In the realm of analog writing instruments, preserving their functionality and charm can be an engaging endeavor. These mechanical wonders have captured the hearts of many enthusiasts, blending nostalgia with the art of written communication. Understanding their intricate workings is essential for those looking to maintain or rejuvenate these treasured artifacts.

Throughout this guide, readers will uncover essential techniques and insights that illuminate the process of bringing these devices back to life. With a focus on common issues and practical solutions, this resource aims to empower individuals to tackle repairs with confidence. Embracing both the artistry and mechanics involved, one can appreciate the timeless appeal of these iconic tools.

As we delve into the specifics, a careful examination of components and mechanisms will reveal the underlying simplicity of their design. By fostering a deeper understanding, enthusiasts can ensure that these machines continue to serve as reliable companions in the pursuit of creativity and expression.

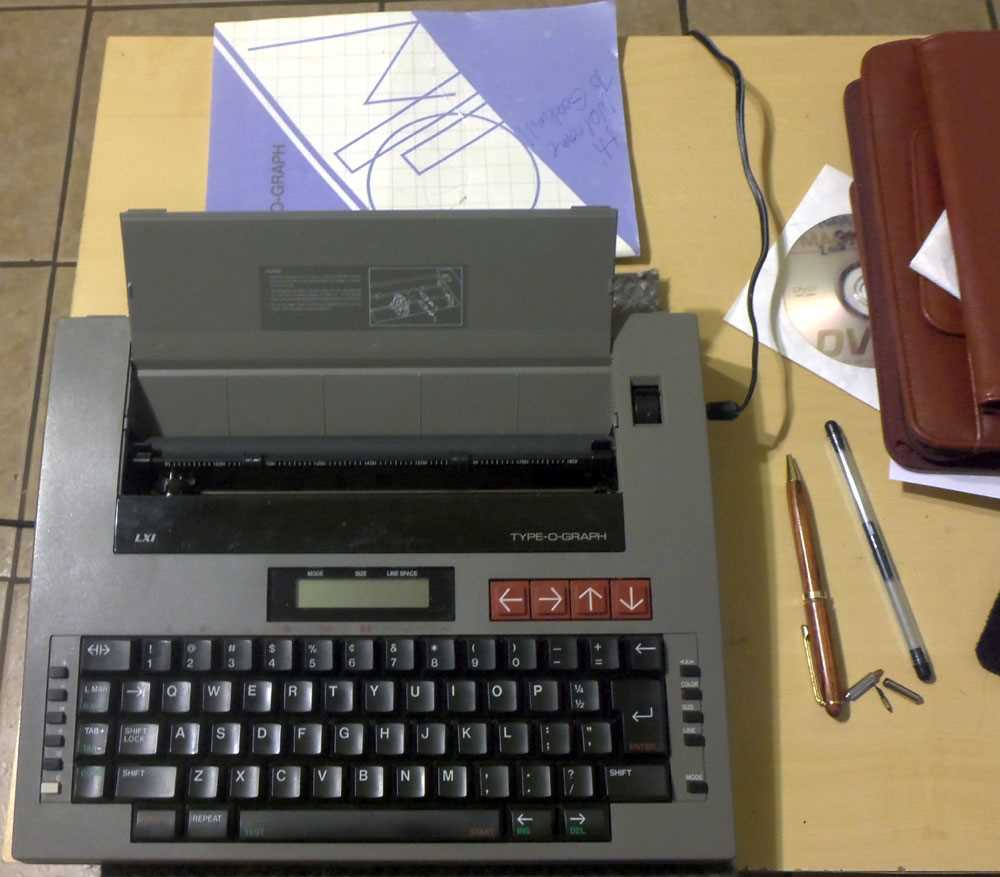

Understanding Brother Typewriter Mechanics

Gaining insight into the intricate workings of mechanical writing devices can significantly enhance their longevity and performance. By familiarizing oneself with the core components and their functions, users can ensure smoother operation and address issues that may arise over time.

Core Components

- Carriage: The mechanism that holds the paper and moves it up and down, allowing for line advancement.

- Keys: The levers that, when pressed, activate the corresponding typebars to imprint characters onto the page.

- Typebars: Metal arms that carry the letters, striking the ribbon and paper when a key is pressed.

- Ribbon: A strip coated with ink that transfers characters to the paper during typing.

- Feed Mechanism: This part controls the movement of the paper, ensuring accurate line spacing.

Common Issues and Solutions

- Sticking Keys: Dust and debris can accumulate, leading to malfunction. Regular cleaning can prevent this.

- Uneven Ink Distribution: If characters appear faint, check the ribbon tension and replace it if necessary.

- Carriage Misalignment: Ensure that the carriage moves freely; lubrication may be needed to resolve friction.

