In the realm of heavy machinery, ensuring optimal performance and longevity requires a comprehensive understanding of maintenance practices. This guide serves as a resource for operators and technicians who seek to enhance the operational efficiency of their compact equipment. By following structured approaches to upkeep, users can prevent breakdowns and extend the lifespan of their machines.

Understanding the intricacies of your equipment is essential for effective service. Familiarity with components and systems allows for timely interventions, reducing downtime and costly repairs. This resource aims to provide insights into troubleshooting, routine checks, and best practices that are crucial for maintaining functionality.

Moreover, equipping oneself with knowledge about assembly and disassembly procedures contributes to a safer working environment. Whether you’re a seasoned professional or a novice, grasping these fundamentals empowers you to handle challenges confidently, ensuring your machinery operates at peak performance.

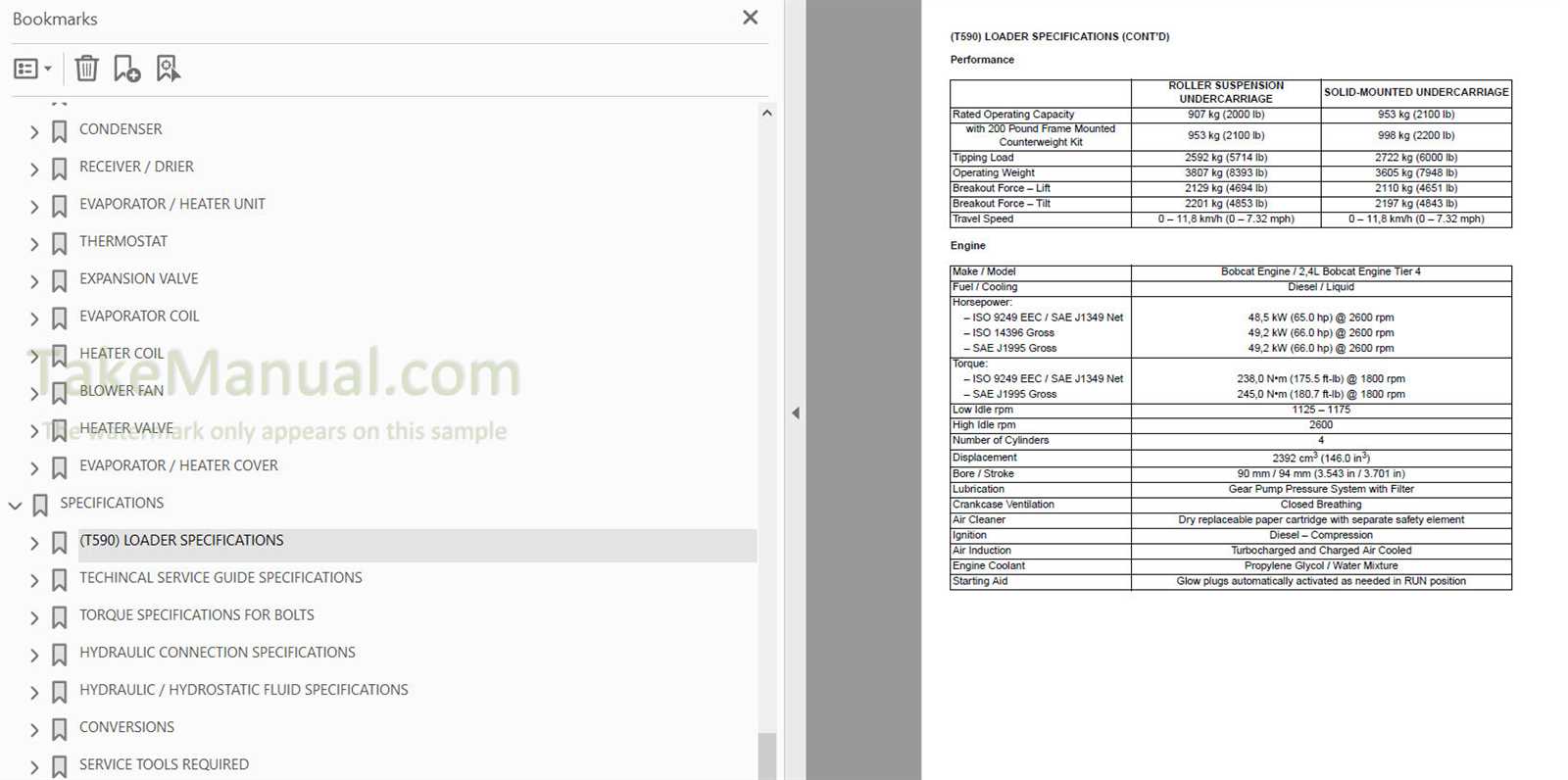

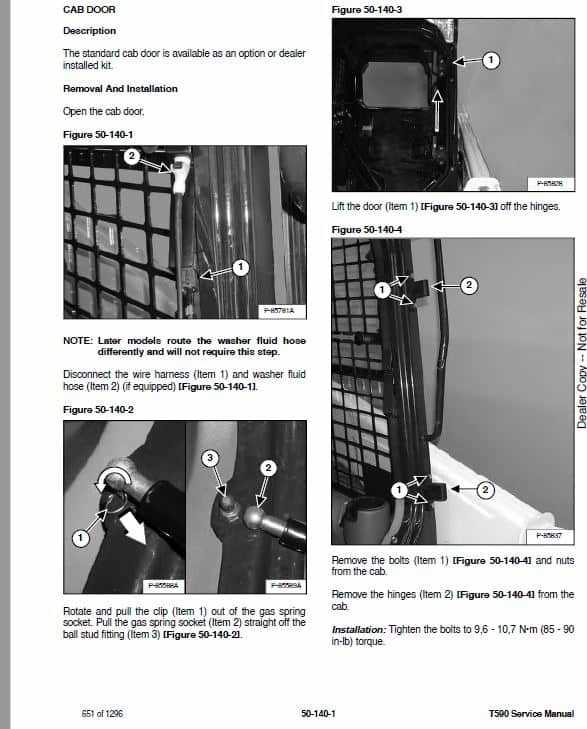

Understanding Bobcat T590 Overview

This section provides a comprehensive look at a versatile piece of machinery designed for various tasks in construction and landscaping. With its compact design and powerful capabilities, this equipment is ideal for both professionals and DIY enthusiasts. Users will benefit from a deeper understanding of its features, performance, and applications.

Key characteristics include:

- Robust engine power

- Compact size for maneuverability

- Advanced hydraulic system

- User-friendly controls

- Versatile attachment options

This machinery excels in numerous environments, making it suitable for tasks such as:

- Excavation and grading

- Landscaping and site preparation

- Material handling

- Snow removal

- Utility work

Understanding the functionalities and operational advantages of this equipment can lead to increased efficiency and productivity on any project.

Common Issues with T590 Models

The compact loader in question is known for its versatility and efficiency, yet it is not immune to certain challenges that users may encounter over time. Understanding these frequent complications can help operators maintain optimal performance and extend the lifespan of the equipment.

