The significance of proper upkeep for farming equipment cannot be overstated. Regular maintenance ensures longevity and optimal performance, allowing operators to maximize productivity and efficiency on their land. Having access to comprehensive documentation is essential for both novice and experienced users alike.

These resources provide invaluable insights into troubleshooting and servicing various models. With step-by-step instructions and detailed illustrations, they empower users to tackle issues independently, reducing downtime and associated costs. Understanding the intricacies of machinery fosters a deeper connection between the operator and the equipment, enhancing overall proficiency.

Furthermore, such documents serve as a vital reference for training new personnel. By familiarizing them with best practices and essential techniques, businesses can cultivate a skilled workforce capable of maintaining high standards in agricultural operations. Ultimately, these guides contribute to the sustainability and success of farming endeavors.

Understanding Belarus Tractors

This section aims to provide insights into a specific line of powerful agricultural machines, renowned for their efficiency and reliability in various farming tasks. These vehicles have become indispensable in modern agriculture, showcasing a blend of innovation and robust engineering.

Key Features of These Agricultural Machines

The vehicles in question are characterized by their strong performance and versatility. Equipped with advanced technology, they can tackle a wide range of tasks, from plowing to hauling heavy loads. Their durable construction ensures longevity, making them a worthwhile investment for any farming operation.

Operational Efficiency

Efficiency is a hallmark of these robust machines. They are designed to maximize productivity while minimizing fuel consumption, which is crucial for maintaining operational costs. Understanding the mechanics and functionalities of these machines can significantly enhance their utilization, leading to improved outcomes in agricultural practices.

Common Issues with Belarus Tractors

Many operators encounter frequent challenges when working with agricultural machinery. Understanding these typical problems can enhance the efficiency and longevity of the equipment.

Engine Performance: One of the most common difficulties is related to engine functionality. Issues such as rough idling, stalling, or reduced power output can hinder overall productivity. Regular maintenance is crucial to ensure optimal performance.

Hydraulic System Failures: Operators often face complications with hydraulic systems, which may manifest as leaks or unresponsive controls. These issues can significantly affect the machine’s operational capabilities, making timely interventions essential.

Electrical Malfunctions: Electrical problems can arise, leading to difficulties in starting the engine or malfunctioning gauges. Ensuring proper wiring and connections is vital for preventing these disruptions.

Transmission Issues: Gear shifting problems are another frequent concern. Operators may experience slipping or grinding when changing gears, indicating the need for adjustments or repairs to the transmission system.

By being aware of these common challenges, users can take proactive measures to maintain their equipment, minimizing downtime and enhancing productivity.

Maintenance Tips for Longevity

Ensuring the enduring performance of your machinery requires a systematic approach to upkeep. Regular attention not only enhances efficiency but also extends the operational life of your equipment.

Regular Inspections

- Conduct frequent checks for wear and tear.

- Monitor fluid levels and replenish as necessary.

- Examine belts and hoses for cracks or signs of aging.

Proper Storage

- Store in a dry, sheltered environment to prevent rust.

- Use protective covers to shield from dust and debris.

- Ensure that the area is well-ventilated to reduce humidity.

Adopting these practices will help maintain peak performance and reliability for years to come.

Essential Tools for Repairs

Having the right equipment is crucial for any maintenance task. Whether working on machinery or performing adjustments, specific implements can significantly enhance efficiency and accuracy. Understanding which tools are indispensable can streamline the process and yield better outcomes.

Basic Hand Tools

Fundamental implements such as wrenches, screwdrivers, and pliers form the backbone of any toolkit. These versatile items are essential for various tasks, enabling users to tighten, loosen, and manipulate components effectively.

Specialized Instruments

In addition to basic hand tools, specialized devices like torque wrenches and alignment gauges play a vital role in ensuring precision. These instruments help maintain optimal performance and prolong the lifespan of the machinery involved.

Where to Find Repair Manuals

Locating guides for maintenance and troubleshooting can be essential for efficient upkeep. Various resources are available for individuals seeking detailed documentation to assist with the servicing of their equipment.

Online Resources

The internet is a valuable asset for finding technical documentation. Numerous websites offer downloadable files and digital versions, often free of charge. Forums and community groups can also provide shared experiences and links to relevant resources, making it easier to access the needed information.

