In the world of household conveniences, there are essential devices that ensure our everyday experiences remain seamless and enjoyable. When these units encounter difficulties, it becomes vital to understand the underlying issues and how to address them effectively. A thorough understanding of these complexities not only extends the lifespan of the device but also enhances its performance.

Comprehensive resources are available to assist individuals in troubleshooting common challenges. These guides equip users with the necessary knowledge to identify problems, explore potential solutions, and ultimately restore functionality. By diving into the intricacies of these appliances, one can foster a deeper appreciation for their design and operation.

Whether you are a seasoned handyman or a novice looking to learn, engaging with detailed instructions can empower you to take charge of your appliance’s health. With the right approach, even the most perplexing situations can be managed, ensuring that your daily life remains uninterrupted.

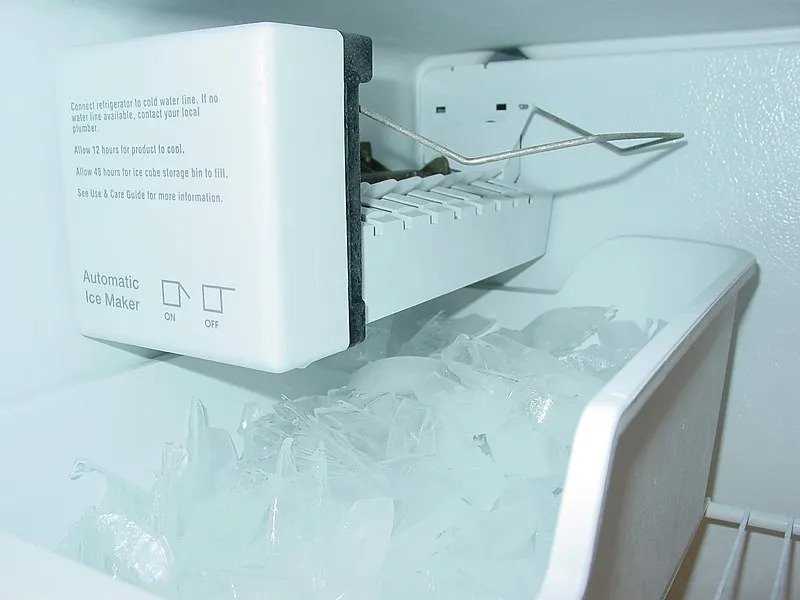

Understanding Ice Maker Components

Gaining insight into the various parts involved in the formation of frozen cubes is essential for effective troubleshooting and maintenance. Each component plays a pivotal role in the overall functionality, and understanding their interactions can lead to more efficient operations and longer lifespan.