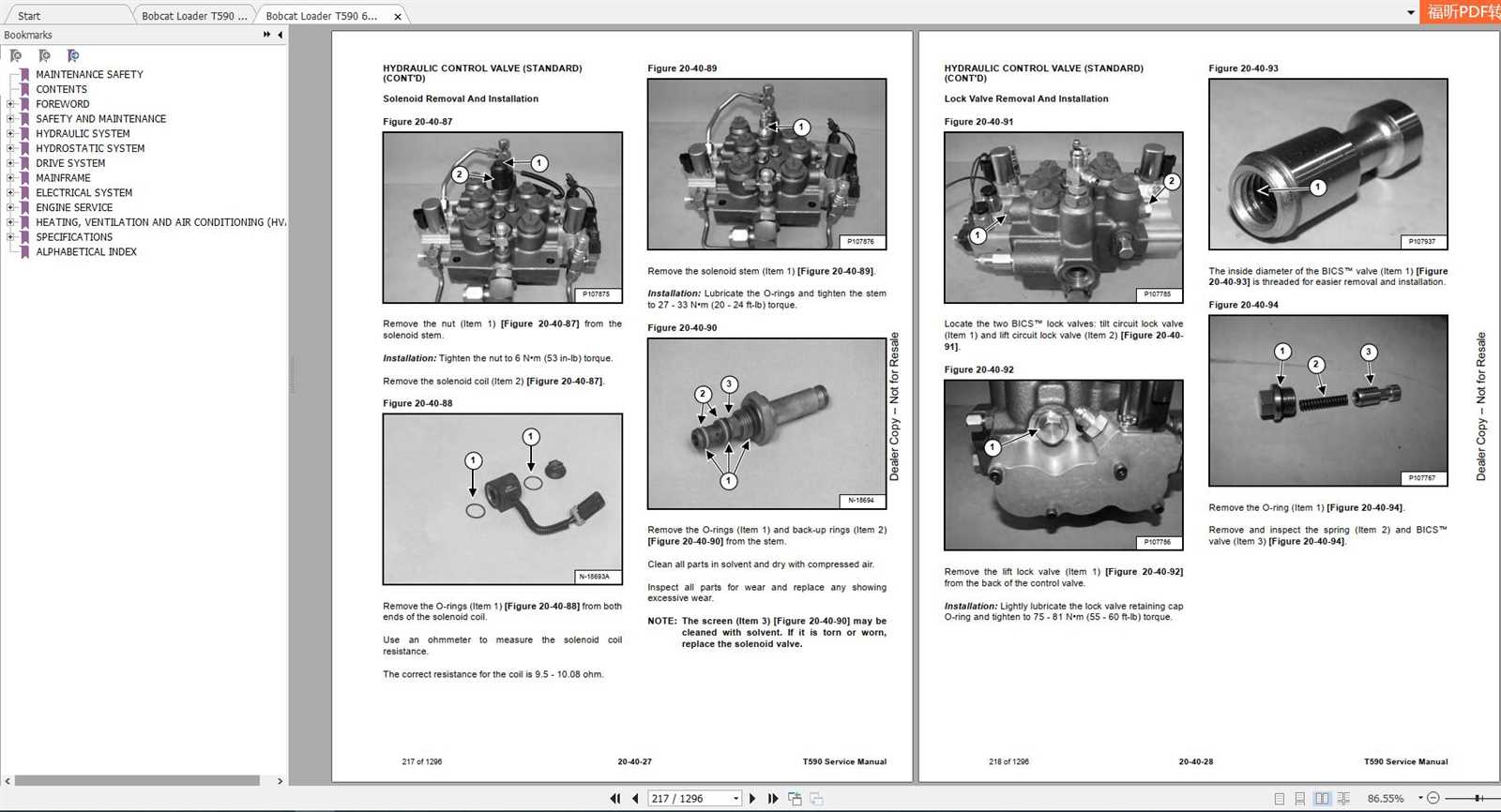

Hydraulic System Failures

One of the most prevalent problems involves the hydraulic system, which is crucial for various functions. Users often report leaks or reduced pressure, leading to sluggish operation or unresponsive controls. Regular inspection of hoses and fittings is essential to identify and address these issues promptly.

Engine Performance Issues

Another common area of concern is engine performance. Operators may notice difficulties in starting or irregular idling, often attributed to fuel delivery problems or air filter obstructions. Ensuring proper maintenance of the fuel system and regular filter changes can significantly mitigate these challenges.

