Understanding the essential aspects of keeping your agricultural machinery in optimal condition is crucial for enhancing productivity and ensuring longevity. This section delves into the necessary procedures and considerations that owners and operators should be aware of when handling their equipment. Regular upkeep not only prevents unexpected breakdowns but also improves efficiency in the field.

By adhering to proper upkeep practices, users can effectively address common issues that may arise during operation. This involves a systematic approach to inspection, troubleshooting, and addressing any complications that could hinder performance. Familiarity with these practices empowers users to maintain their machinery efficiently, resulting in a smoother operational experience.

Incorporating routine assessments and employing sound techniques fosters a deeper understanding of the equipment’s requirements. This knowledge ultimately translates to better performance and reduced operational costs, as well as extending the life of the machinery. Embracing these guidelines ensures that your agricultural investment remains reliable and effective for years to come.

The hydraulic system is a critical component in ensuring the efficient operation of various machinery. Proper diagnosis of any issues within this system is essential for maintaining optimal performance and preventing costly failures. This section outlines essential procedures and techniques for identifying and addressing potential problems in the hydraulic system.

Common Symptoms of Hydraulic Issues

- Unusual noises during operation

- Inconsistent power delivery

- Fluid leaks around fittings or seals

- Slow or erratic movement of hydraulic components

Diagnostic Procedures

- Check fluid levels and quality.

- Inspect hoses and connections for signs of wear or damage.

- Test pressure using a gauge to ensure it meets manufacturer specifications.

- Evaluate the functionality of hydraulic pumps and valves.

By following these steps, operators can effectively identify and resolve issues within the hydraulic system, ensuring longevity and reliability of the equipment.

Transmission Maintenance and Repair

Proper upkeep and troubleshooting of the power transfer system are essential for ensuring optimal performance and longevity of your equipment. This segment focuses on routine care practices and potential issues that may arise, along with effective solutions to address them.

Regular Inspections: Frequent assessments of the components involved in power transfer are crucial. Check for any signs of wear, leaks, or unusual noises that may indicate underlying problems. Timely identification of issues can prevent more significant malfunctions and costly repairs.

Fluid Levels: Maintaining appropriate fluid levels is vital for the smooth operation of the transmission. Regularly inspect the fluid for clarity and ensure it meets the manufacturer’s specifications. Change the fluid as recommended to ensure efficient functioning.

Component Cleaning: Keeping the system free from debris and contaminants is necessary to avoid blockages and damage. Use suitable cleaning methods for the various parts involved, ensuring they are free from dust and grime.

Troubleshooting Common Issues: If you encounter problems such as slipping gears or delayed shifting, it may be indicative of fluid issues or worn components. Address these by consulting diagnostic resources or seeking professional assistance to ensure safe and effective solutions.

Overall, attentive maintenance and prompt repairs of the power transfer system can significantly enhance the reliability and performance of your machinery.

Electrical System Troubleshooting

This section aims to provide guidance on identifying and resolving issues within the electrical framework of your equipment. Understanding the components and their interconnections is crucial for effective diagnostics. A systematic approach can help you pinpoint malfunctions and restore optimal performance.

Common Issues and Their Symptoms

Familiarizing yourself with typical electrical complications can streamline the troubleshooting process. Here are some frequent problems along with their indications:

| Issue | Symptoms |

|---|---|

| Dead Battery | No power to start the system |

| Faulty Alternator | Battery not charging properly |

| Blown Fuse | Electrical components not functioning |

| Wiring Issues | Intermittent power loss |

Troubleshooting Steps

To effectively address electrical concerns, follow these outlined steps:

- Inspect the battery and connections for any signs of corrosion or loose terminals.

- Check the alternator output using a multimeter to ensure it meets specified voltage levels.

- Examine fuses for any blown units and replace them as needed.

- Trace wiring for any visible damage or wear that could disrupt the circuit.

Wheel and Tire Care

Proper maintenance of wheels and tires is essential for ensuring optimal performance and longevity of your equipment. Regular attention to these components can prevent premature wear and enhance overall efficiency, contributing to safer operation.

