When it comes to keeping a machine running smoothly, understanding its essential components and common issues is key. This guide serves as a detailed resource for anyone looking to ensure their equipment operates reliably over time. Designed for practical use, it offers insights into how various parts function together and the importance of regular upkeep.

Within these pages, readers will find valuable information on identifying and addressing common malfunctions, allowing for a hands-on approach to equipment care. Each section is dedicated to explaining particular elements, giving clear instructions on checks and adjustments that may prevent future breakdowns.

This resource covers every essential aspect, from basic performance checks to specific troubleshooting techniques. It’s aimed at helping enthusiasts and professionals alike gain the confidence to approach mechanical issues with a well-informed perspective, offering a wealth of knowledge for sustaining operational health and efficiency.

Force 125 Repair Manual

This guide provides essential knowledge for maintaining and troubleshooting a popular motorized model. Whether addressing mechanical issues, performing preventative maintenance, or inspecting various systems, this section aims to assist owners and technicians in keeping their machines running smoothly and efficiently. Careful attention to each area covered here will enable users to extend the life of their vehicles and optimize performance.

| Component | Common Issues | Recommended Actions | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Engine | Overheating, noise, reduced power | Check coolant levels, inspect belts, clean filters, and ensure proper lubrication. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Transmission | Difficulty shifting, unusual sounds | Inspect for leaks, adjust cables, and examine gears for wear. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Electrical System | Non-responsive components, irregular lights | Check wiring connections, test the battery, and examine fuses. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Brakes | Reduced braking efficiency, squeaking |

| Specification | Description | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Engine Type | Two-stroke, single-cylinder | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Cooling System | Water-cooled for efficient heat dissipation | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Ignition System | Electronic ignition for improved start and reliability | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Displacement | Measured in cubic centimeters to define engine size | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Fuel System | Carburetor-based for optimal fuel-air mixture | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Power Output | Maximum horsepower under ideal conditions | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Lubrication | Premixed oil in fuel for component protection |

| Symptom | Possible Cause | Recommended Action |

|---|---|---|

| Flickering lights | Loose connections | Inspect and tighten connections |

| Equipment won’t start | Dead battery | Check and replace the battery if necessary |

| Intermittent power loss | Faulty wiring | Inspect wiring for damage or wear |

| Unusual noises | Malfunctioning components | Examine components for signs of failure |

| Burning smell | Overheating or short circuit | Turn off the power and investigate the source |

Regular inspection and maintenance of the electrical system are essential to prevent unexpected breakdowns. By promptly addressing any signs of trouble, one can extend the lifespan of the components and ensure safe operation.

