When it comes to keeping small engines in optimal condition, understanding their components and functions is essential. This guide aims to provide valuable insights into troubleshooting and servicing techniques that will enhance the performance and longevity of your machinery. With the right knowledge, even complex issues can be addressed effectively.

Engines equipped with advanced features require meticulous care and attention. This resource is designed to walk you through essential procedures, offering step-by-step instructions that demystify the repair process. By following these guidelines, you will be empowered to maintain your engine with confidence, ensuring it operates smoothly for years to come.

From routine checks to more intricate fixes, mastering these skills can save you time and money. Equip yourself with the right tools and insights, and you’ll be prepared to tackle any challenge that comes your way. Dive into the details of engine upkeep and discover the satisfaction that comes from hands-on maintenance.

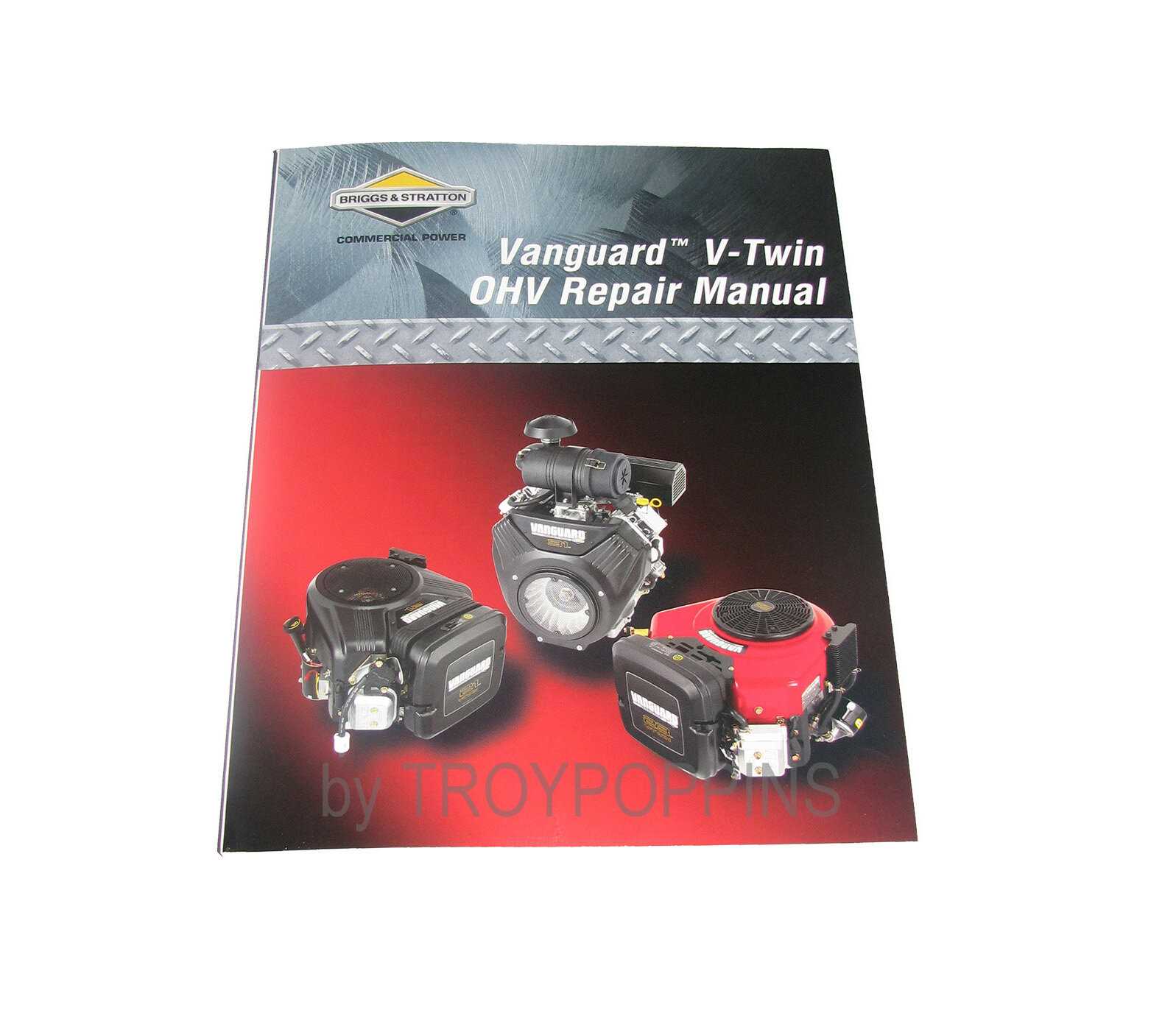

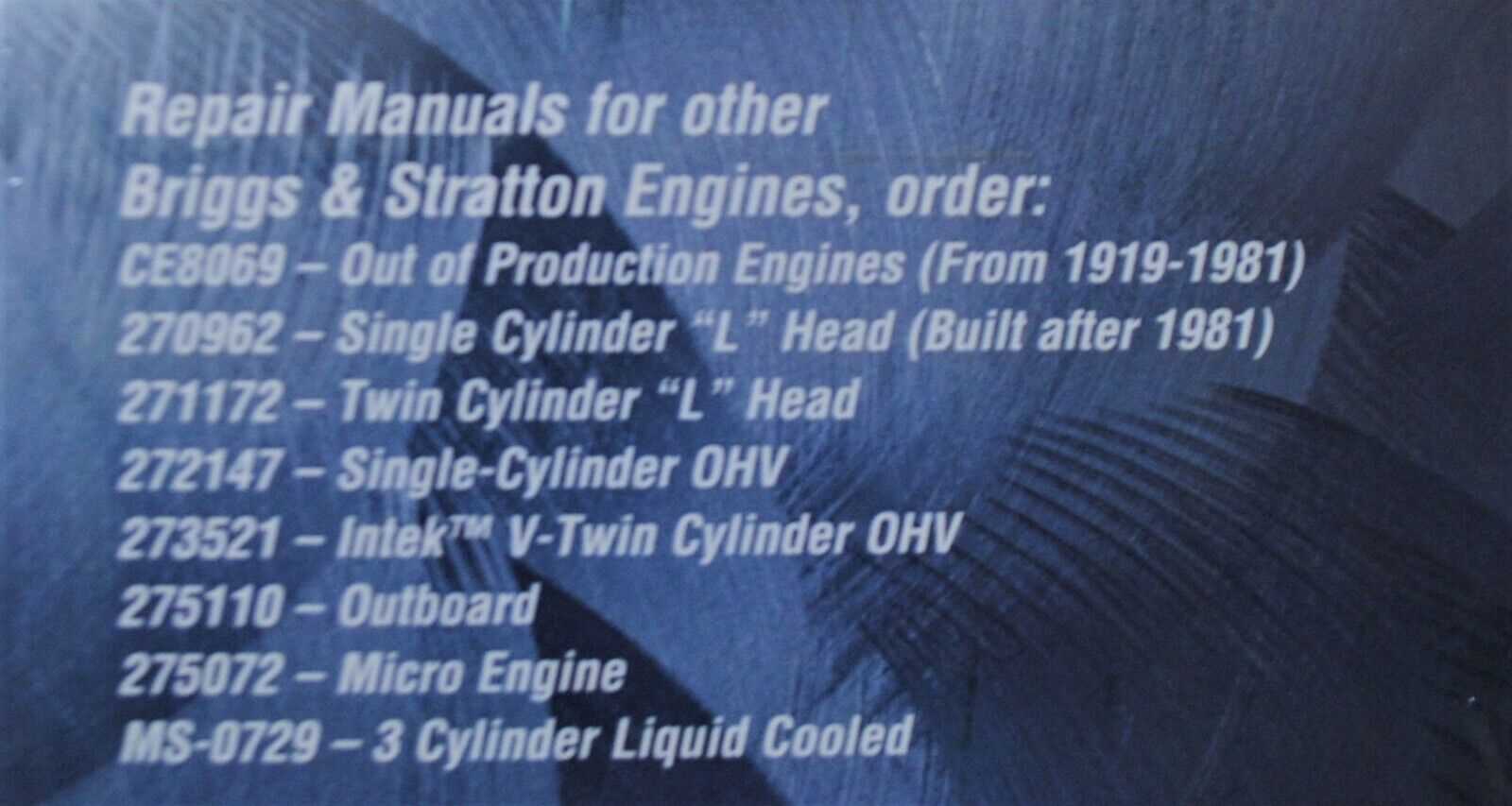

Overview of Briggs & Stratton Engines

Engine technology plays a pivotal role in various outdoor power equipment, delivering reliable performance and efficiency. The engines in question are renowned for their robust construction and adaptability, making them a preferred choice for numerous applications, from lawn care to industrial machinery. This section explores the fundamental characteristics and innovations that define these engines, highlighting their significance in the market.

