In the world of heavy equipment, ensuring optimal performance and longevity is paramount. Proper upkeep not only enhances efficiency but also safeguards against costly downtimes. This section serves as an essential resource for operators and technicians alike, offering invaluable insights into the nuances of machinery servicing.

Understanding the intricacies of these powerful machines is crucial for anyone involved in their operation. This guide delves into various aspects of maintenance procedures, troubleshooting techniques, and component care. Whether you are a seasoned professional or a newcomer, the information presented here will aid in achieving peak functionality.

Equipped with the right knowledge, users can tackle common issues confidently and perform routine checks effectively. By following systematic approaches and adhering to recommended practices, operators can not only extend the life of their equipment but also ensure safety and reliability in every operation.

Join us as we explore detailed methodologies and practical tips designed to enhance your understanding and execution of machinery maintenance. A well-informed operator is the key to a thriving worksite.

Understanding JCB Telehandlers

This section provides an overview of a versatile type of machinery commonly used in construction and agricultural settings. These machines are designed to lift heavy loads and facilitate a wide range of tasks, enhancing efficiency and productivity on various job sites.

Key Features

- Versatility in lifting and moving materials.

- Adjustable boom for reaching elevated areas.

- Compact design for maneuverability in tight spaces.

- Compatibility with various attachments for different applications.

Common Applications

- Construction: Transporting building materials.

- Agriculture: Moving hay bales and pallets of feed.

- Landscaping: Lifting heavy rocks or soil.

- Warehousing: Stacking and retrieving goods.

Key Components of Telehandlers

The functionality and efficiency of lifting equipment depend heavily on its essential elements. Understanding these components is crucial for optimal performance and maintenance. Each part plays a significant role in ensuring that the machinery operates smoothly and safely, catering to various tasks in construction and agriculture.

Hydraulic System

The hydraulic system serves as the powerhouse of the equipment, enabling powerful lifting and extending capabilities. It consists of hydraulic cylinders, pumps, and fluid reservoirs, all working together to convert fluid pressure into mechanical energy. This system is designed to provide precise control, allowing operators to manage heavy loads effectively.

Chassis and Frame

The chassis forms the backbone of the machinery, supporting all other components. Constructed for durability and stability, it is engineered to withstand harsh working conditions. A robust frame not only enhances the overall strength but also ensures better balance and maneuverability, contributing to the safety of operations.

Common Issues in Telehandler Operation

Operating heavy machinery can present various challenges, often leading to decreased efficiency and potential safety hazards. Understanding these common problems is crucial for effective management and troubleshooting, ensuring that operations run smoothly and safely.

Mechanical Failures

One of the primary concerns during operation is mechanical failure. This can manifest as issues with lifting capacity, unexpected drops, or unusual noises from the machinery. Regular inspections and maintenance can help mitigate these risks, but operators should be vigilant for signs of wear and tear, such as hydraulic leaks or engine overheating.

Operator Errors

Another significant factor in operational challenges is human error. Mistakes can occur during loading, maneuvering, or even basic controls. It is essential for operators to be well-trained and familiar with the specific machinery in use. Regular training sessions can enhance skills, reduce accidents, and promote a safer working environment. Additionally, operators should always adhere to safety protocols to minimize risks.

Importance of Regular Maintenance

Consistent upkeep of machinery is crucial for ensuring optimal performance and longevity. Regular attention to equipment can prevent unforeseen breakdowns, enhance efficiency, and ultimately lead to cost savings. Establishing a proactive maintenance routine is essential for anyone relying on heavy machinery for their operations.

Benefits of Regular Upkeep

- Increased Equipment Lifespan: Routine checks can significantly extend the working life of your machinery.

- Enhanced Safety: Regular inspections help identify potential hazards, reducing the risk of accidents.

- Improved Efficiency: Well-maintained machines operate more smoothly and efficiently, leading to higher productivity.

- Cost Savings: Preventative maintenance can reduce the likelihood of major repairs, saving money in the long run.

Key Maintenance Practices

- Scheduled Inspections: Set regular intervals for thorough checks of critical components.

- Fluid Checks and Changes: Ensure that all necessary fluids are at optimal levels and replaced as needed.

- Cleaning: Regularly clean the equipment to prevent build-up that can lead to inefficiencies.

- Part Replacement: Stay ahead of wear and tear by replacing parts before they fail.

Repair Tools You Should Have

Having the right equipment is essential for effective maintenance and servicing. This section highlights the essential implements that can significantly enhance your efficiency and ensure quality outcomes in your tasks.

- Socket Set: A comprehensive set with various sizes allows for flexibility in dealing with different fasteners.

