Proper upkeep of small engines is essential for optimal performance and longevity. Understanding the intricacies of these powerful machines can significantly enhance their functionality and reliability. This section focuses on practical approaches to diagnosing common issues and executing effective solutions, ensuring that your engine operates smoothly for years to come.

Whether you’re a seasoned mechanic or a novice enthusiast, having access to detailed guidance can make a world of difference. From identifying unusual sounds to tackling power loss, this resource aims to equip you with the knowledge needed to address various challenges. Emphasizing straightforward techniques, it encourages confidence in handling both routine maintenance and unexpected repairs.

In the following paragraphs, you will find valuable insights into specific components, tools, and techniques tailored for efficient troubleshooting. Equipped with the right information, you can navigate through repairs with ease, ultimately enhancing your understanding of engine mechanics. Let’s delve into the essential aspects that will empower you to maintain your engine effectively.

Understanding Briggs and Stratton Engines

In the realm of small engines, certain manufacturers have established a reputation for quality and reliability. These power units are commonly found in a variety of outdoor equipment, providing the necessary force for lawn mowers, generators, and other tools. Gaining familiarity with these engines can enhance both performance and longevity.

Key Features of Small Engines

These power units typically showcase a robust design, emphasizing durability and ease of use. One of the standout characteristics is the overhead valve configuration, which allows for improved airflow and fuel efficiency. This leads to smoother operation and greater power output, making them suitable for a range of applications.

Maintenance Essentials

Proper upkeep is crucial for optimal performance. Regular oil changes, air filter replacements, and spark plug inspections are fundamental tasks that can significantly extend the lifespan of the engine. Utilizing quality fuel and following the manufacturer’s recommendations for maintenance schedules can prevent many common issues.

Understanding these engines not only empowers users to maximize their equipment’s capabilities but also fosters a deeper appreciation for the engineering behind these essential machines.

Key Features of OHV Intek Engines

These engines are renowned for their efficient design and robust performance, catering to a variety of applications. Their innovative features contribute to improved functionality, longevity, and user satisfaction.

- Overhead Valve Design: This configuration enhances airflow, resulting in better fuel efficiency and increased power output.

- Durability: Built with high-quality materials, these engines are designed to withstand rigorous use, ensuring a longer operational lifespan.

- Easy Maintenance: Simplified access to key components allows for quick servicing, making upkeep convenient for users.

- Low Emissions: Engineered to meet environmental standards, these models help reduce the carbon footprint, promoting a cleaner environment.

- Quiet Operation: The design minimizes noise levels, providing a more pleasant working atmosphere.

- Versatile Applications: Suitable for a wide range of equipment, including mowers and generators, making them a flexible choice for users.

Overall, these engines stand out for their combination of efficiency, durability, and ease of use, making them a preferred option in the market.

Common Issues with 18.5 HP Models

Engines of this capacity often face a range of typical challenges that can affect performance and longevity. Understanding these common problems can help in diagnosing issues early and ensuring optimal functionality.

- Starting Difficulties: Many users report problems with ignition or starting, which can stem from:

- Faulty spark plugs

- Weak battery

- Clogged fuel lines

- Overheating: Excessive heat can lead to serious damage. Causes include:

- Insufficient oil levels

- Blocked cooling fins

- Dirty air filters

- Loss of Power: A noticeable decrease in power output can result from:

- Worn out components

- Poor fuel quality

- Improper adjustments to the carburetor

- Unusual Noises: Strange sounds during operation may indicate:

- Loose parts

- Worn bearings

- Improperly adjusted belts

lessCopy code

Addressing these issues promptly can enhance the performance and lifespan of the engine, making regular maintenance essential for reliable operation.

Tools Needed for Engine Repairs

When undertaking maintenance or troubleshooting of small engines, having the right tools at your disposal is crucial. The appropriate equipment not only enhances efficiency but also ensures precision during various tasks. From basic hand tools to specialized instruments, a well-equipped workspace can make all the difference in achieving successful outcomes.

Essential Hand Tools

Basic hand tools are fundamental for any repair job. A set of wrenches and screwdrivers in various sizes is necessary for loosening and tightening bolts and screws. Additionally, a ratchet and socket set will come in handy for reaching confined areas. Don’t forget about pliers and cutters, which are useful for manipulating wires and other components.

