When it comes to maintaining an automobile, having access to detailed information is essential for any enthusiast or owner. This section provides valuable insights into the intricacies of a specific model, ensuring that both novices and experienced individuals can navigate the complexities of vehicle upkeep effectively. With the right knowledge, challenges can be transformed into manageable tasks.

From understanding the various components to troubleshooting common issues, this resource aims to empower users with the tools necessary for successful vehicle management. By breaking down the procedures and offering step-by-step guidance, the content fosters confidence and encourages proactive engagement with automotive care.

Whether you are looking to perform routine maintenance or address more significant concerns, the information presented here is designed to facilitate a thorough understanding of essential practices. Engaging with this material will not only enhance your knowledge but also contribute to the longevity and performance of your vehicle.

Comprehensive Guide to Repairing Cougar

This section provides a thorough overview of addressing common issues encountered in a specific vehicle model. By following systematic approaches and best practices, owners can enhance performance, longevity, and safety. Each chapter focuses on distinct components and procedures to ensure a seamless experience during maintenance tasks.

Understanding Common Issues

Before diving into solutions, it’s crucial to identify frequent problems that may arise. Here are some typical concerns:

- Electrical system malfunctions

- Engine performance degradation

- Transmission irregularities

- Suspension and steering challenges

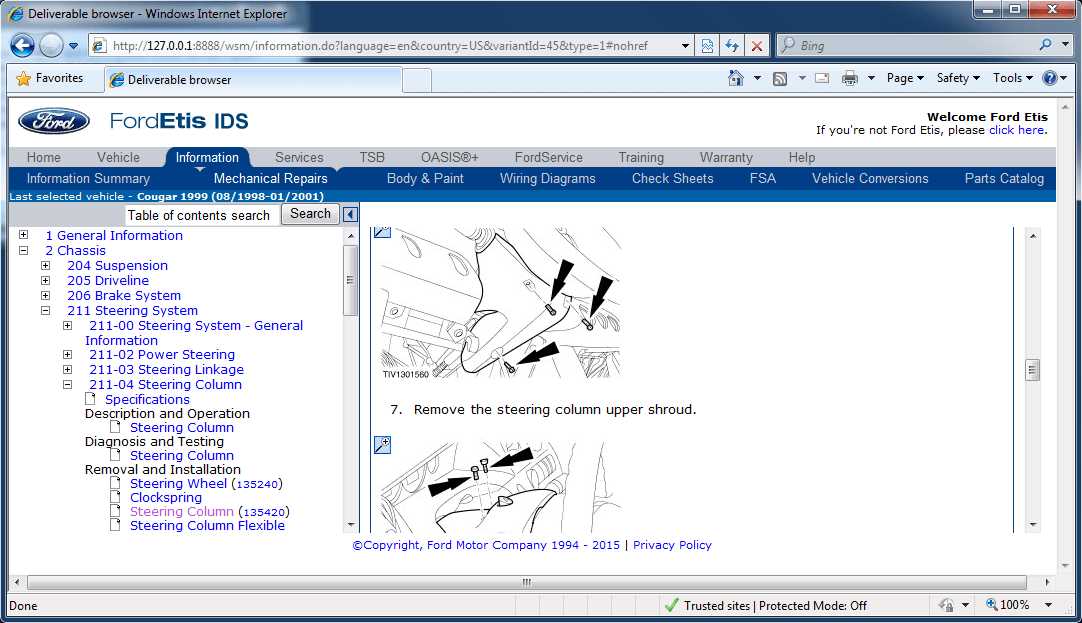

Step-by-Step Troubleshooting Procedures

Addressing vehicle concerns effectively involves a methodical approach. Consider the following steps:

- Gather necessary tools and equipment.

- Consult vehicle specifications for reference.

- Perform a visual inspection of critical components.

- Test electrical systems and sensors for faults.

- Utilize diagnostic tools for comprehensive analysis.

By adhering to this guide, individuals can navigate the complexities of vehicle maintenance with confidence and skill.