Local Libraries and Bookstores

Another avenue worth exploring is local libraries and bookstores. Many institutions maintain archives of technical literature, including specific guides for various machinery. Additionally, specialized bookstores might carry printed editions that can serve as reliable references for users.

Step-by-Step Repair Procedures

This section provides a structured approach to addressing common issues encountered during maintenance tasks. Following a systematic method not only enhances efficiency but also ensures that every aspect is thoroughly examined.

Preparation Phase

- Gather all necessary tools and equipment.

- Ensure a clean and organized workspace.

- Review the relevant specifications and guidelines.

Execution of Tasks

- Identify the specific problem and its symptoms.

- Disconnect power sources and remove any protective covers.

- Inspect components for wear or damage.

- Replace or repair faulty parts as needed.

- Reassemble all components securely and restore power connections.

- Test the system to verify that the issue has been resolved.

By adhering to these procedures, individuals can effectively troubleshoot and rectify issues, ensuring optimal functionality and longevity of the equipment.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance tasks is crucial for preventing accidents and injuries. Awareness of potential hazards and adherence to best practices can significantly enhance the well-being of individuals involved in the process.

Personal Protective Equipment

Using appropriate personal protective gear is essential. Here are some key items to consider:

- Safety glasses to shield eyes from debris

- Gloves to protect hands from sharp objects and chemicals

- Steel-toed boots to prevent foot injuries

- Hearing protection when working with loud machinery

Work Environment

Maintaining a safe workspace is vital. Follow these guidelines:

- Ensure proper lighting to avoid accidents.

- Keep the area organized and free of clutter.

- Use appropriate tools and equipment for each task.

- Verify that emergency exits are accessible at all times.

Diagnosing Engine Problems

Identifying issues with the power unit is crucial for maintaining optimal performance. Various symptoms can indicate underlying malfunctions that require immediate attention. Understanding these signs is the first step towards effective troubleshooting and ensuring longevity.

Common Symptoms of Engine Malfunctions

Unusual noises, decreased power, and excessive smoke are frequent indicators of internal complications. Pay attention to vibrations and fluctuations in performance, as these may signify deeper problems within the system.

Initial Diagnostic Steps

Begin by conducting a visual inspection of the components. Check for leaks, worn-out parts, and loose connections. Utilizing diagnostic tools can aid in pinpointing issues more precisely. Gathering data from sensors and gauges helps in creating a comprehensive understanding of the situation.

Thorough analysis combined with careful observation can lead to effective resolutions, ensuring that the unit operates smoothly and efficiently.

Transmission Troubleshooting Guide

This section aims to assist users in diagnosing and resolving issues related to gear shifting and power transfer systems. By following the guidelines outlined here, operators can enhance the performance and reliability of their machinery.

Common Symptoms

- Difficulty in shifting gears

- Unusual noises during operation

- Slipping or erratic performance

- Fluid leaks around the transmission area

Diagnostic Steps

- Check fluid levels and quality.

- Inspect for visible leaks or damage to hoses.

- Examine the linkage and cables for wear or misalignment.

- Test the operation of the gear shifter.

By systematically addressing these areas, users can often identify and rectify transmission-related issues, ensuring optimal functionality.

