This section serves as a detailed resource for individuals seeking to enhance their understanding of engine upkeep and troubleshooting. With practical insights and methods, it aims to equip users with the necessary knowledge to address common issues effectively.

Engaging with this content will empower you to confidently navigate various challenges related to engine functionality. Through a series of instructions and tips, you will learn how to optimize performance and extend the lifespan of your equipment.

Whether you are a novice or have some experience, this guide provides essential information that caters to different skill levels. Emphasizing clarity and accessibility, it ensures that all users can benefit from the advice offered.

Briggs and Stratton Overview

This section provides a comprehensive look into a renowned manufacturer known for its high-performance engines and related components. The company has established a solid reputation for quality and reliability in the power equipment industry.

Founded over a century ago, this brand has continuously evolved, adapting to the changing needs of consumers and technological advancements. Its products are widely used in various applications, from lawn care to construction, reflecting the versatility and durability of its offerings.

- Innovative design and engineering

- Commitment to sustainability and efficiency

- Wide range of power solutions for different needs

- Strong customer support and service network

With a focus on performance and user satisfaction, the brand remains a leader in the market, ensuring that customers receive reliable solutions for their equipment needs.

Key Features of 28000 Series

This segment highlights the essential characteristics of a specific line of engines, showcasing their unique advantages and functionalities. These units are designed to deliver exceptional performance and reliability, making them suitable for various applications.

Robust Performance: The engines in this collection are engineered for powerful output, ensuring efficient operation even under demanding conditions.

Durability: Constructed with high-quality materials, these units are built to withstand wear and tear, providing long-lasting service.

Ease of Maintenance: The design facilitates straightforward upkeep, allowing users to perform routine checks and repairs without hassle.

Versatility: Suitable for a wide range of applications, these engines can be utilized in various equipment, enhancing their practicality.

Fuel Efficiency: Advanced engineering ensures optimal fuel consumption, contributing to cost savings over time.

Innovative Technology: Incorporating the latest advancements, these engines offer enhanced features for improved functionality and user experience.

Common Issues and Solutions

This section addresses typical challenges encountered with small engines, offering practical solutions to enhance performance and longevity.

Engine Fails to Start

A non-starting engine is a frequent issue that can stem from various causes. Here are some potential reasons and their remedies:

- Fuel Problems: Ensure that fresh fuel is used. Stale or contaminated fuel can hinder starting.

- Battery Issues: Check the battery charge and connections. A weak or dead battery may prevent ignition.

- Ignition System: Inspect the spark plug for wear or damage. Replace it if necessary to restore spark.

Overheating Concerns

Excessive heat can damage components and reduce efficiency. Here are steps to prevent overheating:

- Airflow Blockage: Ensure that the cooling fins are clear of debris. Regular cleaning can improve airflow.

- Oil Levels: Maintain proper oil levels to ensure adequate lubrication. Change oil according to manufacturer recommendations.

- Fuel Quality: Use high-quality fuel to prevent engine knock and overheating.

Maintenance Tips for Longevity

To ensure the extended lifespan of your engine, consistent upkeep is essential. Adopting a few proactive practices can significantly enhance performance and reliability. Regular attention to specific components will prevent premature wear and keep the unit operating smoothly.

1. Regular Oil Changes: Frequent oil changes are crucial for optimal function. Using high-quality lubricant helps reduce friction and prevents overheating. Adhere to the recommended intervals for oil replacement to maintain engine health.

2. Air Filter Maintenance: A clean air filter promotes efficient airflow, enhancing combustion. Inspect and replace the filter as needed to ensure the engine operates at peak performance.

3. Spark Plug Inspection: Checking and replacing spark plugs periodically can prevent starting issues and misfires. Ensure they are clean and functioning correctly for a reliable ignition.

4. Fuel Quality: Utilizing fresh fuel is vital for engine performance. Avoid letting fuel sit for extended periods, as it can degrade and lead to complications.

5. Routine Cleaning: Keeping the exterior and surrounding areas clean helps prevent debris from entering the engine. Regular cleaning can also enhance cooling and reduce the risk of overheating.

Implementing these straightforward maintenance practices will contribute to a longer lifespan and enhanced functionality of your equipment.

Step-by-Step Repair Procedures

This section provides a comprehensive guide to effectively addressing common issues encountered with small engine units. Following a systematic approach can significantly enhance the likelihood of successful restoration and functionality.

1. Identify the Problem: Begin by thoroughly examining the unit to pinpoint the specific malfunction. Listen for unusual sounds and check for visible damage.

2. Gather Necessary Tools: Collect all required tools and replacement components before commencing work. This preparation ensures efficiency and minimizes interruptions during the process.