Essential Tools for Repairs

Having the right instruments is crucial for effective maintenance tasks. Whether you’re addressing minor issues or undertaking significant overhauls, a well-equipped toolkit can make the process smoother and more efficient. Below are some indispensable items that every technician should consider for their toolkit.

Basic Hand Tools

- Wrenches: A variety of sizes, including adjustable and socket types, are essential for loosening and tightening bolts.

- Screwdrivers: A selection of flathead and Phillips screwdrivers will cover most fastening needs.

- Pliers: Needle-nose and standard pliers can assist in gripping, twisting, and cutting tasks.

- Hammers: A ball-peen hammer is useful for driving pins and adjusting parts without causing damage.

Specialized Equipment

- Multimeter: This device is vital for diagnosing electrical issues and ensuring proper voltage levels.

- Torque Wrench: Accurate tightening of bolts to specified settings is essential for safety and performance.

- Oil Filter Wrench: This tool simplifies the removal and installation of oil filters during service tasks.

- Diagnostic Scanner: Advanced tools can help identify error codes and monitor system performance.

Equipping yourself with these fundamental and specialized tools will not only enhance your efficiency but also ensure that you are prepared for a wide range of challenges that may arise during maintenance tasks.

Step-by-Step Maintenance Procedures

Regular upkeep is essential for ensuring the longevity and efficiency of your machinery. Following a systematic approach not only enhances performance but also helps in identifying potential issues before they escalate. Below are detailed procedures that will guide you through essential maintenance tasks.

Daily Checks

- Inspect fluid levels, including engine oil and hydraulic fluid.

- Examine filters for cleanliness and replace if necessary.

- Look for any visible leaks or signs of wear on hoses and connections.

- Ensure all safety features are functional, including alarms and guards.

Weekly Maintenance

- Clean air filters to prevent dust buildup that could hinder performance.

- Grease all moving parts to reduce friction and wear.

- Check tire pressures and inspect for damage or excessive wear.

- Inspect the undercarriage for debris and remove any obstructions.