Specialized Equipment

In addition to standard tools, having specialized equipment can significantly aid in repairs. A compression gauge is essential for testing engine pressure, while a multimeter helps diagnose electrical issues. Moreover, an oil filter wrench simplifies the process of changing lubricants, ensuring clean and effective maintenance. Investing in these tools will enhance your repair capabilities and extend the lifespan of your engine.

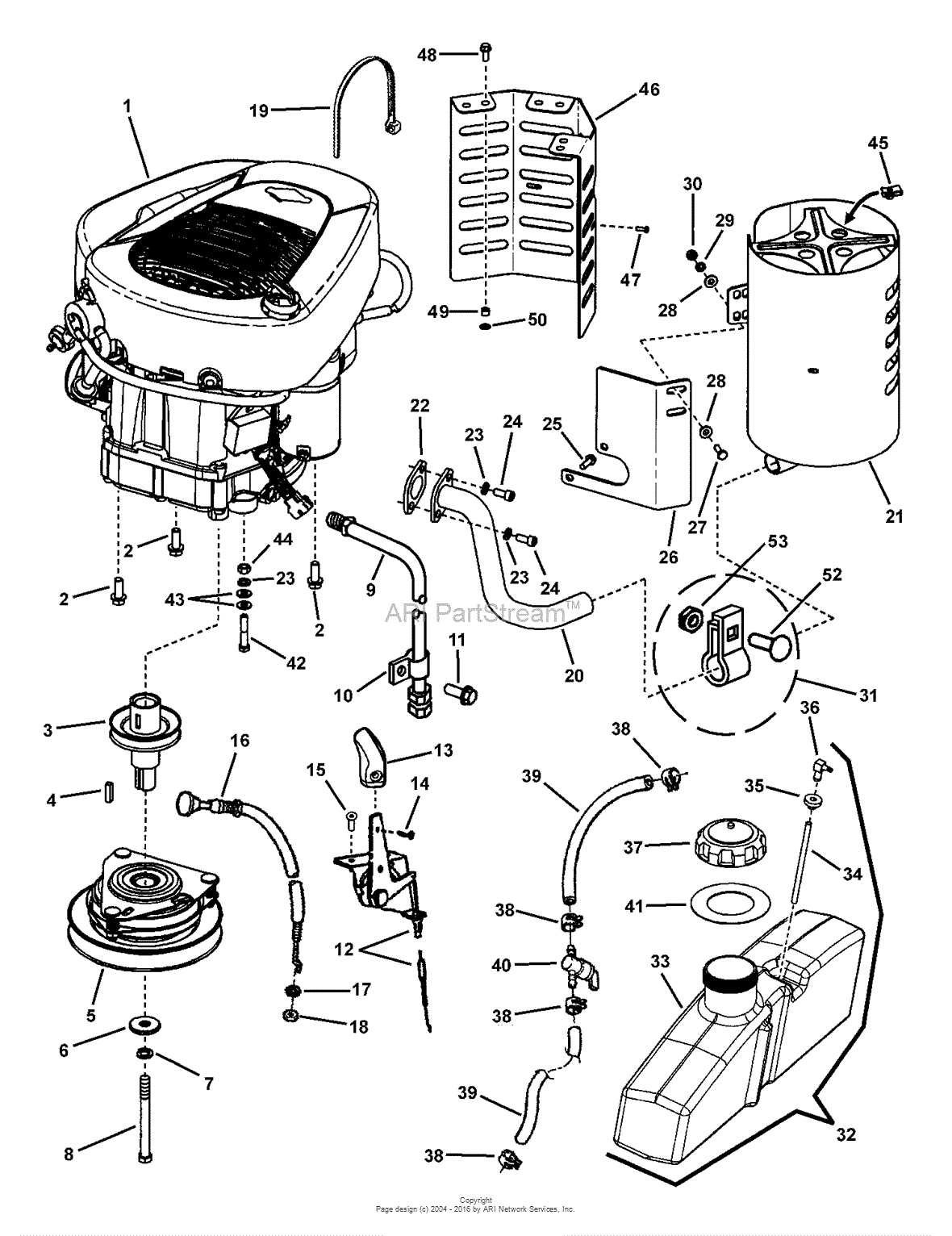

Step-by-Step Repair Guide

This section provides a comprehensive approach to addressing common issues with small engines. By following a systematic method, users can effectively troubleshoot and fix various malfunctions, ensuring optimal performance and longevity of the machinery.