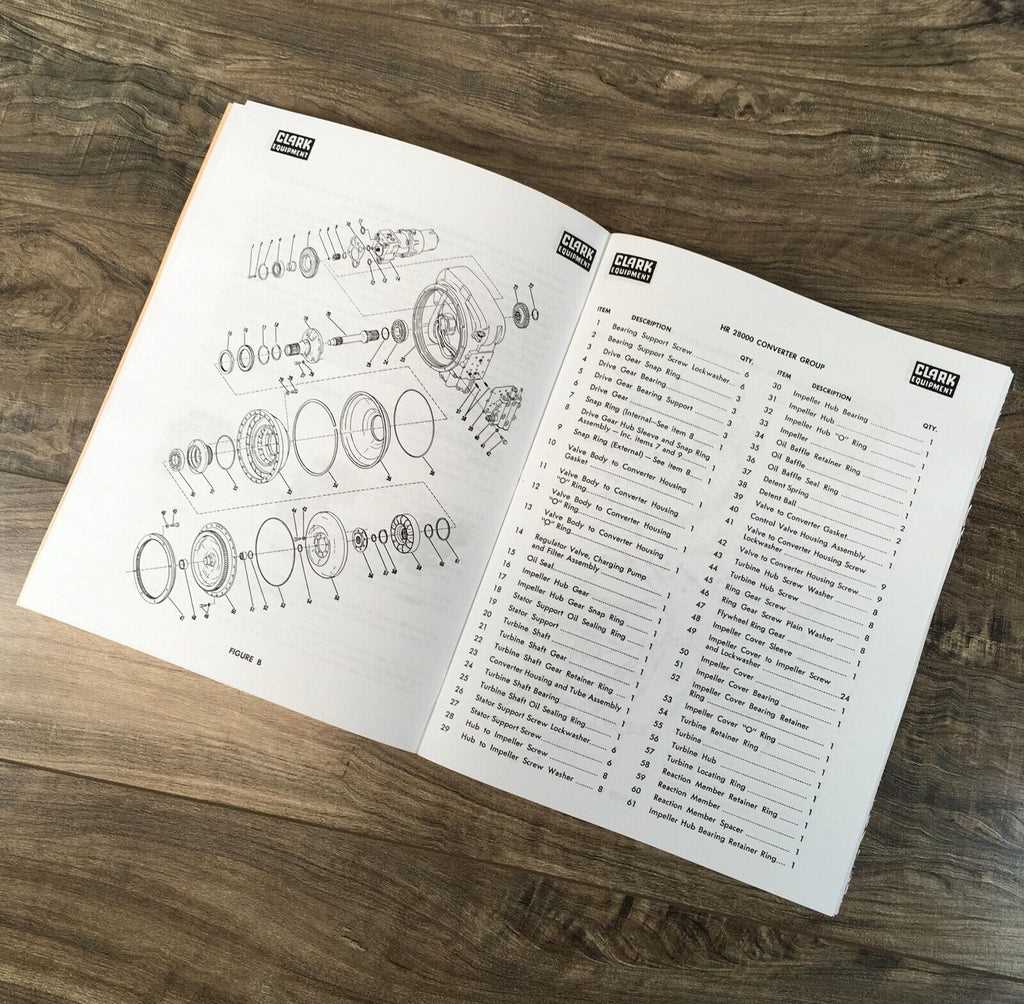

3. Disassemble Components: Carefully detach the relevant parts according to the specific requirements of the task. Take notes or photographs to facilitate reassembly later.

4. Clean and Inspect: Clean all removed components to remove dirt and debris. Inspect each part for wear or damage, as this can affect overall performance.

5. Replace Damaged Parts: If any components are found to be faulty, replace them with suitable alternatives. Ensure that all replacements meet the specifications needed for proper operation.

6. Reassemble the Unit: Reattach all parts in reverse order of disassembly, ensuring a snug fit. Follow any reference materials to confirm that every component is correctly positioned.

7. Test Functionality: After reassembly, conduct a test run to ensure the engine operates smoothly. Monitor for any lingering issues that may require further attention.

Essential Tools for Repairs

When undertaking maintenance tasks on outdoor power equipment, having the right instruments is crucial for achieving optimal results. Various implements facilitate the disassembly and assembly processes, ensuring that adjustments and fixes can be performed efficiently.

Key tools often include a selection of wrenches and screwdrivers for loosening and tightening components, alongside pliers to handle smaller parts securely. A reliable socket set enhances versatility, allowing users to address different sizes of bolts and nuts. Furthermore, a torque wrench is essential for applying the correct amount of force, preventing damage during reassembly.