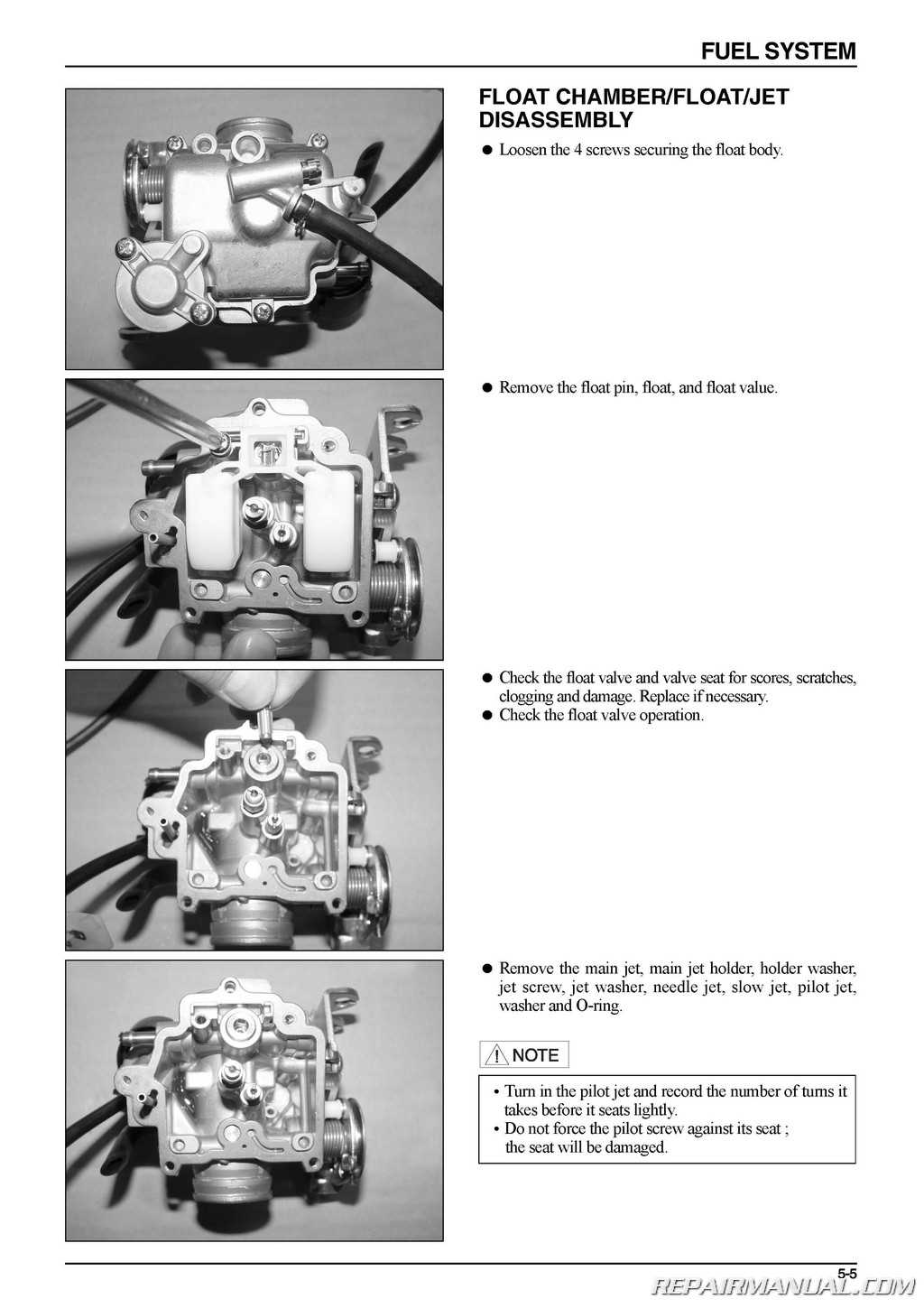

Fuel System Troubleshooting and Fixes

Ensuring optimal performance in any engine relies heavily on the efficiency of its fuel delivery system. When issues arise within this system, they can lead to various operational problems, including poor performance, stalling, or starting difficulties. This section aims to provide insights into identifying common fuel system issues and effective solutions to restore functionality.

Common Symptoms and Diagnoses

Various symptoms can indicate problems within the fuel delivery system. Hard starting often points to fuel starvation, which may be caused by clogged filters or faulty pumps. Similarly, an unusual engine noise or backfiring can suggest incorrect fuel mixture or injector issues. Observing these signs can assist in pinpointing the underlying problems effectively.

Solutions and Preventive Measures

Addressing fuel system issues typically involves several key steps. Regular maintenance of filters and pumps is crucial to prevent blockages and ensure consistent fuel flow. In cases of injector malfunctions, cleaning or replacing them can significantly improve engine response. Moreover, checking fuel lines for leaks and ensuring the correct fuel type is used can prevent many issues from occurring.

Cooling System Maintenance Tips

Proper upkeep of the cooling mechanism is essential for ensuring optimal performance and longevity of any mechanical system. Regular checks and maintenance can prevent overheating and enhance efficiency, allowing the equipment to function smoothly under various conditions.

Here are some important practices to keep the cooling system in top condition:

| Maintenance Task | Frequency | Description |

|---|---|---|

| Check Coolant Levels | Monthly | Ensure that the coolant is at the recommended level to prevent overheating. |

| Inspect Hoses and Connections | Every 3 months | Look for cracks, leaks, or loose connections in hoses that may affect cooling efficiency. |

| Flush the System | Annually | Remove old coolant and sediment by flushing the system to maintain optimal performance. |

| Clean Radiator Fins | Every 6 months | Remove debris from the radiator fins to improve airflow and cooling efficiency. |

| Test Thermostat Functionality | Annually | Ensure the thermostat is opening and closing correctly to regulate engine temperature effectively. |

By following these guidelines, you can significantly enhance the reliability and effectiveness of the cooling system, ultimately leading to a more efficient operation and reducing the likelihood of unexpected failures.