Understanding these elements and their interactions can lead to more effective maintenance and a deeper appreciation for the craftsmanship behind these mechanical wonders.

Common Issues with Brother Typewriters

Mechanical writing devices can experience a range of problems that may hinder their functionality. Understanding these common issues can help users troubleshoot effectively and maintain optimal performance. This section highlights frequent complications and their potential solutions.

Paper Feeding Problems

One of the most prevalent challenges involves issues with paper feeding. Users may notice that sheets do not advance properly or become misaligned. This can often be attributed to worn feed rollers or obstructions in the paper path. Regular cleaning and inspecting these components can significantly improve paper handling.

Ink Ribbon Complications

Another common concern relates to the ink ribbon mechanism. Users might find that the text appears faint or uneven, which can indicate a need for ribbon replacement. Additionally, the ribbon may become tangled or improperly threaded. Ensuring the ribbon is correctly installed and in good condition is essential for achieving clear, consistent output.

Tools Needed for Typewriter Repair

Engaging in the restoration of vintage writing machines requires a specific set of instruments to ensure efficiency and effectiveness. Having the right tools at hand not only simplifies the process but also enhances the quality of the work being done. Understanding which items are essential will aid in addressing various issues that may arise during the overhaul.

Basic Hand Tools are fundamental for any maintenance task. A selection of screwdrivers, particularly flathead and Phillips types, will allow access to various components. Additionally, a pair of pliers can assist in gripping and manipulating smaller parts, while wrenches may be necessary for any nuts or bolts encountered.

Cleaning Supplies play a crucial role in the upkeep of machinery. Using a soft brush helps in removing dust and debris from intricate areas. Compressed air can effectively dislodge particles in hard-to-reach spots, and isopropyl alcohol is ideal for cleaning surfaces without damaging delicate materials.

Replacement Parts might be needed to restore functionality. Having a small assortment of ribbons, rollers, and keys can be invaluable, especially when dealing with aged devices. Ensuring compatibility with the specific model being worked on is essential for optimal performance.

Precision Tools enhance the ability to conduct detailed adjustments. Items such as a caliper for measuring gaps and a magnifying glass for examining small parts can be incredibly beneficial. These instruments allow for accurate modifications, ensuring longevity and reliability in the final product.

Equipping oneself with these essential tools lays a strong foundation for tackling challenges associated with the rejuvenation of classic writing devices. A methodical approach, combined with the right equipment, will lead to successful outcomes in any restoration endeavor.

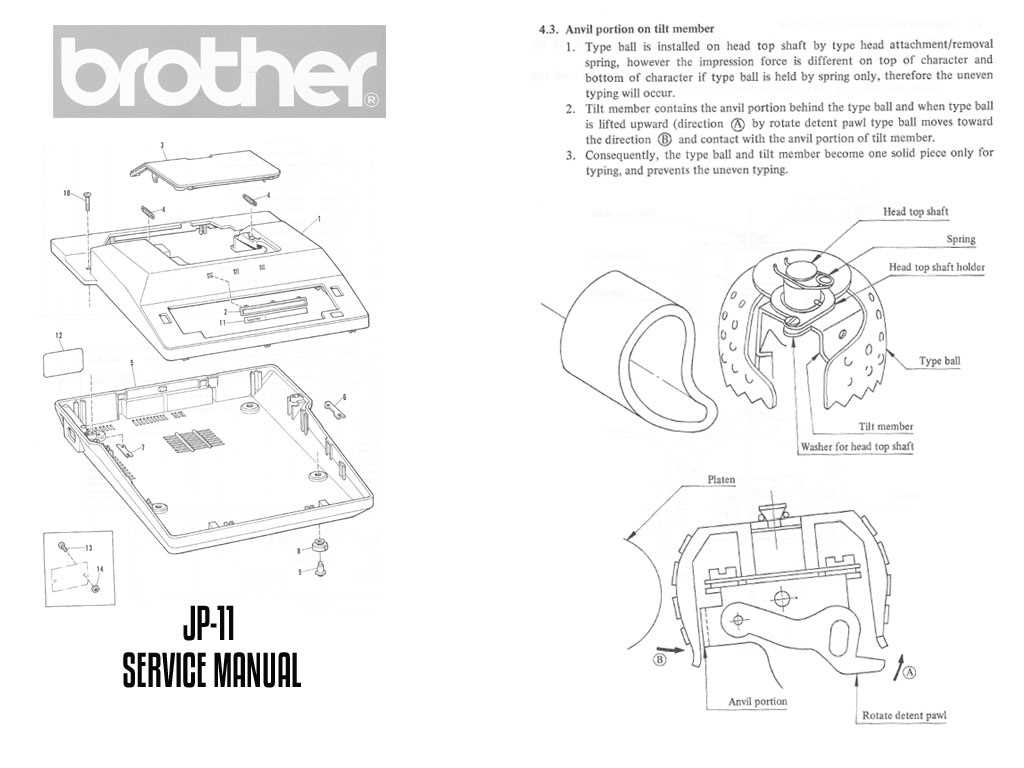

Step-by-Step Repair Procedures

This section provides a detailed guide for addressing common issues that may arise with mechanical writing devices. Each step is designed to help you diagnose problems effectively and perform necessary interventions to restore functionality. Following these procedures will ensure that your equipment remains in optimal condition, allowing for a seamless writing experience.