Additionally, having a multimeter on hand can assist in diagnosing electrical issues, while a fuel line clamp ensures safe fuel management during servicing. Together, these tools form a comprehensive toolkit, equipping individuals to tackle various challenges effectively.

Safety Precautions to Follow

Ensuring safety while operating and maintaining equipment is paramount. Adhering to specific guidelines can prevent accidents and enhance the overall experience. This section outlines essential measures to prioritize for safe handling and usage.

Personal Protective Equipment

Wearing appropriate personal protective equipment (PPE) is crucial. This includes safety goggles to shield the eyes, gloves to protect hands, and sturdy footwear to prevent slips. By equipping yourself properly, you minimize the risk of injury during operation.

Proper Handling Techniques

Employing correct handling techniques significantly reduces hazards. Always ensure that the device is powered down before performing any maintenance. Familiarize yourself with the equipment’s components to avoid mishandling, and keep the workspace organized to prevent accidents.

Understanding Engine Components

Every engine consists of various essential parts that work together to facilitate its operation. A comprehensive grasp of these components is crucial for effective maintenance and troubleshooting. This knowledge enables users to identify issues promptly and make informed decisions regarding upkeep and functionality.

Key elements include the cylinder, which houses the combustion process, and the crankshaft, responsible for converting linear motion into rotational energy. Additionally, the valve train regulates the flow of air and fuel, ensuring optimal performance during operation.

Moreover, the fuel system is vital, as it delivers the necessary energy for the engine to function efficiently. Understanding these interconnected parts aids in recognizing how they contribute to the overall performance and longevity of the engine.

Fuel System Troubleshooting Guide

This section aims to assist users in identifying and resolving common issues related to the fuel system of their equipment. Proper understanding and maintenance of the fuel system are essential for ensuring optimal performance and longevity.

Common Symptoms of Fuel System Issues

- Difficulty starting the engine

- Engine stalling or misfiring

- Unusual noises during operation

- Poor fuel efficiency

Troubleshooting Steps

- Check the fuel level in the tank.

- Inspect fuel lines for leaks or blockages.

- Examine the fuel filter for clogs.

- Ensure the fuel is fresh and free from contaminants.

- Verify that the carburetor is clean and functioning correctly.

By following these guidelines, users can effectively troubleshoot and address fuel system problems, leading to improved performance and reliability of their equipment.

Electrical System Diagnostics

This section focuses on the assessment and troubleshooting of the electrical components within the machinery. Understanding the functionalities and potential issues of the electrical system is crucial for maintaining optimal performance and ensuring reliability.

Identifying Common Issues

Common problems in electrical systems may manifest as failure to start, irregular operation, or inconsistent power delivery. By systematically analyzing the wiring, connections, and components, users can identify underlying issues that may require attention.

Testing and Measurement Techniques

Utilizing appropriate testing tools such as multimeters and oscilloscopes is essential for diagnosing faults. These instruments allow for accurate measurement of voltage, current, and resistance, helping to pinpoint areas that may be malfunctioning or require repairs.

Replacing Parts: A Guide

This section provides a comprehensive overview of the process involved in substituting components within a specific equipment type. Understanding how to correctly exchange these elements is crucial for maintaining optimal performance and extending the lifespan of the machinery.

Before proceeding, ensure you have the necessary tools and replacement items ready. Following the appropriate steps will help facilitate a smoother transition during the replacement procedure.

| Step | Description |

|---|---|

| 1 | Identify the component that requires substitution and verify its compatibility with the equipment. |

| 2 | Disconnect the power source to prevent any accidental activation during the process. |

| 3 | Carefully remove the old part, taking note of how it is positioned for accurate installation of the new one. |

| 4 | Install the new component, ensuring it is secured properly to avoid any operational issues. |

| 5 | Reconnect the power source and conduct a test to confirm that the substitution was successful. |

Regularly replacing worn-out components is essential for ensuring the efficiency and reliability of your equipment. Proper maintenance practices will lead to improved performance and longevity.

Customer Support Resources

This section provides valuable information regarding the various avenues available for assistance and guidance related to your equipment. Utilizing these resources can enhance your experience and help resolve any inquiries or concerns effectively.

- Online Help Center: A comprehensive platform offering articles, FAQs, and troubleshooting guides tailored to common issues.

- Customer Service Hotline: Direct access to trained professionals who can provide real-time support and advice.

- Authorized Service Centers: A network of certified locations where you can receive expert repairs and maintenance services.

- Community Forums: Interactive spaces where users can share experiences, tips, and solutions, fostering a collaborative support environment.

- Email Support: A convenient option to reach out for assistance, allowing for detailed inquiries and follow-up correspondence.

Utilizing these resources ensures you receive the necessary support to maintain optimal functionality and satisfaction with your device.