In the realm of digital storage, maintaining the integrity of optical media is crucial for preserving valuable data. Understanding the processes involved in rejuvenating these items can significantly enhance their longevity and usability. This section delves into the techniques and methodologies that ensure your valuable disks remain functional and reliable.

Whether you are dealing with scratches, smudges, or other imperfections, knowing how to address these issues can save you time and frustration. This comprehensive guide provides insight into various approaches that can be utilized to restore the original quality of your optical items. From simple at-home solutions to more advanced methods, mastering these techniques will empower you to handle and maintain your collection effectively.

Equipped with the right knowledge and tools, you can extend the life of your media, ensuring that your important files and cherished memories are not lost to deterioration. Join us as we explore the essential practices that will help you achieve optimal results in the care of your optical storage devices.

Understanding Elm USA Disc Repair

This section delves into the intricacies of addressing issues with optical media, focusing on methodologies and techniques that enhance the longevity and functionality of such items. A comprehensive understanding of the processes involved can significantly improve performance and usability, ensuring a more enjoyable experience for users.

Common Issues Faced

Users often encounter various challenges, such as scratches, smudges, or other imperfections that affect playback quality. Recognizing these problems is the first step towards finding effective solutions. The typical signs of wear can manifest as skipping, freezing, or distortion, prompting the need for intervention.

Effective Solutions

There are numerous strategies to restore optical media to optimal condition. Techniques range from simple cleaning methods using appropriate solutions to more advanced treatments that involve polishing the surface. Utilizing the right tools and products is essential for achieving the best results without causing further damage.

Maintenance is key; regular care can prevent significant deterioration and extend the lifespan of the media. Educating oneself about the proper handling and storage practices can also make a considerable difference in performance.

Overview of Disc Repair Techniques

In the realm of media restoration, various methodologies exist to address surface imperfections and enhance playback quality. Understanding these techniques is essential for effectively managing and prolonging the lifespan of media formats.

Common approaches to media restoration include:

- Polishing: This method involves using specialized compounds to smooth the surface, thereby reducing scratches and enhancing clarity.

- Cleaning: Regular removal of dust and grime using appropriate cleaning solutions can prevent damage and improve performance.

- Filling: For deeper scratches or pits, materials can be used to fill in the gaps, restoring the surface integrity.

- Laser Treatment: Advanced technology can precisely target and repair imperfections using focused beams, resulting in minimal impact on the media itself.

Each technique offers unique benefits and considerations, making it important to choose the right method based on the type and extent of damage present. By applying these strategies, individuals can effectively enhance the usability of their media collections.

Key Components of the Repair Process

The process of restoring a damaged surface involves several critical elements that ensure effectiveness and longevity. Understanding these components is essential for achieving optimal results and preventing future issues.

Assessment: The initial step is a thorough evaluation of the item’s condition. Identifying the extent of the damage is crucial, as it informs the selection of appropriate techniques and tools for the restoration.

Preparation: Proper preparation of the surface is vital for successful restoration. This may include cleaning, sanding, or any necessary treatment to enhance adhesion and effectiveness of the materials used.

Application: Applying the chosen restorative method requires precision and care. Whether it involves using specialized solutions or employing mechanical methods, adherence to guidelines ensures uniformity and durability.

Finishing: Once the primary restoration is complete, finishing touches are often necessary. This can involve polishing or sealing the surface to provide protection and improve appearance.

Quality Control: The final stage involves a meticulous inspection to confirm that the restoration meets established standards. Addressing any remaining imperfections at this stage is crucial for ensuring lasting results.

Each of these components plays a significant role in the overall success of the restoration endeavor, highlighting the importance of a systematic approach to the task.

Common Issues with Disc Damage

When it comes to the condition of circular media, various complications can arise that hinder functionality. Understanding these common problems is essential for effective troubleshooting and maintenance. Several factors can lead to degradation, impacting performance and usability.

