For enthusiasts of vintage air rifles, achieving smooth functionality and maintaining peak performance over time can present unique challenges. Understanding the intricate components and how they work in harmony is essential for preserving both the accuracy and longevity of such a piece. This guide serves as a comprehensive look at how to assess, fine-tune, and ensure ongoing operation, helping users keep their equipment in optimal condition.

With practical instructions, this guide focuses on adjustments, essential upkeep practices, and addressing common issues that may arise with extended use. Step-by-step insights and tips for troubleshooting will provide users with the know-how to resolve issues and keep their device in prime working order.

From calibrating sensitive parts to ensuring the durability of internal mechanisms, this resource aims to empower hobbyists with actionable knowledge. Whether you’re restoring a long-cherished piece or simply fine-tuning for accuracy, this guide will support your efforts to maintain and enjoy a reliable and precise shooting experience.

Troubleshooting Common Issues in Daisy Model 840

Even the most reliable air-powered equipment may occasionally experience operational issues, and understanding how to identify and address these is crucial for consistent performance. This section outlines frequent challenges users might face and provides practical steps for effective troubleshooting, helping to maintain functionality over time.

Addressing Power and Airflow Concerns

In cases where the device seems to lack adequate propulsion, the problem may be related to air seals or internal mechanisms responsible for maintaining pressure. Begin by examining seals for any visible signs of wear or damage; a compromised seal can result in reduced force and inconsistent operation. Replacing damaged seals or recalibrating the internal components can often restore proper performance. For airflow issues, ensure all passageways are clean and free of obstructions, as debris buildup can hinder performance significantly.

Tackling Misalignment and Loading Problems

Occasionally, alignment or feeding mechanisms may cause issues with functionality. If loading components do not sit correctly, inspect the chamber to verify alignment and ensure there are no obstructions. Properly seated components prevent jams and ensure smooth operation. In addition, check moving parts for debris or residue buildup, as this can also impact alignment and lead to misfires or blockages. A thorough cleaning and regular lubrication can enhance operational reliability and reduce misalignment risks.

Essential Tools for Daisy Model Repairs

When working on these types of air-powered devices, a few key tools ensure effective and safe handling, preserving both functionality and integrity. These instruments simplify disassembly, allow for precise adjustments, and provide the stability needed for sensitive components.

Screwdrivers and Wrenches are fundamental for accessing internal parts, as they enable the removal of screws and bolts without damaging surfaces. Precision screwdrivers, in particular, assist with smaller fasteners commonly found in the internal assembly.

Cleaning and Lubricating Materials are vital for smooth operation and longevity. Using oil specifically designed for air-powered mechanisms keeps moving parts working efficiently, while cleaning brushes and cloths remove dirt and debris from critical areas.

Safety Gear like protective eyewear and gloves ensures safe handling during maintenance, guarding against unexpected discharge or spring tension. Keeping hands and eyes protected reduces the risk of injury and allows for more focused work.

Calibration Tools help in adjusting tension and alignment, ensuring that all parts function as intended. Tools such as measuring gauges and alignment tools assist with precise adjustments that optimize the device’s performance.

