Understanding the intricacies of small engine mechanics is essential for enthusiasts and professionals alike. This section provides valuable insights into troubleshooting and maintaining various types of engines, focusing on the essential components that ensure optimal performance. By mastering these techniques, individuals can extend the life of their machinery and enhance its efficiency.

Effective maintenance plays a crucial role in preventing common issues and ensuring smooth operation. This guide outlines best practices for diagnosing problems, performing routine checks, and executing necessary adjustments. Emphasis is placed on practical approaches that anyone can implement with minimal tools, fostering a hands-on understanding of engine care.

Additionally, readers will discover critical tips for identifying symptoms of wear and tear. With clear instructions and detailed explanations, this resource empowers users to tackle repairs confidently, promoting a deeper appreciation for engine technology. Explore the essentials to keep your machinery running at peak performance and avoid costly downtime.

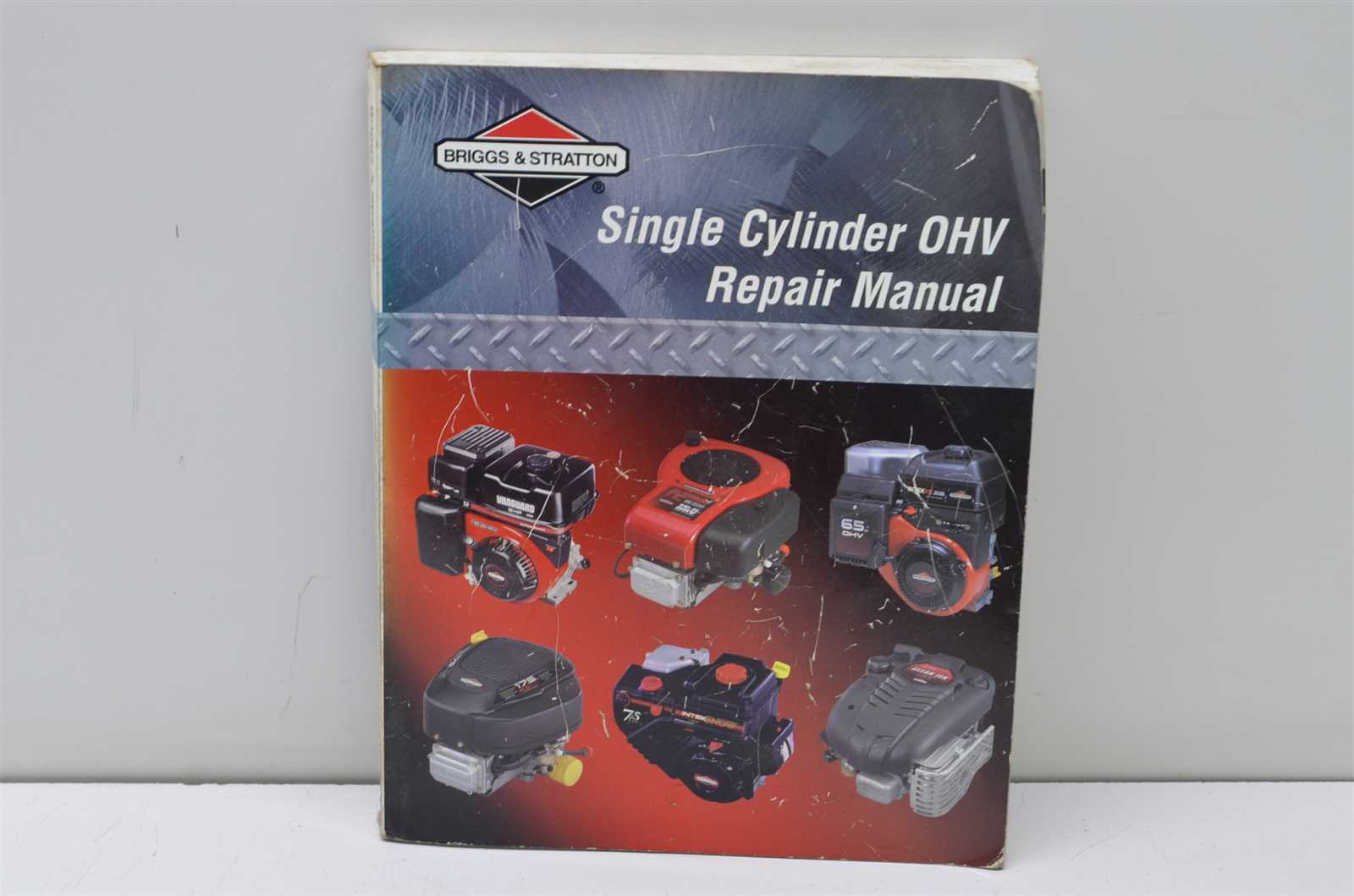

Briggs and Stratton Engine Overview

This section provides a comprehensive understanding of a renowned engine design, highlighting its key features and functionality. The power source is widely recognized for its efficiency and durability, making it a preferred choice among enthusiasts and professionals alike.