Key Elements

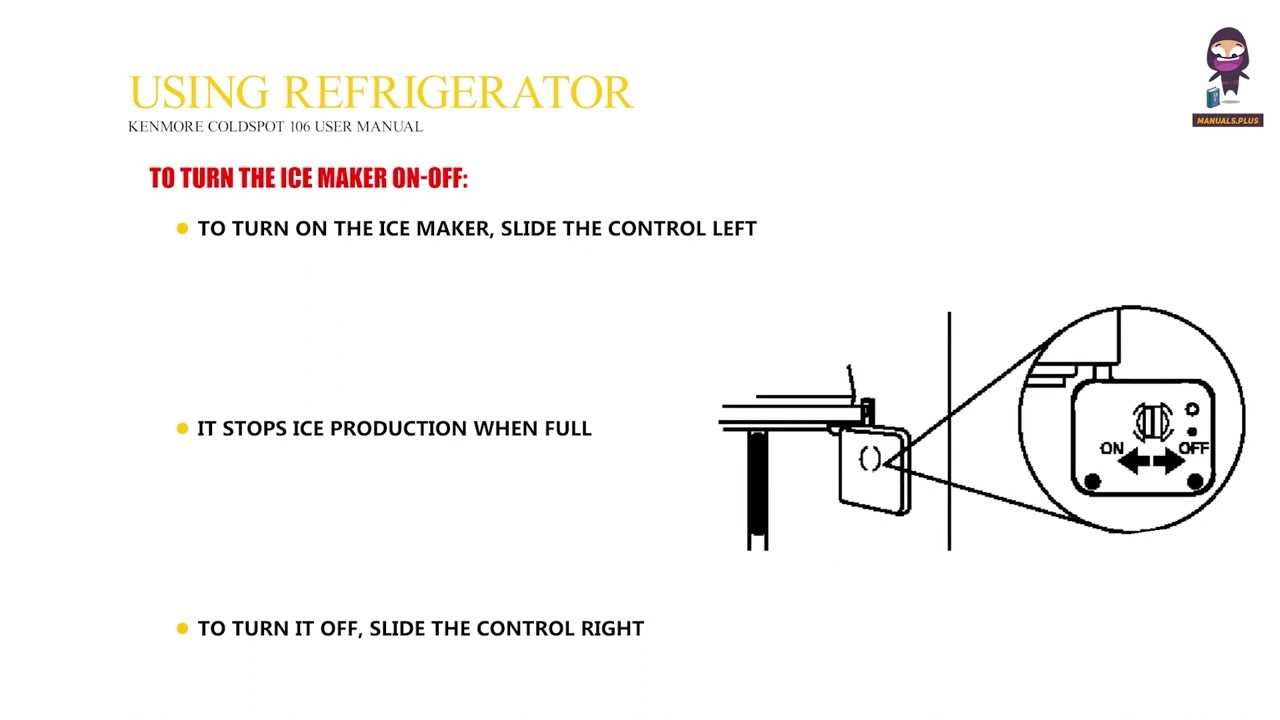

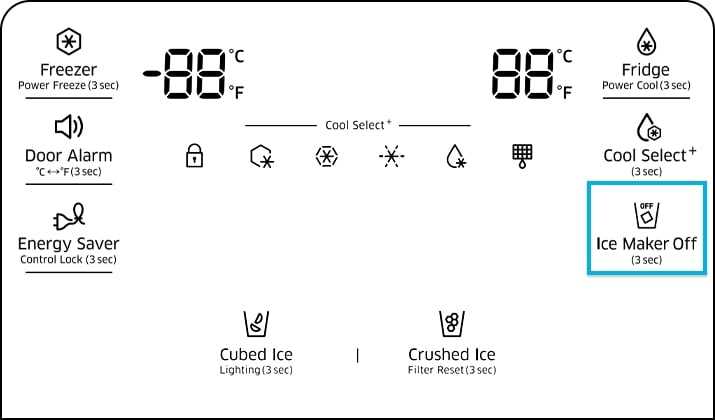

The primary elements consist of the water supply system, freezing chamber, and the dispensing mechanism. The water supply system is responsible for providing the necessary liquid, while the freezing chamber is where the transformation into solid form occurs. Finally, the dispensing mechanism enables the seamless delivery of the finished product.

Common Issues

Identifying common issues related to these components can significantly enhance performance. For instance, blockages in the water supply may lead to insufficient liquid, while a malfunction in the freezing chamber can prevent proper solidification. Regular inspection and timely intervention can mitigate potential problems and ensure optimal functionality.

Common Ice Maker Issues

Many individuals encounter challenges with their freezing appliances, leading to frustration and inconvenience. Understanding these typical problems can help in identifying solutions and ensuring optimal performance.

Insufficient Production: One frequent concern is a lack of output, which can stem from low water supply, clogs, or malfunctioning components. Ensuring proper water flow is essential for efficient operation.

Frozen Components: Accumulation of frost can hinder functionality, causing blocks in the system. Regular defrosting and maintenance can prevent this issue from escalating.

No Dispensing: If the dispensing mechanism fails, it could be due to electrical issues or jammed parts. Troubleshooting these areas can restore normal use.

Noisy Operation: Unusual sounds may indicate worn parts or misalignment. Addressing these noises promptly can help maintain the appliance’s longevity.

Leaking Water: Leakage often points to faulty seals or drainage issues. Identifying the source quickly can prevent further damage and ensure efficiency.

