In the world of fabric arts, maintaining your stitching device is essential for seamless creativity. Understanding the intricacies of your equipment not only enhances performance but also prolongs its lifespan. This section delves into effective strategies for addressing common issues that may arise during usage.

Every machine, regardless of its brand or model, can encounter challenges over time. From thread jams to inconsistent stitching, these problems can hinder your projects and lead to frustration. Here, we explore practical solutions and expert tips to help you navigate through the typical hurdles faced by sewing enthusiasts.

By familiarizing yourself with the mechanisms of your tool and learning how to perform routine checks, you can ensure smooth operation. This guide aims to empower users with the knowledge needed to troubleshoot effectively, enabling you to focus on what you love most–creating beautiful works of art with fabric.

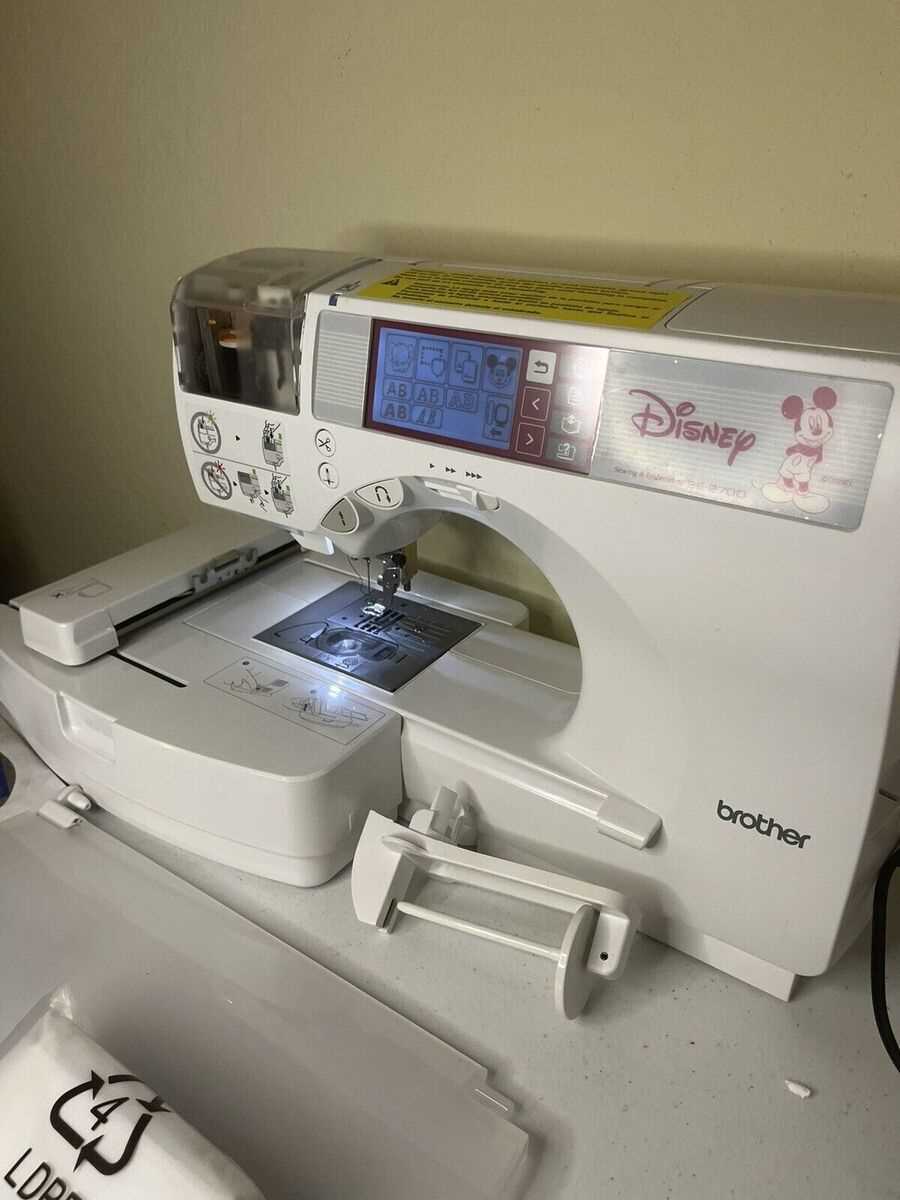

Understanding Brother SE-270D Features

This section explores the various attributes and capabilities of a well-known embroidery and sewing machine, designed for both beginners and experienced users. With a blend of modern technology and user-friendly design, this device offers a range of functionalities that enhance creativity and ease of use in textile arts.