To maintain wheels and tires effectively, consider the following aspects:

| Aspect | Recommendation |

|---|---|

| Pressure Check | Regularly inspect and adjust tire pressure according to the manufacturer’s specifications to promote even wear. |

| Visual Inspection | Examine tires for any signs of damage, such as cuts, punctures, or bulges, and replace if necessary. |

| Alignment and Balancing | Ensure that wheels are properly aligned and balanced to reduce strain and improve handling. |

| Cleaning | Remove dirt and debris from tires and wheels to prevent buildup that can lead to corrosion. |

| Rotation | Rotate tires periodically to ensure even wear and extend their lifespan. |

Safety Practices During Repairs

Ensuring a secure environment while performing maintenance tasks is crucial for both personal well-being and efficient operations. Adopting safety measures not only prevents accidents but also enhances the overall effectiveness of the procedures being undertaken. It is essential to follow specific guidelines and recommendations to mitigate risks associated with mechanical activities.

Preparation and Planning

Before initiating any work, thorough preparation is key. Consider the following steps:

- Review the relevant guidelines and instructions thoroughly.

- Gather all necessary tools and materials beforehand to minimize distractions.

- Ensure the workspace is clean and organized to prevent mishaps.

Personal Protective Equipment

Wearing appropriate personal protective gear significantly reduces the likelihood of injury. The following items are recommended:

- Safety goggles to protect eyes from debris and harmful substances.

- Gloves to safeguard hands against sharp edges and chemicals.

- Steel-toed boots to prevent foot injuries from heavy objects.

- Ear protection if working in noisy environments.

By adhering to these safety practices, individuals can ensure a more secure and efficient working atmosphere during maintenance tasks.

Finding Genuine Replacement Parts

When it comes to maintaining the functionality of your machinery, sourcing authentic components is crucial. Quality parts ensure optimal performance and longevity, safeguarding your investment. It is essential to understand where to find these reliable replacements to avoid issues down the line.

Importance of Authentic Components

Utilizing genuine parts not only guarantees compatibility but also enhances the overall efficiency of your equipment. Imitation products may seem cost-effective initially but can lead to significant problems, including decreased performance and increased wear on the machinery.

Where to Locate Authentic Parts

There are several reliable sources for obtaining genuine components:

| Source Type | Description |

|---|---|

| Authorized Dealers | These sellers provide a full range of authentic components, often with warranties and customer support. |

| Manufacturer Websites | Official online platforms typically offer direct purchasing options for genuine items and have detailed specifications. |

| Reputable Distributors | Established distributors often stock a variety of authentic parts and can provide guidance on selection. |

| Online Marketplaces | Some trusted online marketplaces feature verified sellers offering genuine parts, though caution is advised to avoid counterfeit products. |

Service Schedule

A regular maintenance schedule is essential for ensuring the longevity and optimal performance of your agricultural machinery. Adhering to a systematic plan helps in identifying potential issues before they escalate, ensuring that the equipment operates efficiently during critical tasks.

Here are key service intervals and tasks to consider:

- Daily Checks:

- Inspect fluid levels (oil, coolant, fuel).

- Examine belts and hoses for wear.

- Check tire pressure and condition.

- Weekly Maintenance:

- Clean air filters and screens.

- Lubricate moving parts and pivot points.

- Inspect electrical connections and battery health.

- Monthly Services:

- Change engine oil and replace filters.

- Examine hydraulic fluid levels and condition.

- Test safety features and emergency systems.

- Annual Overhaul:

- Conduct a comprehensive inspection of all systems.

- Replace worn components and perform necessary upgrades.

- Evaluate performance and adjust settings as needed.

By following these outlined steps, operators can ensure their equipment remains in peak condition, reducing downtime and enhancing productivity during operations.

Using the Repair Manual Effectively

Utilizing a comprehensive guide is essential for achieving optimal performance and longevity of machinery. This resource serves as a valuable tool for individuals looking to troubleshoot issues, perform maintenance tasks, and enhance their understanding of the equipment’s functionalities. A systematic approach to consulting this guide can lead to significant improvements in efficiency and reliability.