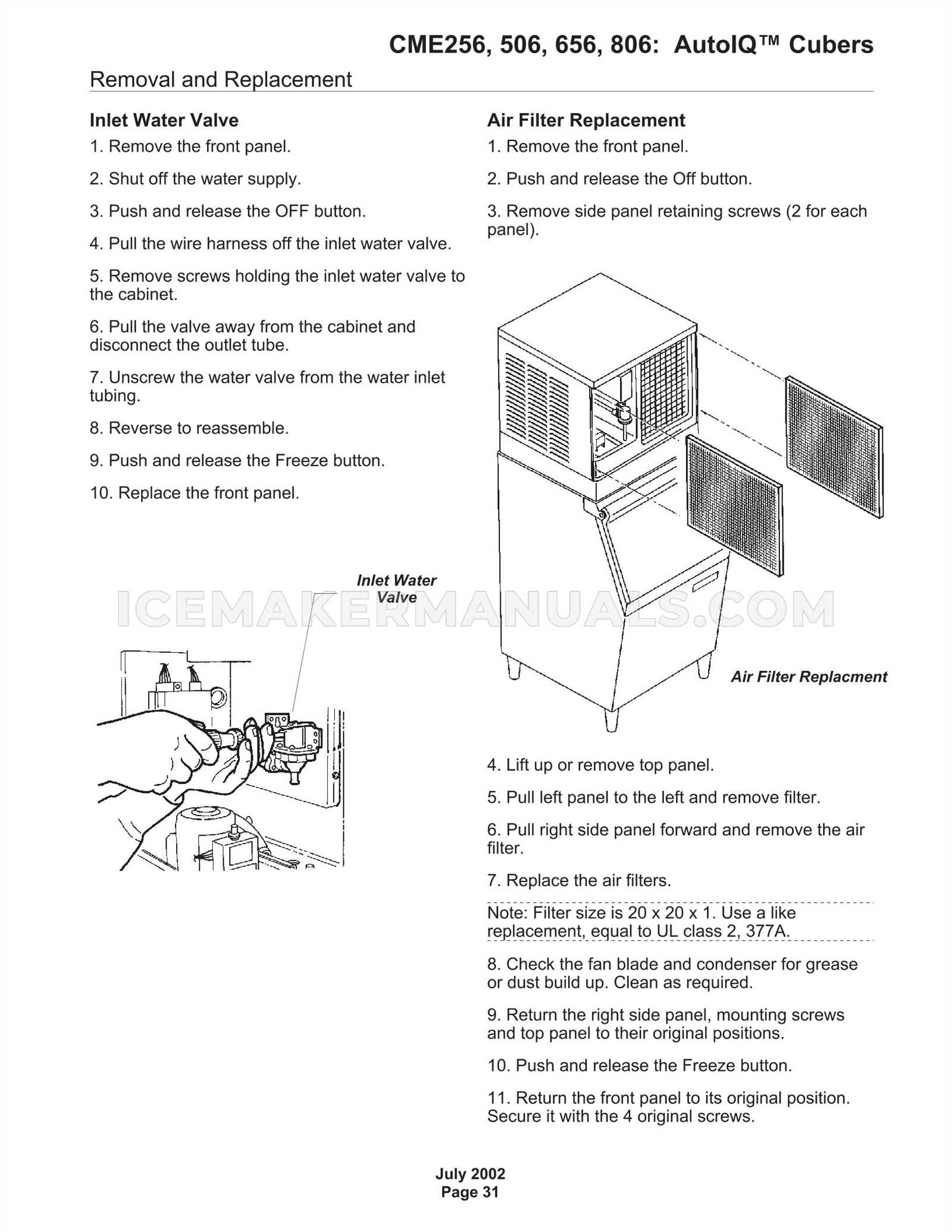

Step-by-Step Repair Instructions

This section provides a structured approach to troubleshooting and resolving common issues encountered with your appliance. Following these detailed guidelines will help you identify problems effectively and implement the necessary fixes, ensuring your device operates smoothly once again.

Preparation Steps

- Gather necessary tools: screwdriver, multimeter, and pliers.

- Unplug the appliance to ensure safety during the process.

- Review the symptoms and identify the specific issue you are facing.

Troubleshooting Process

- Check the power supply: Ensure the outlet is functioning and the cord is intact.

- Inspect internal components: Look for any visible signs of wear or damage.

- Test relevant parts: Use a multimeter to check the functionality of fuses and sensors.

- Replace faulty components: Obtain suitable replacements for any defective parts identified.