1. Initial Assessment: Begin by observing the device for any visible signs of damage or malfunction. Check for jammed keys, misaligned components, or unusual noises during operation. Make notes of any irregularities to guide your next steps.

2. Disassembly: Carefully disassemble the unit, ensuring that you keep track of all screws and components. Use a small container to organize parts, preventing loss or confusion during reassembly.

3. Cleaning: Once disassembled, clean all accessible parts using a soft cloth and appropriate cleaning solution. Pay special attention to areas prone to dust and debris accumulation, as these can hinder performance.

4. Lubrication: Apply a light lubricant to moving parts, such as levers and gears, to reduce friction. Ensure that excess lubricant is wiped away to avoid attracting dust and grime.

5. Reassembly: Carefully reassemble the device, reversing the disassembly steps. Double-check that all parts are correctly positioned and secure to prevent future issues.

6. Testing: After reassembly, conduct a thorough test to ensure that all functions operate smoothly. Pay attention to key responsiveness and overall performance.

7. Final Inspection: Perform a final inspection to confirm that everything is in place and functioning as intended. Address any lingering issues before considering the task complete.

Maintaining Your Typewriter for Longevity

Proper upkeep is essential for ensuring the durability and optimal performance of your writing machine. By adopting a few simple practices, you can significantly extend its lifespan and keep it in excellent working condition.

Regular Cleaning: Dust and debris can accumulate over time, affecting functionality. Use a soft brush or a gentle vacuum to remove particles from the keys and internal mechanisms. Periodic deep cleaning will help maintain smooth operation.

Lubrication: Keeping moving parts well-lubricated is crucial. Apply a small amount of oil to the pivot points and other mechanical components to prevent wear and ensure fluid movement. Be cautious not to over-lubricate, as excess oil can attract dirt.

