This section aims to provide a thorough understanding of vehicle upkeep and troubleshooting techniques, catering to both novice and experienced enthusiasts. It emphasizes the importance of having access to detailed guidance that facilitates the maintenance process and enhances overall performance.

Within this context, readers will discover a structured approach to vehicle servicing, focusing on various aspects of mechanical systems and components. Each topic is designed to offer clarity and actionable insights, making it easier to identify issues and implement solutions.

Furthermore, the material is enriched with practical tips and best practices that ensure optimal functionality and longevity of automotive parts. This resource is invaluable for those looking to deepen their knowledge and confidence in handling automotive tasks effectively.

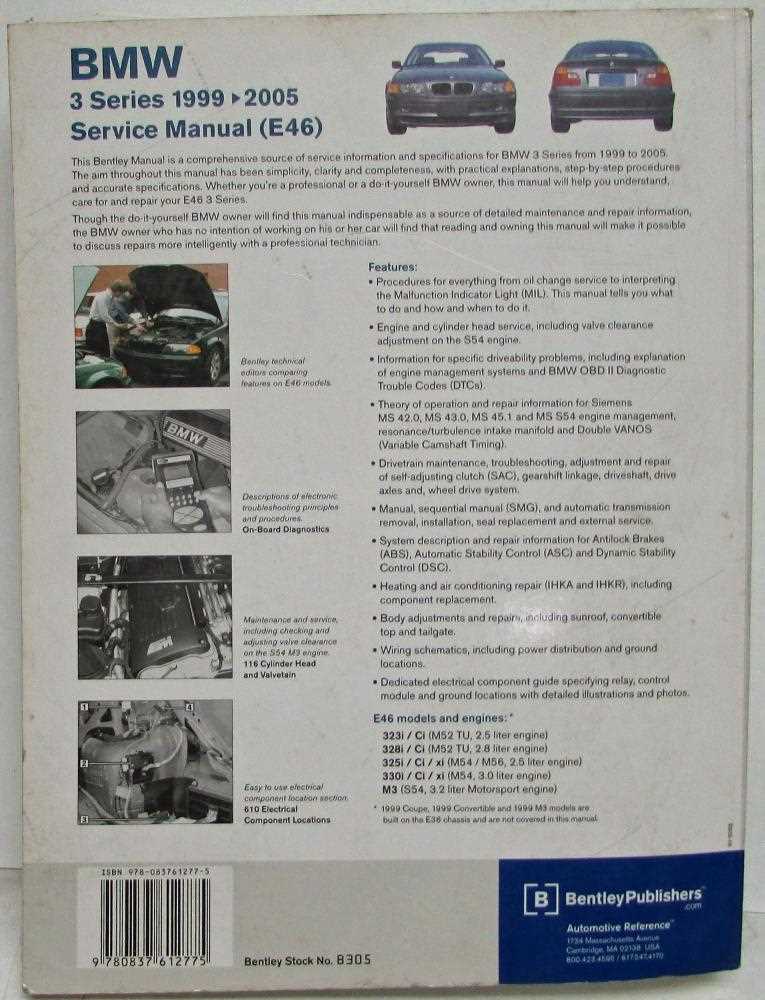

Overview of the Repair Guide for BMW Models

This section provides an in-depth look at a comprehensive resource designed to assist automotive enthusiasts and professionals in maintaining and servicing a specific series of BMW vehicles. The guide is structured to deliver essential information for both novice and experienced users, ensuring clarity and ease of use throughout the maintenance process.

Key Features

- Detailed troubleshooting procedures

- Step-by-step disassembly and assembly instructions

- Extensive wiring diagrams for electrical systems

- Specifications for various components and systems

- Maintenance schedules and service intervals

Benefits of Using This Resource

- Enhances understanding of vehicle systems

- Facilitates accurate diagnostics and repairs

- Promotes efficient maintenance practices

- Supports DIY enthusiasts in performing repairs at home

- Encourages informed decisions regarding part replacements

Key Features of the Manual

This guide offers an extensive range of essential information for vehicle enthusiasts and technicians. It serves as a comprehensive resource, facilitating effective understanding and troubleshooting of automotive systems.