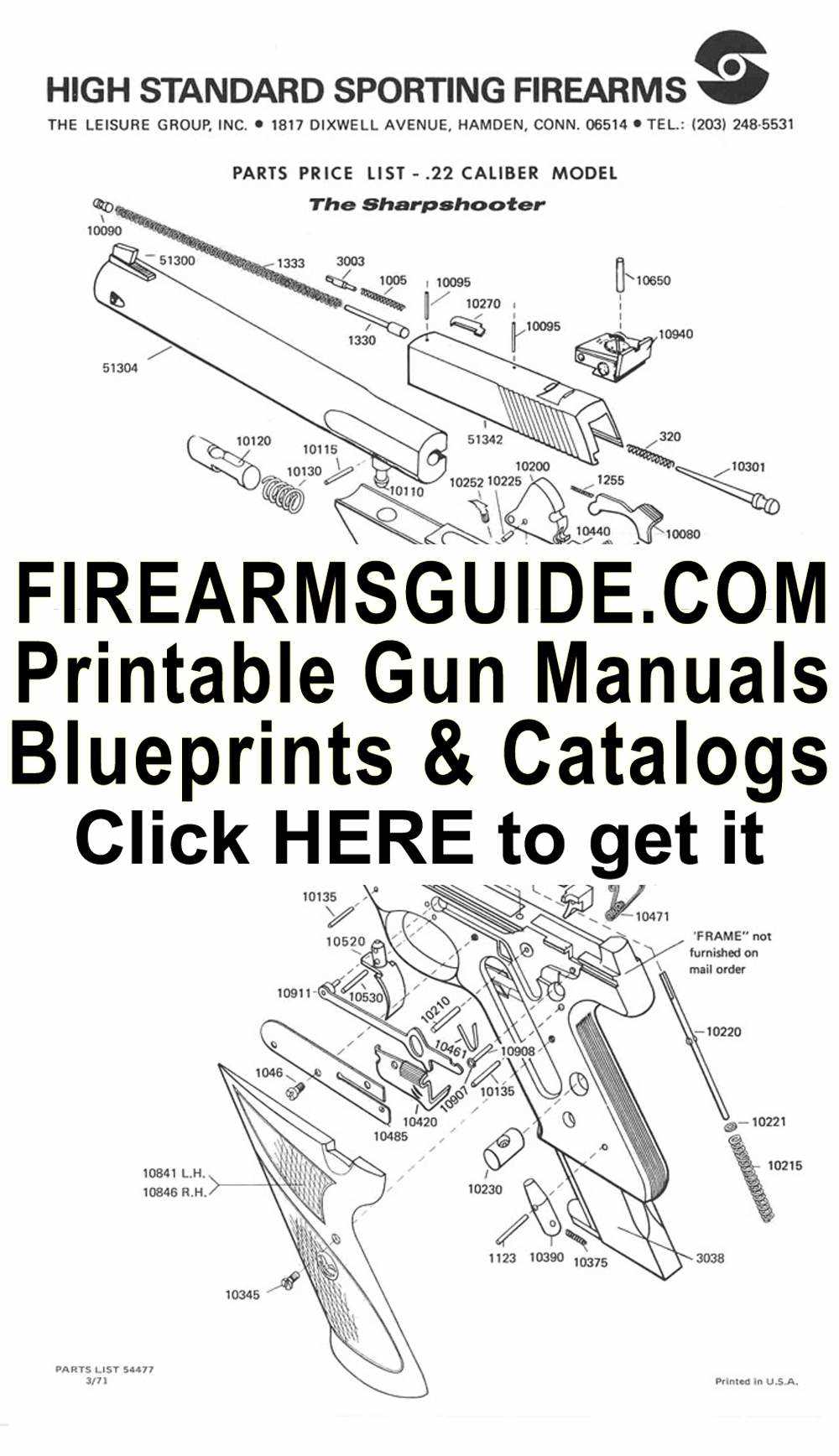

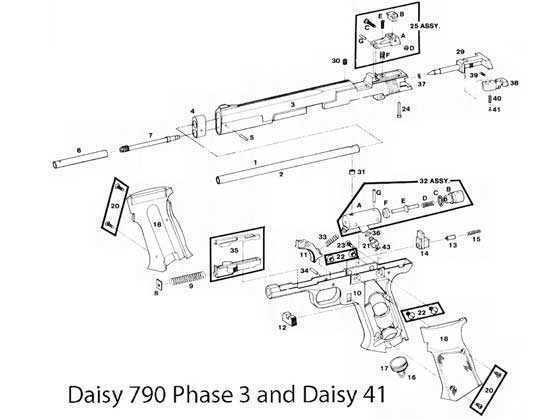

Guide to Disassembling the Daisy 840

In this section, we’ll walk through the key steps to safely and efficiently dismantle this classic air-powered device, highlighting important techniques to avoid damage to any of its intricate components. Familiarity with the internal layout is essential, as it helps prevent accidental wear during disassembly and ensures each part can be smoothly reassembled later.

Start by securing the item on a stable, clean surface, with all tools laid out within easy reach. Begin loosening exterior screws carefully to avoid stripping, which can complicate reassembly. Work in a systematic order, noting any parts that may require special handling, such as springs or seals, which can be delicate or pressurized.

As each section is removed, take care to document the arrangement for later steps. Certain components may need extra caution, particularly any compressed parts, to prevent unintended release of tension. Organizing each part separately will facilitate the reassembly process and help maintain the longevity and functionality of the device.

Cleaning Techniques for Optimal Performance

Proper cleaning is essential to maintain the longevity and functionality of your equipment. Regular care and removal of dirt and residue can help ensure consistent and reliable operation over time, reducing the need for extensive maintenance.