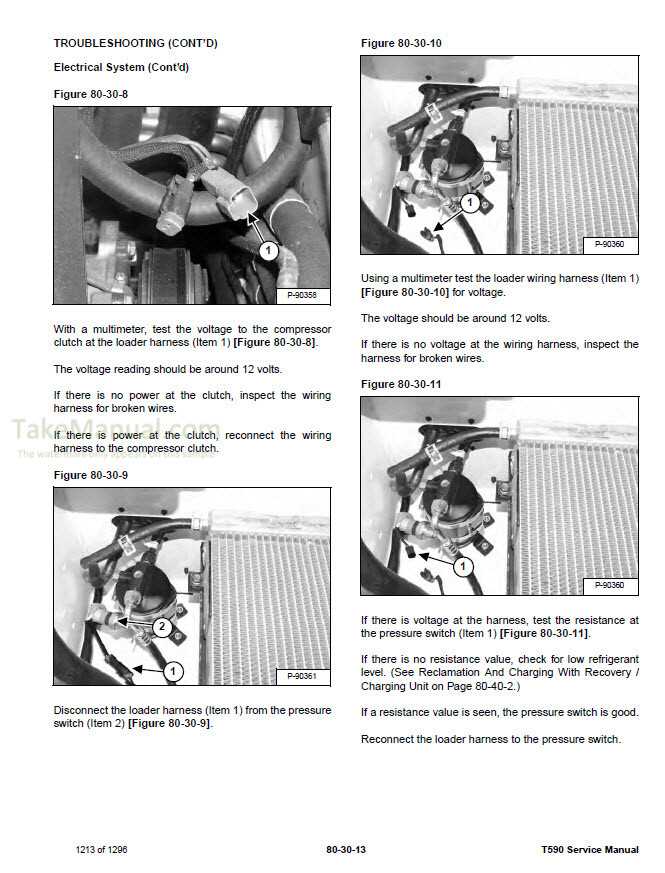

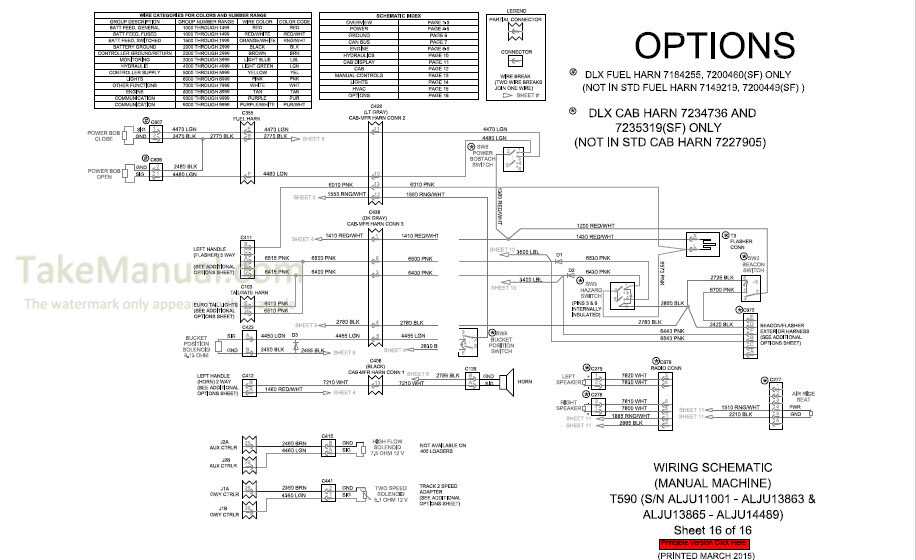

Electrical Systems Troubleshooting Guide

This section provides a comprehensive overview for diagnosing issues within electrical systems. Understanding the common problems and their solutions can significantly enhance the efficiency of maintenance tasks and prolong the lifespan of the equipment.

Key aspects to consider when troubleshooting electrical systems include:

- Power Supply Issues

- Circuit Integrity

- Component Functionality

- Wiring Connections

- Control System Performance

Follow these steps for effective troubleshooting:

- Identify Symptoms: Note any irregularities such as flickering lights, unresponsive controls, or unexpected shutdowns.

- Check Power Sources: Ensure that all power sources are functional and properly connected.

- Inspect Wiring: Look for damaged, loose, or corroded wires. Repair or replace as necessary.

- Test Components: Use a multimeter to check the voltage and resistance of various components to ensure they are operating correctly.

- Review Control Systems: Analyze control panels and switches for any faults or operational errors.

By following this guide, you can systematically identify and resolve electrical issues, ensuring your machinery operates smoothly and efficiently.