- Detailed Illustrations: Each section is accompanied by clear diagrams that enhance comprehension and simplify complex procedures.

- Step-by-Step Instructions: Users can follow straightforward, sequential steps for maintenance and diagnostics, ensuring accuracy and efficiency.

- Comprehensive Coverage: The content spans various aspects of the vehicle, including electrical systems, engine mechanics, and bodywork.

- Common Troubleshooting Guides: A dedicated section addresses frequent issues, providing solutions and preventive measures.

- Specifications and Data: Detailed technical specifications help users understand the necessary parameters for repairs and upgrades.

This resource is designed to empower users with the knowledge needed to maintain and enhance their automotive experience effectively.

Understanding Common E46 Issues

Owners of this particular vehicle model often encounter a range of recurring challenges that can affect performance and comfort. Identifying these problems early can save time and money, ensuring a smooth driving experience. Below are some prevalent concerns that enthusiasts and drivers should be aware of.

Cooling System Failures: One of the most significant issues reported is related to the cooling system. Components such as the radiator and water pump may wear out over time, leading to overheating. Regular inspection can help prevent severe damage.

Electrical Problems: Many users have experienced electrical malfunctions, including issues with power windows, locks, and dashboard displays. These problems may stem from faulty wiring or failing control modules, requiring careful diagnostics.

Suspension Wear: Over time, the suspension components can deteriorate, resulting in poor handling and an uncomfortable ride. Signs of wear may include unusual noises or a noticeable decrease in ride quality, necessitating timely attention.

Oil Leaks: Another common issue is oil leaks, often originating from gaskets or seals that have aged. Keeping an eye on fluid levels can help identify leaks early and avoid more significant engine problems.

By staying informed about these frequent concerns, owners can take proactive steps to maintain their vehicles, ensuring longevity and reliability.

Maintenance Tips for E46 Owners

Proper upkeep is essential for ensuring the longevity and performance of your vehicle. Regular attention to various components can prevent minor issues from escalating into major problems, ultimately enhancing your driving experience.

Regular Fluid Checks

Monitoring and replacing fluids is crucial. Ensure that engine oil, coolant, transmission fluid, and brake fluid are at the appropriate levels. Changing oil regularly will help maintain engine health and efficiency.

Tire Care

Maintaining optimal tire pressure and tread depth enhances safety and fuel efficiency. Rotate tires every 5,000 to 7,500 miles to promote even wear. Inspecting your tires for signs of damage or irregular wear can prevent unexpected blowouts.

Step-by-Step Repair Procedures

This section provides a comprehensive guide to performing various maintenance and restoration tasks on your vehicle. By following these detailed instructions, you can ensure that each procedure is executed correctly, leading to optimal performance and longevity of your automobile.

Begin by gathering all necessary tools and parts to streamline the process. Having everything prepared beforehand minimizes downtime and allows for a more efficient workflow.

Next, ensure that you have a clear workspace that is well-lit and organized. This enhances safety and facilitates easy access to your tools and components throughout the task.

For each specific task, start by consulting the corresponding steps that outline the procedures in chronological order. Pay attention to any special techniques or precautions that may be highlighted, as these are crucial for successful completion.

Always document your progress. Taking notes or photographs can be invaluable for future reference and helps in tracking any changes made during the process.

Once you have completed the necessary steps, conduct a thorough inspection to confirm that everything is in order. This final check ensures that no details have been overlooked and that your vehicle is ready for operation.

Following these guidelines will not only aid in the maintenance of your automobile but also enhance your understanding of its systems and components.

Tools Required for E46 Repairs

When undertaking maintenance tasks for your vehicle, having the right set of instruments is essential. A well-equipped workspace enhances efficiency and ensures that the job is completed correctly. Below is a compilation of essential tools to consider for effective vehicle servicing.

- Socket Set: A comprehensive socket set is crucial for various bolt sizes.

- Wrenches: Both open-end and closed-end wrenches facilitate access to tight spots.

- Screwdrivers: A variety of flathead and Phillips screwdrivers are necessary for different fasteners.

- Torque Wrench: Ensures bolts are tightened to manufacturer specifications, preventing damage.

