In today’s fast-paced world, ensuring the functionality of household equipment is crucial for seamless daily operations. A comprehensive understanding of troubleshooting techniques can significantly enhance the longevity and efficiency of these essential devices. Knowledge in this area not only empowers users to address minor issues but also fosters a proactive approach to equipment management.

Home appliances are intricate systems that require periodic attention and care. By familiarizing oneself with the common problems and their solutions, individuals can save both time and money. This insightful guide aims to provide practical strategies for identifying and resolving typical malfunctions, equipping readers with the tools necessary for effective maintenance.

Whether dealing with electric cooking tools or heating systems, knowing the fundamental aspects of functionality can prevent minor inconveniences from escalating into major repairs. Understanding the operational principles and components involved is key to diagnosing problems accurately. Thus, this resource serves as an invaluable asset for anyone looking to optimize their household equipment performance.

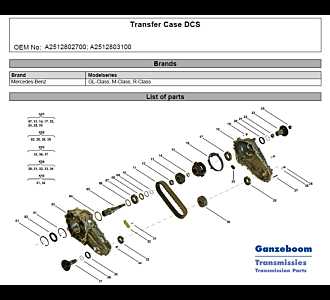

Understanding DCS Range Components

The effective operation of complex systems relies on the seamless integration of various elements, each fulfilling a specific function. A comprehensive grasp of these components is crucial for optimizing performance and ensuring reliability. This section delves into the essential parts that contribute to the overall functionality, highlighting their roles and interconnections.

Key Elements and Their Functions

At the core of these systems are several pivotal elements. Each component serves a unique purpose, from data collection to processing and transmission. Understanding the specifics of these parts enables operators to troubleshoot issues effectively and maintain operational efficiency. The interplay among these elements is fundamental to achieving desired outcomes in various scenarios.

Interconnected Systems

The interconnected nature of these components means that a change in one part can significantly impact others. It is essential to recognize these relationships and how they contribute to the system’s overall performance. By analyzing these connections, users can better anticipate potential challenges and implement proactive solutions.

Common Issues in DCS Ranges

Various challenges can arise during the operation and maintenance of simulation environments. Understanding these common pitfalls is essential for effective troubleshooting and ensuring optimal performance.

- Inaccurate Data Representation:

Discrepancies in the data displayed can lead to confusion and misinterpretation. This may be caused by:

- Software glitches

- Improper calibration of sensors

- Outdated firmware

- Connectivity Issues:

Problems with network connectivity can disrupt the flow of information. Common causes include:

- Faulty cables

- Network configuration errors

- Insufficient bandwidth

- Hardware Malfunctions:

Physical components may fail due to wear and tear, leading to operational difficulties. Typical hardware-related issues involve:

- Overheating components

- Power supply failures

- Worn-out connectors

- User Interface Challenges:

A confusing user interface can hinder usability. Factors contributing to this may include:

- Poor design choices

- Lack of intuitive navigation

- Insufficient training resources

- Environmental Factors:

External conditions can significantly impact functionality. Key environmental issues include:

- Temperature fluctuations

- Humidity levels

- Electromagnetic interference

Addressing these challenges promptly can enhance the overall efficiency and reliability of the systems in question.

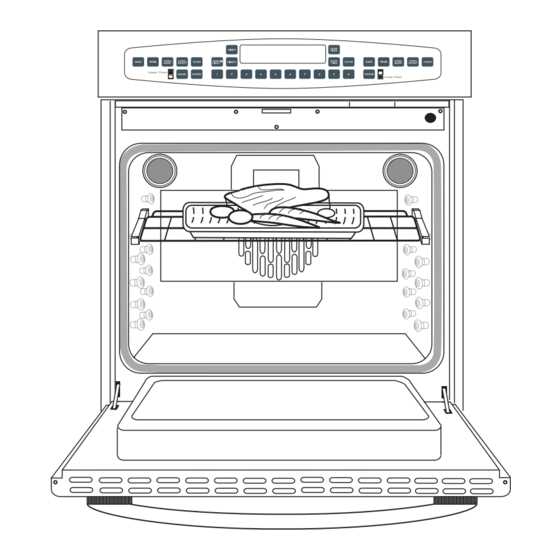

Step-by-Step Repair Process

When faced with issues in kitchen appliances, a structured approach can significantly ease the troubleshooting and fixing journey. This section outlines a comprehensive procedure that ensures efficient diagnosis and resolution of common problems.