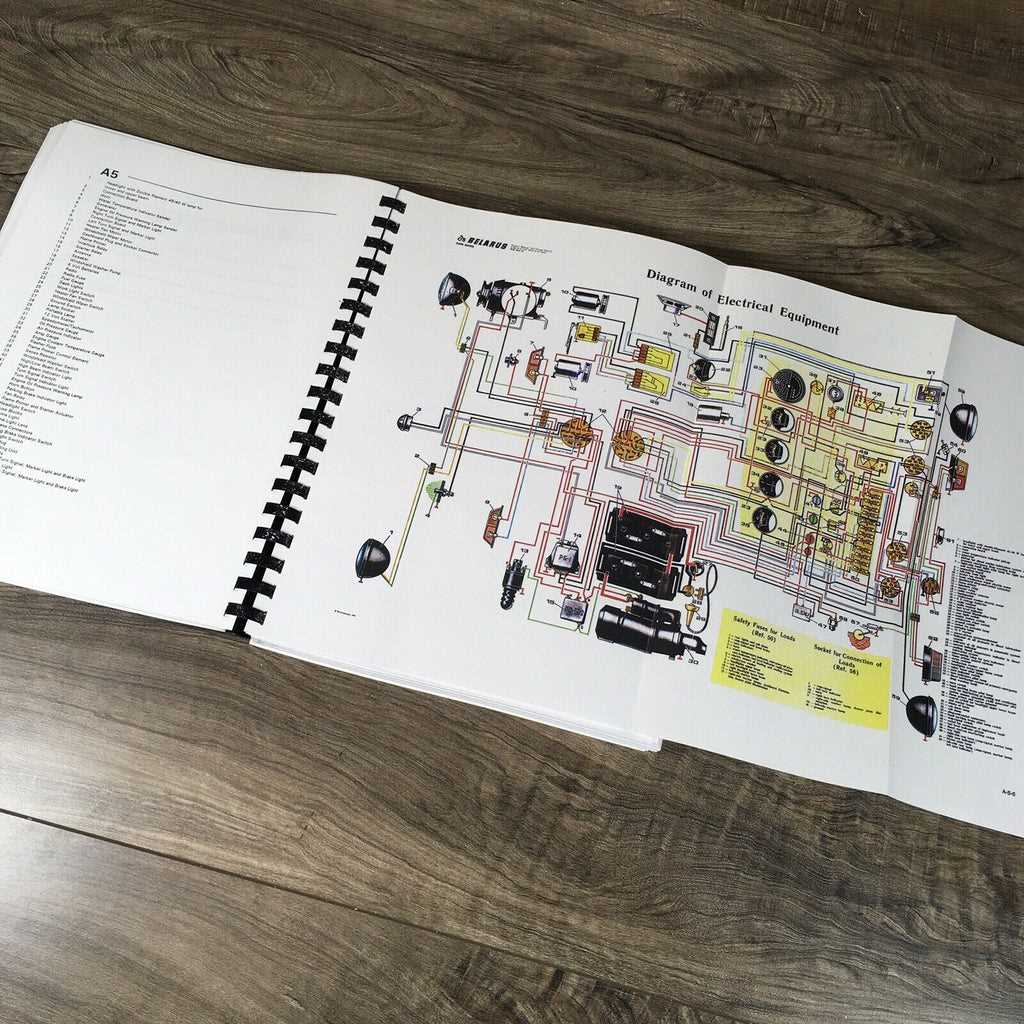

Electrical System Maintenance

Regular upkeep of the electrical components is crucial for ensuring optimal performance and longevity of any machinery. Proper care not only prevents unexpected failures but also enhances the overall efficiency of the system. This section highlights essential practices and checks to maintain a reliable electrical infrastructure.

To achieve effective maintenance, it’s important to follow a systematic approach. Below are key areas to focus on during the maintenance process:

| Component | Maintenance Task | Frequency |

|---|---|---|

| Batteries | Check fluid levels and clean terminals | Monthly |

| Wiring | Inspect for wear and secure connections | Quarterly |

| Fuses | Test functionality and replace if necessary | Annually |

| Switches | Clean and lubricate to ensure smooth operation | Biannually |

Adhering to these maintenance guidelines will help in sustaining the efficiency and reliability of the electrical system, minimizing downtime and potential costly repairs.