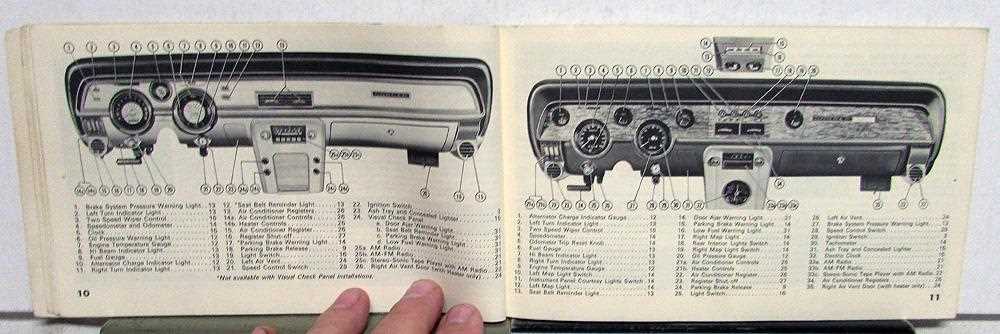

Understanding Vehicle Specifications and Features

Grasping the specifications and features of a vehicle is crucial for owners and enthusiasts alike. These details provide insight into the capabilities, performance, and overall characteristics of the automobile. Knowledge of these elements not only enhances the ownership experience but also aids in making informed decisions regarding maintenance, upgrades, and repairs.

Key Specifications

Specifications often encompass a variety of technical details, such as engine type, horsepower, torque, and fuel efficiency. Understanding these parameters helps in assessing the vehicle’s performance and suitability for different driving conditions. For instance, knowing the power output can indicate how well the vehicle will respond under acceleration.

Notable Features

In addition to technical specifications, features such as safety ratings, entertainment systems, and interior comforts play a vital role in the driving experience. Evaluating these aspects allows potential buyers to select a vehicle that aligns with their lifestyle and preferences. A comprehensive understanding of both specifications and features ensures a well-rounded perspective on the vehicle’s value and performance.

Essential Tools for Effective Repairs

Having the right equipment is crucial for completing automotive tasks efficiently and safely. Whether tackling routine maintenance or addressing specific issues, a well-stocked toolkit can make a significant difference in the quality of the work performed.

Here are some fundamental items that should be included in any comprehensive automotive toolkit:

| Tool | Purpose |

|---|---|

| Socket Set | For loosening and tightening bolts and nuts of various sizes. |

| Wrenches | Essential for gripping and turning fasteners in tight spaces. |

| Screwdriver Set | Used for driving screws in different sizes and types, including flat and Phillips head. |

| Pliers | Useful for gripping, twisting, and cutting wires or small components. |

| Torque Wrench | Ensures that bolts are tightened to the manufacturer’s specifications. |

| Jack and Jack Stands | For lifting the vehicle safely to access the underside. |

| Multimeter | For diagnosing electrical issues and measuring voltage, current, and resistance. |

Equipping yourself with these essential tools will not only facilitate efficient tasks but also enhance your confidence in handling various challenges that may arise during automotive work.

Troubleshooting Common Mechanical Issues

Addressing mechanical challenges in your vehicle can be a straightforward process if approached methodically. By recognizing typical symptoms and employing a systematic approach, you can identify the root causes of various malfunctions. This section aims to guide you through common problems, providing insights and solutions to ensure smooth operation.

Engine Noises: Unusual sounds from the engine compartment may indicate underlying issues. A persistent knocking or tapping noise could suggest problems with the valvetrain or engine bearings. Regular inspection and timely maintenance are crucial in preventing further damage.

Overheating: If your vehicle’s temperature gauge frequently indicates overheating, this may signal issues with the cooling system. Check for coolant leaks, a malfunctioning thermostat, or a faulty water pump. Addressing these concerns promptly can prevent catastrophic engine failure.

Brake Performance: If you experience reduced braking efficiency, inspect the brake pads, rotors, and fluid levels. Worn pads or damaged rotors can lead to increased stopping distances and potential safety hazards.

Transmission Slippage: Difficulty in shifting gears or slippage during acceleration may point to transmission problems. Regular fluid checks and maintaining proper fluid levels can help avoid serious transmission issues. If problems persist, consider seeking professional assistance.

By staying vigilant and conducting routine inspections, you can mitigate many common mechanical concerns and enhance the longevity of your vehicle.

Engine Maintenance and Performance Tips

Proper upkeep of your vehicle’s powertrain is essential for enhancing efficiency and longevity. Regular attention to various components can lead to improved functionality and a smoother driving experience. This section outlines key strategies to optimize engine performance and maintenance practices.

