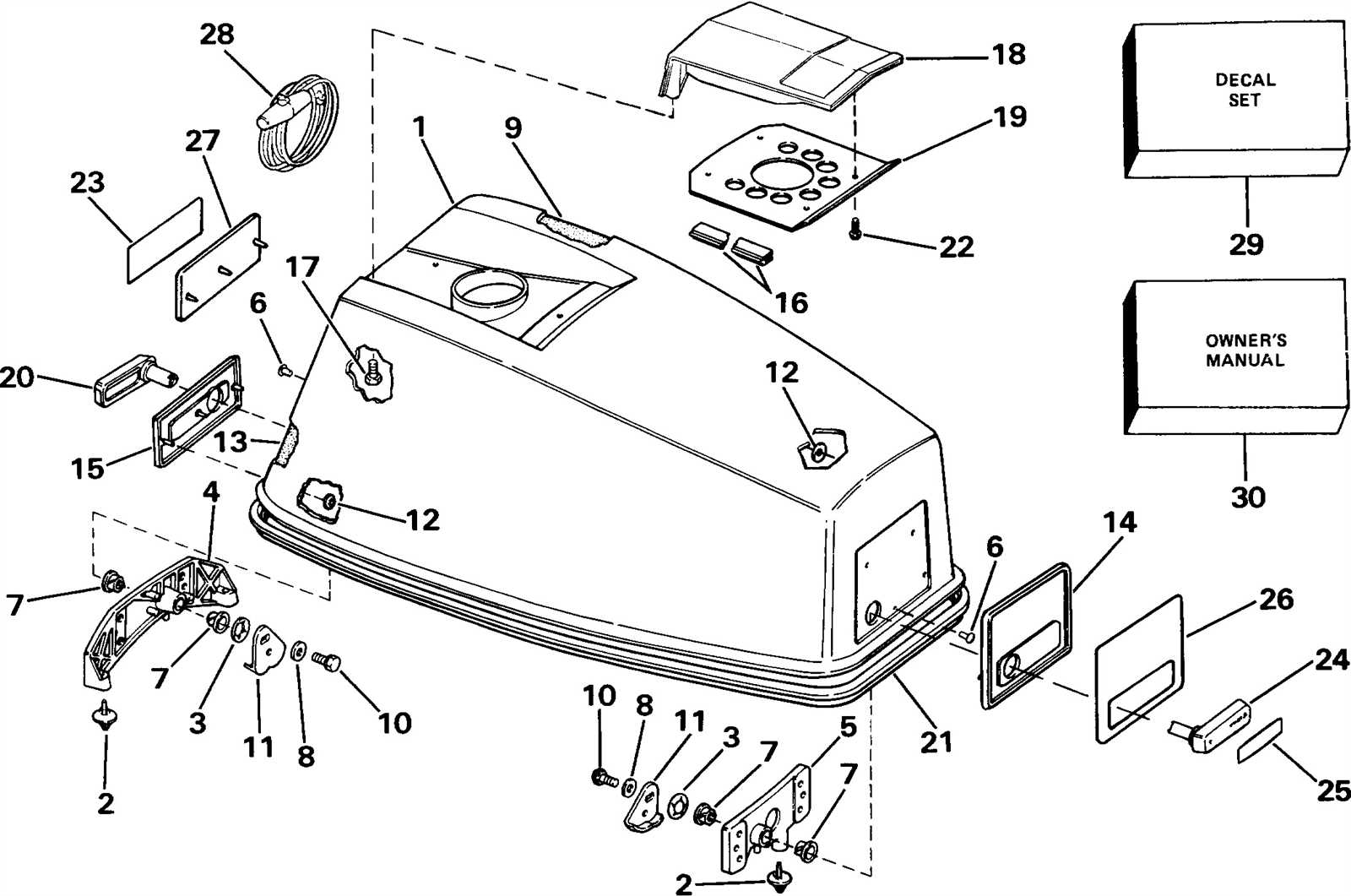

Step-by-Step Repair Procedures

This section outlines a systematic approach to troubleshooting and fixing common issues associated with outboard engines. Following a structured process can ensure that problems are addressed efficiently, minimizing downtime and enhancing performance.

