The world of precision shooting offers enthusiasts a rewarding blend of skill and technology. Ensuring that your equipment operates at peak performance is crucial for achieving consistent results. Understanding the intricacies of maintaining these specialized tools not only enhances their lifespan but also elevates your overall shooting experience.

In this section, we will delve into the essential techniques and best practices for keeping your shooting apparatus in top condition. From basic troubleshooting to advanced adjustments, the following guidelines will equip you with the knowledge needed to handle common challenges effectively. With the right approach, you can ensure that your device remains reliable and performs optimally when it matters most.

Whether you are a novice or a seasoned marksman, having a solid foundation in maintenance principles will empower you to address issues confidently. This resource aims to demystify the processes involved, providing you with the tools necessary for successful upkeep and enhancement of your shooting experience. Let’s explore the various components and their care in detail.

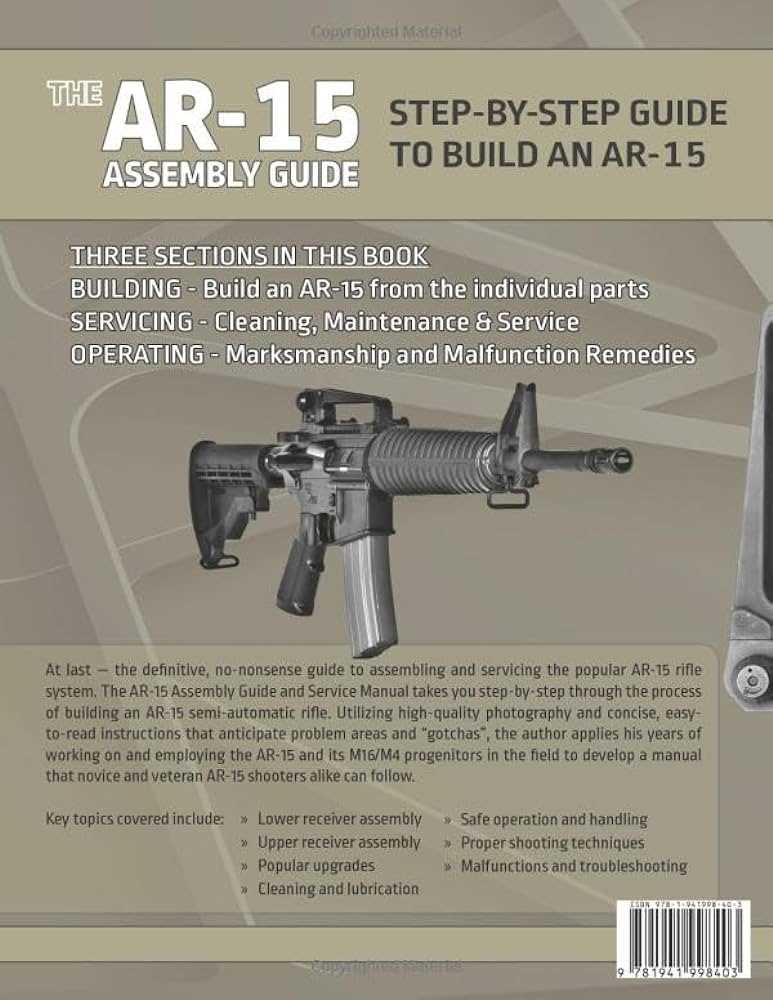

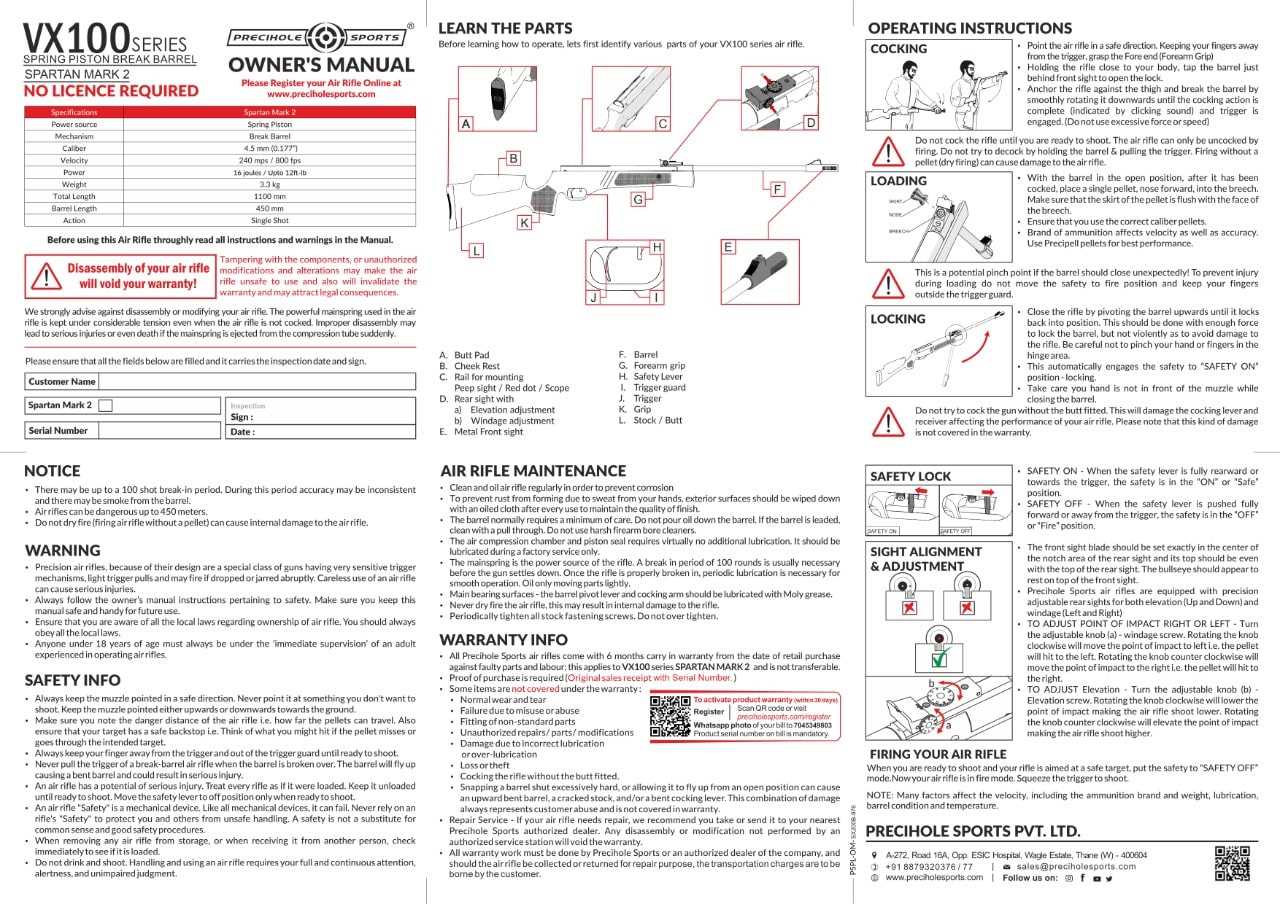

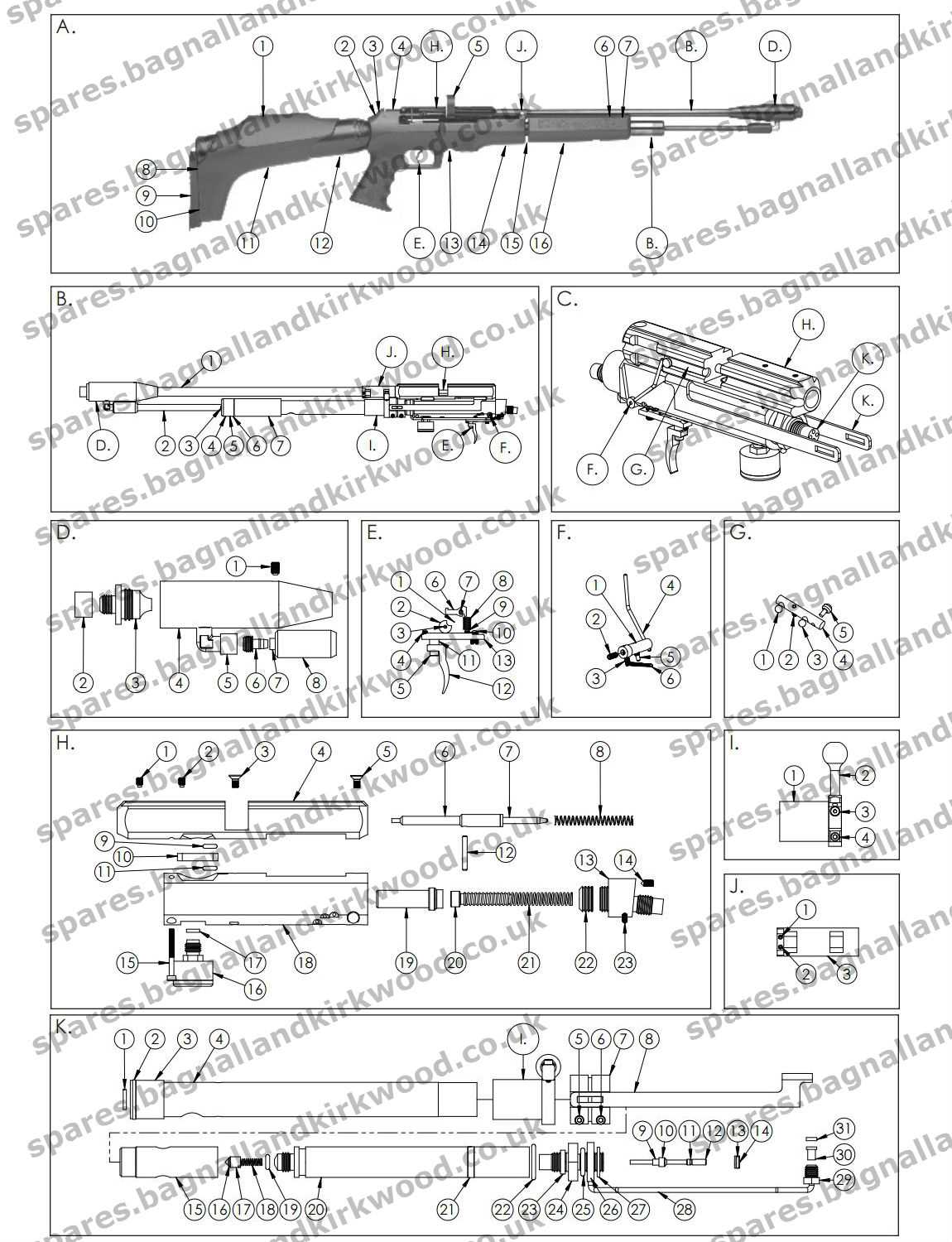

Understanding Air Rifle Mechanics

Gaining insight into the inner workings of pneumatic shooting devices is essential for enthusiasts and practitioners alike. This knowledge encompasses the fundamental principles that govern how these tools operate, enhancing both performance and safety. By delving into the intricacies of pressure systems, projectile propulsion, and accuracy mechanisms, users can develop a deeper appreciation for their functionality.

At the core of these devices is the interplay between air pressure and mechanical components. Various types of mechanisms, whether spring-powered, pre-compressed, or gas-operated, contribute to how effectively a projectile is launched. Understanding these differences can inform choices about maintenance, usage, and overall performance optimization.

| Mechanism Type | Description | Advantages |

|---|---|---|

| Spring-Piston | Utilizes a spring to compress air for propulsion. | Reliable and simple design; minimal maintenance required. |

| Pre-Charged Pneumatic | Pre-fills a chamber with air for multiple shots. | Consistent power and reduced recoil. |

| Gas Ram | Replaces the traditional spring with a gas-filled cylinder. | Improved consistency and durability over time. |

Understanding these various types not only aids in the selection of the right tool but also empowers users to troubleshoot and maintain their equipment effectively. Knowledge of the specific mechanics at play ensures a safer and more enjoyable experience in the field.