- Reassemble the unit carefully and plug it back in.

- Run a test cycle to confirm the issue has been resolved.

Tools Needed for Ice Maker Repairs

When addressing issues with your chilling appliance, having the right equipment is essential for effective troubleshooting and restoration. Utilizing the appropriate tools not only simplifies the process but also ensures that the job is done safely and efficiently. Below are key instruments that will aid you in the task.

Essential Hand Tools

Among the basic instruments, a screwdriver set is crucial for accessing various components. Different types, such as flathead and Phillips, will help you navigate screws of all sizes. Additionally, a wrench set will be necessary for loosening or tightening fittings, ensuring proper connections throughout the system.

Specialized Equipment

In some cases, more specialized items are required. A multimeter is invaluable for diagnosing electrical issues, allowing you to check voltage and continuity in circuits. For cleaning and maintenance, having a tube cleaner can help clear out any blockages that might impede performance. Finally, an insulation tool may be beneficial for addressing any thermal inefficiencies.

Diagnosing Ice Maker Problems

Understanding the common issues that arise with freezing appliances can greatly enhance your troubleshooting process. Identifying symptoms accurately allows for more efficient resolution of issues, ensuring your unit operates smoothly.

| Symptom | Possible Cause | Recommended Action |

|---|---|---|

| No production | Power supply interruption | Check electrical connections and ensure the unit is plugged in. |

| Slow production | Temperature setting too high | Lower the temperature setting and allow time for adjustments. |

| Clumping or uneven shapes | Water quality issues | Replace the water filter and ensure clean water supply. |

| Excessive noise | Loose components | Tighten any loose parts and check for foreign objects. |

By examining these factors systematically, you can pinpoint the root of the issue and implement appropriate solutions effectively.

Preventative Maintenance Tips

Regular upkeep is essential for ensuring the longevity and efficiency of your equipment. By implementing a few simple practices, you can significantly reduce the risk of unexpected breakdowns and maintain optimal performance over time. These strategies not only enhance functionality but also save you time and resources in the long run.

Routine Cleaning

One of the most effective ways to prolong the lifespan of your unit is through consistent cleaning. Dust and debris can accumulate in various components, hindering performance. Schedule periodic cleanings to remove any buildup and ensure that air circulation remains unobstructed. This practice helps maintain temperature consistency and prevents wear on mechanical parts.

Regular Inspections

Conducting frequent inspections is crucial for early detection of potential issues. Examine seals, hoses, and connections for signs of wear or leaks. Addressing minor concerns promptly can prevent them from escalating into more significant problems. Additionally, keep an eye on any unusual sounds or changes in operation, as these can indicate underlying issues that need attention.

Safety Precautions During Repairs

Ensuring safety during maintenance tasks is paramount. Understanding potential hazards and taking appropriate measures can prevent accidents and injuries. Proper preparation and awareness of surroundings are crucial for a successful and safe experience.

- Always disconnect the power supply before starting any work to avoid electric shock.

- Wear protective gear, including gloves and goggles, to shield against sharp objects and harmful substances.

- Use tools that are in good condition and appropriate for the task at hand.

- Keep the workspace clean and organized to minimize the risk of trips and falls.

Additionally, it’s important to familiarize yourself with the specific unit you are handling. Knowledge about its components and operation can greatly enhance safety measures.

- Read the manufacturer’s guidelines thoroughly before beginning.

- Check for any signs of wear or damage that could pose risks during maintenance.

- Ensure adequate ventilation if working with any chemicals or materials that emit fumes.

By adhering to these precautions, individuals can safeguard themselves and ensure a smoother, more efficient process.