Engine Type: The unit typically consists of an overhead valve configuration that enhances performance and reduces emissions. This design contributes to a smoother operation and improved fuel efficiency.

Key Components: Major parts include the crankshaft, piston, and camshaft, which work in harmony to generate power. Each element is meticulously engineered to ensure longevity and reliability in various applications.

Applications: These engines find use in a variety of outdoor equipment, such as lawn mowers, generators, and pressure washers. Their versatility is one of the reasons they are highly regarded in the industry.

Maintenance: Regular upkeep is essential for optimal performance. Basic tasks include oil changes, air filter replacements, and spark plug inspections to keep the engine running smoothly.

Common Issues with Single Cylinder Engines

Engines with a single power unit can experience various challenges that affect their performance and reliability. Identifying these problems early can help ensure optimal operation and longevity of the unit. Here, we explore some typical concerns encountered with these types of motors.

| Issue | Description | Possible Solutions |

|---|---|---|

| Starting Difficulties | Engines may struggle to start due to fuel delivery issues or faulty ignition systems. | Check fuel levels, inspect the spark plug, and ensure proper battery condition. |

| Excessive Vibrations | Unusual vibrations can indicate misalignment or worn-out components. | Examine mounting hardware and inspect moving parts for wear. |

| Overheating | High temperatures can lead to engine damage, often caused by inadequate cooling or lubrication. | Ensure sufficient coolant levels and check the oil for quality and quantity. |

| Power Loss | A noticeable decrease in output may arise from air or fuel restrictions. | Inspect the air filter, fuel lines, and carburetor for clogs or blockages. |

Essential Tools for Repairs

Having the right instruments at your disposal is crucial for effective maintenance and troubleshooting of small engines. The appropriate tools can significantly enhance your efficiency and ensure that each task is completed with precision. Below is a list of essential equipment that every technician should consider when working on these engines.

- Wrenches: A variety of sizes is necessary for loosening and tightening bolts.

- Screwdrivers: Both flathead and Phillips types are vital for accessing different components.

- Socket Set: A comprehensive socket set will help tackle various fasteners with ease.

- Torque Wrench: Ensures that bolts are tightened to the manufacturer’s specifications.

- Pliers: Useful for gripping and bending wires or holding small parts.

In addition to these basic tools, consider the following specialized instruments that can enhance your capabilities:

- Feeler Gauges: Essential for measuring clearances and gaps accurately.

- Compression Tester: Helps assess the engine’s compression levels for performance evaluation.

- Fuel Pressure Gauge: Useful for diagnosing fuel system issues.

- Multimeter: A critical device for electrical diagnostics and troubleshooting.

- Cleaning Brushes: Important for maintaining cleanliness in fuel and air passages.

Equipping yourself with these tools will not only simplify the maintenance process but also improve the overall functionality and longevity of the engine.

Step-by-Step Maintenance Guide

Proper upkeep of small engines is essential for ensuring optimal performance and longevity. This section outlines a systematic approach to maintaining these power units, providing you with clear steps to follow for effective care.

Preparation and Safety

Before starting any maintenance tasks, ensure that the engine is cool and the spark plug is disconnected. This will prevent accidental starts. Gather necessary tools, including wrenches, screwdrivers, and a clean workspace. Wearing protective gloves and eyewear is also advisable.

Routine Checks

Begin with inspecting the air filter for dirt and debris. A clean filter promotes efficient airflow. Next, examine the fuel system for leaks and ensure the fuel is fresh. Check the oil level, and if needed, change it to maintain smooth operation. Lastly, inspect the spark plug for wear and replace it if necessary to ensure reliable ignition.

Regular attention to these aspects will enhance performance and extend the life of your engine.

Troubleshooting Engine Starting Problems

Starting issues can arise from a variety of factors, making it essential to methodically assess potential causes. Identifying the root of the problem involves examining various components that contribute to engine functionality. A systematic approach will help in pinpointing the issue efficiently.