Common Issues in Air Rifles

Every enthusiast knows that issues can arise with any shooting device over time. Recognizing these problems early can help maintain performance and ensure a smooth shooting experience. Below are some prevalent challenges encountered by users.

1. Accuracy Problems

Inconsistent shot placement can stem from various sources. Understanding these can help pinpoint the root cause:

- Improper Sight Alignment: Misaligned optics or sights can lead to missed targets.

- Pellet Quality: Using low-quality or damaged projectiles can severely affect precision.

- Environmental Factors: Wind and humidity can impact trajectory significantly.

2. Mechanical Failures

Mechanical issues can disrupt functionality and safety. Common failures include:

- Seal Damage: Worn or damaged seals can lead to loss of pressure and reduced power.

- Spring Fatigue: Over time, the compression mechanism may weaken, affecting velocity.

- Loading Mechanism Issues: Jams or misfeeds can occur, hindering smooth operation.

Awareness of these common difficulties can enhance longevity and reliability, ensuring optimal performance for all users.

Essential Tools for Repairs

Having the right instruments is crucial when it comes to fixing or maintaining your equipment. A well-equipped workspace can significantly streamline the process and improve the quality of your work. Below is a list of must-have items to ensure that you are prepared for any task.

- Screwdrivers: A variety of sizes and types, including flathead and Phillips, are essential for loosening or tightening screws.

- Wrenches: Adjustable and fixed wrenches help in handling nuts and bolts of different sizes.

- Pliers: Needle-nose and standard pliers are invaluable for gripping and twisting components.

- Cleaning Kit: Brushes and cloths for maintaining cleanliness and functionality of the components.

- Lubricants: Oils and greases designed for mechanical parts can enhance performance and prevent wear.

- Calipers: Useful for measuring precise dimensions to ensure proper fitting of parts.

- Safety Gear: Gloves and goggles to protect yourself during maintenance tasks.

Equipping yourself with these tools will not only facilitate the process but also ensure that you can effectively tackle any challenges that arise during your projects.

Step-by-Step Maintenance Guide

Proper upkeep is essential for ensuring optimal performance and longevity of your equipment. This guide provides a systematic approach to maintaining your device, allowing enthusiasts and users to enhance reliability and accuracy. Follow these steps carefully to keep your setup in prime condition.

-

Gather Necessary Tools:

- Cleaning rod

- Soft cloths

- Lubrication oil

- Protective gloves

- Wrenches and screwdrivers

-

Initial Inspection:

- Check for any visible damage or wear.

- Examine seals and joints for any signs of leakage.

- Ensure all components are securely fastened.

-

Cleaning Process:

- Use a cleaning rod to remove debris from the barrel.

- Wipe exterior surfaces with a soft cloth.

- Pay special attention to hard-to-reach areas.

-

Lubrication:

- Apply lubrication oil to moving parts as recommended.

- Avoid over-lubrication to prevent buildup.

-

Final Checks:

- Reinspect all components for functionality.

- Test the setup to ensure everything operates smoothly.

By adhering to this guide, you can ensure your equipment remains in excellent working condition, ready for your next adventure or activity.

How to Diagnose Air Rifle Problems

Identifying issues with your shooting device requires a systematic approach. Understanding common symptoms and performing a series of checks can help pinpoint the underlying causes of any malfunction. This guide will provide insights into effective diagnostic techniques, enabling you to restore optimal performance.

Visual Inspection

The first step in troubleshooting involves a thorough visual examination. Look for any obvious signs of damage or wear, such as cracks in the housing or loose components. Pay attention to the seals, as deterioration can lead to leaks, affecting functionality. A meticulous check can reveal problems that may not be immediately apparent.

Performance Testing

After conducting a visual assessment, proceed to performance testing. Observe how the device functions during use. Note any irregularities, such as inconsistent pressure, unusual noises, or misfiring. Keeping a record of these observations will assist in isolating the issue. If the device fails to achieve expected accuracy or velocity, it may indicate a deeper problem that warrants further investigation.

In conclusion, a methodical approach to diagnosing issues is essential. By combining visual inspection with performance testing, you can effectively determine the necessary steps to restore functionality.