Key Functionalities

The machine comes equipped with numerous built-in designs and stitch patterns, allowing users to personalize their projects effortlessly. Its intuitive interface simplifies the process of selecting and customizing patterns, making it accessible for all skill levels. Additionally, the automatic needle threading feature reduces preparation time, enabling seamless transitions between tasks.

Enhanced Performance

Engineered for efficiency, this sewing tool provides adjustable speed settings that cater to different project requirements. Its durable construction ensures longevity, while the included accessories further expand the possibilities for various types of fabrics and techniques. Overall, this machine stands out as a versatile solution for anyone passionate about sewing and embroidery.

Common Issues with Brother SE-270D

This section addresses frequently encountered problems that users may face with their embroidery and sewing machines. Understanding these issues can aid in troubleshooting and maintaining optimal performance.

- Thread Breakage:

This can occur due to several reasons, including incorrect threading, poor quality thread, or tension settings being off. Regular checks and adjustments can mitigate this issue.

- Skipped Stitches:

Skipped stitches often result from a dull needle, incorrect needle type, or improper threading. Ensuring the right needle and maintaining its sharpness can help prevent this problem.

- Tension Problems:

Inconsistent stitches may be a sign of tension issues. Factors like thread type, fabric thickness, and machine settings can all contribute. Adjusting the tension dial can often resolve this.

- Fabric Jamming:

Fabric can jam if it is not fed correctly or if there are obstructions in the machine. Keeping the work area clean and ensuring proper feeding can reduce the likelihood of jams.

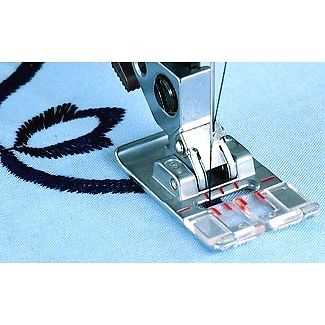

- Uneven Stitching:

This problem may arise from incorrect presser foot pressure or improper fabric handling. Adjusting the presser foot and ensuring even feeding can help achieve more consistent results.

By recognizing these common challenges, users can implement preventative measures and make informed decisions when issues arise, ensuring a smoother sewing experience.

Essential Tools for Repairing SE-270D

When tackling maintenance tasks on sewing machines, having the right set of instruments is crucial for ensuring efficiency and precision. The appropriate tools not only facilitate troubleshooting but also enhance the overall performance of the device. Below is a comprehensive list of essential instruments that will aid in servicing and maintaining the equipment effectively.

| Tool | Description |

|---|---|

| Screwdriver Set | A variety of screwdrivers, both flathead and Phillips, for accessing different parts. |

| Wrench | Used for loosening or tightening nuts and bolts during disassembly. |

| Pliers | Essential for gripping small parts or wires that may be difficult to handle. |

| Seam Ripper | A handy tool for removing stitches that need correction. |

| Cleaning Brush | A soft brush to remove dust and lint from the interior mechanisms. |

| Lubricant | Specialized oil to ensure smooth operation of moving parts. |

| Needle Set | A range of needles suitable for different fabrics and tasks. |

| Thread | Quality thread in various colors for stitching and repairs. |

Equipping yourself with these tools will significantly improve your ability to diagnose issues and perform necessary adjustments with confidence. Proper maintenance is key to extending the lifespan and functionality of the machine.

Step-by-Step Troubleshooting Guide

This section provides a comprehensive approach to diagnosing and resolving common issues that may arise during the operation of your sewing machine. By following a structured methodology, you can identify the root cause of a problem and implement effective solutions, ensuring your equipment performs optimally.

Identifying the Problem

Before diving into solutions, it’s essential to clearly understand the issue at hand. Here are some steps to help you identify the problem:

- Check for unusual noises or malfunctions.

- Examine the fabric and thread for tangles or snags.

- Note any error messages or warning lights on the machine.

Common Issues and Solutions

Once you have pinpointed the issue, refer to the following common problems and their respective solutions:

- Machine Not Starting

- Ensure the power cord is securely plugged in.

- Check the outlet for functionality by testing another device.

- Thread Bunching

- Re-thread the upper thread and check for proper tension.

- Inspect the bobbin for correct placement and alignment.

- Skipped Stitches

- Change the needle if it is dull or bent.

- Adjust the tension settings and ensure the thread is not too thick for the needle.