Key Features

These power units are designed with several standout attributes that enhance their usability and performance. Below are some of the critical features:

| Feature | Description |

|---|---|

| Durability | Constructed with high-quality materials to withstand harsh conditions. |

| Fuel Efficiency | Engineered for optimal fuel consumption, providing longer run times. |

| Ease of Maintenance | Designed for straightforward serviceability, simplifying upkeep. |

| Power Output | Available in various power ratings to suit different tasks. |

Applications

The versatility of these engines allows them to be utilized across a wide range of equipment. Common applications include lawn mowers, pressure washers, and generators. This adaptability ensures that users can find a suitable engine for their specific needs, enhancing overall productivity and performance in outdoor tasks.

Understanding the Intek V-Twin Series

The Intek V-Twin Series represents a significant advancement in engine design, providing robust performance and reliability for various applications. This series is engineered to deliver exceptional power while maintaining efficiency, making it a popular choice for both residential and commercial use.

Key Features

- High-performance design for optimal power output

- Durable construction to withstand demanding conditions

- Efficient fuel consumption for cost-effectiveness

- Enhanced cooling system to prolong engine life

Applications

This series is widely utilized in numerous settings, including:

- Residential lawn care equipment

- Commercial landscaping tools

- Generators for home and industrial use

- Light construction machinery

With its blend of power and efficiency, the Intek V-Twin Series stands out in the market, catering to the diverse needs of users across various industries.

Common Issues with Intek V-Twin

The V-Twin engine model is widely recognized for its efficiency and power, but like any mechanical system, it can encounter a variety of problems over time. Understanding these common issues can help users maintain optimal performance and prolong the engine’s lifespan. This section outlines frequent complications and offers insights into their possible causes.

1. Overheating Problems

Overheating is a prevalent issue that can arise from several factors. Blocked air filters and insufficient oil levels are typical culprits. Signs of overheating include unusual smells, smoke, and a decrease in performance. Regular maintenance, such as cleaning air intake areas and checking oil levels, can prevent these problems.

2. Fuel System Complications

Another common area of concern involves the fuel system. Issues like clogged fuel lines and dirty filters can disrupt the engine’s operation. Symptoms often manifest as difficulty starting or irregular engine performance. Ensuring the fuel system is clean and using high-quality fuel can mitigate these risks.

Essential Tools for Engine Repair

Proper maintenance and troubleshooting of engines require a set of fundamental instruments that facilitate efficient work. Understanding the necessary tools is crucial for anyone looking to enhance their mechanical skills and ensure optimal performance of their machinery. These implements not only simplify tasks but also contribute to achieving precise outcomes in various engine-related projects.

Basic Hand Tools

Every engine enthusiast should have a selection of hand tools readily available. Wrenches, sockets, and screwdrivers form the backbone of any toolkit. Wrenches are essential for tightening or loosening nuts and bolts, while sockets allow for more versatile handling of fasteners in tight spaces. Screwdrivers come in various sizes and types, making them indispensable for a range of applications, from securing panels to adjusting components.

Diagnostic Equipment

In addition to basic tools, having access to diagnostic equipment can greatly enhance the troubleshooting process. Devices such as multimeters and compression testers are vital for assessing electrical systems and measuring engine performance. Using these tools allows for accurate identification of issues, leading to more effective solutions and improved longevity of the engine.

Step-by-Step Repair Process

This section outlines a systematic approach to addressing common issues in small engine units. By following a structured method, you can effectively diagnose and resolve problems, ensuring optimal performance and longevity of your equipment.

Initial Assessment

Begin by examining the engine for visible signs of damage or wear. Check the fuel system, air filter, and spark plug for any irregularities. Taking notes during this phase will help you track potential issues and streamline the subsequent steps.