Step 1: Preparation

Gather all necessary tools and replacement parts before beginning the process. Ensure the workspace is clean and well-lit to facilitate efficient work.

Step 2: Safety Measures

Before starting, disconnect the spark plug to prevent accidental ignition. Always wear protective gear, such as gloves and goggles, to ensure personal safety during the maintenance process.

Step 3: Inspection

Carefully examine the engine for any visible signs of wear or damage. Look for leaks, cracks, or loose components that may need attention.

Step 4: Cleaning

Remove dirt and debris from the exterior and internal parts of the engine. A clean workspace allows for better visibility and enhances the effectiveness of repairs.

Step 5: Component Replacement

Identify any faulty components that require replacement. Follow the manufacturer’s specifications to ensure the correct parts are used, maintaining compatibility and performance.

Step 6: Reassembly

Once repairs are completed, carefully reassemble the engine parts. Ensure all screws and bolts are tightened to the recommended torque specifications.

Step 7: Testing

Reconnect the spark plug and start the engine to test functionality. Observe for any unusual noises or performance issues, making adjustments as necessary.

Step 8: Regular Maintenance

Implement a routine maintenance schedule to prevent future issues. Regular checks on oil levels, air filters, and spark plugs can greatly extend the life of the engine.

Maintenance Tips for Longevity

Ensuring the extended life of your engine requires regular upkeep and attention to detail. By implementing simple maintenance practices, you can enhance performance, prevent breakdowns, and avoid costly repairs. Consistent care not only prolongs the lifespan of your equipment but also optimizes its efficiency during operation.

Regular Oil Changes

Changing the oil at recommended intervals is crucial for maintaining proper lubrication. Fresh oil reduces friction and wear on internal components. Be sure to check the oil level regularly and replace it with the correct type to ensure smooth functioning.

Air Filter Maintenance

A clean air filter is essential for optimal airflow and performance. Inspect the filter frequently and clean or replace it as necessary. A clogged filter can lead to reduced efficiency and increased fuel consumption, impacting overall engine longevity.

Incorporating these practices into your routine will help safeguard your engine, ensuring it operates reliably for years to come.

Diagnosing Engine Performance Problems

Identifying issues with engine performance is crucial for maintaining efficiency and longevity. Recognizing symptoms early can prevent more significant damage and costly repairs. A systematic approach to troubleshooting can help pinpoint the underlying causes of reduced power, poor fuel efficiency, or irregular operation.

Common symptoms of engine performance issues include unusual noises, decreased power output, or difficulty starting. Each symptom can be linked to various mechanical or electrical failures, and understanding these connections is vital for effective diagnosis.

| Symptom | Possible Causes | Suggested Actions |

|---|---|---|

| Poor acceleration | Clogged fuel filter, dirty air filter | Replace filters, check fuel lines |

| Engine stalling | Faulty spark plug, fuel starvation | Inspect spark plug, check fuel levels |

| Excessive smoke | Oil leakage, worn piston rings | Check oil levels, perform compression test |

| Unusual noises | Loose components, bearing wear | Tighten parts, inspect for damage |

By methodically evaluating these symptoms and their potential causes, operators can effectively narrow down the source of the problem. Keeping a maintenance log and adhering to routine checks can significantly aid in preventing performance issues before they escalate.

Parts Replacement and Compatibility

Ensuring proper functionality of small engines often requires timely replacement of components. Understanding which parts are interchangeable can significantly enhance performance and extend the lifespan of the machinery. This section focuses on identifying suitable replacements and the importance of compatibility in maintaining optimal operation.

Identifying Compatible Components

When seeking replacements, it is crucial to consider the following factors:

- Model Specifications: Always refer to the specifications of your engine to find compatible parts.

- OEM vs. Aftermarket: Original equipment manufacturer parts may offer better reliability, while aftermarket options can provide cost savings.

- Part Numbers: Cross-reference part numbers to ensure accuracy in selection.

Commonly Replaced Parts

Several components are frequently replaced due to wear and tear:

- Air Filters: Essential for maintaining airflow and engine efficiency.

- Spark Plugs: Crucial for ignition; replacing them regularly ensures smooth starts.