By systematically addressing these common issues, you can enhance the performance and longevity of your sewing machine. Remember to document any changes made during the troubleshooting process for future reference.

Replacing the Sewing Machine Needle

Changing the needle in your stitching device is a crucial maintenance task that ensures optimal performance and high-quality results. A dull or damaged needle can lead to uneven stitches, fabric snags, and even machine malfunctions. Regularly replacing the needle is a simple yet effective way to enhance your sewing experience.

Here are the steps to successfully change the needle:

- Gather Your Tools:

- New needle appropriate for your projects

- Screwdriver (if needed)

- Cleaning brush (optional)

- Turn Off the Machine: Always ensure the device is powered down to prevent any accidents.

- Remove the Old Needle:

- Loosen the needle clamp screw using your screwdriver.

- Gently pull the needle down and out of the holder.

- Insert the New Needle:

- Take the new needle and insert it into the clamp with the flat side facing the back.

- Tighten the needle clamp screw securely.

- Check Alignment: Ensure the needle is straight and properly positioned for optimal sewing.

- Test the Machine: Power on the device and run a few stitches on scrap fabric to confirm everything is functioning smoothly.

Following these steps will help maintain your machine’s efficiency and extend its lifespan. Regular needle changes will contribute to a more enjoyable and successful sewing experience.

Fixing Thread Tension Problems

Maintaining the right thread tension is crucial for achieving optimal stitching results. When tension is off, it can lead to various issues such as uneven stitches, thread breakage, or puckering. Understanding how to adjust tension settings effectively can help ensure that your sewing projects turn out perfectly every time.

To address tension problems, it is important to first identify whether the issue originates from the upper or lower thread. Each type of thread and fabric may require different tension adjustments to achieve the best results.

| Issue | Possible Cause | Solution |

|---|---|---|

| Loose stitches | Upper thread tension too low | Increase upper tension by adjusting the tension dial. |

| Tight stitches | Upper thread tension too high | Decrease upper tension by adjusting the tension dial. |

| Thread breakage | Incorrect tension settings | Check and adjust both upper and bobbin tensions. |

| Puckering fabric | Improper thread tension | Loosen the upper tension and use appropriate presser foot pressure. |

Regular maintenance and proper threading techniques also play vital roles in preventing tension issues. Ensuring that the thread is correctly positioned and the machine is clean can greatly improve performance and reduce the likelihood of complications.

Maintenance Tips for Longevity

Ensuring the durability of your device requires regular care and attention. By following a few essential practices, you can significantly extend its lifespan and maintain optimal performance.

Regular Cleaning

- Dust and debris can accumulate over time, leading to operational issues. Use a soft, lint-free cloth to clean the exterior regularly.

- Check and clean any accessible internal components according to the manufacturer’s guidelines to prevent buildup.

- Utilize compressed air to remove dust from hard-to-reach areas, ensuring that all vents and openings are free from obstructions.

Proper Usage and Storage

- Always follow the recommended usage instructions to avoid strain on the device.

- Store the equipment in a cool, dry place to protect it from moisture and extreme temperatures.

- Avoid exposing the device to direct sunlight for prolonged periods, as this can lead to overheating and damage.

Implementing these strategies will help ensure that your equipment remains in top condition for years to come, enhancing both its functionality and reliability.

How to Clean the Machine Effectively

Maintaining cleanliness is essential for the optimal performance of your sewing device. Regular cleaning not only prolongs its lifespan but also ensures high-quality stitching. This section provides guidance on effective cleaning techniques that can help keep your equipment in excellent condition.

Essential Cleaning Supplies

Before starting the cleaning process, gather the necessary tools. You will need:

- A soft brush for dust removal

- Lint-free cloths to wipe surfaces

- Cleaning solution suitable for your equipment

- Small screwdriver for disassembling parts

Step-by-Step Cleaning Process

1. Disconnect the Power: Always unplug the device before cleaning to ensure safety.

2. Remove Dust and Lint: Use the soft brush to gently remove dust and lint from the surface and inside the machine. Pay special attention to areas around the needle and bobbin.

3. Wipe Down Surfaces: Dampen a lint-free cloth with a cleaning solution and wipe down the exterior. Avoid using excessive liquid, as moisture can damage internal components.

4. Inspect and Clean Moving Parts: If accessible, carefully disassemble parts using a screwdriver. Clean each component and reassemble them securely.

5. Regular Maintenance: Establish a routine cleaning schedule to prevent buildup of debris, ensuring your equipment operates smoothly.