Disassembly and Inspection

Carefully disassemble the necessary components to access the internal parts. Pay close attention to gaskets, seals, and mounting bolts, ensuring they are not damaged. Inspect each part for wear or failure, and replace any components that do not meet specifications.

Maintaining Your Intek V-Twin Engine

Proper upkeep of your small engine is essential for optimal performance and longevity. Regular attention to various components can prevent unexpected failures and enhance efficiency. This section will guide you through key maintenance practices to keep your engine running smoothly.

Regular Oil Changes

Changing the oil at recommended intervals is vital for engine health. Fresh oil lubricates internal parts, reduces friction, and helps dissipate heat. Always use high-quality oil suited for your specific engine type. Check the oil level frequently and top off as needed.

Air Filter Care

The air filter plays a crucial role in maintaining proper airflow and preventing contaminants from entering the engine. Inspect the filter regularly, cleaning or replacing it as necessary. A clean air filter improves efficiency and performance while prolonging engine life.

Emphasizing regular maintenance will not only enhance performance but also save you from costly repairs in the future. By following these simple steps, you ensure that your engine remains reliable and efficient for years to come.

Identifying Engine Components and Functions

Understanding the various parts of a small engine and their respective roles is essential for effective maintenance and troubleshooting. Each component contributes to the overall performance and efficiency of the engine, ensuring it operates smoothly and reliably.

Cylinder Block: This is the main structure of the engine, housing the cylinders where combustion occurs. It provides support and is critical for maintaining engine integrity.

Piston: The piston moves up and down within the cylinder, compressing the fuel-air mixture and transferring the force generated by combustion to the crankshaft.

Crankshaft: The crankshaft converts the linear motion of the piston into rotational motion, which ultimately drives the machinery connected to the engine.

Valves: These components regulate the intake of air and fuel into the combustion chamber and the expulsion of exhaust gases. Proper functioning is vital for optimal engine performance.

Camshaft: The camshaft operates the valves, ensuring they open and close at the right times during the engine cycle. Its design directly affects the engine’s timing and efficiency.

Ignition System: This system is responsible for igniting the fuel-air mixture in the combustion chamber, typically through a spark plug. A reliable ignition system is crucial for starting and running the engine smoothly.

Fuel System: This system delivers fuel to the engine, often comprising a fuel tank, pump, and carburetor. Efficient fuel delivery is essential for optimal combustion and performance.

Each of these components plays a significant role in the operation of the engine, and understanding their functions can greatly assist in maintaining and troubleshooting any issues that may arise.

Replacing Gaskets and Seals

Maintaining optimal performance in engines often requires attention to the integrity of various components, including gaskets and seals. These critical elements help prevent leaks and ensure that the engine operates efficiently. When they wear out or become damaged, replacing them is essential to avoid performance issues and prolong the life of the machinery.

Identifying Signs of Wear

Before proceeding with replacements, it is important to recognize the signs that indicate gaskets and seals need attention. Common symptoms include oil leaks, coolant leaks, or decreased engine performance. Observing these signs early can save time and resources in the long run.

Steps for Replacement

To replace gaskets and seals, start by gathering the necessary tools and materials. Carefully disassemble the components where the gaskets or seals are located. Clean the surfaces thoroughly to remove any remnants of the old materials. Next, align the new gaskets or seals properly before reassembling the engine. Ensure everything is tightened according to specifications to maintain a proper seal.

Remember to consult manufacturer guidelines for specific torque settings and recommendations to achieve the best results. Taking these steps will help ensure a reliable and efficient operation of your engine.

Tuning the Carburetor Effectively

Proper adjustment of the fuel delivery system is essential for optimal engine performance. Ensuring that the air-fuel mixture is balanced can significantly enhance efficiency, improve throttle response, and reduce emissions. This process requires careful attention to various components to achieve the best results.

Key Steps for Tuning

Start by inspecting the current settings and make adjustments based on the engine’s behavior. Here are some crucial steps:

| Step | Description |

|---|---|

| 1 | Check for leaks in the intake manifold. |

| 2 | Adjust the idle speed to recommended RPM. |

| 3 | Fine-tune the mixture screws for optimal performance. |

| 4 | Test the engine under load and adjust as necessary. |

Final Considerations

After tuning, always conduct a test run to assess performance. Regular maintenance and periodic adjustments will ensure longevity and efficiency, providing the ultimate operational experience.