Begin by checking the fuel system, ensuring that fresh fuel is available and that the lines are clear of obstructions. Additionally, inspect the ignition system for signs of wear or malfunction. A proper examination of these systems will often reveal common issues that hinder starting.

| Potential Issue | Possible Solution |

|---|---|

| No Fuel Supply | Check fuel level and ensure the shut-off valve is open. |

| Clogged Fuel Filter | Replace the fuel filter if necessary. |

| Weak Battery | Test the battery voltage and charge or replace as needed. |

| Defective Spark Plug | Inspect and clean or replace the spark plug. |

| Blocked Air Filter | Clean or replace the air filter to ensure proper airflow. |

By following these steps, users can systematically address common issues that prevent engine starting. Maintaining regular checks and ensuring all components are in optimal condition will significantly enhance reliability.

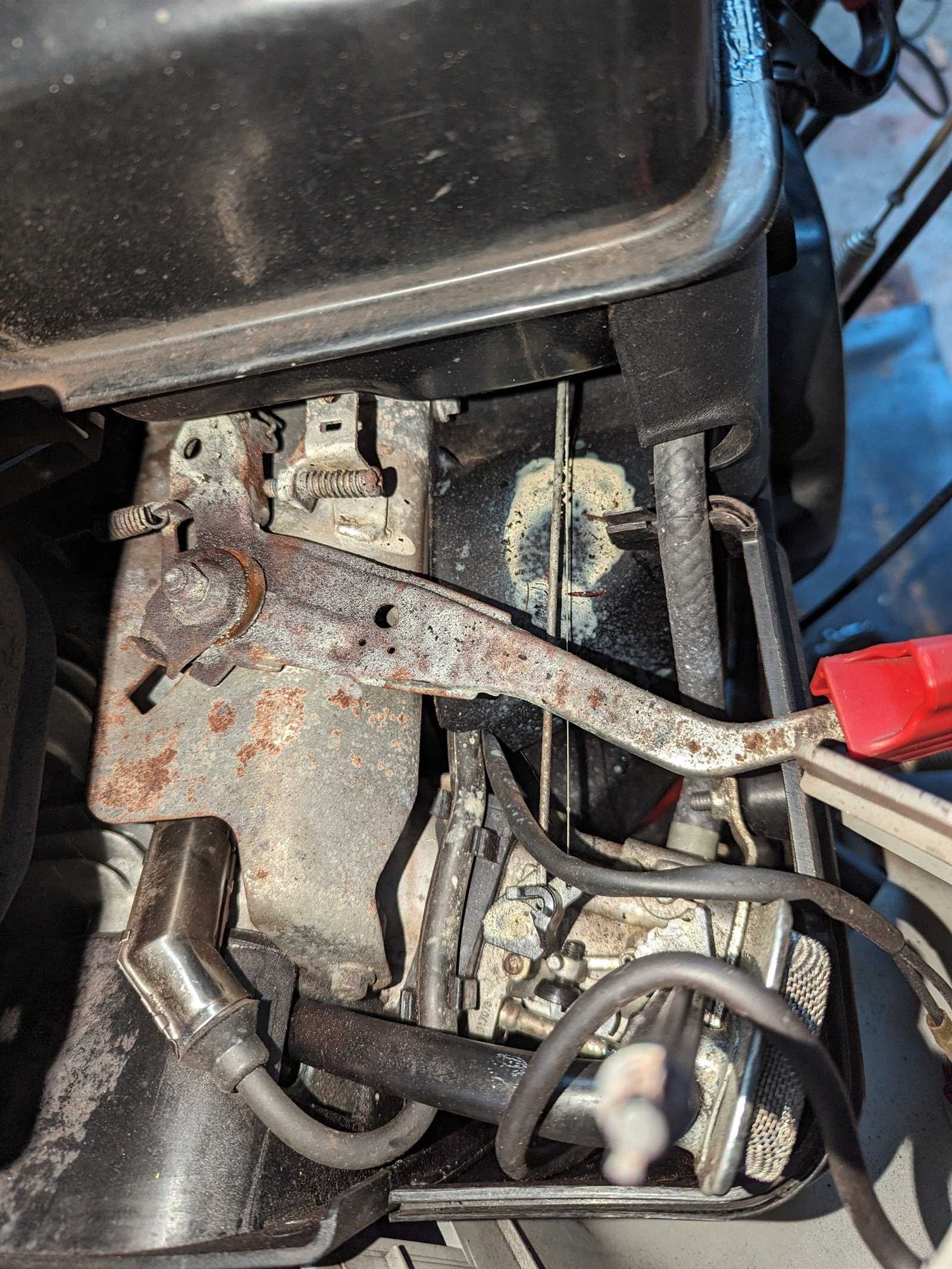

Understanding OHV Engine Components

In the world of small power units, the design and arrangement of internal elements play a crucial role in performance and efficiency. Each part is intricately linked, contributing to the overall functionality of the machine. A deeper comprehension of these components aids in effective maintenance and troubleshooting.