- Wrenches: Both adjustable and fixed wrenches are crucial for tightening and loosening bolts and nuts.

- Torque Wrench: Ensures that fasteners are tightened to the correct specifications, preventing damage.

- Multimeter: Essential for diagnosing electrical issues by measuring voltage, current, and resistance.

- Oil Filter Wrench: Simplifies the process of removing and installing oil filters.

- Hand Tools: Hammers, pliers, and screwdrivers in various types will cover a multitude of tasks.

Equipping yourself with these vital tools will not only streamline your workflow but also enhance the longevity of the machinery being serviced.

Step-by-Step Repair Guide

This section provides a comprehensive approach to troubleshooting and fixing common issues in heavy lifting machinery. Following a systematic method can greatly enhance efficiency and ensure safety during the process.

Essential Tools and Materials

Before starting the process, gather the necessary equipment and supplies:

- Wrenches and socket sets

- Diagnostic tools

- Replacement parts

- Lubricants and cleaning agents

- Protective gear

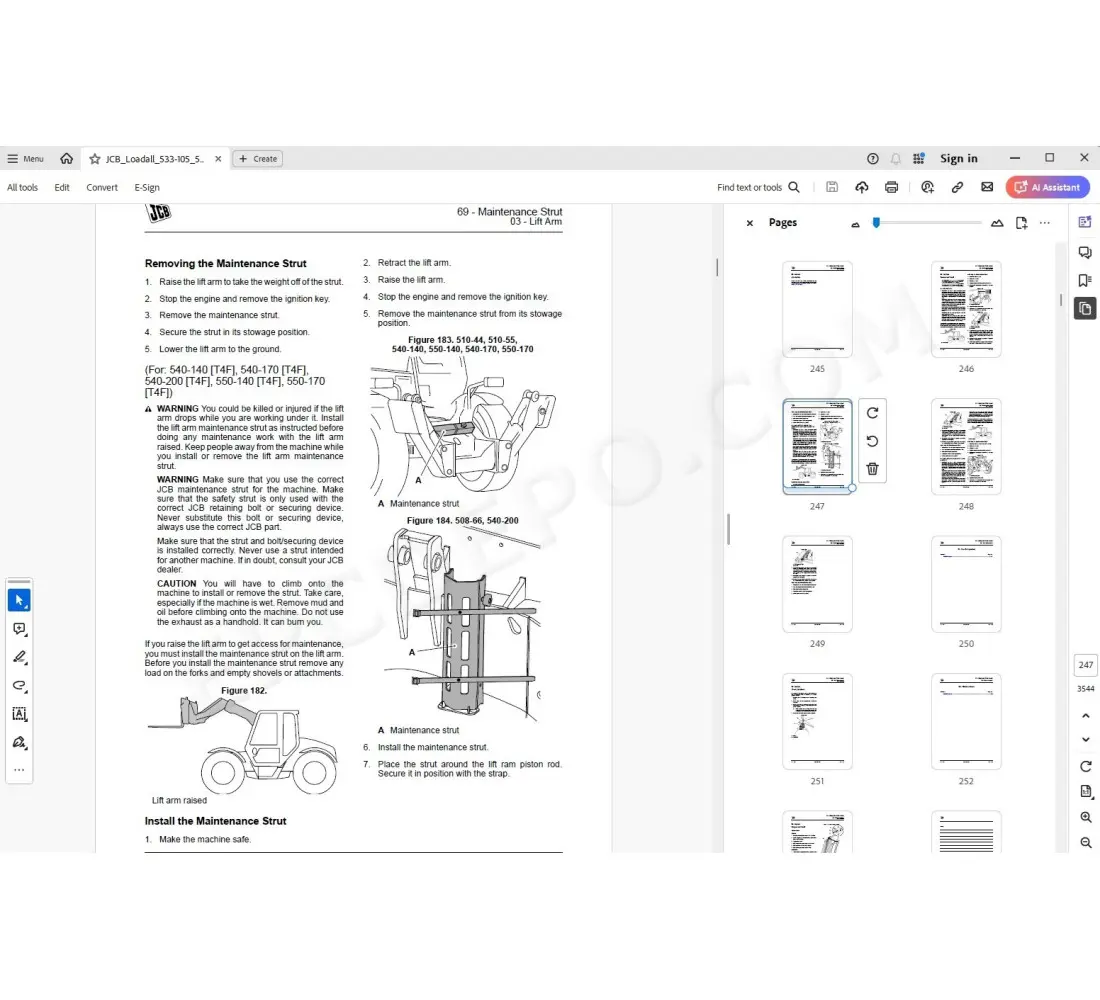

Procedure Overview

Adhere to these steps for effective maintenance:

- Assess the situation and identify the issue.

