Ensuring the optimal performance of your winter machinery is essential for tackling seasonal challenges effectively. A well-functioning unit not only enhances efficiency but also extends the lifespan of the equipment. This section provides insights into troubleshooting and optimizing your outdoor gear for snowy conditions.

Understanding common issues is the first step in maintaining your device. By recognizing the signs of malfunction early, you can prevent more significant problems down the line. Regular inspections and minor adjustments can make a considerable difference in performance.

In this guide, you will discover practical tips and techniques to keep your winter machinery in prime condition. Whether you are looking to fine-tune functionality or address specific concerns, the information provided here will empower you to handle your equipment with confidence.

Essential Tools for Snowblower Repair

When it comes to maintaining outdoor equipment, having the right instruments is crucial for efficient service. Proper tools not only enhance the quality of work but also ensure safety and accuracy during the maintenance process. Understanding which items are necessary can streamline any task, making it easier to address issues that may arise.

| Tool | Purpose |

|---|---|

| Socket Set | To remove and tighten bolts and nuts. |

| Screwdriver Set | For loosening and tightening screws of various sizes. |

| Wrench | To provide leverage for tightening or loosening fittings. |

| Pliers | For gripping and manipulating small components. |

| Fuel Container | To store and transfer fuel safely. |

| Oil Can | For lubricating moving parts. |

| Torque Wrench | To ensure bolts are tightened to the manufacturer’s specifications. |

Common Issues with Craftsman Snowblowers

Operating a snow-clearing device can sometimes lead to various challenges, particularly during the harsh winter months. Understanding frequent problems helps users address them effectively and maintain optimal functionality.

Engine Performance Problems

Power failure is a common concern, where the engine may not start or could stall unexpectedly. This can stem from issues such as improper fuel supply, a faulty spark plug, or clogged filters. Regular maintenance can help mitigate these issues, ensuring reliable operation when needed most.

Auger and Drive Issues

Another typical challenge involves the auger or drive mechanism, which may become stuck or malfunction. Factors like ice buildup or worn-out components can lead to reduced effectiveness. Checking for blockages and performing routine inspections can prevent these problems and enhance performance.

Step-by-Step Maintenance Procedures

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. This section outlines practical steps that can be easily followed to maintain functionality and prevent common issues. Adhering to these guidelines will help keep your machinery running smoothly throughout its operational life.

Cleaning the Components

Thoroughly clean the various parts of your machine to remove dirt and debris. Start by detaching any accessible panels to gain better access to the internal components. Use a soft brush or compressed air to eliminate buildup. Be cautious not to damage any sensitive parts during this process.

Checking the Oil Levels

Maintaining the correct oil levels is crucial for proper lubrication. Inspect the oil reservoir periodically and replace the oil as needed. Ensure you are using the appropriate type of lubricant for your device. Follow the manufacturer’s guidelines for the recommended oil specifications to avoid any potential damage.

Troubleshooting Snowblower Performance Problems

Addressing issues related to winter equipment can significantly enhance its efficiency and prolong its lifespan. Recognizing and rectifying performance-related concerns is essential for ensuring optimal functionality during snowy conditions. This section outlines common problems and provides effective solutions to maintain the machine’s effectiveness.

- Insufficient Power:

- Check the fuel level and ensure that it is fresh.

- Inspect the spark plug for wear or damage.

- Verify that the air filter is clean and unobstructed.

- Poor Clearing Ability:

- Examine the auger for blockages or damage.

- Adjust the height of the scraper blade to ensure proper contact with the surface.

- Ensure that the chute is clear of ice and debris.

- Difficulty Starting:

- Check the ignition system and battery condition.

- Inspect the fuel lines for leaks or cracks.

- Make sure that the choke is functioning correctly.

- Unusual Noises:

- Listen for any grinding or rattling sounds, which may indicate loose components.

- Inspect belts and cables for fraying or damage.

- Check for foreign objects caught in the auger or impeller.

By following these guidelines and performing regular maintenance, users can effectively troubleshoot and resolve performance issues, ensuring a reliable experience during winter months.