Importance of Regular Oil Changes

Regularly changing the lubricant in your engine is crucial for maintaining its overall health and performance. Over time, oil can become contaminated with dirt, debris, and combustion byproducts, leading to increased friction and wear on engine components. Ensuring that the lubricant is fresh and clean helps to protect vital parts, enhance efficiency, and prolong the lifespan of the engine.

Here are several key reasons why timely oil changes are essential:

- Reduces Wear and Tear: Fresh oil provides a protective barrier between moving parts, minimizing friction and wear.

- Improves Engine Efficiency: Clean oil promotes smoother operation, which can enhance fuel efficiency and overall performance.

- Prevents Overheating: Oil helps dissipate heat. Old, degraded oil can lead to overheating, risking severe damage.

- Removes Contaminants: Regular changes eliminate built-up sludge and particles that can hinder engine function.

- Enhances Longevity: Consistent maintenance practices contribute to a longer lifespan of the engine, saving money on repairs and replacements.

In conclusion, prioritizing regular lubricant changes is a straightforward yet effective way to ensure your engine operates at its best. By adhering to a scheduled maintenance routine, you can protect your investment and enjoy optimal performance for years to come.

Safety Precautions During Repairs

When engaging in maintenance tasks, prioritizing safety is essential to prevent accidents and injuries. Understanding the potential hazards associated with the machinery and using proper techniques can greatly enhance your work environment.

Always wear appropriate personal protective equipment, such as gloves and safety goggles, to shield yourself from debris and harmful substances. Additionally, ensure the work area is well-ventilated to minimize inhalation risks from fumes or dust.

Before starting any task, disconnect the power source to prevent accidental activation. Familiarize yourself with the equipment’s components and follow the manufacturer’s guidelines for disassembly and reassembly.

Keep tools organized and within reach to avoid unnecessary movements that could lead to accidents. Moreover, maintain a clean workspace to reduce the risk of slips and falls.

Lastly, if you encounter unfamiliar issues, consult a knowledgeable professional instead of attempting to resolve complex problems on your own. This approach not only protects your safety but also ensures effective handling of the situation.

Finding Genuine Replacement Parts

Ensuring the longevity and efficiency of your engine often hinges on the quality of its components. Sourcing authentic replacement elements is crucial for maintaining optimal performance and avoiding potential issues caused by inferior products. This section will guide you on how to identify and acquire the right parts for your machinery.

Why Authenticity Matters

Using genuine components significantly enhances the reliability of your equipment. These parts are specifically designed to fit perfectly and function seamlessly with your engine, minimizing the risk of malfunctions. Counterfeit or generic options may appear similar but can lead to decreased performance and even damage over time.

Where to Find Genuine Components

To locate authentic parts, start by visiting authorized dealers or trusted retailers that specialize in engine components. Online platforms often provide a wide selection, but ensure that the seller has a solid reputation. Manufacturer websites are also excellent resources, as they typically list approved suppliers and may offer direct purchasing options. Always check for product authenticity labels and warranty information when making a purchase.

Tips for Troubleshooting Engine Problems

Troubleshooting engine issues can seem daunting, but with a systematic approach, you can identify and resolve common problems efficiently. Understanding the basic components and their functions is essential for effective diagnosis. By following a few key strategies, you can pinpoint the source of the malfunction and apply the necessary solutions.

Conducting Initial Checks

Start with simple observations. Check for fuel levels, ensuring that there is adequate fuel in the tank. Examine the battery condition; a weak battery can lead to starting difficulties. Additionally, inspect the air filter for blockages, as restricted airflow can severely impact performance. Regular maintenance can prevent many issues, so ensure that routine tasks are up to date.

Systematic Diagnosis

If initial checks do not reveal the problem, proceed with a more detailed examination. Listen for unusual noises during operation; strange sounds can indicate specific issues, such as internal wear or loose components. If the engine fails to start, consider the ignition system, including spark plugs and wiring. Performing a compression test can also provide insights into the health of the engine. Document your findings, as this will help you track patterns and identify persistent issues over time.