- Disconnect the power source to ensure safety.

- Remove any coverings or panels to access components.

- Check for loose or damaged parts and replace as necessary.

- Reassemble all components carefully.

- Reconnect the power source and perform a test run.

- Document the maintenance process for future reference.

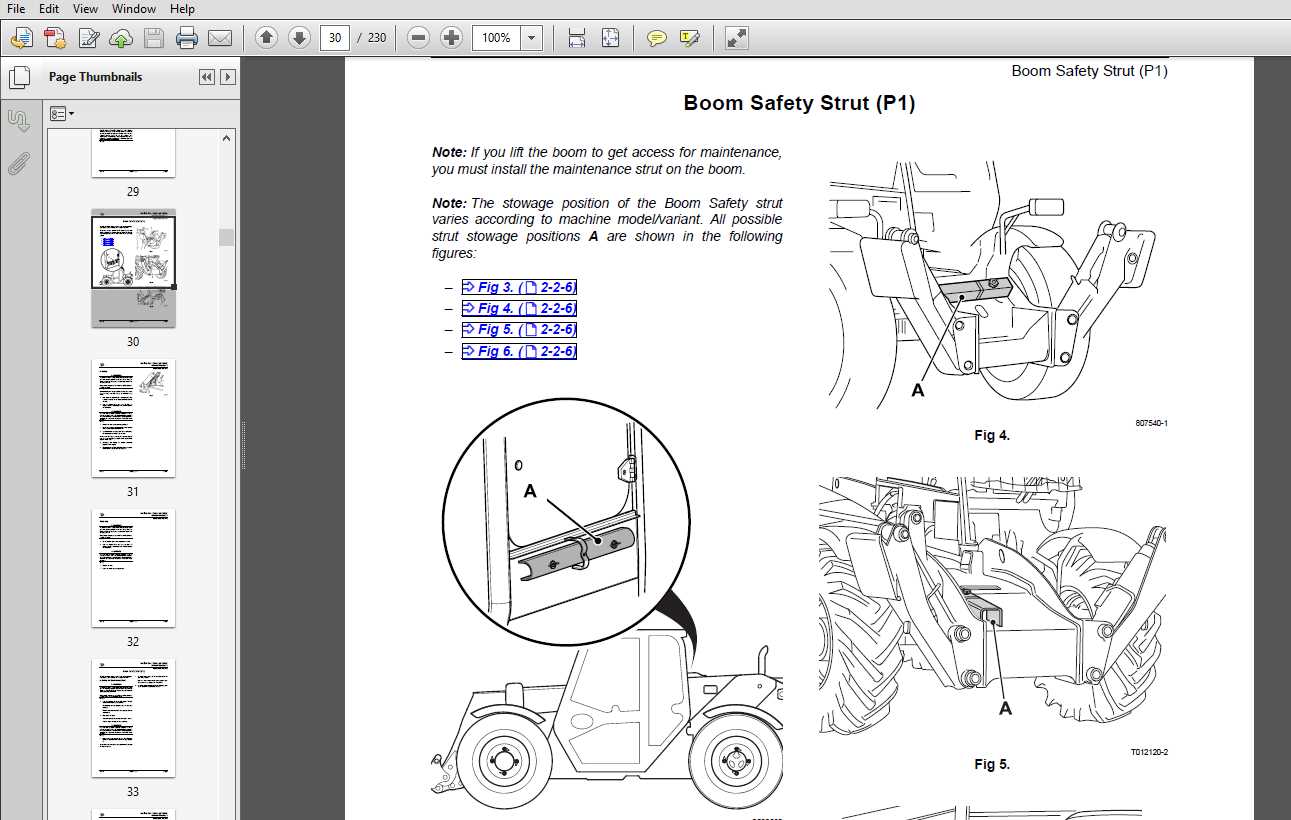

Safety Precautions During Repairs

Ensuring safety during maintenance tasks is crucial to prevent accidents and injuries. By following established guidelines and using proper equipment, individuals can protect themselves and others while conducting necessary work on machinery.