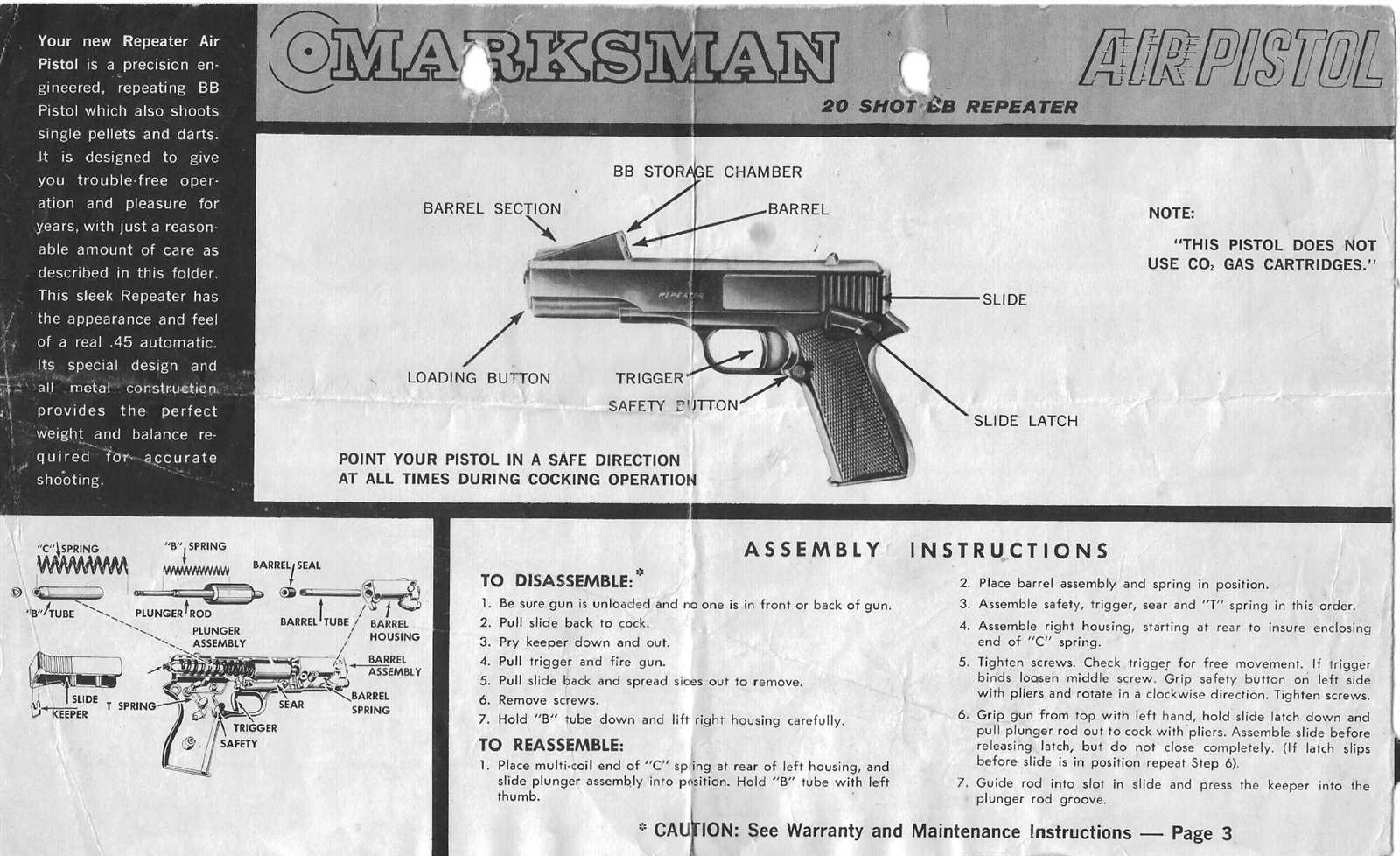

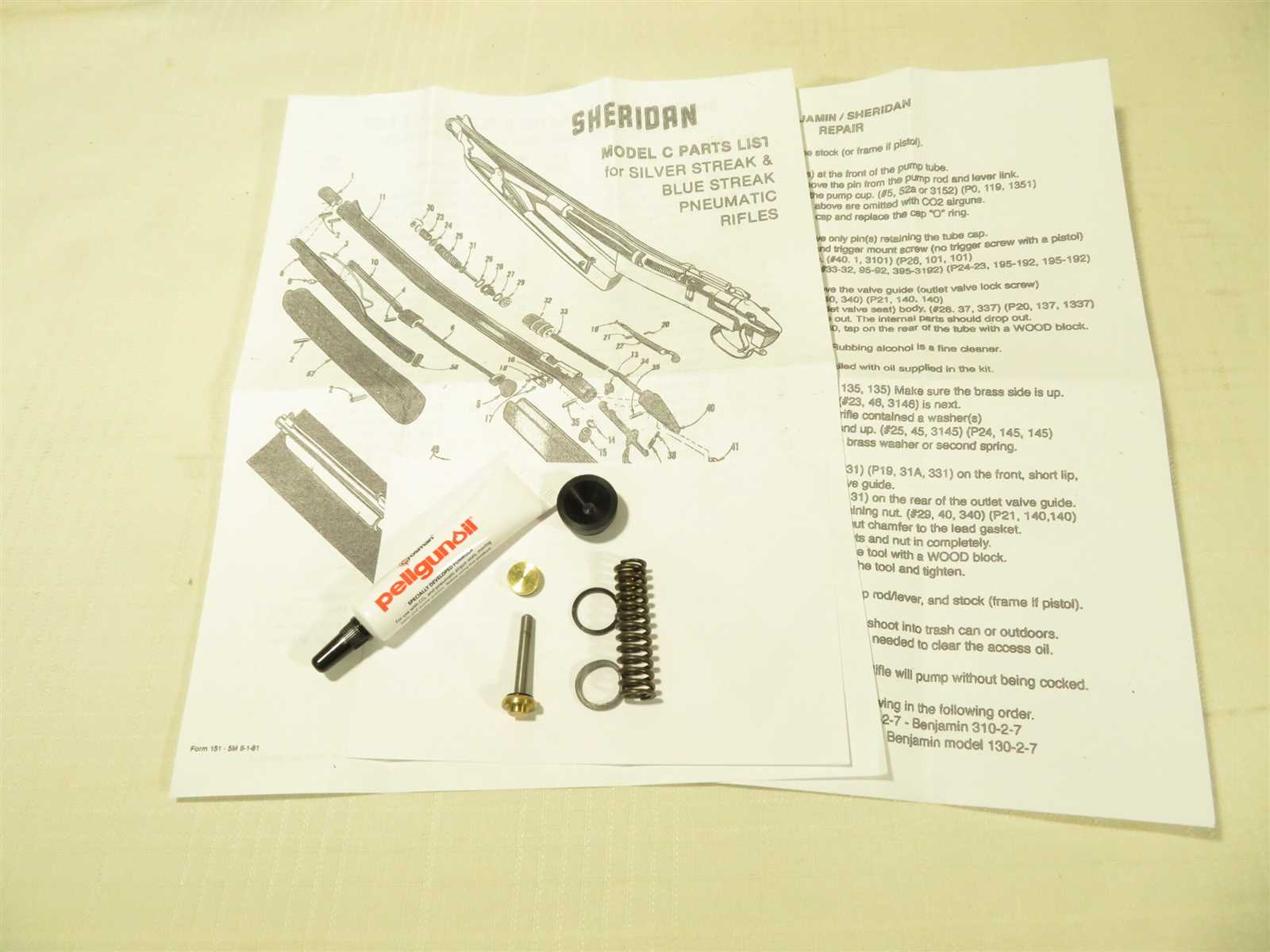

Replacing Seals and O-Rings

Maintaining optimal performance in pneumatic devices often requires the replacement of seals and O-rings. Over time, these components can wear down, leading to air leaks and decreased efficiency. Understanding the process is essential for ensuring longevity and reliability.

Here are the key steps involved in the replacement process:

- Gather necessary tools and materials, including replacement seals, O-rings, and a suitable lubricant.