To ensure that your engine operates at peak performance, consider the following recommendations:

| Tip | Description |

|---|---|

| Regular Oil Changes | Replace engine oil and filter according to manufacturer guidelines to maintain lubrication and reduce wear. |

| Check Fluid Levels | Consistently monitor coolant, brake fluid, and transmission fluid to prevent overheating and maintain efficiency. |

| Inspect Belts and Hoses | Examine drive belts and hoses for cracks or wear, replacing them as necessary to avoid breakdowns. |

| Replace Air Filter | Change the air filter periodically to ensure optimal airflow and improve fuel combustion. |

| Monitor Tire Pressure | Keep tires inflated to recommended levels to enhance handling and fuel efficiency. |

| Use Quality Fuel | Select high-quality fuel to promote engine cleanliness and optimal performance. |

Implementing these practices can significantly impact the overall functionality of your vehicle, leading to a more reliable and enjoyable driving experience.

Electrical Systems: Diagnostics and Solutions

This section focuses on the assessment and troubleshooting of electrical components, ensuring optimal functionality in automotive systems. Proper diagnostics are crucial for identifying issues and implementing effective solutions to enhance performance and reliability.

Common Electrical Issues

- Battery Problems: Insufficient charge, corrosion, or loose connections.

- Wiring Faults: Damaged or frayed wires leading to intermittent issues.

- Component Failures: Malfunctioning sensors, relays, or fuses affecting system operation.

- Lighting Failures: Dimming or non-functional lights due to wiring or bulb issues.

Diagnostic Techniques

- Visual Inspection: Examine wiring and connectors for signs of wear or damage.

- Multimeter Testing: Measure voltage and resistance across components to ensure proper function.

- Scan Tool Utilization: Use diagnostic tools to retrieve error codes and monitor system performance.

- Load Testing: Assess the battery and alternator under load conditions to confirm functionality.

By following these steps and addressing common issues, vehicle owners can maintain the integrity of their electrical systems and prevent more significant problems in the future.

Suspension and Steering Adjustments

Proper alignment and adjustment of the suspension and steering systems are crucial for enhancing vehicle handling and ensuring a smooth driving experience. This section outlines essential practices for optimizing these components, leading to improved stability and tire longevity.

Key Adjustment Areas

When addressing the suspension and steering systems, several areas require attention to achieve optimal performance. Regular checks and adjustments can prevent uneven tire wear and maintain accurate steering response. The primary focus areas include:

| Adjustment Area | Description |

|---|---|

| Camber Angle | The angle of the wheels in relation to the vertical axis, affecting tire contact with the road. |

| Toe Angle | The alignment of the wheels, determining how they point in relation to each other. |

| Caster Angle | The angle of the steering pivot point, influencing steering stability and return. |

Importance of Regular Maintenance

Routine inspection and adjustment of these systems not only enhances performance but also prolongs the lifespan of key components. Staying proactive in maintenance helps identify issues before they escalate, ensuring a safe and enjoyable driving experience.

Brake System Inspection and Repair

The braking mechanism is a critical component of any vehicle, ensuring safety and control during operation. Regular evaluation and maintenance of this system are essential to prevent potential issues and guarantee optimal performance. This section outlines the procedures for assessing and addressing concerns related to the braking system.

Begin by visually inspecting the brake components for any signs of wear or damage. Pay close attention to the brake pads, rotors, and calipers, as these elements are crucial for effective stopping power. Ensure that there are no leaks in the hydraulic lines, which could compromise the system’s functionality.

| Component | Inspection Criteria | Action Required |

|---|---|---|

| Brake Pads | Thickness, wear indicators | Replace if worn below specifications |

| Brake Rotors | Surface condition, thickness | Resurface or replace if damaged |

| Brake Calipers | Leaking fluid, movement | Repair or replace if necessary |

| Hydraulic Lines | Visible leaks, cracks | Replace if damaged |

After the initial inspection, conduct a functional test of the braking system. This involves applying the brakes while the vehicle is in motion, listening for unusual noises and assessing responsiveness. Any abnormal sounds or a decrease in braking effectiveness may indicate the need for further investigation.

Upon identifying any issues, follow the manufacturer’s guidelines for parts replacement or repair procedures. Regular maintenance will not only extend the life of the braking system but also enhance the overall safety of the vehicle.