Before commencing any service activities, it is essential to assess the work environment and prepare adequately. This includes familiarizing oneself with the equipment, understanding potential hazards, and utilizing appropriate personal protective gear (PPE).

| Safety Measures | Description |

|---|---|

| Personal Protective Equipment | Wear helmets, gloves, goggles, and steel-toed boots to minimize injury risks. |

| Work Area Inspection | Ensure the workspace is free of obstructions and well-lit to enhance visibility. |

| Lockout/Tagout Procedures | Implement these protocols to ensure machinery is not inadvertently activated during service. |

| Proper Lifting Techniques | Use correct lifting methods or mechanical aids to prevent strain or injury. |

| Tool Maintenance | Regularly check tools for wear and tear to ensure they are in safe working condition. |

By adhering to these safety protocols, individuals can significantly reduce the likelihood of accidents and ensure a safe working environment during maintenance procedures.

How to Identify Faulty Parts

Recognizing defective components in machinery is crucial for maintaining operational efficiency and safety. Proper diagnostics can prevent minor issues from escalating into major problems, ensuring longevity and reliability of the equipment. Understanding common signs of wear and employing systematic checks can aid in identifying parts that require attention.

Common Symptoms of Defective Components

Several indicators can signal that a component may be malfunctioning. Observing these signs can help in early detection and timely intervention.

| Symptom | Possible Cause |

|---|---|

| Unusual noises | Worn bearings or loose connections |

| Decreased performance | Clogged filters or failing pumps |

| Visible leaks | Damaged seals or hoses |

| Inconsistent operation | Faulty electronics or sensors |

Inspection Techniques

Regular inspections are vital for identifying potential failures before they become critical. Utilizing both visual checks and technical diagnostic tools can enhance detection accuracy. Look for wear patterns, measure component performance, and listen for irregular sounds to gain insight into the equipment’s condition.

Benefits of Professional Servicing

Ensuring that heavy machinery operates at its peak efficiency is crucial for productivity and safety. Engaging skilled technicians for regular maintenance offers numerous advantages that go beyond mere functionality.

- Expert Knowledge: Trained professionals possess a deep understanding of equipment mechanics, enabling them to diagnose and address issues accurately.

- Enhanced Lifespan: Routine servicing helps prevent wear and tear, extending the operational life of the machinery.

- Safety Assurance: Regular inspections minimize the risk of malfunctions, ensuring safer working conditions for operators.

- Cost Efficiency: Preventative maintenance can save money in the long run by avoiding costly repairs and unplanned downtime.

- Quality Parts: Professionals often use high-quality components that meet manufacturer standards, ensuring optimal performance.

By investing in professional care, operators can secure reliability and efficiency, ultimately enhancing overall productivity.

Telehandler Troubleshooting Techniques

Effective diagnostics are crucial for maintaining optimal functionality in heavy machinery. Understanding common issues and employing systematic approaches can significantly enhance efficiency and reduce downtime. This section explores key strategies for identifying and resolving malfunctions in these versatile lifting devices.

Common Issues and Symptoms

Recognizing typical problems is the first step in addressing them. Operators should be aware of signs that may indicate underlying faults.

| Symptom | Possible Cause |

|---|---|

| Engine Won’t Start | Battery Failure or Fuel Issues |

| Uneven Lifting | Hydraulic Fluid Leaks or Cylinder Damage |

| Overheating | Cooling System Malfunction |

Troubleshooting Steps

When faced with issues, a methodical approach is essential. Begin with visual inspections, followed by operational tests, and then review mechanical systems. Documenting findings can aid in future diagnostics and repairs.

Keeping Your Manual Accessible

Having quick access to your equipment’s guidance materials is essential for efficient operation and maintenance. Whether you’re on-site or in the office, knowing where to find important documents can save time and prevent costly mistakes.

To ensure you can easily retrieve your reference materials, consider the following strategies:

- Digital Copies: Store electronic versions on your devices or in the cloud for instant access.

- Physical Location: Designate a specific place for printed versions, ensuring they are organized and easy to reach.

- Backup Options: Keep duplicates in different locations, such as your vehicle or toolbox, for emergencies.

- Indexing System: Create a simple indexing method for quick navigation through the materials.

Regularly reviewing and updating your collection will further enhance accessibility. By implementing these practices, you can ensure that you are always prepared to address any operational challenges that may arise.

Resources for Further Learning

Expanding your knowledge in equipment maintenance and troubleshooting is essential for effective operation and longevity. Numerous resources are available to enhance your understanding and skills in this field.

- Online Courses: Various platforms offer structured learning through courses focused on machinery operation and servicing.

- Books and eBooks: Look for titles that cover maintenance techniques, safety protocols, and industry standards.

- Forums and Online Communities: Engaging with peers can provide insights and practical tips from experienced operators.

- YouTube Channels: Visual tutorials and demonstrations can aid in grasping complex concepts effectively.

Utilizing these resources can greatly enhance your expertise and confidence in handling machinery effectively.