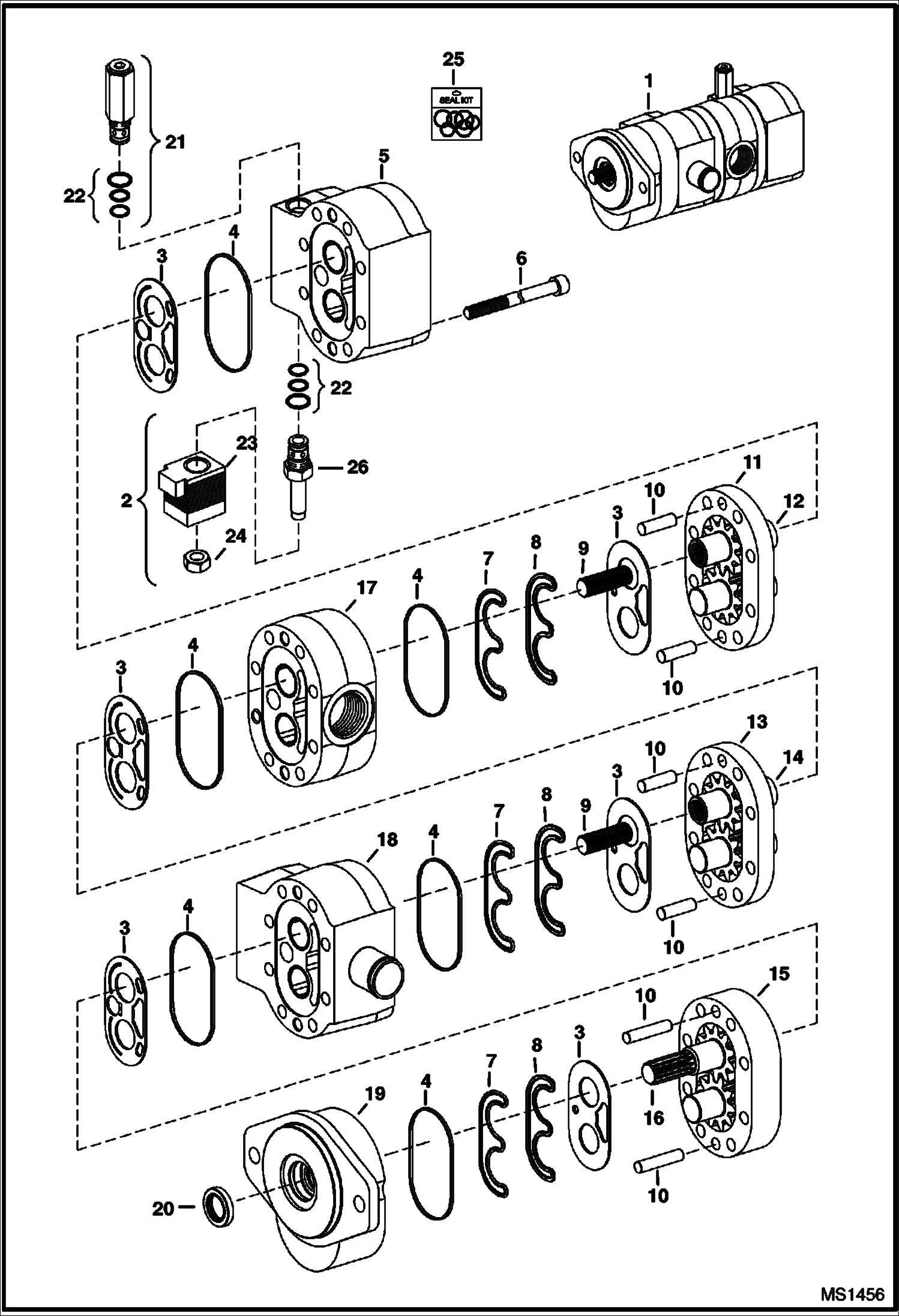

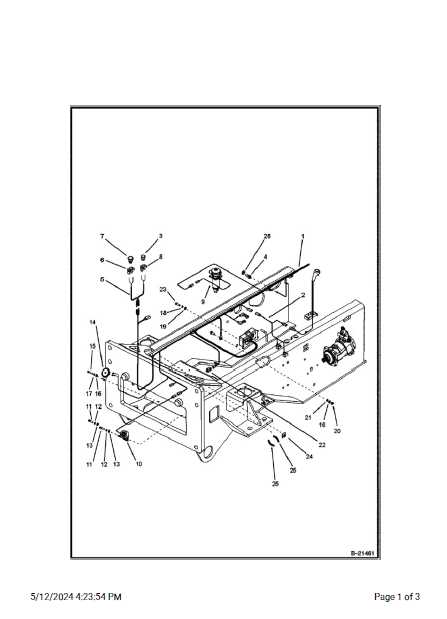

Hydraulic System Maintenance Tips

Maintaining the hydraulic system is crucial for ensuring the longevity and efficiency of your equipment. Regular checks and timely interventions can prevent costly repairs and enhance performance. Here are some essential practices to keep your hydraulic components in top condition.