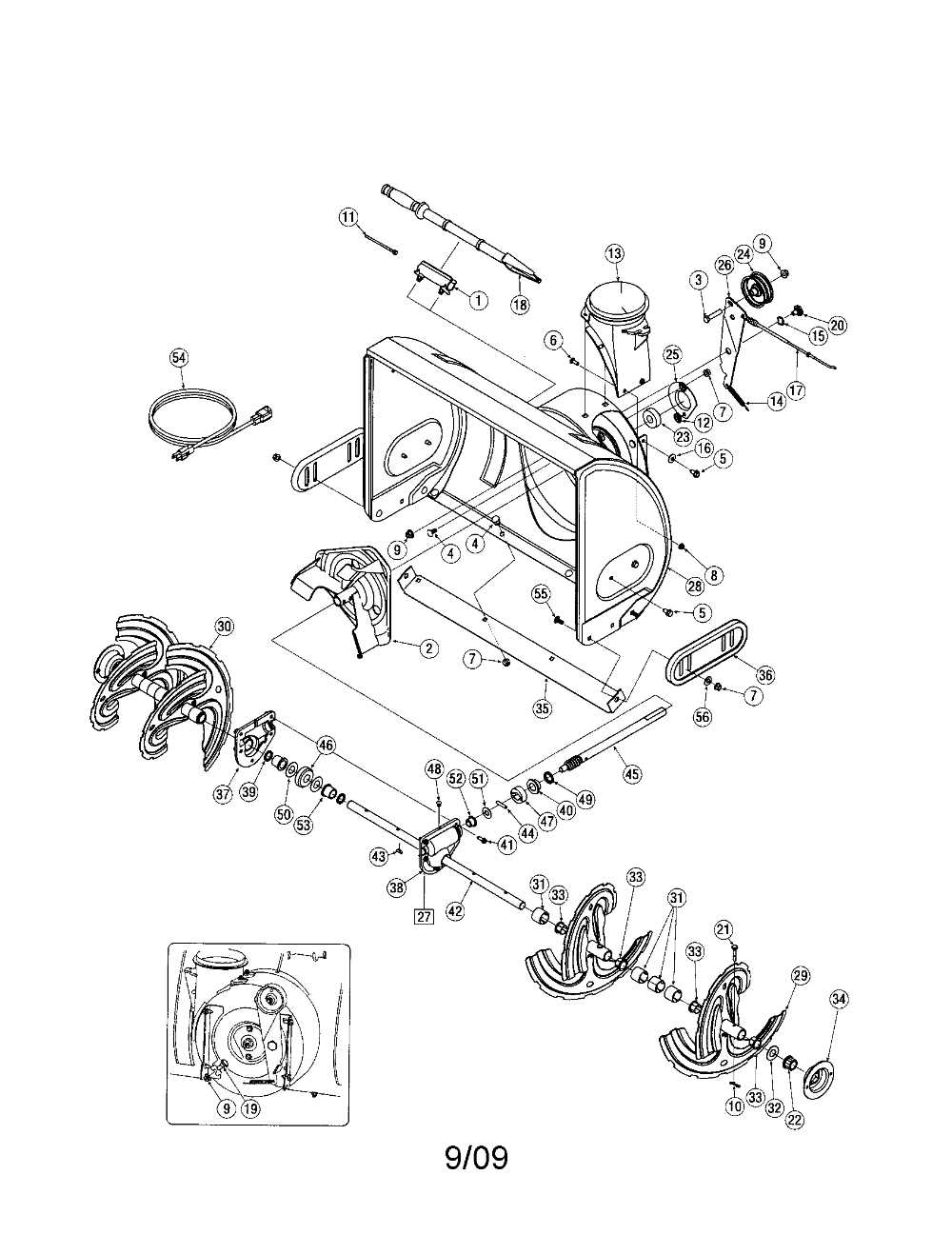

How to Replace Snowblower Parts

Maintaining your equipment is essential for ensuring optimal performance during winter conditions. Understanding the steps involved in swapping out various components can enhance efficiency and extend the lifespan of your machinery.