- Carefully disassemble the unit, noting the arrangement of parts for reassembly.

- Remove the old seals and O-rings, taking care not to damage surrounding components.

- Clean the surfaces where new components will be installed, ensuring no debris remains.

- Apply a light coat of lubricant to the new seals and O-rings to facilitate installation.

- Install the new components, ensuring a snug fit to prevent future leaks.

- Reassemble the unit, following the notes taken during disassembly.

- Test the device to confirm proper functioning.

By following these steps, you can significantly enhance the performance and lifespan of your equipment.

Adjusting the Trigger Mechanism

Proper calibration of the release system is crucial for achieving optimal performance and enhancing user experience. A finely tuned mechanism allows for greater accuracy and control, ensuring that the shooter can respond effectively during use. This section will provide guidance on how to achieve the desired settings for your equipment.

Tools Required

Before beginning the adjustment process, ensure you have the following tools on hand:

| Tool | Purpose |

|---|---|

| Small screwdriver | To access and modify adjustment screws |

| Torque wrench | To ensure correct tightness of components |

| Cleaning cloth | To keep components free of debris |

| Caliper | For precise measurement of adjustments |

Adjustment Steps

Follow these steps carefully to adjust the release mechanism:

- Ensure that the device is unloaded and safe to handle.

- Identify the adjustment screws, typically located near the trigger assembly.

- Using a small screwdriver, turn the screws gradually to modify the pull weight and travel distance.

- Check the mechanism after each adjustment to ensure it operates smoothly and meets your preferences.

- Once satisfied, use a torque wrench to secure all screws to the recommended specifications.

Barrel Cleaning Techniques

Maintaining the inner tube of your shooting device is crucial for optimal performance and longevity. Regular cleaning helps to eliminate residue, ensuring accuracy and reliability during use. This section outlines effective methods for achieving a pristine bore, enhancing both safety and efficiency.

1. Essential Tools

Before starting the cleaning process, gather the necessary tools: a cleaning rod, brushes, patches, and a suitable solvent. Selecting high-quality materials will improve results and prevent potential damage to the internal surfaces.

2. Dry Swabbing

Begin with a dry patch attached to the cleaning rod. Insert it gently into the bore and twist it as you withdraw. This initial step removes loose debris without the risk of using solvents prematurely, allowing for a clearer assessment of buildup.

3. Solvent Application

After dry swabbing, apply a few drops of the chosen solvent to a clean patch. Carefully run this patch through the bore several times. This process dissolves stubborn residues, such as lead and carbon deposits, that can affect performance.

4. Brushing

Next, use a bore brush that fits snugly within the tube. Attach it to the cleaning rod and scrub the interior in a back-and-forth motion. This action helps to dislodge any remaining particles, enhancing the cleaning effect.

5. Final Drying

After scrubbing, follow up with another dry patch to remove any remaining solvent. Ensure the bore is completely dry before reassembling or storing the device. This final step is crucial for preventing rust and ensuring a reliable performance during your next session.

By following these techniques, enthusiasts can maintain the cleanliness of their shooting apparatus, resulting in improved accuracy and safety. Regular attention to barrel hygiene will contribute significantly to the overall experience and effectiveness of the equipment.

Upgrading Internal Components

Enhancing the inner mechanisms of your device can significantly improve its overall performance and longevity. By focusing on specific parts, you can achieve increased efficiency, accuracy, and reliability. Below are some key considerations for optimizing these crucial elements.

- Identify Key Components

- Research Available Upgrades

- Evaluate Compatibility

Before beginning any modifications, it is essential to understand which components can be upgraded. The most common areas include:

- Seals and O-rings

- Compression chamber

- Trigger mechanism

- Barrel and transfer port

Once you’ve pinpointed the components, investigate the options available in the market. Look for parts that enhance performance metrics such as:

- Increased velocity

- Improved consistency

- Enhanced durability

Ensure that any new components are compatible with your existing setup. This may involve checking specifications and consulting with manufacturers or experienced users. Proper integration is crucial for achieving optimal results.