Regular Inspection

- Examine hoses and connections for leaks or wear.

- Check fluid levels and quality; top off or replace as necessary.

- Inspect filters for clogs and replace them according to the manufacturer’s recommendations.

Fluid Management

- Use the correct type of hydraulic fluid specified for your system.

- Change the hydraulic fluid at recommended intervals to remove contaminants.

- Monitor the fluid temperature to prevent overheating.

By following these maintenance tips, you can help ensure that your hydraulic system operates smoothly and efficiently, minimizing downtime and maximizing productivity.

Replacing T590 Tracks and Tires

Maintaining the undercarriage of your compact loader is crucial for optimal performance and longevity. Replacing tracks and tires ensures that your machine operates smoothly and efficiently, enhancing traction and stability on various terrains. This section will guide you through the necessary steps to complete this task effectively.

Preparation: Before starting, ensure you have the appropriate tools and replacement components on hand. This may include a hydraulic jack, track removal tool, and new tracks or tires designed specifically for your equipment. It’s also advisable to consult the specifications for any weight restrictions or operational guidelines.

Removing Old Components: Begin by safely lifting the machine with the hydraulic jack. Once elevated, inspect the current tracks or tires for wear. If the rubber is cracked or if the tread has significantly worn down, it’s time for a change. Carefully detach the old tracks or tires, taking care to note the orientation and attachment method for reinstallation.

Installing New Tracks and Tires: Align the new components with the mounting points and securely attach them. For tracks, ensure they fit snugly around the drive wheels and idlers. Double-check that all fasteners are tightened to the manufacturer’s specifications to prevent slippage during operation.

Final Checks: After installation, lower the equipment and test the new tracks or tires in a controlled environment. Monitor for any unusual sounds or vibrations, which could indicate improper installation. Regular inspections after replacement will help maintain performance and safety.

Engine Diagnostics and Repairs

This section focuses on the critical processes involved in assessing and rectifying issues related to the power unit of your machinery. Understanding the symptoms of mechanical failures and implementing effective solutions are essential for maintaining optimal performance and longevity.

Common Symptoms of Engine Issues

Recognizing early indicators of engine problems can prevent more extensive damage. Typical signs include unusual noises, decreased power output, or abnormal exhaust emissions. Monitoring fluid levels and engine temperature can also provide valuable insights into the machine’s health.

Diagnostic Procedures

To accurately identify faults, employ systematic diagnostic techniques. Start with visual inspections for leaks or damaged components. Utilizing specialized tools for measuring pressure and temperature can further pinpoint issues. Once diagnosed, repairs may involve replacing worn parts, adjusting settings, or conducting thorough cleaning to restore functionality.

Regular maintenance plays a crucial role in preventing future complications. Implementing a scheduled check-up routine can ensure that all components operate efficiently, enhancing reliability and reducing downtime.

By prioritizing engine diagnostics and appropriate corrective measures, operators can ensure their equipment remains in peak condition, ready to tackle demanding tasks.

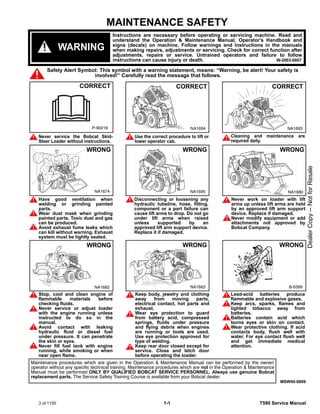

Safety Precautions During Repairs

Ensuring safety while performing maintenance tasks is crucial for both the technician and the machinery. Proper precautions help prevent accidents and injuries, promoting a secure working environment. Awareness of potential hazards and adherence to safety guidelines is essential for effective and secure service procedures.

Before starting any work, it’s vital to wear appropriate personal protective equipment (PPE), such as gloves, goggles, and helmets. These items safeguard against physical injuries and exposure to harmful substances. Additionally, ensuring the workspace is clear of obstacles reduces the risk of tripping or falling.

