In the world of typewriters, few models have achieved such lasting admiration for their engineering and durability. Known for their precision and timeless design, these vintage machines remain popular among enthusiasts and professionals alike, even decades after their debut. This guide aims to provide practical steps for maintaining and enhancing the functionality of one such iconic machine, allowing it to continue performing at its best.

For those passionate about vintage technology, restoring and tuning up a classic typing device offers not only a rewarding hands-on experience but also ensures the legacy of an exceptional piece of office equipment. Each component requires careful attention, and this guide covers the essential methods to handle and optimize every detail. With patience and the right approach, you can bring a trusted workhorse back to life.

Maintaining these machines calls for both care and precision, as small adjustments can make a significant difference in performance. Whether it’s addressing alignment, recalibrating the typing mechanism, or fine-tuning the settings, this resource will walk you through the essential processes. Embark on a journey to restore the reliability and charm of a timeless classic.

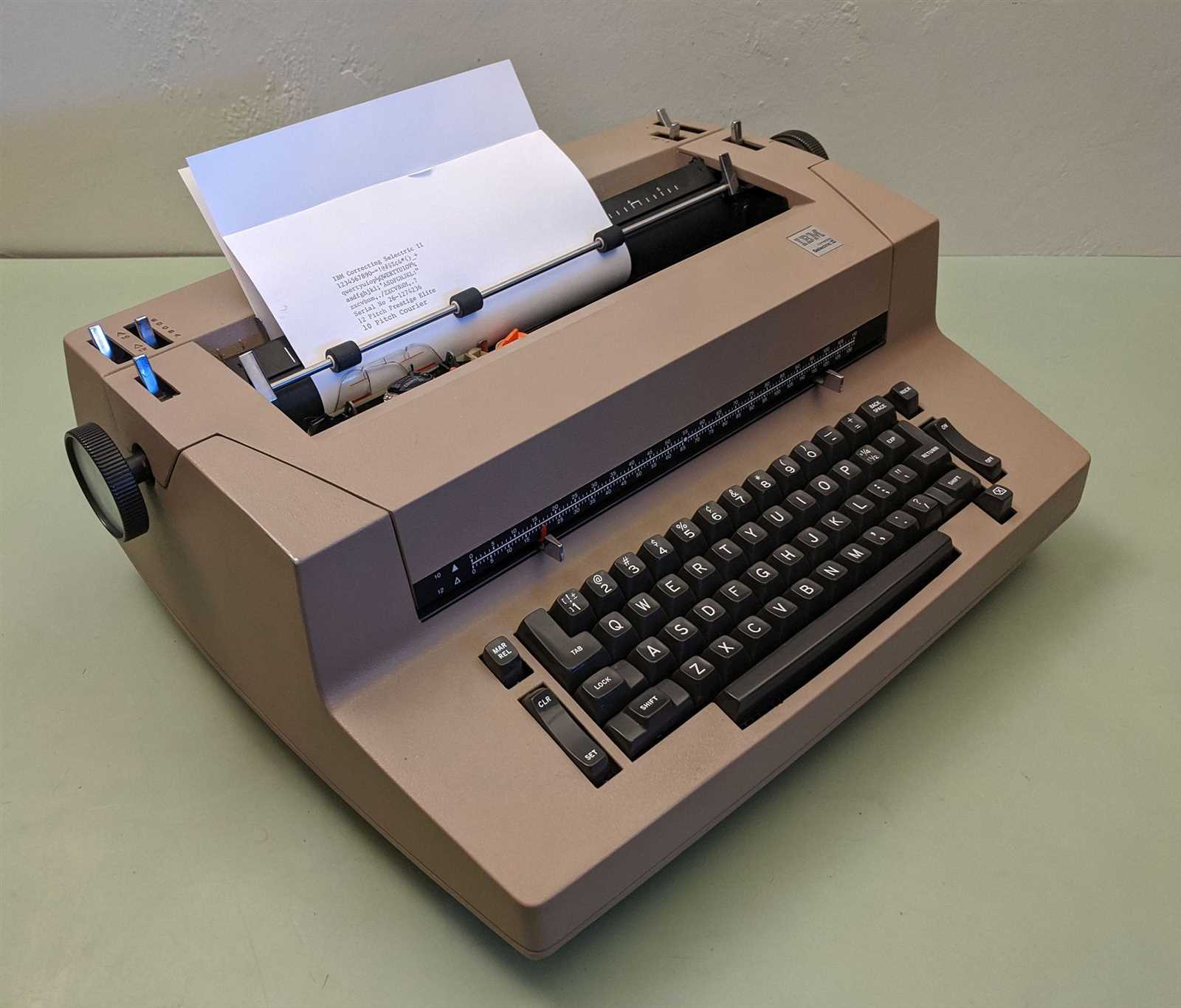

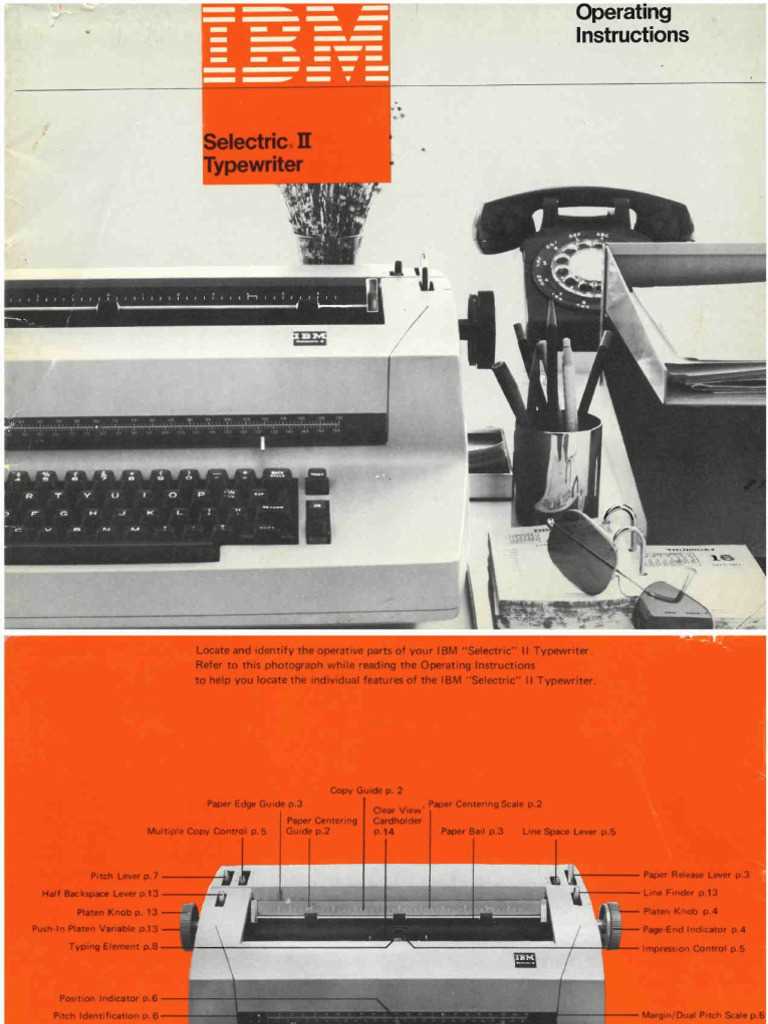

IBM Selectric II Repair Guide

This section provides insights into maintaining and troubleshooting one of the most iconic typing machines of its time. The following instructions cover common challenges faced by users and solutions for ensuring continued functionality and smooth operation.

Essential Maintenance Steps

Regular upkeep plays a vital role in extending the life of your device. Here’s a step-by-step approach to basic upkeep:

- Clean the typewriter components: Periodically remove dust and debris from the internal and external parts to avoid malfunctions.

- Check for signs of wear: Inspect mechanical parts for any wear that could affect performance.

- Lubricate moving parts: Apply the recommended lubricant to critical areas to keep the typing mechanism smooth.

Troubleshooting Common Issues

Users may encounter occasional challenges. Below are typical problems and simple adjustments to improve functionality:

- Stuck keys: Clean around the key mechanism and ensure there is no obstruction.