- Pliers: Needle-nose and regular pliers are useful for gripping and twisting wires.

- Jack and Jack Stands: Essential for lifting the vehicle safely during inspections or repairs.

- Multimeter: A valuable tool for diagnosing electrical issues and ensuring proper connections.

- Fluid Catch Pan: Necessary for catching any fluids during maintenance tasks.

- Brake Tool: Special tools may be required for brake pad replacements and adjustments.

By ensuring you have these instruments at your disposal, you can tackle a variety of tasks with confidence, making your vehicle maintenance experience smoother and more effective.

Wiring Diagrams and Schematics

This section provides essential insights into the electrical systems of vehicles, showcasing the importance of visual representations in understanding complex wiring. Such diagrams serve as invaluable tools for diagnosing issues and comprehending the interconnections among various components.

Utilizing these schematics can significantly enhance one’s ability to troubleshoot and maintain electrical systems. The following points outline their key benefits:

- Clarification of circuit layouts.

- Identification of component functions.

- Facilitation of effective repairs and modifications.

- Support in understanding power flow and connectivity.

When working with electrical systems, familiarity with wiring diagrams is crucial. Here are some common types of diagrams that one may encounter:

- Block Diagrams: Provide a high-level overview of the electrical system.

- Schematic Diagrams: Detail the relationships and functions of components in a circuit.

- Wiring Diagrams: Illustrate the physical connections and layout of wires.

- Flowcharts: Demonstrate the operational flow and troubleshooting steps.

By mastering these diagrams, individuals can enhance their proficiency in diagnosing and addressing electrical challenges effectively.

Engine Specifications and Insights

This section delves into the intricate details and performance attributes of the powertrain, highlighting essential specifications that contribute to the overall efficiency and capabilities of the vehicle. Understanding these parameters provides valuable insights for enthusiasts and professionals alike, enhancing maintenance practices and performance modifications.

| Specification | Value |

|---|---|

| Engine Type | Inline 6-cylinder |

| Displacement | 3.0 liters |

| Max Power | 225 hp at 5,900 rpm |

| Max Torque | 214 lb-ft at 3,500 rpm |

| Compression Ratio | 10.2:1 |

| Fuel System | Multi-Point Fuel Injection |

| Fuel Type | Premium unleaded |

These specifications reflect the robust engineering designed to deliver a harmonious balance of power and efficiency, essential for both daily driving and spirited performance. Regular monitoring and understanding of these attributes can lead to improved longevity and driving experience.

Transmission Maintenance Guidelines

Maintaining the transmission system is crucial for ensuring optimal performance and longevity of your vehicle. Regular checks and preventive measures can help avert costly repairs and extend the lifespan of this essential component.

Fluid Checks: Regularly inspect the transmission fluid level and quality. Low or dirty fluid can lead to poor shifting and potential damage. It is advisable to check the fluid at specified intervals, as outlined in your vehicle’s guidelines.

Filter Replacement: Over time, the transmission filter can become clogged with debris and contaminants. Replacing the filter at regular intervals is important to maintain proper fluid flow and prevent wear on internal components.

Leak Inspection: Routinely examine the area around the transmission for any signs of fluid leaks. Early detection of leaks can prevent further damage and ensure that the system operates smoothly.

Temperature Monitoring: High operating temperatures can negatively impact transmission performance. Consider installing a temperature gauge to monitor fluid temperatures, particularly during heavy use or towing.

Software Updates: For modern vehicles, ensuring that the transmission control module software is up to date can enhance shifting performance and efficiency. Regularly check for any available updates from the manufacturer.

By adhering to these guidelines, vehicle owners can significantly improve the reliability and efficiency of their transmission system, leading to a more enjoyable driving experience.

Suspension and Steering Adjustments

Proper alignment and calibration of the suspension and steering systems are crucial for optimal vehicle performance and handling. Ensuring that these components function effectively not only enhances driving comfort but also prolongs the lifespan of the vehicle. This section outlines key adjustments necessary for maintaining these systems, contributing to a smoother ride and improved road feedback.