Always disconnect the power source before undertaking any service. This simple step can prevent unexpected equipment movement or electrical shocks. It is also advisable to utilize proper tools and equipment designed for the specific tasks, as using incorrect tools can lead to accidents or damage.

When working on elevated surfaces, utilize ladders or platforms that are stable and secure. Avoid overreaching or leaning too far, as this can lead to falls. Moreover, ensure that any hydraulic systems are depressurized before starting work to avoid sudden releases of pressure.

Lastly, remain vigilant and communicate clearly with team members. Understanding your surroundings and notifying others of your actions fosters a safer atmosphere. By following these precautions, the likelihood of mishaps during service can be significantly reduced, ensuring a more efficient and safe working process.

Service Schedule Recommendations

Maintaining equipment in optimal condition is essential for ensuring longevity and efficient performance. A well-structured service schedule helps prevent unexpected breakdowns and costly repairs, while also enhancing operational productivity. Below are key recommendations for establishing an effective maintenance routine.

- Daily Inspections:

- Check fluid levels, including oil and hydraulic fluids.

- Inspect tires for wear and proper inflation.

- Examine all safety features for functionality.

- Weekly Maintenance:

- Clean air filters and check for any blockages.

- Lubricate moving parts to minimize friction.

- Inspect the undercarriage for debris accumulation.

- Monthly Checks:

- Replace oil and hydraulic filters as needed.

- Perform a comprehensive inspection of electrical systems.

- Test all operational features to ensure they are functioning correctly.

- Seasonal Maintenance:

- Conduct a thorough cleaning of the entire unit.

- Inspect belts and hoses for signs of wear or cracking.

- Review the overall condition and make necessary adjustments.

By adhering to these scheduled checks, operators can significantly reduce the risk of failures and extend the lifespan of their machinery. Regular attention to maintenance not only enhances performance but also contributes to a safer working environment.

Finding Genuine Replacement Parts

When it comes to maintaining the efficiency and longevity of your machinery, sourcing authentic components is crucial. Using original parts ensures compatibility and performance, preventing potential issues that can arise from inferior alternatives. This section will guide you on how to locate these essential items effectively.

Start by identifying the specific parts you need for your equipment. Refer to your original documentation or part numbers to streamline your search. Knowing the exact specifications will save you time and ensure you find the right fit for your machine.

Next, consider reaching out to authorized dealers or manufacturers. These sources typically offer genuine items, and their staff can assist you in confirming compatibility. Additionally, they may provide warranties or guarantees, giving you peace of mind with your purchase.

Another option is to explore trusted online retailers specializing in machinery components. Look for websites that have a good reputation and positive customer reviews. Ensure that they clearly state their commitment to providing authentic parts.

Lastly, participating in online forums or communities related to your equipment can be beneficial. Other users often share their experiences and recommendations for sourcing genuine components, helping you make informed decisions.

Expert Tips for DIY Enthusiasts

For those who love to tackle projects on their own, having the right knowledge and strategies is essential. This section offers valuable insights that can help enhance your skills and ensure successful outcomes in your endeavors.

- Research Thoroughly: Before starting any project, take the time to gather information. Utilize online resources, forums, and videos to familiarize yourself with the specific tasks at hand.

- Gather the Right Tools: Invest in quality tools that are appropriate for the job. Having the correct equipment can make a significant difference in the ease and effectiveness of your work.

- Follow Safety Protocols: Always prioritize safety. Wear appropriate protective gear and ensure your workspace is organized to minimize hazards.

- Take Notes: Document your process. Writing down steps or observations can help you troubleshoot issues and improve your techniques for future projects.

- Seek Community Input: Engage with fellow enthusiasts. Joining a community can provide support, ideas, and solutions to common challenges.

By following these expert tips, you can elevate your DIY skills and approach each project with confidence and competence.