By following these steps, you can keep your sewing apparatus clean and functioning optimally, allowing for enjoyable and efficient sewing experiences.

Electrical Problems and Solutions

Understanding electrical issues is crucial for maintaining the optimal performance of your device. This section aims to provide insights into common electrical malfunctions and their corresponding remedies, ensuring a smoother operation and longevity.

- Power Failure:

- Check the power source to ensure it’s functioning.

- Inspect the power cord for any visible damage.

- Verify that the outlet is operational by testing it with another device.

- Intermittent Operation:

- Examine connections and ensure they are secure.

- Look for signs of wear on cables or connectors.

- Consider resetting the device to clear any temporary faults.

- Unusual Noises:

- Identify the source of the noise to determine if it’s mechanical or electrical.

- Check for loose components that may be causing vibrations.

- Consult user guides for specific noise indicators related to your model.

- Overheating:

- Ensure the device is in a well-ventilated area.

- Clean any dust buildup from vents and fans.

- Monitor usage patterns; excessive use may lead to overheating.

By addressing these common electrical concerns, users can significantly improve the reliability and efficiency of their equipment. Always prioritize safety and consult a professional if problems persist.

Finding Replacement Parts Easily

Locating the right components for your machine can be a straightforward process if you know where to look. With the advancement of technology and the internet, accessing the necessary items has never been simpler. Understanding the available resources and platforms can save you time and effort, ensuring your device remains functional.

One effective way to source components is by visiting specialized online retailers. These websites often stock a wide range of items tailored for specific models, allowing for efficient browsing and purchasing. Be sure to check customer reviews and ratings to ensure the reliability of the seller.

Another option is to explore local supply stores. Many shops offer parts for various equipment, and a knowledgeable staff can assist in identifying the right component for your needs. Additionally, building a rapport with local technicians can provide insights into the best sources for parts.

Online forums and communities dedicated to enthusiasts of similar devices can also be invaluable. Engaging with fellow users can lead to recommendations for trustworthy suppliers and even second-hand options that are still in good condition.

Lastly, don’t overlook the importance of keeping a record of your device’s specifications. Having model numbers and details readily available will streamline your search process, ensuring you find the correct parts efficiently.

Utilizing the User Manual Wisely

Understanding how to effectively navigate an instruction guide can significantly enhance your experience with any device. It serves as a valuable resource, offering insights into features, troubleshooting steps, and maintenance tips. By leveraging this document, users can optimize their usage and ensure longevity of the product.

To make the most out of the provided guidance, consider the following strategies:

| Strategy | Description |

|---|---|

| Familiarization | Spend time reviewing the entire document to understand its layout and content structure. |

| Index Usage | Utilize the index or table of contents to quickly locate specific topics or sections that are relevant to your needs. |

| Follow Instructions | Adhere to the provided guidelines step-by-step to avoid errors and ensure proper operation. |

| Regular Reference | Keep the guide accessible for ongoing reference, especially during setup or troubleshooting scenarios. |

| Highlight Important Sections | Mark crucial information or frequently used procedures for quick access in the future. |

By incorporating these practices, users can navigate their devices with confidence and efficiency, turning challenges into manageable tasks.

When to Seek Professional Help

Determining the right moment to enlist the assistance of a skilled technician can significantly impact the outcome of your troubleshooting efforts. While many issues can be resolved through self-guided methods, some situations demand expert intervention to avoid further complications or damage.

Signs You Need Expert Assistance

Recognizing specific indicators can help you decide when to contact a professional. Below are common signs that may suggest it’s time to seek help:

| Indicator | Explanation |

|---|---|

| Persistent Problems | If issues continue despite repeated attempts to fix them, professional evaluation may be necessary. |

| Unusual Noises | Sounds that are out of the ordinary can indicate underlying mechanical issues requiring specialized knowledge. |

| Burning Smells | Any scent resembling burning can be a serious concern, often signaling electrical faults that need immediate attention. |

| Visible Damage | Cracks, fraying, or any visible signs of wear can compromise functionality and should be assessed by a professional. |

| Loss of Functionality | If essential features are no longer operational, it may indicate a need for expert diagnosis and repair. |

Benefits of Professional Intervention

Engaging a qualified expert can bring several advantages. They possess specialized training and experience, enabling them to diagnose issues accurately and implement effective solutions. Moreover, seeking help from a technician can often save time and prevent potential long-term damage that might occur with improper handling.