Start by Disassembling Key Parts: Begin by carefully separating the accessible components. This will allow for a thorough cleaning and prevent residue from affecting performance. Use tools that won’t damage the parts, ensuring each piece is handled with caution.

Choose the Right Cleaning Supplies: Select mild cleaning agents and non-abrasive cloths. Strong chemicals or rough materials can harm delicate components, so using gentle supplies will preserve the equipment’s integrity.

Focus on High-Contact Areas: Pay attention to parts that experience frequent handling or movement, as these areas often accumulate the most dirt. Wipe each part carefully to remove buildup that may hinder functionality.

Dry and Reassemble: Ensure all parts are completely dry before reassembling. Moisture can lead to internal issues, so a quick inspection for any remaining dampness can help prevent potential problems.

With these methods, your device will stay in optimal condition, enhancing performance and extending its lifespan.

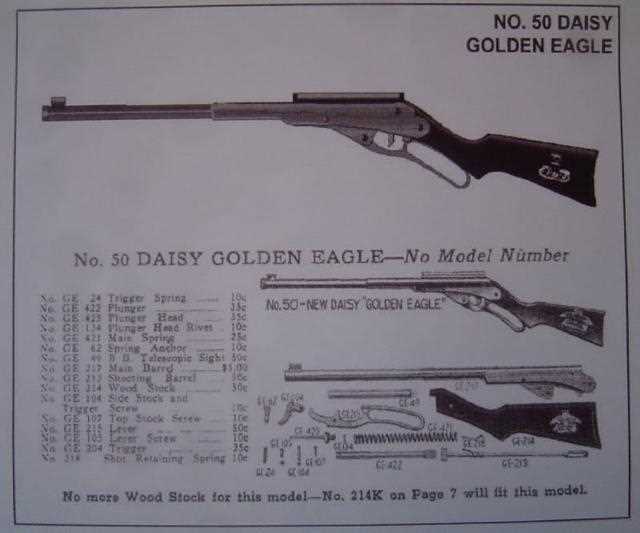

Replacing Worn-Out Parts Effectively

Maintaining performance and extending the lifespan of equipment often involves replacing components that show signs of wear. Identifying such parts and addressing them promptly is crucial to avoid larger issues and to ensure the unit continues operating smoothly. This section provides practical insights for replacing aging elements in an efficient manner, improving overall reliability and functionality.

Identifying Key Components for Replacement

Before beginning any replacement work, carefully examine the main operational parts, as they are often the first to deteriorate with frequent use. Look for signs such as reduced performance, unusual noises, or visible damage. Prioritizing these parts can prevent further complications and make replacement efforts more straightforward.

Choosing Quality Replacement Parts

For a successful restoration, it’s essential to select compatible, high-quality replacement components. Investing in parts made from durable materials can provide longer-lasting results, reducing the need for frequent repairs. Carefully match new components to the specifications of the original ones to ensure smooth integration and reliable performance post-repair.

Checking and Adjusting Trigger Mechanisms

The accuracy and performance of a shooting device heavily rely on the efficiency of its trigger system. Ensuring that the trigger operates smoothly and responds correctly to user input is essential for optimal functionality. Regular checks and precise adjustments can enhance both safety and shooting experience.

Begin by inspecting the trigger assembly for any visible wear or damage. Lubricate moving parts to minimize friction, which can affect responsiveness. A well-maintained trigger should engage and release without hesitation. Pay attention to the pull weight; it should feel comfortable without being too loose or too stiff.

After lubrication, test the mechanism by performing a dry fire. This involves pulling the trigger without ammunition to ensure it functions correctly. If you notice any irregularities, such as a rough pull or failure to reset, further adjustments may be necessary. Fine-tune the tension springs as needed, ensuring they are set to provide an appropriate level of resistance.

Finally, reassemble the trigger assembly and perform a thorough function check. Confirm that the device safely engages and releases as intended. This maintenance process not only extends the lifespan of the trigger components but also significantly improves overall shooting accuracy.

Inspecting the Barrel and Air Chamber

Examining the cylindrical section and the reservoir of compressed air is crucial for ensuring optimal performance of the airgun. Regular checks can help identify wear, damage, or blockages that may affect shooting accuracy and overall functionality. Proper maintenance of these components enhances the longevity and reliability of the device.