Scratches and Scuffs

Surface abrasions are among the most frequent concerns. These imperfections can disrupt the reading process, causing interruptions or failures in playback. The depth and location of these marks play a crucial role in determining the severity of the issue.

Cracks and Breaks

Structural damage, such as fissures or complete breaks, poses a significant challenge. Even minor cracks can expand over time, leading to more extensive failures. Proper handling and storage are vital to preventing such damages and prolonging the lifespan of the media.

Step-by-Step Repair Instructions

This section provides a clear and concise guide to fixing your equipment effectively. By following these detailed steps, you can restore functionality and enhance performance without needing professional assistance. The process is designed to be straightforward, allowing you to tackle the task confidently.

Tools and Materials Needed

- Cleaning cloth

- Specialized solution for treatment

- Screwdriver set

- Protective gloves

- Soft brush

Repair Process

- Prepare your workspace: Ensure you have a clean and well-lit area to work in.

- Gather all necessary tools and materials: This will help streamline the process.

- Begin with a thorough cleaning: Use the cleaning cloth and specialized solution to remove any dirt or debris from the surface.

- Inspect for damage: Carefully examine the item for any signs of wear or breakage that may need attention.

- Follow the detailed procedures for fixing specific issues: Refer to the guidelines related to the problem you are addressing.

- Reassemble the parts: Once repairs are made, put everything back together securely.

- Test the functionality: Ensure everything is working correctly before concluding the process.