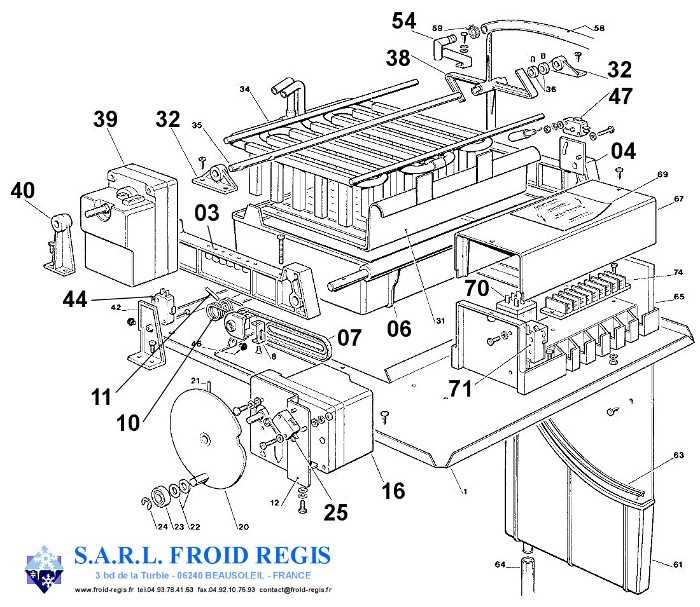

Replacing Ice Maker Parts

Ensuring optimal performance of your refrigeration unit often involves addressing various components. Over time, specific elements may wear out or malfunction, necessitating their replacement to restore functionality.

Identifying which parts require attention can streamline the process. Common issues may arise from:

- Blockages in the water line

- Defective sensors

- Faulty motors

- Worn-out switches

When embarking on a replacement task, it’s essential to follow a structured approach:

- Disconnect the unit from its power source to ensure safety.

- Gather necessary tools and replacement components.

- Consult a schematic to understand part locations and functions.

- Carefully remove the damaged component, taking note of its connections.

- Install the new piece, ensuring all connections are secure.

- Reconnect the power and test the system for proper operation.

By following these steps, you can effectively address issues and enhance the longevity of your unit.

When to Call a Professional

Understanding when to seek expert assistance can save time, money, and frustration. Certain situations may arise where the complexity of the issue exceeds basic troubleshooting steps. Recognizing these moments is crucial for effective resolution.

Here are some key indicators that it may be time to consult a specialist:

| Indicator | Description |

|---|---|

| Persistent Issues | If problems continue despite following standard guidelines, it’s a sign that deeper issues may exist. |

| Unusual Noises | Strange sounds can indicate mechanical failure or component wear, which often requires professional attention. |

| Water Leakage | Leaks can lead to significant damage; timely intervention from a technician is recommended. |

| Electrical Problems | If there are issues with power supply or wiring, it’s essential to engage an expert to avoid safety hazards. |

| Complex Repairs | Any task involving intricate components or requiring specialized tools should be left to a trained professional. |

In any of these cases, opting for professional expertise ensures that issues are diagnosed and addressed correctly, helping to prevent further complications down the line.

Finding Reliable Repair Manuals

Locating trustworthy guides for fixing appliances can significantly streamline the troubleshooting process. With the right resources, users can gain insights into common issues, maintenance techniques, and effective solutions. A reliable source not only enhances understanding but also boosts confidence in tackling challenges independently.

Evaluating Sources

When searching for valuable references, prioritize established websites, forums, and manufacturer resources. Look for content that is frequently updated and backed by expert advice. User reviews and testimonials can also offer insight into the credibility of the information provided.

Accessing Community Knowledge

Engaging with online communities can be an invaluable resource. Forums and social media groups often feature discussions where users share their experiences and tips. This collective knowledge can lead to discovering practical solutions that may not be available in traditional documentation.

Cost-Effective Repair Solutions

Finding affordable ways to fix common appliances can save both time and money. By understanding various approaches, individuals can effectively address issues without breaking the bank. This section outlines practical strategies to consider when troubleshooting and resolving problems.

- DIY Approaches: Many issues can be resolved at home with basic tools and online tutorials. Engaging in self-repair not only cuts costs but also enhances knowledge.

- Identify Common Problems: Recognizing frequently encountered issues allows for quicker diagnosis and resolution. This understanding can lead to more effective solutions.

- Use Quality Parts: Sourcing reliable components from reputable suppliers ensures longevity and efficiency, preventing future expenses.

- Consult Community Forums: Engaging with online communities can provide insights and advice from experienced users, often leading to innovative solutions.

- Routine Maintenance: Implementing regular upkeep can minimize the likelihood of serious malfunctions, thus saving on costly interventions.

By adopting these methods, individuals can enhance their problem-solving skills and manage appliance issues more effectively, all while keeping expenses low.