Transmission Troubleshooting Techniques

Identifying issues within a vehicle’s shifting system requires a systematic approach. This section aims to equip you with effective methods for diagnosing and resolving common problems associated with automatic or manual gear mechanisms.

Start with Basic Checks: Begin by inspecting the fluid levels and condition. Low or dirty fluid can lead to shifting difficulties. Ensure that the transmission fluid is at the correct level and appears clean. If necessary, replace it and see if that resolves the issue.

Listen for Unusual Sounds: Pay attention to any strange noises when changing gears. Grinding or whining sounds could indicate worn components or insufficient lubrication. These auditory cues are essential for pinpointing the source of the malfunction.

Observe Shifting Behavior: Take note of how the vehicle shifts during operation. Hesitation, slipping, or harsh engagements can point to specific problems. Analyze whether the issues occur only during certain conditions, such as cold starts or after prolonged driving.

Utilize Diagnostic Tools: Employing a diagnostic scanner can reveal error codes related to the transmission system. These codes provide valuable insights into underlying issues, helping to streamline the troubleshooting process.

Check Electrical Connections: Modern vehicles often integrate electronic components within the shifting mechanism. Ensure that all wiring and connectors are secure and free of corrosion. Electrical faults can significantly impact transmission performance.

Test the Solenoids: In automatic systems, solenoids control fluid flow. Testing these components for functionality can determine whether they are operating correctly. A malfunctioning solenoid may prevent proper shifting.

By following these techniques, you can systematically address transmission-related challenges, ensuring optimal vehicle performance and longevity.

Bodywork and Interior Restoration Ideas

Revitalizing the exterior and interior of a vehicle can significantly enhance its aesthetic appeal and value. This section presents innovative concepts for refurbishing bodywork and interior spaces, focusing on creativity and practicality.

Exterior Enhancements

To achieve a stunning transformation, consider a combination of techniques such as repainting, dent removal, and panel refinishing. Utilizing modern materials and tools can yield impressive results without extensive labor.

| Technique | Description |

|---|---|

| Repainting | Applying a fresh coat of high-quality paint to restore vibrancy and protect surfaces. |

| Dent Removal | Using specialized tools to eliminate minor dents and imperfections, enhancing the overall finish. |

| Panel Refinishing | Restoring damaged or faded panels using techniques like sanding and polishing. |

Interior Revitalization

Refreshing the interior space involves cleaning, reupholstering, and replacing worn components. Thoughtful upgrades can provide comfort and style, making every drive enjoyable.

Finding Replacement Parts Efficiently

Locating suitable components for vehicle maintenance can be a daunting task. However, with the right approach, you can streamline the process and ensure you obtain quality items without unnecessary hassle. This section outlines effective strategies to help you source the necessary parts quickly and reliably.

Utilizing Online Resources

The internet offers a wealth of information and tools for finding components. Start by exploring dedicated automotive websites that specialize in parts sales. These platforms often provide detailed catalogs, allowing you to search by make, model, and year. Take advantage of user reviews and ratings to assess the reliability of the sellers. Additionally, consider joining online forums where enthusiasts share their experiences and recommendations.

Local Auto Parts Stores

Don’t overlook the benefits of visiting local automotive supply stores. Many shops have knowledgeable staff who can assist you in identifying the right components for your needs. Moreover, purchasing items in person allows you to inspect their quality firsthand. Establishing a relationship with local suppliers can lead to valuable insights and potential discounts for future purchases.

Safety Practices During Vehicle Repairs

Ensuring a safe environment while working on vehicles is crucial for both personal well-being and the integrity of the project. Following established safety protocols helps prevent accidents and injuries, fostering a more efficient and productive workspace.

Essential Safety Gear

- Always wear protective eyewear to shield against flying debris.

- Use gloves to protect your hands from chemicals and sharp objects.

- Wear sturdy footwear to prevent foot injuries from heavy components.

- Consider using ear protection when operating loud machinery.

Workspace Organization

- Keep the workspace clean and free from clutter to reduce tripping hazards.

- Ensure tools are properly stored after use to prevent accidents.

- Label hazardous materials clearly and store them in designated areas.

- Maintain adequate lighting to enhance visibility and reduce strain.