Repairing Common Transmission Problems

Transmission issues can significantly impact vehicle performance and safety. Understanding the typical challenges and their solutions is essential for maintaining optimal functionality. This section outlines prevalent concerns associated with gear systems, offering insights into diagnosing and addressing these complications effectively.

Identifying Symptoms

Before addressing transmission issues, it’s crucial to recognize the symptoms. Common indicators include slipping gears, unusual noises, and delayed engagement. By paying attention to these signs, one can determine the underlying problems and take appropriate action.

Troubleshooting Steps

Once symptoms are identified, follow these steps to troubleshoot the problem:

| Issue | Possible Cause | Recommended Action |

|---|---|---|

| Slipping Gears | Low fluid level or contaminated fluid | Check and refill fluid; replace if contaminated |

| Unusual Noises | Worn bearings or gears | Inspect and replace damaged components |

| Delayed Engagement | Faulty transmission control module | Test module and replace if necessary |

By following these troubleshooting steps, one can effectively address common challenges encountered in gear systems, ensuring reliable vehicle operation.

Brake System Inspection and Repair

The brake system is a critical component of any vehicle, ensuring safety and control during operation. Regular evaluation and maintenance of this system are essential to prevent accidents and enhance performance. This section will guide you through the essential steps for assessing and addressing issues within the braking mechanism.

Begin by performing a visual inspection of all components associated with the braking system. Look for signs of wear, damage, or leaks that could compromise functionality. Common elements to check include brake pads, rotors, calipers, and brake lines. It’s important to assess both the front and rear systems, as well as the parking brake if applicable.

| Component | Inspection Criteria | Recommended Action |

|---|---|---|

| Brake Pads | Thickness, cracking, and uneven wear | Replace if below minimum thickness or damaged |

| Rotors | Surface condition, warping, and thickness | Resurface or replace if uneven or below specifications |

| Calipers | Seals for leaks, operation | Replace if leaking or malfunctioning |

| Brake Lines | Cracks, leaks, and rust | Replace if damaged or corroded |

Once inspections are complete, proceed with any necessary replacements or repairs to ensure optimal performance. Always refer to specifications for torque settings and component compatibility when installing new parts. Maintaining the brake system not only enhances safety but also contributes to the overall longevity of the vehicle.

Routine Lubrication and Fluid Checks

Maintaining optimal performance in machinery involves regular attention to lubrication and fluid levels. Properly lubricated components reduce friction and wear, leading to enhanced efficiency and longevity. Additionally, routine checks of fluid levels ensure that the system operates smoothly and prevents potential damage from inadequate lubrication.

Importance of Lubrication

Lubrication serves as a critical element in minimizing wear on moving parts. Over time, lubricants can degrade, losing their effectiveness. Regularly replacing or replenishing these substances is essential to maintain operational integrity. This practice not only enhances performance but also aids in heat dissipation, keeping components within safe temperature limits.

Fluid Level Monitoring

Checking the levels of various fluids is equally important. This includes engine oil, hydraulic fluid, and coolant. Low fluid levels can lead to overheating, inadequate hydraulic function, and reduced engine performance. Implementing a routine check schedule ensures that these fluids are maintained at appropriate levels, safeguarding against premature wear and potential failures.

Safety Precautions for Maintenance Work

Engaging in servicing activities necessitates a careful approach to ensure the safety of both the technician and the equipment. Adhering to established guidelines and best practices significantly reduces the risk of accidents and enhances the efficiency of the task at hand.

Personal Protective Equipment

Wearing appropriate personal protective equipment (PPE) is crucial during any maintenance task. This includes gloves to shield hands from chemicals and sharp objects, safety glasses to protect eyes from debris, and steel-toed boots to prevent foot injuries. It is essential to choose PPE that fits properly to ensure maximum protection.

Work Area Preparation

Before starting any servicing work, ensure that the workspace is organized and free from hazards. Keep the area well-ventilated and adequately lit. Remove any unnecessary tools or materials that may cause tripping or falling. Additionally, securing loose items and managing electrical cords can help maintain a safe environment.