- Irregular spacing: Examine the spacing controls and reset as needed to align output correctly.

- Inconsistent typing motion: Check for loose components, securing any parts that may have shifted.

With these tips, you can maintain efficient operati

Common Issues with Selectric II

Over time, mechanical writing devices can encounter several common problems that may hinder their smooth operation. Recognizing these potential challenges can help users maintain consistent performance and longevity for their equipment.

Type Alignment and Consistency

A frequently observed issue is misalignment in letter impressions, often causing uneven text appearance on the page. This can result from worn components or subtle shifts in the internal mechanisms. To maintain clear and uniform text, regular maintenance of the typing elements is crucial.

Key and Lever Jamming

Jamming of keys or levers can be another recurring problem, especially with devices that have seen extensive use. This can be caused by accumulated dust, worn parts, or inadequate lubrication. Periodic cleaning and proper lubrication are essential to prevent key resistance and ensure smooth functionality.

For users of mechanical devices, understanding these common issues and addressing them promptly can significantly enhance the reliability and precision of their typing instruments.

Identifying Broken or Worn Parts

Recognizing the signs of wear or damage is essential for maintaining the effectiveness and longevity of your typewriter. Consistent observation of its components can help in noticing subtle or significant changes that could affect its operation. Paying close attention to common areas of wear can prevent minor issues from developing into larger, more costly problems.

Examining Mechanical Components

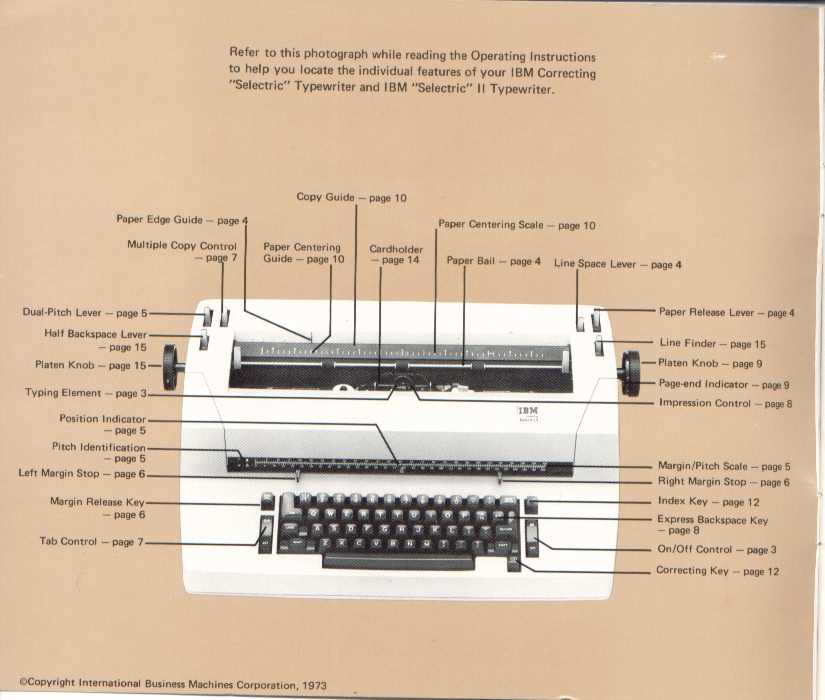

Begin by checking the primary moving parts, such as the typebars, gears, and levers. Over time, these areas may show signs of loosening or stiffness, which can disrupt smooth operation. Inspect for any misalignment or unusual resistance, as these can indicate that parts have shifted or sustained wear. Keeping these elements aligned and functional will ensure optimal performance.

Spotting Signs of Wear in Key Areas

Additionally, investigate sections that frequently encounter friction or pressure, as these are more susceptible to wear. Check for any buildup of residue or dust, which can interfere with the precision of certain parts. Components with visible cracks, bends, or irregularities may need closer examination, as these issues can hinder accuracy and overall functionality.

Steps to Clean the Machine

Regular maintenance and proper cleaning of this device are essential to ensure its smooth operation and extend its lifespan. Follow these steps to remove dust, debris, and ink residue that can accumulate during extended use.