In conclusion, upgrading internal mechanisms can greatly enhance the functionality of your device. By carefully selecting and installing compatible parts, you can enjoy a marked improvement in performance and reliability.

Safety Precautions During Repairs

Engaging in maintenance tasks requires a strong emphasis on safety to prevent accidents and ensure effective outcomes. Adhering to proper guidelines is essential not only for the individual performing the work but also for those in the surrounding environment. Understanding potential risks and implementing preventive measures is key to a successful and safe experience.

Personal Protective Equipment

Utilizing appropriate personal protective equipment (PPE) is crucial. Always wear safety goggles to shield your eyes from debris, and use gloves to protect your hands from sharp edges and harmful substances. Hearing protection may also be advisable in noisy settings, ensuring your hearing is preserved while working.

Workspace Organization

Maintaining a tidy and organized workspace significantly reduces the likelihood of accidents. Ensure that all tools are within reach, and hazardous materials are stored correctly. Keep the area free of clutter to minimize tripping hazards. Implementing good housekeeping practices creates a safer environment conducive to focused and effective work.

Recommended Lubricants and Oils

Proper maintenance of precision shooting devices requires the use of high-quality substances that reduce friction and ensure smooth operation. Selecting the right lubricants can significantly enhance performance and extend the lifespan of components, providing a seamless shooting experience.

1. Silicone Oil: This lubricant is ideal for synthetic materials and provides excellent moisture resistance. It helps prevent rust and corrosion while ensuring that moving parts function smoothly.

2. Gun Grease: A thicker alternative, this substance is perfect for high-friction areas. It stays in place longer than oils, making it suitable for parts that endure heavy use.

3. CLP (Clean, Lubricate, Protect): This versatile solution cleans surfaces while offering lubrication and protection against moisture. It’s particularly useful for routine maintenance and overall care.

4. Graphite Powder: For those who prefer a dry lubricant, graphite is a great choice. It doesn’t attract dirt and debris, making it suitable for dusty environments.

5. Lightweight Oil: Ideal for intricate mechanisms, this oil flows easily into tight spaces and provides a thin film of protection without adding bulk.

When choosing lubricants, consider the specific requirements of your equipment. Regular application and proper selection will ensure optimal functionality and longevity of your gear.

Testing Performance After Repairs

After conducting maintenance on a shooting device, it’s essential to assess its functionality to ensure optimal performance. This evaluation helps to confirm that all adjustments and replacements have been effectively implemented, and that the equipment operates as intended. A thorough examination can identify any lingering issues that may need further attention.

Begin by checking the accuracy of the projectile’s trajectory. This involves shooting at a designated target and noting the placement of each shot. Consistency in grouping is crucial; ideally, shots should cluster closely together. If there are significant deviations, further investigation may be required.

Next, evaluate the velocity of the projectiles. Using a chronograph can provide precise measurements of speed, allowing for comparisons with manufacturer specifications. Any discrepancies may indicate underlying problems that need addressing.

Additionally, pay attention to the overall operation of the device. Listen for any unusual sounds during firing, and observe the smoothness of the loading and firing mechanisms. These factors contribute to a reliable shooting experience.

Finally, document your findings for future reference. Keeping a record of performance tests can help track improvements and pinpoint areas that may require additional work. This practice ensures a well-maintained device, enhancing both safety and enjoyment in use.

Finding Professional Repair Services

When it comes to maintaining precision equipment, enlisting the help of skilled technicians is crucial. Locating qualified services ensures that your device receives the expertise it deserves, prolonging its lifespan and enhancing performance.

Here are some tips to help you find reliable professionals:

- Research Online: Utilize search engines and review sites to find local specialists. Pay attention to ratings and customer feedback.

- Ask for Recommendations: Reach out to fellow enthusiasts or local clubs. Personal experiences can lead you to trustworthy service providers.

- Check Qualifications: Verify the credentials of technicians. Look for certifications and relevant experience in the field.

- Inquire About Services: Before committing, ask about the range of services offered and whether they cater to your specific needs.

Finding the right experts can make a significant difference in the upkeep and functionality of your equipment. Take your time and choose wisely to ensure optimal results.