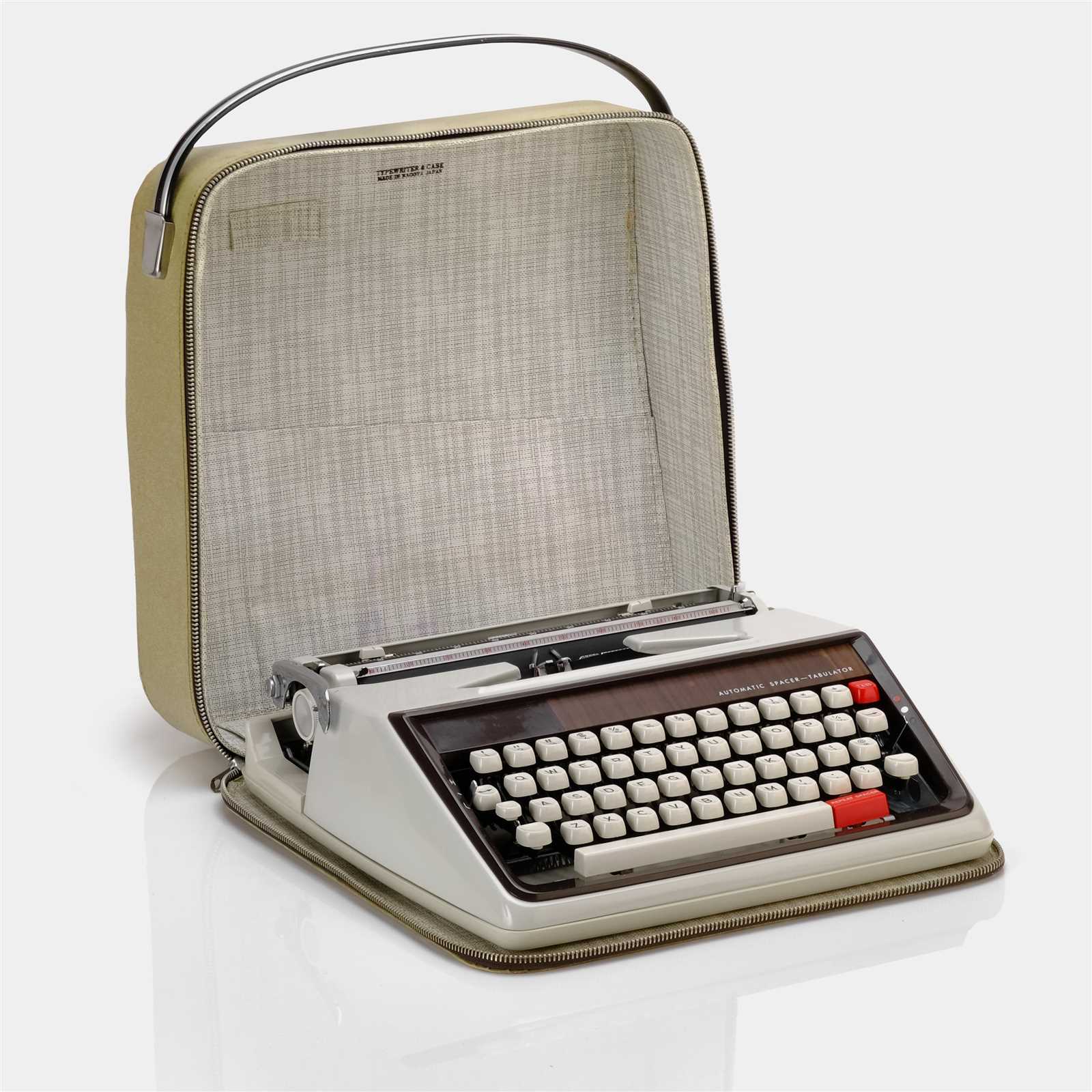

Storage Conditions: Proper storage plays a vital role in preserving your device. Keep it in a dry, climate-controlled environment to avoid rust and deterioration. Using a protective cover when not in use will also shield it from dust and moisture.

Periodic Inspections: Regularly check for any signs of wear or damage. Look for misaligned components, frayed ribbons, or worn-out keys. Early detection of issues can prevent more significant problems and costly fixes.

Use Quality Supplies: Always choose high-quality ribbons and paper specifically designed for your writing machine. Inferior materials can lead to jams and other complications, ultimately shortening its lifespan.

By implementing these strategies, you can ensure that your writing device remains reliable and functional for years to come, providing you with a satisfying writing experience.

Finding Replacement Parts Online

Locating components for vintage writing machines can be a daunting task, but the internet offers numerous resources to assist enthusiasts and repairers alike. With a bit of research and some savvy searching, you can discover a variety of suppliers and platforms that cater to your needs, ensuring your device remains functional and well-maintained.

Popular Online Platforms

Several websites specialize in vintage equipment parts. Here are some of the most reliable sources:

| Website | Description |

|---|---|

| eBay | A marketplace with a wide range of new and used components from various sellers. |

| Amazon | Offers a selection of parts, often with customer reviews to guide your purchase. |

| Specialty Parts Stores | Websites dedicated to vintage machines may provide hard-to-find components and accessories. |

Tips for Successful Searches

When searching for parts, using specific keywords can significantly improve your results. Include terms related to the model and type of component you need. Additionally, joining online forums or communities can provide valuable leads on where to find rare items and recommendations from fellow enthusiasts.

Cleaning Techniques for Typewriters

Maintaining a vintage writing machine requires proper attention to ensure optimal performance. Regular cleaning not only enhances functionality but also prolongs the life of the device. This section will explore effective methods to keep your equipment in pristine condition.

Dust Removal: Begin by gently removing surface dust with a soft brush or a lint-free cloth. Pay special attention to crevices and hard-to-reach areas to prevent debris buildup.

Key Cleaning: For a deeper clean, use a cotton swab lightly moistened with isopropyl alcohol to clean around the keys. This technique helps eliminate grime that accumulates over time.

Interior Maintenance: Open the machine carefully and use compressed air to blow out dust from the internal components. This will help ensure smooth operation and prevent any mechanical issues.

Exterior Care: Wipe down the outer casing with a damp cloth and a mild detergent. Avoid harsh chemicals that could damage the finish. Regular upkeep will keep your device looking new.

Implementing these techniques will not only enhance the aesthetic appeal but also contribute to the ultimate functionality of your writing companion.

Troubleshooting Paper Jams Effectively

Encountering issues with paper getting stuck can be frustrating, but identifying and resolving the problem can often be straightforward. Understanding the common causes of such disruptions allows users to take informed steps toward restoring functionality. This section provides practical guidance to address these obstacles and ensure a smoother operation.

| Common Causes | Solutions |

|---|---|

| Poor paper quality | Use high-quality, compatible paper to minimize jams. |

| Incorrect paper loading | Ensure that the paper is loaded correctly and aligned with the guides. |

| Dust and debris accumulation | Regularly clean the interior components to remove any foreign particles. |

| Worn or damaged rollers | Inspect and replace rollers if they show signs of wear or damage. |

| Improper paper type | Check the specifications for supported media types and avoid using incompatible options. |

By following these recommendations, users can effectively tackle and prevent paper-related issues, enhancing overall performance and reliability.