Key Components Overview

The core elements of a typical engine include the block, crankshaft, camshaft, and valves. The block serves as the main housing, where other parts are housed and connected. The crankshaft transforms linear motion into rotational power, while the camshaft orchestrates the timing of valve openings and closings, crucial for optimal airflow and fuel intake. Valves are essential for regulating the flow of air and fuel into the combustion chamber, ensuring that the engine operates smoothly.

Importance of Each Component

Understanding the function of each component is vital for maintaining engine performance. Regular inspections can identify wear and tear, preventing potential failures. Furthermore, being aware of how these parts interact allows for better troubleshooting when issues arise. Proper care ensures longevity and reliable operation of the unit, making knowledge of these components indispensable for any operator.

Replacing the Spark Plug

Changing the ignition component is a vital maintenance task that ensures optimal engine performance. A fresh unit can significantly improve starting efficiency and overall functionality, making it an essential part of routine upkeep.

Tools Needed

Before starting, gather the necessary tools to make the process smooth:

| Tool | Description |

|---|---|

| Socket Wrench | Used to remove the old spark component. |

| Gap Tool | Ensures the correct distance between electrodes on the new unit. |

| Clean Cloth | To wipe any debris around the opening before installation. |

Step-by-Step Instructions

Follow these steps to replace the ignition component:

- Ensure the engine is cool and disconnected from any power source.

- Locate the ignition component and use the socket wrench to carefully unscrew it.

- Inspect the old unit for wear or damage before disposing of it.

- Prepare the new ignition unit by checking the gap with the gap tool and adjusting if necessary.

- Insert the new component into the socket, ensuring it is seated correctly.

- Secure it by tightening with the socket wrench, but avoid over-tightening.

- Reconnect the power source and start the engine to verify proper function.

Oil Change Procedures Explained

Changing the lubricant in your engine is a vital maintenance task that ensures optimal performance and longevity. Regularly updating the oil not only enhances efficiency but also prevents potential damage caused by contaminants. This guide will outline essential steps for executing this procedure effectively.

-

Gather Necessary Tools and Materials:

- Fresh lubricant

- Oil filter

- Wrench or socket set

- Oil drain pan

- Funnel

- Rags or paper towels

-

Prepare the Engine:

Ensure the machine is on a flat surface and allow it to cool if it has been running. This will prevent burns and ensure a safe working environment.

-

Drain the Old Lubricant:

Position the drain pan beneath the engine’s oil pan. Remove the drain plug carefully, allowing the used oil to flow into the pan. Be cautious to avoid spills.

-

Replace the Oil Filter:

Utilize a wrench to unscrew the old filter. Apply a small amount of new lubricant to the gasket of the new filter before installing it. This will create a better seal and facilitate removal during the next change.

-

Add Fresh Lubricant:

Using a funnel, pour the new oil into the engine through the fill cap. Refer to the engine specifications for the correct type and amount of lubricant.

-

Check Oil Level:

After adding oil, replace the fill cap and start the engine for a few minutes. Allow it to circulate, then turn it off and wait a moment. Check the dipstick to ensure the oil level is within the recommended range.

-

Dispose of Old Oil Properly:

Transfer the used oil to a sealed container and take it to a recycling center or an appropriate disposal facility. Never dispose of oil in regular trash or down drains.

By following these steps, you can maintain your engine’s health and performance. Regular oil changes will ensure a smoother operation and extend the lifespan of your equipment.

Fuel System Care and Repair

The proper functioning of the fuel delivery system is essential for optimal engine performance. Regular maintenance and prompt attention to any issues can help prevent costly damage and ensure longevity. This section outlines key practices to maintain and fix the fuel system effectively.

Maintenance Tips

To keep the fuel system in top condition, consider the following recommendations:

- Regularly inspect the fuel lines for signs of wear or leaks.

- Clean or replace the fuel filter as needed to prevent clogs.

- Use fresh fuel to avoid contamination that can harm engine components.