1. Initial Assessment: Begin by identifying the symptoms. Observe any unusual behavior, sounds, or error messages that can provide clues. Make notes of these observations, as they will be useful in the subsequent steps.

2. Safety Precautions: Before diving into any work, ensure your safety. Disconnect the appliance from the power source and take necessary precautions to avoid any hazards.

3. Gather Tools and Supplies: Compile the necessary tools and replacement parts based on the identified issues. Having everything at hand will streamline the process and minimize interruptions.

4. Disassembly: Carefully disassemble the appliance, taking care to remember the arrangement of parts. Documenting the process with photos can help during reassembly.

5. Inspection: Examine the internal components for any signs of damage, wear, or loose connections. This step is crucial for pinpointing the root cause of the malfunction.

6. Component Replacement: If damaged parts are found, proceed to replace them with compatible components. Ensure that all replacements meet the necessary specifications to maintain functionality.

7. Reassembly: Once repairs are complete, carefully reassemble the appliance. Follow your earlier documentation to ensure every part is correctly positioned.

8. Testing: After reassembly, reconnect the appliance and conduct a series of tests to confirm that the issue has been resolved. Monitor for any recurring symptoms.

9. Final Cleanup: After successful testing, clean up your workspace and properly dispose of any waste materials. This ensures a safe and organized environment for future tasks.

10. Documentation: Finally, keep a record of the work done, including any parts replaced and observations noted. This documentation can be invaluable for future reference.

Tools Required for DCS Repair

Having the right equipment is essential for effective maintenance and troubleshooting of complex systems. This section outlines the necessary tools that facilitate efficient diagnostics and restoration of functionality. Proper tools not only enhance the precision of your work but also ensure safety and longevity of the components involved.

- Multimeter: Vital for measuring voltage, current, and resistance.

- Screwdrivers: A variety of sizes and types, including Phillips and flathead, are necessary for assembling and disassembling components.

- Wrenches: Adjustable and fixed wrenches for tightening and loosening bolts and nuts.

- Pliers: Needle-nose and standard pliers are useful for gripping and bending wires.

- Soldering Iron: Essential for repairing or replacing electronic connections.

In addition to the basic tools, certain specialized instruments may be required for specific tasks:

- Oscilloscope: For visualizing electrical signals, crucial in diagnosing circuit issues.

- Wire Strippers: To remove insulation from wires without damaging the conductor.

- Heat Gun: Useful for shrinking tubing and softening materials for easier manipulation.

- Calibration Equipment: Ensures that devices are functioning within specified parameters.

Utilizing the right tools will not only streamline the process but also improve the overall quality of the work performed. Proper maintenance can significantly extend the life of the systems involved.

Troubleshooting Electrical Problems

Identifying and resolving electrical issues can often be a challenging task, yet it is essential for ensuring the optimal functioning of your appliance. This section provides guidance on systematically diagnosing and rectifying common electrical malfunctions. By following these steps, you can improve your understanding of potential faults and enhance the efficiency of your device.

Common Issues and Solutions

| Issue | Possible Cause | Solution |

|---|---|---|

| Power Failure | Blown fuse or tripped circuit breaker | Check and replace the fuse or reset the circuit breaker. |

| Inconsistent Heating | Faulty heating element | Inspect the heating element for damage and replace if necessary. |

| Unresponsive Controls | Defective control board | Test the control board connections and consider replacement if malfunctioning. |

Safety Precautions

Always prioritize safety when dealing with electrical components. Ensure the appliance is unplugged before conducting any inspections or repairs. Use insulated tools and wear appropriate protective gear to minimize the risk of electric shock.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of kitchen appliances requires regular care and attention. By implementing a few simple practices, users can significantly extend the lifespan of their devices while enhancing their efficiency. This section outlines essential strategies for maintaining functionality and reliability.

Regular Cleaning

Consistent cleanliness is vital for any kitchen equipment. Make it a habit to wipe down surfaces after each use to prevent the buildup of grime and residue. Utilize a soft cloth and gentle cleaning agents to avoid damaging sensitive components. Deep cleaning every few months can help eliminate hidden dirt and ensure smooth operation.