Follow these general steps to effectively change parts:

- Gather Necessary Tools: Before starting, collect all required tools, including wrenches, screwdrivers, and replacement components.

- Disconnect Power Source: Ensure the machine is powered down and disconnected to avoid accidents during the process.

- Access the Part: Depending on the specific component being replaced, remove any panels or covers to gain access.

- Remove the Old Part: Carefully detach the worn component, noting how it is secured to aid in the installation of the new piece.

- Install the New Component: Position the replacement part in place, ensuring it aligns properly with existing fittings and connections.

- Reassemble the Equipment: Once the new part is secured, replace any panels or covers that were removed during the process.

- Reconnect Power and Test: Reconnect the power source, then conduct a test run to ensure everything operates smoothly.

Regularly replacing worn components not only enhances functionality but also contributes to safer and more reliable performance during use.

Safety Precautions During Repairs

When performing maintenance on outdoor equipment, it is essential to prioritize safety to prevent accidents and injuries. Understanding the potential hazards associated with the task can significantly reduce risks and ensure a smooth process.

Always wear appropriate personal protective equipment, such as gloves, goggles, and sturdy footwear, to shield yourself from debris and sharp components. This basic precaution can help mitigate injuries during the maintenance process.

Before starting any work, ensure the machinery is turned off and disconnected from its power source. This step is crucial to avoid unintentional activation, which can lead to serious injuries.

Maintain a clean and organized workspace to minimize the risk of tripping or misplacing tools. A tidy environment allows for better focus and can help prevent accidents while you work.

Familiarize yourself with the equipment before beginning. Knowing the layout and operation of the device will aid in identifying potential hazards and understanding the proper handling techniques required.

Keep a first aid kit nearby and ensure that you know how to use it. Being prepared for emergencies can make a significant difference in response time should an accident occur.

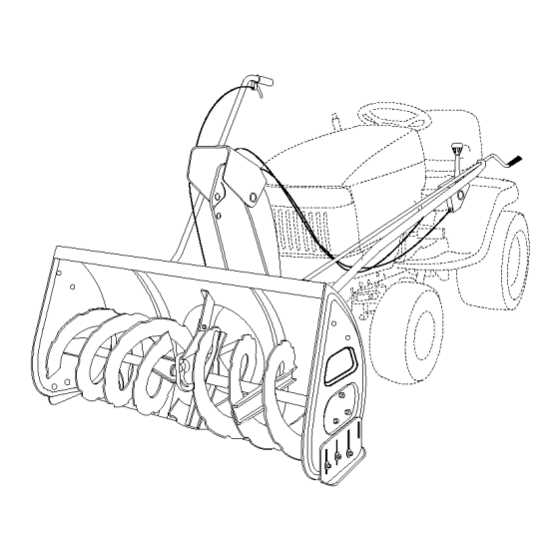

Winter Preparation and Equipment Check

As the cold season approaches, ensuring that your outdoor machinery is ready for action is essential. Proper maintenance and equipment checks can significantly enhance performance and longevity. This section will guide you through key steps to prepare your tools for the winter months.

Essential Maintenance Tasks

Before the first snowfall, carry out a thorough inspection and maintenance of your equipment. Key tasks include checking fuel levels, inspecting belts and cables, and ensuring all moving parts are lubricated. Here’s a quick checklist:

| Task | Description |

|---|---|

| Fuel Check | Ensure there is fresh fuel and check for leaks. |

| Battery Inspection | Test the battery and clean terminals to prevent corrosion. |

| Blades and Auger | Inspect for wear and replace if necessary for optimal performance. |

Safety Precautions

Safety should always be a priority. Before operating any machinery, make sure to wear appropriate clothing and gear. Additionally, familiarize yourself with the equipment’s controls and emergency shutoff features to ensure a safe working environment.