Troubleshooting Common Issues

If performance problems arise, follow these steps to diagnose the fuel system:

| Issue | Possible Cause | Solution |

|---|---|---|

| Engine won’t start | Clogged fuel filter | Replace or clean filter |

| Engine runs rough | Contaminated fuel | Drain and refill with fresh fuel |

| Poor acceleration | Faulty fuel lines | Inspect and replace damaged lines |

By adhering to these guidelines and addressing issues promptly, you can maintain the efficiency of the fuel system and enhance the overall performance of your engine.

Diagnosing Overheating Issues

Identifying the root causes of excessive heat generation in small engines is crucial for maintaining optimal performance and longevity. Overheating can stem from various factors, and recognizing these can help prevent further damage.

One common issue may be insufficient airflow due to obstructions in the cooling system. Debris or dirt accumulation around the engine can restrict airflow, leading to inadequate cooling. Regular cleaning of the air intake and cooling fins is essential.

Another factor to consider is the quality of lubrication. Low oil levels or degraded oil can significantly affect the engine’s ability to dissipate heat. Ensure the oil is at the recommended level and replace it if it appears dirty or contaminated.

Furthermore, check the fuel mixture. An improper fuel-to-oil ratio can cause combustion temperatures to rise excessively, contributing to overheating. Adhering to manufacturer specifications for fuel mixtures is vital.

Lastly, examine the condition of the spark plug. A worn or faulty spark plug can lead to incomplete combustion, generating more heat than normal. Regular inspections and timely replacements can mitigate this risk.

Adjusting Valve Clearance Correctly

Ensuring proper spacing between engine components is essential for optimal performance and longevity. This adjustment allows for the smooth operation of the engine’s mechanisms, preventing potential damage caused by insufficient or excessive gaps.

Tools Needed: To begin, gather the necessary tools, including a feeler gauge, wrench set, and screwdrivers. Having the right equipment ensures a smooth adjustment process.

Preparation Steps: First, ensure the engine is cool. Remove any covers or components obstructing access to the valve area. It’s crucial to have a clear workspace for effective adjustments.

Adjustment Process: Rotate the crankshaft to position the piston at the top dead center (TDC) of the compression stroke. This ensures both valves are closed. Using the feeler gauge, check the clearance at each valve. If adjustments are needed, loosen the lock nut on the rocker arm, insert the gauge, and adjust until the desired gap is achieved. Tighten the lock nut securely once completed.

Final Checks: After adjustments, rotate the engine manually a few times to ensure no binding occurs. Recheck the clearance to confirm it remains within the specified range. Once satisfied, reassemble any removed components and start the engine to listen for smooth operation.

Regularly monitoring and adjusting valve spacing can significantly enhance performance and prolong engine life, making this maintenance task a critical aspect of engine care.

Safety Precautions During Repairs

When undertaking maintenance tasks on small engine units, it is essential to prioritize safety to prevent accidents and injuries. Adhering to certain guidelines can significantly reduce the risk associated with mechanical work. Proper preparation and awareness of the environment can lead to a smoother and safer experience.

Before starting any maintenance procedures, ensure that the workspace is organized and free from hazards. Familiarize yourself with the tools and equipment you will use, as improper handling can lead to injuries.

| Precaution | Description |

|---|---|

| Wear Protective Gear | Always use gloves, goggles, and other appropriate protective equipment to shield against debris and chemicals. |

| Disconnect Power Source | Before beginning any work, ensure the power source is disconnected to avoid accidental starts. |

| Work in a Well-Ventilated Area | Ensure proper airflow to avoid inhaling harmful fumes or gases from the engine. |

| Keep Tools Organized | Maintain a tidy workspace to prevent accidents caused by misplaced tools. |

| Read Documentation | Familiarize yourself with the operational guidelines specific to the engine type before proceeding. |

Following these measures will help create a safer working environment and contribute to successful maintenance activities.

Finding Replacement Parts Easily

Locating suitable components for your equipment can significantly enhance its performance and longevity. Understanding where to search and how to identify the right parts is essential for efficient maintenance. This section will guide you through the best practices for sourcing replacements without hassle.

Online Resources

The internet is a vast reservoir of information and options. Here are some effective strategies:

- Visit manufacturer websites for authentic components and specifications.

- Utilize online marketplaces that specialize in machinery parts.

- Join forums or communities focused on small engine repairs; they often share valuable leads on where to find parts.

Local Suppliers

While online shopping is convenient, don’t overlook local suppliers. Here’s how to leverage them:

- Identify local hardware or automotive stores that stock engine components.

- Inquire about specialty shops dedicated to small machinery.

- Network with local mechanics who may provide recommendations for reliable sources.

By exploring both online and local options, you can ensure that you find the appropriate components to keep your machinery running smoothly.