- Begin by unplugging the machine to ensure complete safety during cleaning. Remove any loose parts that are meant to be detached, such as the cover or ribbon if applicable.

- Use a soft brush or compressed air to gently sweep away any visible dust or particles from the surface and internal areas. Focus on the keyboard and type mechanism, as these areas can collect the most dirt.

- With a lint-free cloth slightly dampened with mild detergent, carefully wipe down external surfaces. Avoid applying excessive moisture to prevent any potential damage.

- If the device has a platen, roll it to check for ink stains or dust. Clean it by gently rubbing with a cloth and a small amount of alcohol, taking care to let it dry thoroughly before moving to the next step.

- Inspect the ribbon path and type bars. Remove any build-up with a cotton swab dipped in cleaning solution, being careful not to leave any fibers behind.

- Once all parts are clean, reassemble any components that were removed. Plug in the machine, and test its functions to ensure it operates smoothly.

Replacing the Typeball Mechanism

The typeball mechanism is a vital component that directly influences text quality and typing efficiency. Ensuring that this part functions correctly helps maintain the overall effectiveness of the machine, providing smooth and precise typing. When issues arise with this mechanism, a straightforward replacement can restore optimal operation.

Removing the Old Typeball

To begin, carefully lift the cover to expose the typeball mechanism. Gently grasp the typeball and apply slight upward pressure while turning it counterclockwise. This action will release it from its mount. Take care not to apply excessive force to prevent damage to surrounding components. Once free, set the typeball aside.

Installing the New Typeball

Position the new typeball on the same mount, aligning it with the guide markings. Rotate it clockwise until you feel it securely lock into place. Test the new component by pressing a few keys to ensure it engages correctly. After installation, close the cover and verify that the machine produces consistent characters with each keystroke.

With the new typeball in place, the typing system should return to smooth functionality, allowing for clean and efficient text production. Routine checks and timely replacements of this part will help sustain performance over time.

Troubleshooting Stuck Keys

Dealing with unresponsive keys can be a frustrating experience, impacting the efficiency of your typing tasks. Identifying the root causes and implementing effective solutions is essential for restoring functionality.

Begin by examining the surface around the keys. Dust, dirt, and debris can accumulate, preventing smooth movement. Gently remove any visible particles using a soft brush or compressed air to ensure a clean area. In some instances, key caps may become misaligned or stuck due to wear. If a key feels resistant, carefully pry it off with a small tool, clean beneath it, and reseat it firmly.

Additionally, check for mechanical issues within the key mechanism. Sometimes, springs or levers may become dislodged. If you hear unusual sounds when pressing the keys, this may indicate internal damage. In such cases, further disassembly may be necessary to assess and repair the mechanism.

Regular maintenance, including periodic cleaning and lubrication of moving parts, can help prevent these issues from arising in the future. By taking proactive steps, you can maintain optimal performance and extend the lifespan of your device.

Adjusting the Ribbon Cartridge

Ensuring optimal performance of your typing device involves regular maintenance, including proper adjustment of the ink cartridge. This task is crucial for achieving high-quality text output and preventing ink smudging or uneven printing. By following the necessary steps to align and configure the ribbon system, users can enhance the longevity and functionality of their equipment.

Identifying the Cartridge Mechanism

To begin the adjustment process, it is essential to familiarize yourself with the cartridge mechanism. This component typically consists of a spool system that holds the ink ribbon, allowing it to feed correctly during use. Understanding how this system operates will aid in making precise adjustments.

Steps for Adjustment

Follow these steps to ensure proper alignment and functionality of the ink cartridge:

| Step | Description |

|---|---|

| 1 | Remove the cartridge from the device carefully. |

| 2 | Check for any obstructions or damage on the spool. |

| 3 | Rewind the ribbon slightly if it has become loose. |

| 4 | Ensure the ribbon is threaded correctly through the guides. |

| 5 | Reinsert the cartridge and test the output quality. |

Fixing Paper Feed Problems

Issues with paper feeding can disrupt the workflow and lead to frustration. Understanding the common causes of these problems is essential for effective troubleshooting. By identifying the underlying factors, users can implement practical solutions to ensure smooth operation.