Understanding Your Snowblower’s Manual

When it comes to maintaining and operating your outdoor equipment, having a comprehensive guide at your fingertips is crucial. This resource offers essential insights and instructions that can enhance your experience and ensure optimal performance.

Key Components of the guide typically include detailed descriptions of various features, troubleshooting tips, and maintenance schedules. Familiarizing yourself with these sections can greatly assist in identifying issues before they escalate.

Navigation through the document may seem daunting at first, but once you grasp the layout and terminology, it becomes an invaluable tool. Each chapter is designed to cater to specific needs, whether you’re looking for assembly guidelines or safety precautions.

Seasonal Storage Tips for Snowblowers

Properly storing your winter equipment during the off-season is crucial for maintaining its longevity and ensuring it’s ready for use when the next snowfall arrives. By following a few essential guidelines, you can keep your machine in optimal condition and avoid potential issues.

- Clean Thoroughly: Before storing, remove any dirt, ice, and debris from the exterior and undercarriage. This prevents rust and damage during storage.

- Fuel Treatment: If your device has a fuel tank, consider adding a fuel stabilizer to prevent the fuel from degrading. Alternatively, you can run the engine until the fuel is consumed.

- Oil Change: Changing the oil before storage can help eliminate contaminants and keep the engine clean. Make sure to follow the manufacturer’s recommendations.

- Inspect Belts and Cables: Check for wear and tear on belts and cables, replacing any that show signs of damage. This ensures they are ready for operation when needed.

- Battery Care: If your equipment uses a battery, remove it and store it in a cool, dry place. Keep it charged to extend its lifespan.

By following these steps, you can ensure that your winter tool remains in excellent working condition and is ready for action when the snow begins to fall again.

DIY Repairs vs. Professional Services

When it comes to maintaining outdoor equipment, enthusiasts often face a choice between handling issues themselves or seeking assistance from experts. Each option has its advantages and considerations, which can significantly impact both the outcome and cost of service.

- Advantages of DIY Repairs:

- Cost savings: Performing tasks yourself eliminates labor costs associated with hiring professionals.

- Flexibility: You can work at your own pace and schedule, making it convenient for your routine.

- Skill development: Tackling repairs can enhance your understanding and proficiency with tools and equipment.

- Considerations for DIY:

- Time commitment: Repairs can be time-consuming, especially for complex issues.

- Skill level: Not everyone has the necessary experience, which could lead to mistakes.

- Access to parts: Sourcing the right components may be challenging for some individuals.

- Advantages of Professional Services:

- Expertise: Professionals have the training and experience to diagnose and resolve issues effectively.

- Warranty protection: Using services may preserve any existing warranties on your equipment.

- Efficiency: Experts can often complete repairs faster, minimizing downtime.

- Considerations for Professional Services:

- Cost: Hiring professionals can be more expensive than handling repairs yourself.

- Scheduling: You may need to align your availability with the service provider’s schedule.

- Less control: Relying on others means you might not have as much influence over the repair process.

Ultimately, the decision between DIY approaches and professional help depends on your confidence, skills, and the specific situation at hand. Assessing the complexity of the issue and weighing the pros and cons can guide you toward the best choice for your needs.

Frequently Asked Questions about Snow Removal Equipment

This section addresses common inquiries regarding winter maintenance tools designed for clearing pathways and driveways. Understanding the typical concerns can enhance the user experience and ensure efficient operation.

What are the common issues with these devices?

Users often face challenges such as engine starting problems, inadequate power, and issues with the auger or impeller. Regular maintenance can help mitigate these concerns.

How can I improve performance during heavy snowfall?

Ensuring the equipment is well-maintained, using the right settings, and keeping the blades sharp can significantly improve efficiency during demanding conditions.

Is there a way to prevent clogging?

To minimize blockages, it’s advisable to clear snow regularly and maintain a consistent speed. Using a non-stick spray on the blades can also help.

What safety precautions should I take?

Always wear appropriate winter gear, avoid loose clothing, and be aware of your surroundings. Disconnecting the power source before servicing is crucial to prevent accidents.