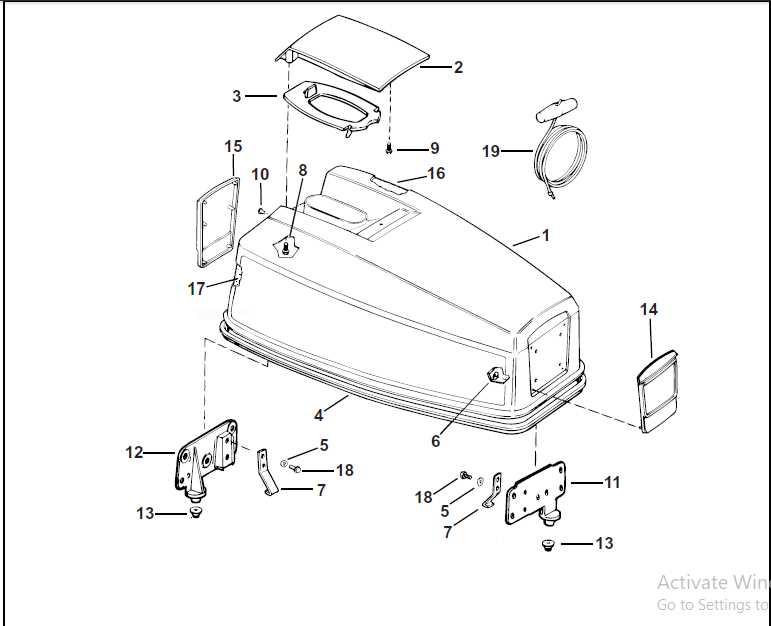

Preparation

- Gather necessary tools and materials.

- Review safety precautions to ensure a safe working environment.

- Consult reference guides for specific engine details.

Troubleshooting Steps

- Identify the symptoms of the issue.

- Perform a visual inspection for obvious signs of wear or damage.

- Check fuel and oil levels, ensuring they meet recommended standards.

- Test electrical connections for continuity and secure fittings.

- Run diagnostic checks using appropriate equipment.

- Address any identified issues, replacing parts as necessary.

- Reassemble components and ensure everything is securely in place.

- Conduct a final test to confirm that the engine operates smoothly.

Following these steps methodically will help in restoring the functionality of the engine effectively.

Tools Required for Johnson 60 Repair

Ensuring proper maintenance and troubleshooting of your marine engine requires specific instruments and equipment. Having the right tools at hand not only facilitates the process but also enhances efficiency and safety during work.

Some essential instruments include wrenches for loosening and tightening bolts, screwdrivers for adjusting various components, and pliers for gripping and manipulating parts. Additionally, multimeters are invaluable for diagnosing electrical issues, while socket sets provide versatility for different fasteners.

It is also advisable to have gaskets, seals, and other replacement parts ready, as these often wear out over time. For safety, a first aid kit should always be accessible, along with personal protective equipment like gloves and goggles. Finally, a service manual can serve as a vital reference to guide you through specific procedures and specifications.

Maintenance Tips for Longevity

Ensuring the durability and reliability of your equipment requires consistent care and attention. Implementing routine practices can significantly enhance performance and extend the lifespan of your machinery. Adopting these strategies will help you achieve optimal functionality and prevent unnecessary issues.

Regular Inspections: Conduct periodic checks to identify any signs of wear or damage. Early detection of potential problems can save time and resources in the long run.

Proper Cleaning: Keep the components clean to prevent the buildup of debris and corrosion. Use suitable cleaning agents that won’t harm the surfaces.

Fluid Checks: Monitor and maintain fluid levels consistently. Regularly changing oils and lubricants ensures smooth operation and reduces friction.

Storage Practices: When not in use, store the equipment in a dry and secure environment. Protecting it from harsh weather conditions can prevent premature deterioration.

Follow Guidelines: Adhere to the manufacturer’s recommendations for maintenance intervals and procedures. This adherence fosters a better understanding of specific needs and requirements.