Adjusting Typewriter Tension Settings

Proper tension adjustment is crucial for achieving optimal performance in mechanical writing devices. This process ensures that the character imprint is consistent and clear, reducing the chances of misalignment or smudging. Tension levels affect the feel and responsiveness of the keys, contributing to a smoother typing experience.

Before proceeding with adjustments, it’s important to gather the necessary tools, including a screwdriver and a tension gauge if available. Always consult the specific guidelines for your model, as different devices may have unique mechanisms.

| Tension Setting | Effect |

|---|---|

| High | Increased key responsiveness, potential for jamming |

| Medium | Balanced performance, ideal for most users |

| Low | Decreased resistance, risk of unclear impressions |

To adjust the tension, locate the appropriate screws or levers as indicated in your guidelines. Turning these adjustments incrementally can help achieve the desired feel and function. After making changes, test the device to ensure that it performs satisfactorily before completing the process.

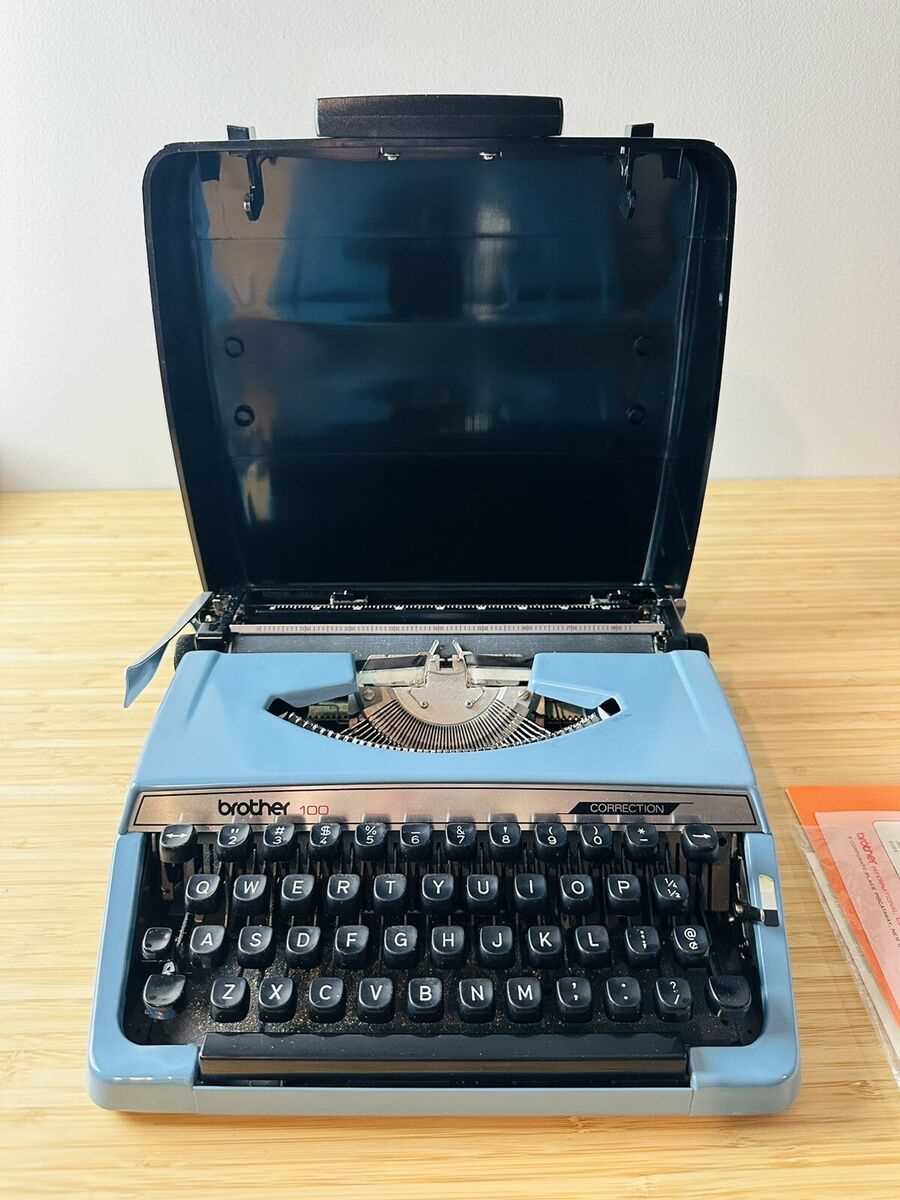

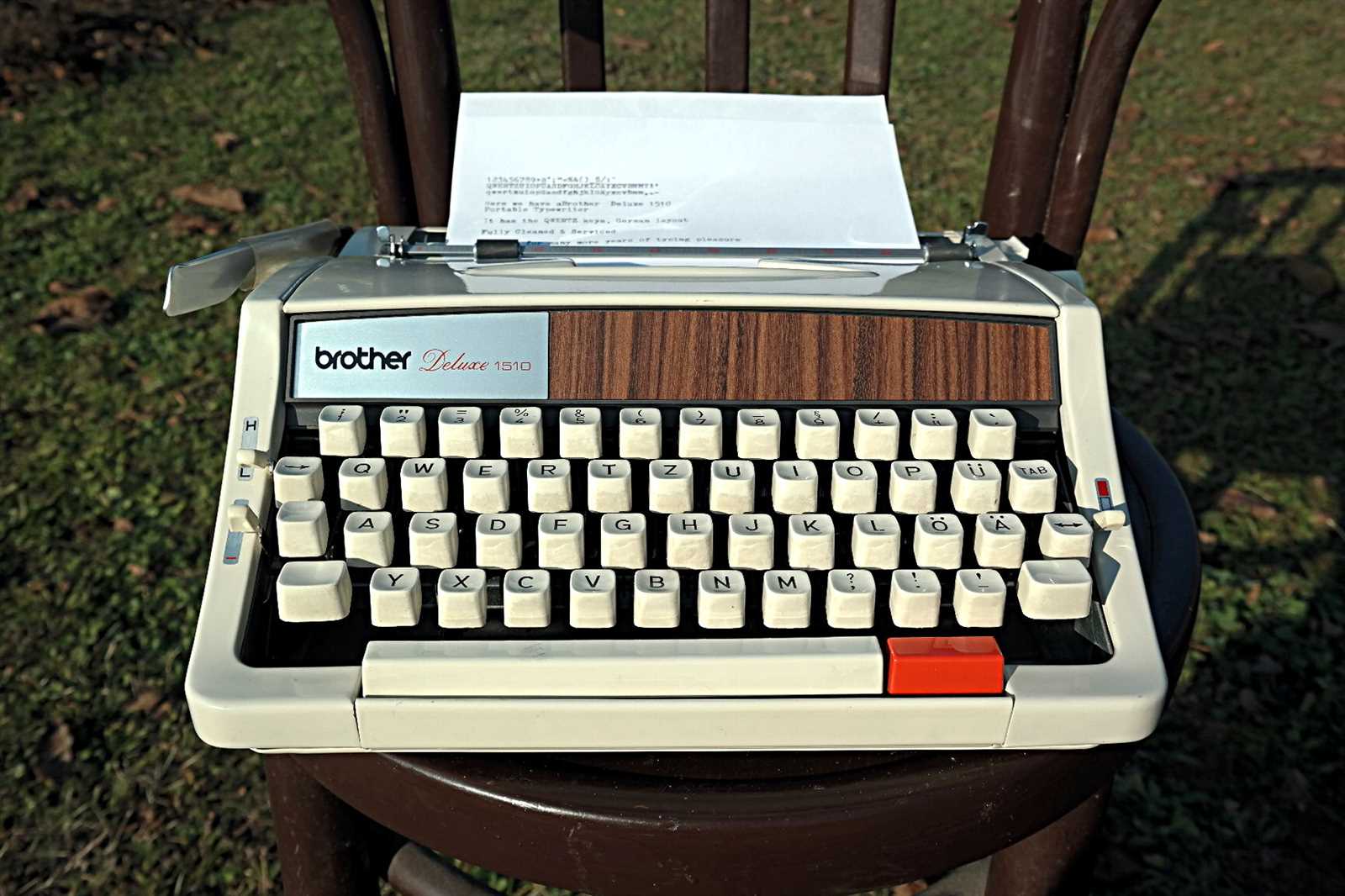

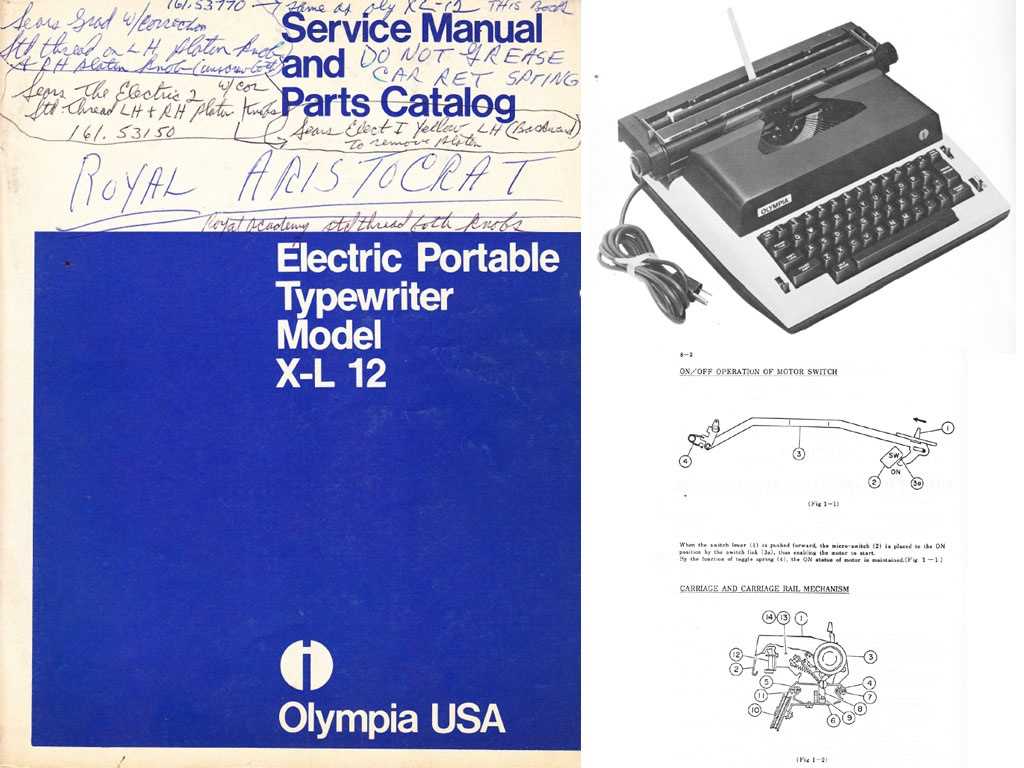

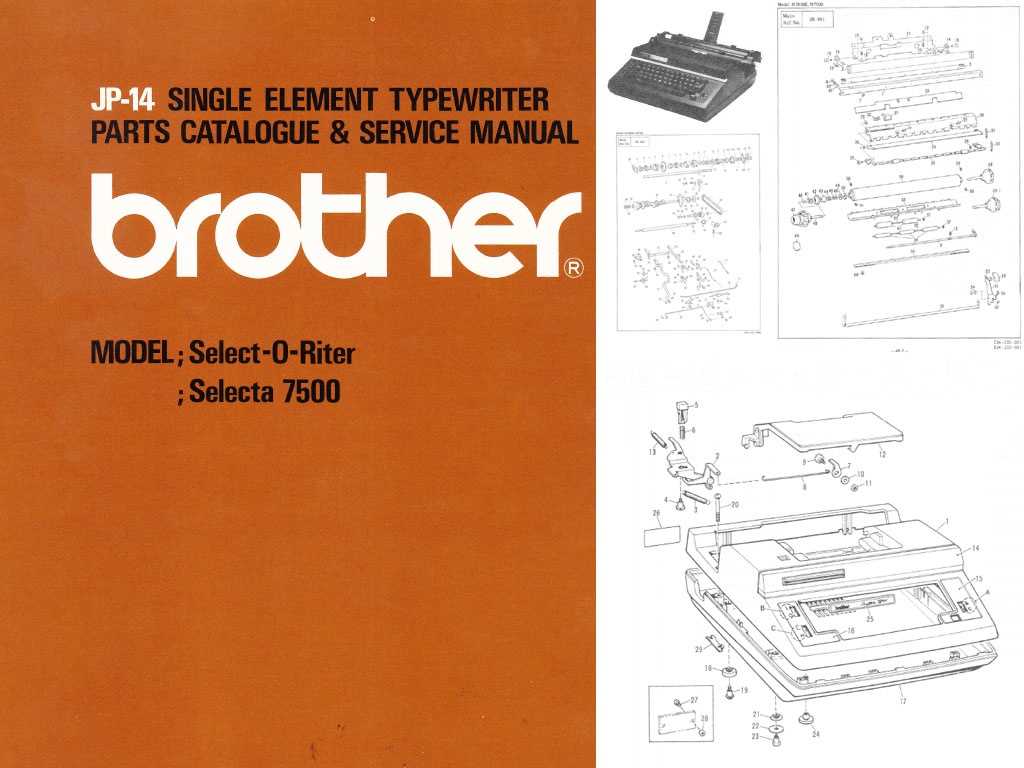