Common Causes of Paper Feed Issues

Several factors can contribute to difficulties in feeding paper. These include misalignment, debris accumulation, and worn components. Recognizing these aspects can significantly assist in addressing the challenges.

Troubleshooting Steps

To resolve paper feed issues, follow these steps:

| Step | Description |

|---|---|

| 1 | Check for any obstructions in the paper path that may impede feeding. |

| 2 | Ensure that the paper tray is correctly loaded with the appropriate size and type of paper. |

| 3 | Inspect rollers for wear and replace them if necessary to maintain optimal performance. |

| 4 | Clean any accumulated debris or dust from the feed mechanism. |

By systematically addressing these factors, users can restore efficient paper feeding and enhance overall functionality.

Restoring Electrical Components

The process of rejuvenating electrical components involves a careful assessment and meticulous attention to detail. This ensures that each element functions optimally, enhancing the overall performance of the device. Proper restoration not only improves functionality but also extends the lifespan of these critical parts.

Begin by inspecting each component for signs of wear or damage. Look for corrosion, loose connections, or frayed wires, as these issues can significantly affect performance. Cleaning contacts and connections with appropriate solutions can help restore electrical conductivity and prevent future failures.

When replacing any defective parts, always select high-quality substitutes that match the original specifications. This is vital for maintaining the integrity of the entire system. After replacement, it’s essential to conduct thorough tests to ensure that everything is functioning correctly.

Finally, consider implementing preventive measures to protect the restored components from future issues. Regular maintenance and inspections can help catch potential problems early, ensuring longevity and reliability in operation.

Lubrication Tips for Smooth Operation

Proper lubrication is essential for ensuring optimal performance and longevity of mechanical devices. By applying the right lubricants at appropriate intervals, you can significantly enhance the efficiency of the moving parts, minimize wear and tear, and reduce noise during operation.

Choosing the Right Lubricant

When selecting a lubricant, consider the specific requirements of the equipment. Utilize high-quality oils or greases designed for mechanical applications. Synthetic lubricants are often recommended due to their superior performance in extreme conditions. Ensure that the lubricant is compatible with the materials of the device to avoid any adverse reactions.

Application Techniques

Before applying any lubricant, clean the surfaces thoroughly to remove dust and debris. Use a precision applicator for accurate delivery of the lubricant to hard-to-reach areas. Apply just the right amount to avoid excess, which can attract dirt and lead to buildup. Regularly check and replenish the lubricant to maintain optimal functionality.

Aligning Print Head Mechanism

Ensuring precise alignment of the printing component is crucial for achieving optimal performance and print quality in typewriters. Misalignment can lead to inconsistent character placement, smudging, or incomplete prints. This section outlines the steps necessary to adjust the printing mechanism effectively.

Tools Required

To perform the alignment, gather the following tools: a screwdriver, a ruler or caliper for measuring, and a soft cloth for cleaning. These items will facilitate the adjustment process and ensure that all components are in proper condition.

Adjustment Steps

Begin by unplugging the machine and removing the cover to access the print head. Carefully inspect the print head for any debris or obstructions that may hinder its movement. Using the screwdriver, loosen the screws securing the print head mechanism, allowing for slight adjustments. Align the print head according to the manufacturer’s specifications, ensuring it is parallel to the paper feed. Once aligned, tighten the screws to secure the position and test the alignment with a sample print.

Testing After Repairs

Ensuring the functionality of a device following maintenance is crucial for optimal performance. This phase involves a series of evaluations designed to confirm that all components are operating as intended. Careful assessment not only validates the effectiveness of the recent adjustments but also helps in identifying any lingering issues that may need attention.

Functional Evaluation

Begin by conducting a comprehensive functional evaluation. This process includes testing all major features to verify that they operate smoothly. Observing the performance under various conditions can reveal inconsistencies or malfunctions that weren’t apparent during the initial assessment.

Performance Check

After the functional evaluation, a detailed performance check should be executed. This involves monitoring key indicators such as speed, responsiveness, and overall efficiency. Maintaining high performance standards is essential to ensure that the device meets user expectations. Should any anomalies be detected, further investigation and adjustment may be required.