By integrating these essential practices into your routine, you can maximize the efficiency and lifespan of your machinery, ensuring reliable performance for years to come.

Replacing the VRO Pump

Maintaining optimal performance in marine engines often requires the timely replacement of essential components. One critical part of the fuel delivery system is responsible for mixing fuel and oil in the correct ratio, ensuring the engine runs smoothly and efficiently. When this component malfunctions, it can lead to serious engine issues, making replacement necessary for reliable operation.

Signs of a Failing Component

Before proceeding with the replacement, it’s important to identify the symptoms indicating that this component needs attention. Common signs include:

| Symptoms | Description |

|---|---|

| Inconsistent Engine Performance | Unstable idling or unexpected stalling. |

| Oil Leaks | Visible oil pooling around the engine. |

| Excessive Smoke | Noticeable smoke emissions during operation. |

Replacement Process

To replace the component effectively, follow these steps:

- Disconnect the power supply and remove any necessary covers.

- Carefully detach the failing unit from its mounting.

- Install the new unit, ensuring secure connections to fuel and oil lines.

- Reconnect the power supply and test for leaks before operating the engine.

Regular checks and timely replacement of this component are essential for maintaining engine health and performance.

Troubleshooting Fuel System Problems

Fuel system issues can significantly impact engine performance, leading to inefficient operation or complete failure. Identifying the root cause of these problems is essential for restoring optimal functionality. Common symptoms include poor acceleration, stalling, and irregular idling, which often indicate that attention is needed in the fuel delivery mechanism.

Identifying Symptoms

Begin by observing the behavior of the engine. If it struggles to start or exhibits a rough idle, it may be indicative of fuel flow disruptions. Additionally, unusual noises from the fuel pump or a decrease in fuel pressure can further signal underlying issues. Check for any warning lights on the dashboard, as these can provide valuable diagnostic information.

Common Issues and Solutions

Clogged Fuel Filters: A frequent cause of fuel flow problems is a blocked filter. Regularly inspect and replace the fuel filter to ensure unobstructed fuel delivery.

Faulty Fuel Pump: If the pump is not functioning correctly, it can lead to inadequate fuel supply. Testing the pump’s pressure can help determine its condition. If it fails to meet specifications, replacement may be necessary.

By systematically addressing these areas, one can effectively resolve fuel system malfunctions and restore engine performance to expected levels.