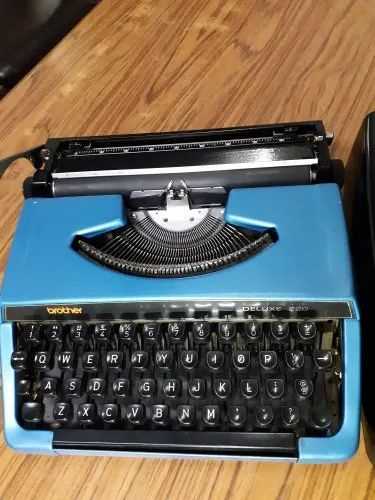

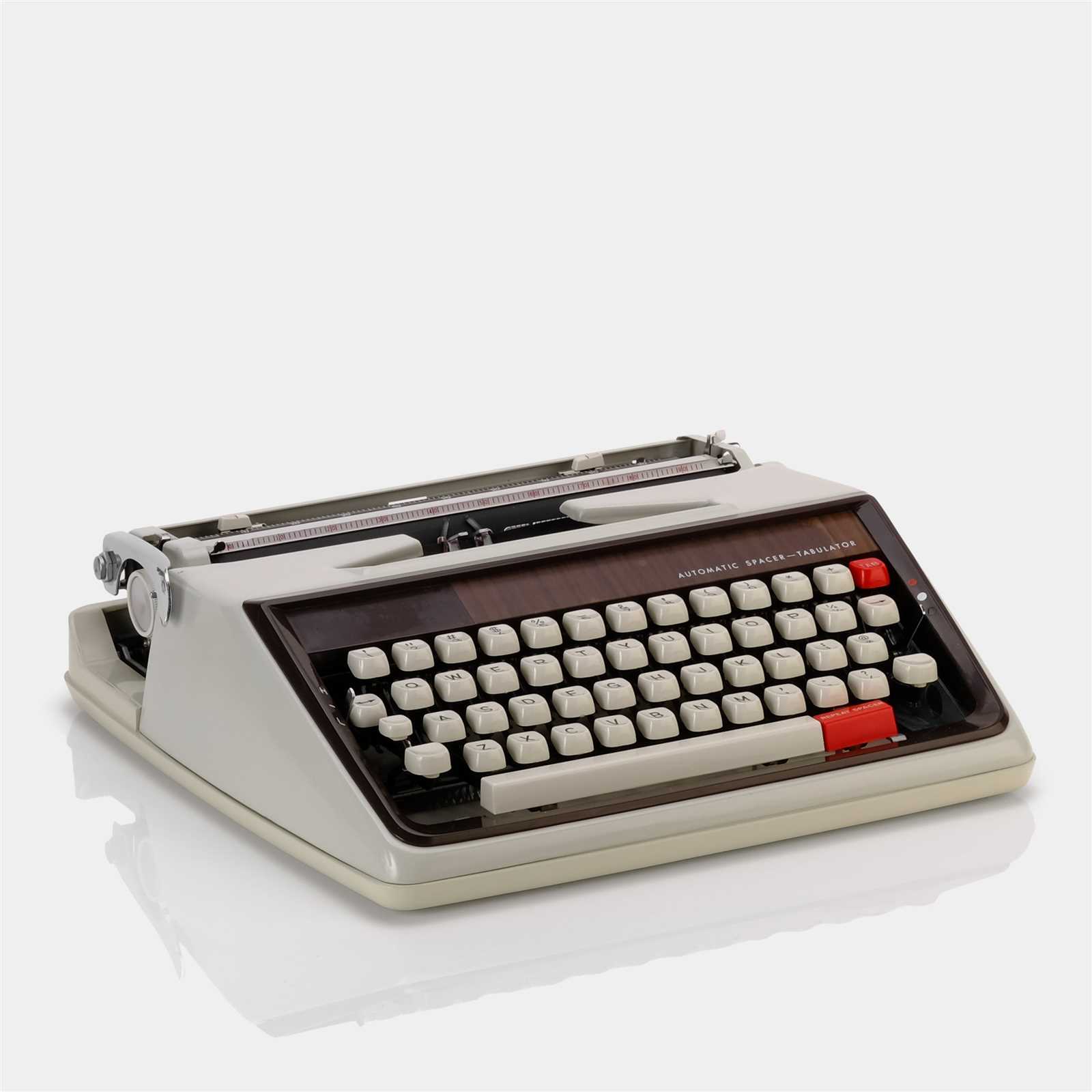

Restoring Vintage Brother Models

Reviving classic writing machines is a rewarding endeavor that connects enthusiasts with the rich history of personal craftsmanship and technology. These vintage devices, often found in attics or thrift stores, possess a charm that modern alternatives lack. The process of bringing them back to life involves careful attention to detail and an appreciation for their unique mechanics.

Assessment and Disassembly

The first step in rejuvenating these vintage pieces is a thorough evaluation. Inspect the exterior for signs of wear and the interior mechanisms for functionality. Carefully disassemble the components, taking note of the arrangement and condition of each part. This methodical approach ensures that reassembly will be straightforward and effective.

Cleaning and Replacement

Once disassembled, the next phase involves cleaning each part meticulously. Use appropriate solvents and tools to remove dirt and grime without causing damage. In some cases, certain components may need to be replaced or repaired. Sourcing authentic parts can enhance the authenticity and performance of the machine, ensuring that it operates smoothly for years to come.