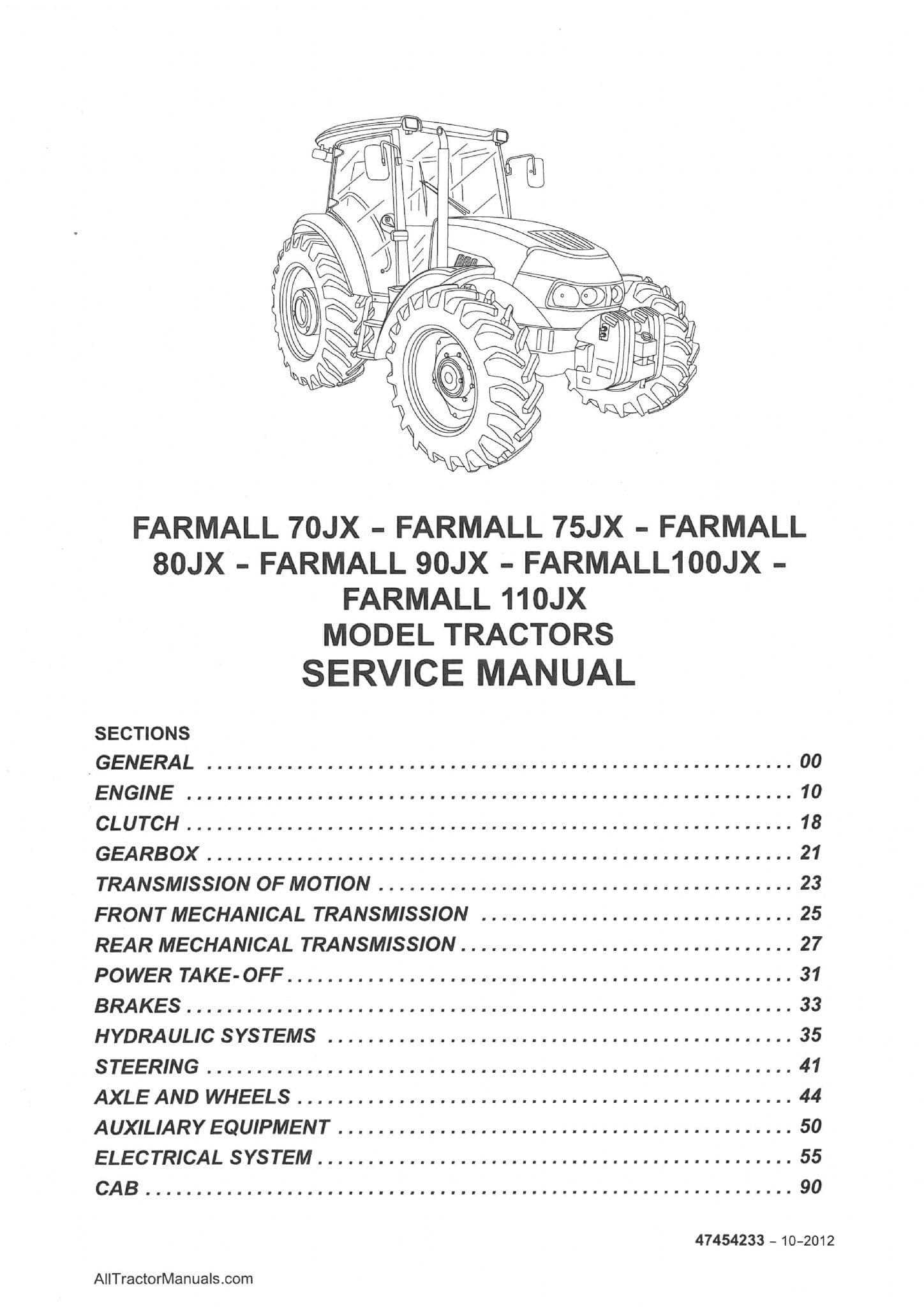

Understanding the Structure

Familiarizing yourself with the organization of the guide is crucial. Typically, it is divided into sections covering various aspects such as troubleshooting, maintenance schedules, and specific component details. Knowing where to find relevant information allows for a more efficient problem-solving process and minimizes downtime.

Following Instructions Carefully

Adhering to the outlined procedures is vital for ensuring successful outcomes. Each step is designed to facilitate the correct execution of tasks, thereby preventing potential mistakes or mishaps. Attention to detail during these processes not only enhances the effectiveness of the work but also contributes to the overall safety of the operations.