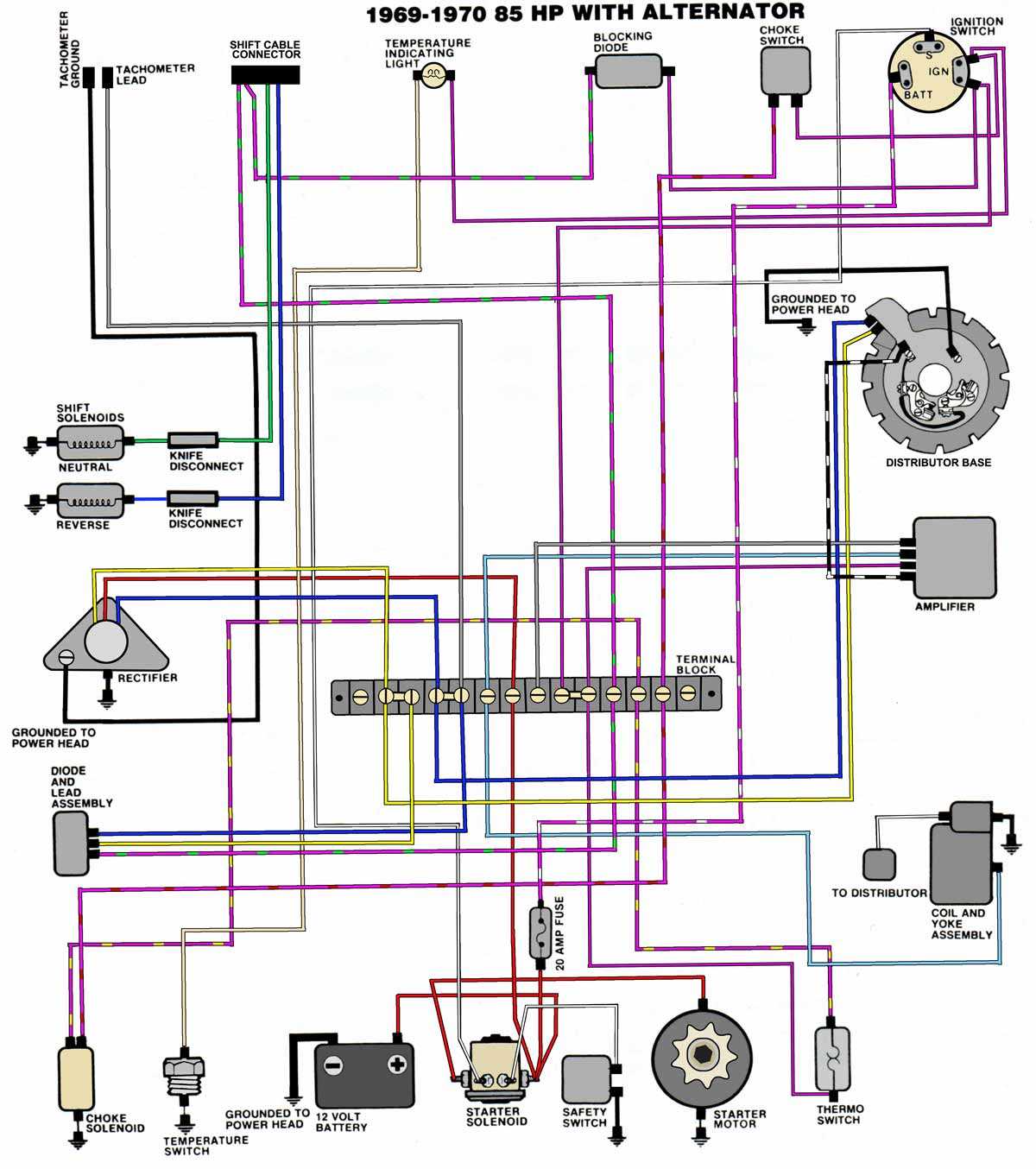

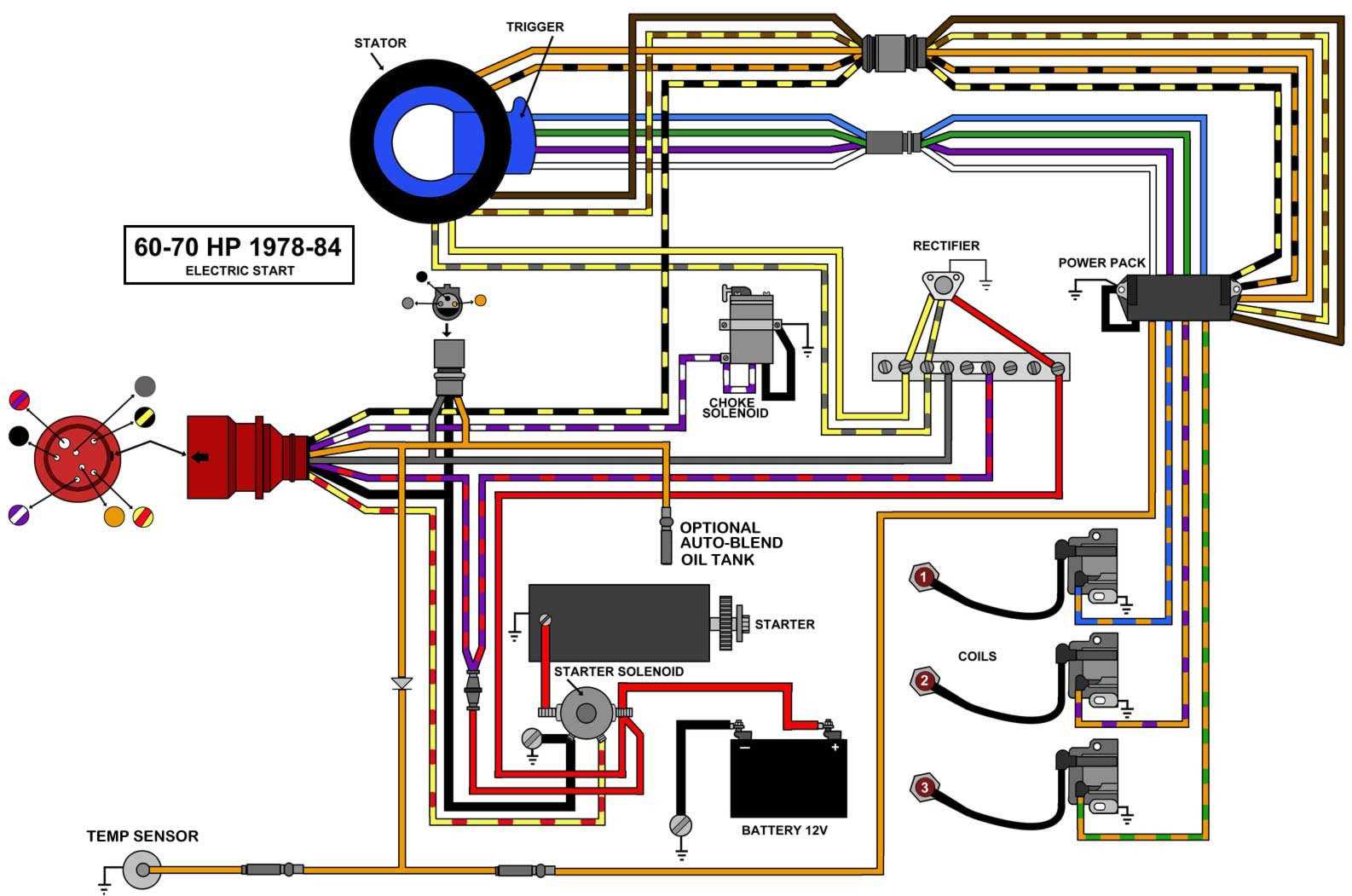

Electrical Components: A Guide

This section delves into the crucial elements of electrical systems found in marine engines. Understanding these components is essential for ensuring optimal performance and reliability. From circuits to sensors, each part plays a vital role in the overall functionality of the engine.

Key Electrical Parts

Several primary components make up the electrical system, including batteries, ignition systems, and wiring harnesses. Batteries provide the necessary power to start the engine and run auxiliary systems. The ignition system is responsible for generating the spark needed for combustion, while wiring harnesses connect all electrical elements, ensuring efficient communication between them.

Maintenance and Troubleshooting

Regular inspection and maintenance of electrical components are vital for preventing issues. Look for signs of wear, corrosion, or damage in connectors and wiring. Troubleshooting can often involve checking connections, testing batteries, and ensuring that all components function as intended. By staying proactive, you can enhance the longevity and reliability of your engine’s electrical system.

Preventative Measures for Your Engine

Ensuring the longevity and optimal performance of your power unit requires proactive steps that go beyond routine checks. By implementing regular maintenance and monitoring practices, you can significantly reduce the risk of unexpected failures and costly repairs.

Regular Inspections: Conduct frequent examinations of critical components such as fuel lines, electrical systems, and cooling mechanisms. This vigilance helps identify wear and tear before it escalates into a serious issue.

Fluid Maintenance: Keeping an eye on the quality and levels of essential fluids, including oil and coolant, is crucial. Replace these fluids according to the manufacturer’s recommendations to ensure proper lubrication and temperature control.

Proper Storage: When not in use, store your engine in a dry and sheltered location. Use protective covers to shield it from dust and moisture, which can cause corrosion and damage over time.

Seasonal Preparations: Before and after each season, perform a thorough check. Winterizing your unit, for instance, involves draining fuel and ensuring all systems are protected against cold temperatures.

Component Upgrades: Consider upgrading to high-quality parts and accessories that can enhance performance and durability. Investing in superior components often pays off in terms of efficiency and reduced maintenance needs.

By incorporating these practices into your routine, you can extend the lifespan of your engine and ensure it operates smoothly, allowing you to enjoy your activities without interruption.