Assessing the Barrel Condition

Begin the inspection by carefully examining the interior of the barrel for any signs of corrosion, residue, or obstructions. A clean and smooth bore is essential for maintaining precision during operation. Utilize a soft cloth or a cleaning rod with a suitable brush to remove any buildup. Inspecting for scratches or dents on the exterior is also important, as these imperfections can lead to decreased accuracy and potential safety hazards.

Evaluating the Air Chamber Integrity

The next step involves scrutinizing the air chamber for leaks or structural issues. Check for any cracks or deformities that could compromise air pressure. Using a soap solution can help detect leaks; apply it to the joints and connections, watching for bubbles that indicate escaping air. Ensure that seals and O-rings are intact and replace them if necessary to maintain optimal pressure and performance.

Steps to Reassemble the Daisy 840

Reassembling the airgun involves a systematic approach to ensure all components are securely fitted and function properly. Following a clear sequence will help avoid common pitfalls and enhance the performance of the device.

Gather Necessary Tools and Components

Before starting the reassembly process, collect all required tools, such as screwdrivers, pliers, and any specific hardware needed. Ensure that all parts are clean and undamaged to facilitate a smooth assembly. This preparation minimizes the risk of overlooking critical components.

Reassembly Process

Begin by positioning the main body and carefully fitting internal components back into place. Align screws and fasteners accurately to prevent any misalignment. Utilize a gentle tightening approach to avoid over-torquing, which could lead to damage. Once the main assembly is complete, conduct a thorough inspection to confirm that everything is in its correct position and operates as intended.

Maintaining Consistent Shooting Accuracy

Achieving reliable precision in shooting requires a combination of proper technique, equipment care, and regular practice. Ensuring that each shot is executed with consistency hinges on various factors, including stability, alignment, and the condition of the firearm.

To start, it is crucial to maintain a firm grip and stable stance while shooting. This foundation minimizes movement and enhances control, allowing for better alignment of the sights with the target. Additionally, regular calibration of the sights ensures that adjustments are made to accommodate any shifts in performance over time.

Another important aspect is the upkeep of the shooting apparatus itself. Regular cleaning and inspection of key components prevent malfunctions and preserve accuracy. Lubrication should be applied judiciously to ensure smooth operation while avoiding excess that could attract dirt.

Finally, consistency in ammunition choice plays a vital role. Using the same type and brand of ammunition allows shooters to develop familiarity with their performance, leading to improved results over time. By focusing on these elements, shooters can significantly enhance their ability to hit their targets accurately and reliably.

Preventative Care for Longevity

Ensuring the durability and optimal performance of equipment requires regular maintenance and attention to detail. By implementing a proactive approach, users can extend the lifespan of their devices, minimizing the risk of unexpected failures. This section outlines essential practices to promote longevity and reliability.

Routine Maintenance Tasks

- Regularly inspect components for wear and tear.

- Keep all surfaces clean and free from debris.

- Ensure moving parts are lubricated to prevent friction.

- Check electrical connections for signs of corrosion.

Environmental Considerations

- Store the unit in a dry, temperature-controlled environment.

- Avoid exposure to extreme humidity or dust.

- Utilize protective covers when the device is not in use.

Adopting these strategies fosters a dependable performance and enhances the overall functionality of your equipment.

Final Testing and Calibration Tips

Ensuring optimal performance of your device requires thorough testing and precise calibration after any adjustments or repairs. This phase is crucial for verifying functionality and accuracy, ultimately leading to a reliable operational state.

Start with a Visual Inspection: Before proceeding with functional tests, conduct a careful visual examination of all components. Look for any signs of wear, loose connections, or misalignments that may affect performance.

Utilize Diagnostic Tools: Employ appropriate diagnostic equipment to assess the device’s functionality. This may include multimeters, oscilloscopes, or other specialized instruments tailored to the specific nature of the apparatus.

Calibrate Settings: Adjust settings to manufacturer specifications, ensuring that all parameters align with expected values. Follow the recommended calibration procedures to maintain accuracy and reliability.

Perform Functional Tests: After calibration, execute a series of functional tests to confirm that the device operates as intended. Pay close attention to any irregularities or deviations from expected behavior during these tests.

Document Results: Keep detailed records of all tests and calibration adjustments. This documentation serves as a valuable reference for future maintenance and troubleshooting efforts.

Conduct Regular Maintenance: To prolong the lifespan and functionality of your device, establish a routine maintenance schedule. Regular checks and adjustments will help identify potential issues before they become significant problems.