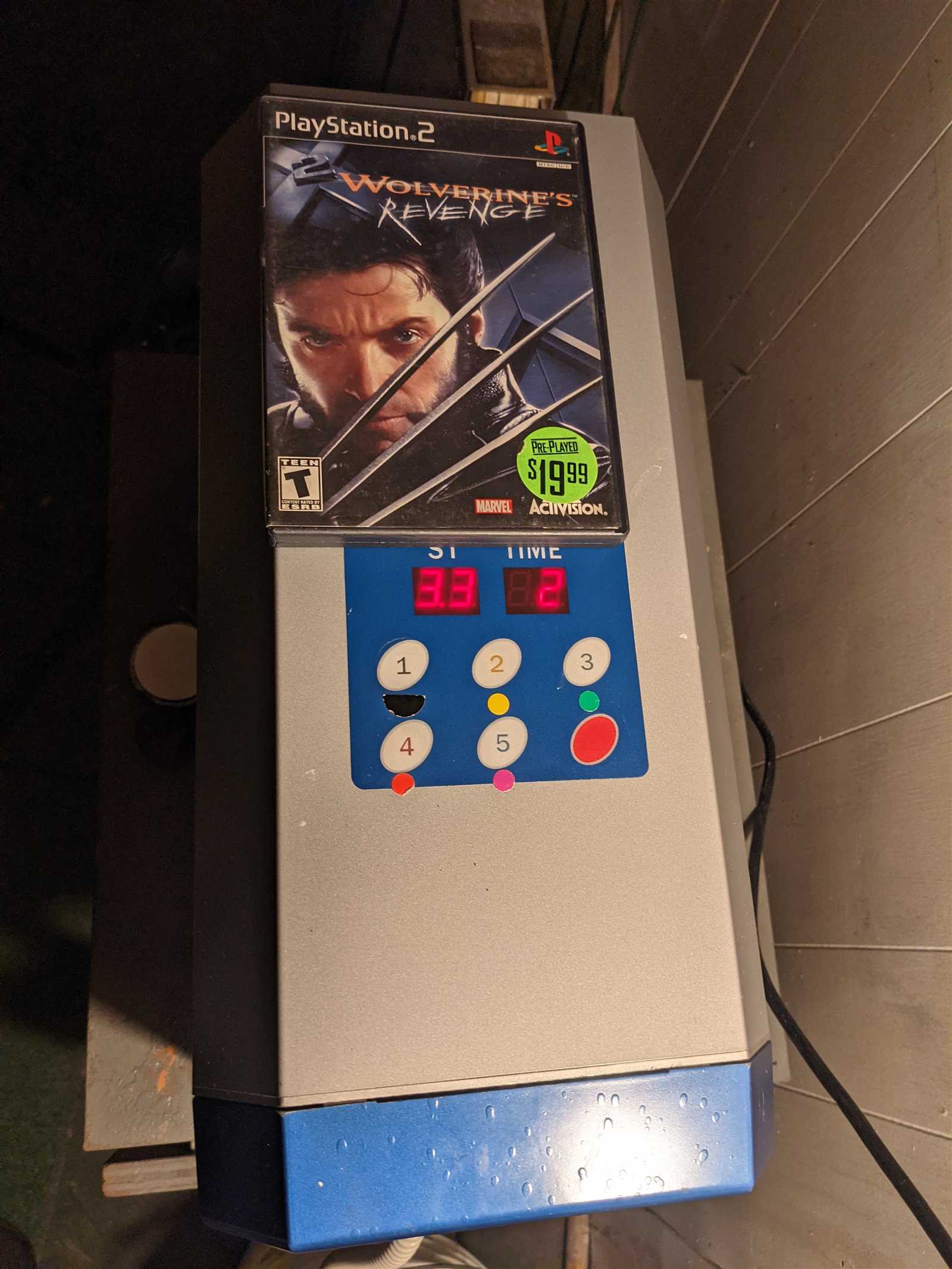

Essential Tools for Disc Repair

When it comes to restoring optical media, having the right instruments at your disposal is crucial for achieving optimal results. Various devices and materials are designed to address different types of imperfections, ensuring that your media is in the best possible condition for playback or use. Understanding these essential implements can greatly enhance your effectiveness in this task.

Polishing Machine: A quality polishing device is vital for removing scratches and restoring clarity. These machines often feature adjustable speeds and various polishing pads to cater to different levels of damage.

Cleaning Solution: A specialized cleaning liquid is important for eliminating dirt and fingerprints without causing additional harm. It is best to choose a solution specifically formulated for optical surfaces.

Microfiber Cloth: Utilizing a soft, lint-free cloth helps to prevent scratching while cleaning the surface. Microfiber materials are particularly effective in lifting grime and debris without leaving residue.

Repair Kits: Comprehensive kits typically include multiple tools, such as applicators, pads, and solutions, tailored for various types of surface flaws. Investing in a reliable kit can streamline the process and provide you with everything you need in one package.

Light Source: A bright, focused light is essential for inspecting the surface for imperfections. It allows for a detailed examination of scratches and other issues, ensuring that no damage goes unnoticed during the restoration process.

Equipping yourself with these fundamental tools will significantly enhance your ability to maintain and rejuvenate your optical media, ensuring longevity and optimal performance.

Preventative Measures for Disc Longevity

Maintaining the integrity of your optical media is essential for ensuring its long-term usability. By adopting specific practices, you can significantly extend the lifespan of these items and safeguard the valuable data they contain. Here are some key strategies to consider for optimal preservation.

Storage Solutions

- Keep media in protective cases to prevent scratches and dust accumulation.

- Avoid exposure to extreme temperatures and humidity, as these conditions can cause warping.

- Store items vertically to reduce pressure and potential damage from weight.

Handling Practices

- Always hold media by the edges to minimize the risk of fingerprints and smudges.

- Clean surfaces gently with a soft, lint-free cloth when necessary.

- Avoid touching the reflective layer, as this can lead to degradation over time.

Implementing these preventative measures will help ensure your optical media remains in optimal condition for years to come.

Safety Precautions During Repair

Ensuring safety during maintenance tasks is crucial for both the individual performing the work and the equipment involved. Adhering to specific guidelines helps prevent accidents and injuries, creating a secure environment for effective operations. Awareness of potential hazards and proper preparation can significantly mitigate risks associated with the process.