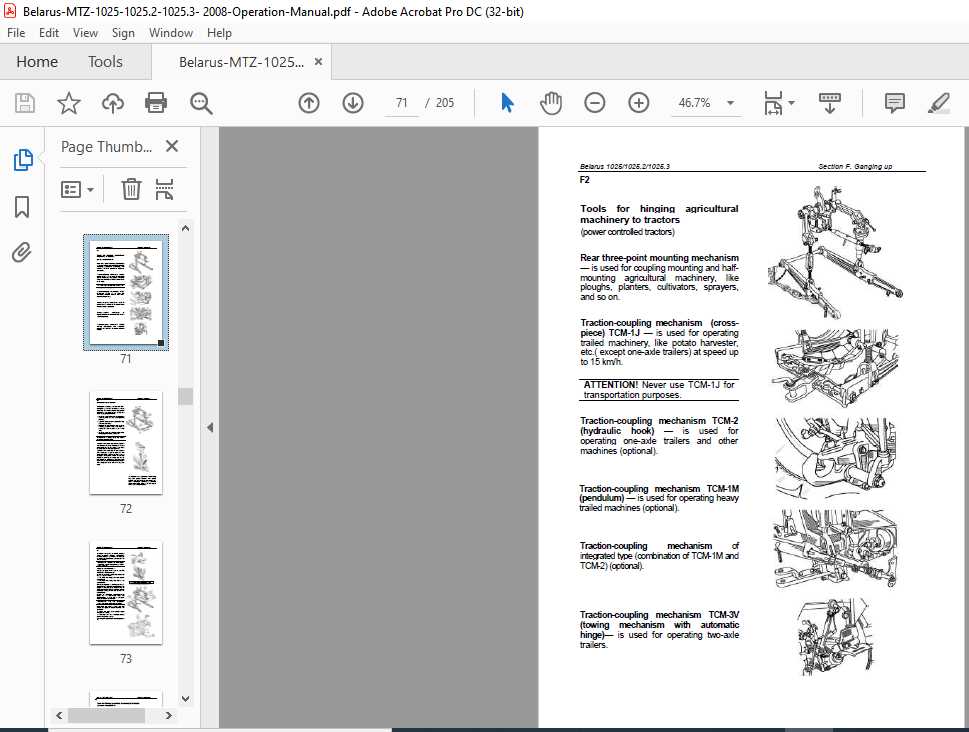

Hydraulic System Diagnostics

The assessment of hydraulic mechanisms is crucial for ensuring optimal performance and longevity of heavy machinery. Understanding the underlying principles and indicators of malfunction can help in promptly addressing issues and maintaining efficiency. This section delves into various diagnostic approaches to identify potential failures within hydraulic circuits.

Common Symptoms of Hydraulic Failures

Operators may encounter several signs that indicate a malfunction in the hydraulic system. These can include erratic movements, unusual noises, or a significant drop in pressure. Recognizing these symptoms early can prevent more severe damage and costly repairs.

Diagnostic Techniques

Effective diagnosis involves a combination of visual inspections, pressure testing, and fluid analysis. Checking for leaks, monitoring pressure gauges, and examining the fluid condition are essential steps. Utilizing specialized diagnostic tools can further enhance the accuracy of assessments, allowing for timely and informed maintenance decisions.

Parts Replacement Techniques

Effective replacement methods are crucial for maintaining optimal performance and longevity of machinery. Understanding various approaches to component substitution ensures that equipment remains in top working condition while minimizing downtime.

When considering the best practices for switching out parts, it’s essential to assess compatibility, precision, and the necessary tools. Here are some common techniques employed in the field:

| Technique | Description |

|---|---|

| Direct Replacement | Simply removing the faulty component and installing a new one, ensuring all specifications match. |

| Upgrading | Replacing an existing part with a newer model that offers improved performance or efficiency. |

| Modular Replacement | Substituting entire modules rather than individual components for easier maintenance and improved reliability. |

| Reconditioning | Restoring worn-out parts to a usable state, often more cost-effective than full replacement. |

| Custom Fabrication | Creating a unique component tailored to specific requirements when standard parts are unavailable. |

Implementing these techniques with care and expertise will enhance the functionality of equipment and extend its operational life.

Upgrading Your Belarus Tractor

Enhancing the capabilities of your agricultural machinery can significantly improve performance and efficiency. By focusing on key areas for enhancement, you can achieve better productivity and longevity of your equipment.

Here are some essential upgrades to consider:

- Engine Enhancements: Increasing horsepower through performance chips or turbochargers can provide a noticeable boost in power.

- Hydraulic System Improvements: Upgrading to more efficient hydraulic components can enhance lifting capacity and responsiveness.

- Transmission Modifications: Installing an advanced transmission can improve gear shifting and overall driving experience.

- Cab Comfort: Adding ergonomic seats and improved climate control systems can make long hours of operation much more enjoyable.

- Tire Upgrades: Switching to high-traction tires can enhance stability and reduce soil compaction during fieldwork.

When planning your enhancements, consider consulting with professionals to ensure compatibility and optimal performance. Regular maintenance checks post-upgrade are crucial to sustain improvements and avoid potential issues.