Adjustments may include alterations to various angles, such as camber, caster, and toe settings, which directly influence tire wear and vehicle stability. It is essential to adhere to manufacturer specifications to achieve the best results.

| Adjustment Type | Description | Recommended Range |

|---|---|---|

| Camber | Angle of the wheels in relation to the vertical axis | -1.0° to -0.5° |

| Toe | Angle of the wheels in relation to the centerline of the vehicle | 0.0° to +0.1° |

| Caster | Angle of the steering axis in relation to the vertical axis | 3.0° to 5.0° |

Regular checks and adjustments to these parameters are recommended, especially after modifications or repairs to the suspension or steering systems. Maintaining proper settings can significantly improve handling characteristics and driving safety.

Brake System Troubleshooting Techniques

Effective diagnosis of brake issues is essential for ensuring vehicle safety and performance. By systematically evaluating various components, you can identify potential problems before they escalate. This section outlines key strategies for troubleshooting braking concerns.

Common Symptoms and Their Causes

- Squeaking or Grinding Noise: Often indicates worn brake pads or damaged rotors.

- Pulsating Brake Pedal: May suggest warped rotors or uneven brake pad wear.

- Soft or Spongy Brake Pedal: Could be a sign of air in the brake lines or a fluid leak.

- Vehicle Pulling to One Side: Often caused by uneven brake pad wear or malfunctioning calipers.

Diagnostic Steps

- Start by inspecting the brake pads and rotors for wear and damage.

- Check the brake fluid level and look for any leaks around the system.

- Test the brake lines for any signs of corrosion or air pockets.

- Examine the calipers for proper function and alignment.

- Perform a test drive to assess braking performance under different conditions.

By following these techniques, you can effectively diagnose and address brake system issues, ensuring optimal vehicle safety and reliability.

Electrical Systems Diagnostics

This section focuses on the evaluation and troubleshooting of electrical systems within vehicles. It aims to provide a structured approach to identifying issues, understanding system functions, and applying effective solutions to ensure optimal performance.

Electrical diagnostics play a crucial role in maintaining the overall efficiency of a vehicle. By systematically analyzing various components, technicians can pinpoint failures and prevent further complications. Here are some essential steps involved in the diagnostic process:

| Step | Description |

|---|---|

| Visual Inspection | Check for visible damage, loose connections, or corroded terminals. |

| Testing Voltage | Use a multimeter to measure voltage levels at different points in the system. |

| Continuity Testing | Ensure circuits are complete by testing for continuity with appropriate tools. |

| Component Evaluation | Assess individual parts such as sensors, relays, and switches for functionality. |

| System Scanning | Utilize diagnostic scanners to retrieve fault codes and system data for analysis. |

By adhering to these practices, technicians can effectively diagnose electrical issues, ensuring that all systems operate seamlessly and enhancing the reliability of the vehicle.

Bodywork Repair and Restoration Tips

Restoring the exterior of a vehicle requires a combination of skill, attention to detail, and the right techniques. This section provides essential insights into maintaining and rejuvenating the car’s body, ensuring it remains in top condition while enhancing its aesthetic appeal.

Here are some valuable suggestions to consider:

- Assessment: Before beginning any work, conduct a thorough evaluation of the vehicle’s exterior. Look for dents, scratches, and rust spots that need addressing.

- Surface Preparation: Clean the affected areas to remove dirt and debris. Use sandpaper or a grinder to smooth out imperfections and ensure a proper bond with new materials.

- Rust Treatment: Apply a rust-inhibiting primer to areas affected by corrosion. This will help prevent further deterioration and provide a solid foundation for paint or other finishes.

- Filler Application: For deeper dents or holes, use an appropriate filler. Once applied, allow it to cure completely before sanding it down to achieve a smooth surface.

- Painting Techniques: When repainting, ensure that the environment is dust-free. Use a high-quality primer and topcoat to achieve a professional finish. Consider using spray paint for an even application.

- Clear Coat Protection: After the paint has dried, apply a clear coat for additional protection against UV rays and environmental damage.

- Final Inspection: Once all processes are complete, inspect the work meticulously to ensure that every detail meets your standards. Look for imperfections that may need further attention.

By following these guidelines, you can achieve impressive results that enhance both the appearance and longevity of the vehicle’s exterior. Remember, patience and precision are key components of any successful restoration project.