Personal Protective Equipment

Utilizing appropriate personal protective gear is essential. This includes safety glasses to shield the eyes from debris, gloves to protect hands from sharp objects or chemicals, and steel-toed boots to guard against heavy items. Additionally, wearing a mask may be necessary to avoid inhaling harmful particles or fumes, ensuring a safer working atmosphere.

Work Area Management

Maintaining a clean and organized workspace is vital. Clutter can lead to accidents, making it difficult to navigate the area safely. Ensure that tools are stored correctly, and any spills are cleaned promptly. Adequate lighting should be provided to enhance visibility, further reducing the likelihood of mishaps during the task.

Repairing Different Disc Formats

In the realm of optical media, various types demand unique approaches for restoration. Understanding the nuances of each format is essential for achieving optimal results.

Common formats include:

- CDs

- DVDs

- Blu-ray discs

Each type presents specific challenges and techniques:

- CDs: Focus on removing scratches using polishing compounds or specialized tools.

- DVDs: Address issues with data retrieval by ensuring the surface is clean and free from smudges.

- Blu-ray discs: Handle repairs with caution, as their surface is more sensitive to damage.

By mastering the methods for each format, one can effectively restore functionality and extend the life of optical media.

Evaluating Repair Success

Assessing the effectiveness of restoration efforts is crucial for ensuring optimal performance and longevity. This process involves analyzing various indicators to determine whether the undertaken actions have yielded the desired outcomes. By examining these factors systematically, one can make informed decisions about future maintenance and enhancements.

Key Performance Indicators

To gauge the success of the undertaken procedures, several key performance indicators should be considered. These may include functionality, visual appearance, and overall durability. Observing improvements in these areas provides a clear picture of the efficacy of the methods applied.

Feedback and Monitoring

Continuous feedback is essential for ongoing evaluation. Engaging with users and conducting regular inspections allows for the identification of any lingering issues. This iterative approach not only helps in understanding current results but also informs strategies for potential future interventions.

Frequently Asked Questions

This section addresses common inquiries related to the maintenance and restoration of specific equipment. Here, you will find answers to popular questions, helping you navigate the processes with ease and confidence.

What tools are needed for effective maintenance?

To ensure optimal functioning, you will require basic tools such as screwdrivers, wrenches, and cleaning supplies. Additionally, specialized instruments may be necessary for certain tasks.

How often should I perform maintenance tasks?

Regular upkeep is essential for longevity. It is recommended to conduct routine checks every three to six months, with more frequent inspections if the equipment is used heavily.

Resources for Further Learning

Enhancing your understanding of equipment maintenance and restoration can be greatly facilitated by various resources available today. Whether you are seeking practical advice or in-depth knowledge, there are numerous avenues to explore that can help you become proficient in this area.

- Online Courses: Many platforms offer comprehensive courses focusing on maintenance techniques, tools, and safety protocols.

- YouTube Channels: A variety of content creators provide visual guides and tutorials, making complex processes easier to grasp.

- Books: Look for texts that cover fundamental concepts as well as advanced techniques in your area of interest.

- Forums and Online Communities: Engage with others who share your passion. These platforms can be invaluable for advice and troubleshooting.

By leveraging these resources, you can deepen your expertise and gain confidence in your skills, ultimately leading to successful outcomes in your projects.

Customer Support and Warranty Information

Ensuring a seamless experience for our clients is a top priority. We offer comprehensive assistance to address any inquiries or concerns regarding our products. Our dedicated support team is available to guide you through any issues that may arise, providing expert solutions tailored to your needs.

In addition to our support services, we also provide a robust warranty for all products. This coverage reflects our commitment to quality and customer satisfaction. Should you encounter any defects or operational challenges, our warranty policy is designed to offer you peace of mind, allowing you to make the most of your purchase.

For assistance, please reach out to our customer support channels, where you can expect prompt responses and personalized service. We appreciate your trust in our products and strive to maintain the highest standards in both service and quality assurance.