Proper Usage and Settings

Understanding how to use your appliances correctly is key to preventing wear and tear. Always refer to the manufacturer’s guidelines regarding temperature settings and recommended cooking practices. Avoid overloading devices and ensure adequate ventilation to prevent overheating, which can lead to premature failure.

Safety Precautions During Repairs

Ensuring a secure environment while conducting maintenance tasks is essential for both the technician and the appliance. Adhering to certain safety measures can significantly reduce the risk of accidents and injuries. It is vital to approach these tasks with caution and a well-thought-out plan.

First and foremost, always disconnect the device from its power source before beginning any work. This step is crucial to prevent electrical shocks or unexpected activations. Utilize appropriate tools designed for the specific tasks to enhance efficiency and safety.

Furthermore, wear suitable personal protective equipment (PPE), such as gloves and safety goggles. These items can protect against sharp edges and potential chemical exposure, which may arise during maintenance. Always ensure your workspace is tidy and free of obstructions to minimize the risk of tripping or falling.

Additionally, familiarize yourself with the equipment’s operational guidelines and follow manufacturer recommendations. If uncertain about any procedure, consult professional assistance or reliable resources before proceeding. This cautious approach can prevent mishaps and ensure a successful outcome in the maintenance process.

Replacing Damaged Parts Effectively

When components fail, timely and precise replacement is crucial for maintaining optimal performance. This section outlines essential practices to ensure that damaged elements are swapped out efficiently, minimizing downtime and preserving functionality.

Assessment and Preparation

Before initiating the replacement process, a thorough assessment is vital. This involves identifying the specific parts that require attention and gathering necessary tools and materials. Consider the following steps:

- Conduct a visual inspection to pinpoint visible damage.

- Refer to technical specifications to confirm part compatibility.

- Organize required tools to streamline the process.

Replacement Process

Once the assessment is complete, follow these guidelines for effective replacement:

- Power down the unit to ensure safety.

- Carefully remove the damaged part, taking note of its connections.

- Install the new component, ensuring secure fitment.

- Reconnect any necessary wiring or attachments.

- Power on the unit to test functionality before finalizing the installation.

Adhering to these practices will facilitate a smooth transition, prolonging the lifespan of your equipment and enhancing its overall performance.

Upgrading Your DCS Range

Enhancing your cooking appliance can transform your culinary experience, making it more efficient and enjoyable. This section will explore various ways to modernize your equipment, improving functionality and aesthetics while ensuring safety and performance.

Choosing New Features

When considering an upgrade, think about the additional functionalities you desire. Modern appliances often come with advanced features such as touch controls, smart technology integration, and improved heat distribution. These enhancements not only streamline your cooking process but also elevate the overall experience.

Maintaining Aesthetics

Upgrading isn’t solely about performance; aesthetics play a crucial role as well. Selecting a stylish finish or coordinating with your kitchen’s decor can significantly enhance the visual appeal. Consider options that match your personal style while ensuring durability and ease of cleaning.

In conclusion, investing in modern features and aesthetic upgrades can greatly enhance your cooking setup, making it a more enjoyable space for culinary creativity.

When to Call a Professional

Understanding when to seek expert assistance can save you time, money, and frustration. While some issues may seem manageable, there are situations where the knowledge and skills of a trained technician are essential for safe and effective resolution.

Identifying Complex Issues

It is crucial to recognize signs that indicate a problem may be beyond your expertise. Complex malfunctions often require specialized tools and experience to diagnose and fix properly. Here are some scenarios where professional help is recommended:

| Signs of Trouble | Why Call an Expert? |

|---|---|

| Persistent malfunction | Repeated failures suggest underlying issues that need thorough investigation. |

| Unusual noises or smells | These can indicate serious problems that may pose safety risks. |

| Inconsistent performance | Fluctuations in functionality often require technical adjustments or parts replacement. |

Safety Concerns

Another critical factor in determining the need for a specialist is safety. If you encounter any signs that could endanger your well-being or that of others, it is vital to refrain from attempting repairs yourself. Always prioritize safety by contacting a qualified individual when in doubt.