- Fuel Filters: Keep the fuel system clean by replacing filters periodically.

- Oil Filters: Essential for maintaining proper lubrication and preventing engine damage.

By selecting the right parts and ensuring their compatibility, you can achieve enhanced performance and reliability in your machinery.

Safety Precautions During Repairs

When undertaking maintenance or troubleshooting tasks on machinery, ensuring safety should always be a top priority. Proper precautions not only protect the individual performing the work but also extend the life of the equipment being serviced. Following established guidelines can help prevent accidents and injuries.

Essential Safety Guidelines

- Always wear appropriate personal protective equipment (PPE), such as gloves, goggles, and steel-toed boots.

- Ensure that the engine is turned off and cooled down before beginning any work.

- Disconnect the spark plug to prevent accidental starting while working on the machine.

- Keep the workspace clean and organized to minimize hazards.

- Use the right tools for the job to avoid injury and damage to components.

Working with Fuel and Fluids

- Handle fuel with care. Always work in a well-ventilated area and avoid open flames or sparks.

- Store flammable liquids in appropriate containers and away from heat sources.

- Dispose of waste fluids properly, following local regulations.

By adhering to these safety measures, individuals can ensure a safer and more efficient working environment, leading to successful maintenance outcomes.

Understanding Engine Specifications

Engine specifications play a crucial role in determining the performance and suitability of a power unit for various applications. By delving into the details of these parameters, users can make informed decisions about maintenance, troubleshooting, and overall functionality. This section aims to elucidate the importance of recognizing and comprehending the various attributes that define an engine’s capabilities.

One fundamental aspect of engine specifications is the power output, which directly impacts how effectively the unit can handle tasks such as mowing, tilling, or other heavy-duty operations. Additionally, torque figures are essential, as they indicate the engine’s ability to perform under load. Understanding the interplay between these metrics can greatly enhance the efficiency of the equipment.

Another critical specification involves displacement, which refers to the total volume of the engine’s cylinders. This measurement influences both power generation and fuel consumption, making it vital for users to assess their requirements accurately. Furthermore, features such as cooling systems and lubrication methods contribute significantly to the longevity and reliability of the engine.

Lastly, recognizing the importance of emission standards and fuel types is imperative. Compliance with environmental regulations not only affects performance but also impacts the overall usability of the engine in specific contexts. By grasping these specifications, operators can ensure optimal performance while adhering to necessary guidelines.

Using the Repair Manual Effectively

To maximize the benefits of a service guide, it’s essential to approach it with a clear strategy. Familiarizing yourself with the layout and structure can streamline your troubleshooting process. By understanding where to find vital information quickly, you can save both time and effort during maintenance or repairs.

Understanding Sections and Navigation

Each part of the guide is organized to provide specific insights into components and procedures. Take the time to explore the table of contents, which will help you locate sections relevant to your needs. Bookmarking or noting key pages can also enhance your efficiency, allowing you to access crucial details without unnecessary delays.

Following Instructions Carefully

Detailed steps are outlined to ensure successful outcomes. Adhering strictly to these instructions is crucial, as even minor deviations can lead to complications. Additionally, consulting any diagrams or illustrations can provide further clarity, making complex tasks more manageable and reducing the likelihood of errors.

Where to Find Replacement Parts

Locating suitable components for your engine can be a straightforward task if you know where to look. Having access to reliable sources ensures that you can maintain optimal performance and extend the life of your equipment. Here are some recommended avenues for sourcing the necessary parts.

- Authorized Dealers: Visit local retailers that specialize in engine products. They often carry a wide range of original components and can provide expert advice.

- Online Marketplaces: Websites such as eBay, Amazon, and specialized e-commerce platforms offer a vast selection of parts. Always check the reviews and ratings before purchasing.

- Manufacturer’s Website: Many manufacturers have online catalogs where you can order parts directly. This is often the best way to ensure you are getting genuine items.

- Local Repair Shops: Sometimes local mechanics can source specific components for you or may have them in stock. Building a relationship with a local shop can be beneficial.

- Salvage Yards: For those looking to save money, salvage yards can be a treasure trove of used parts. Inspect items carefully to ensure they meet your quality standards.

By exploring these options, you can easily find the parts you need to keep your engine running smoothly and efficiently.