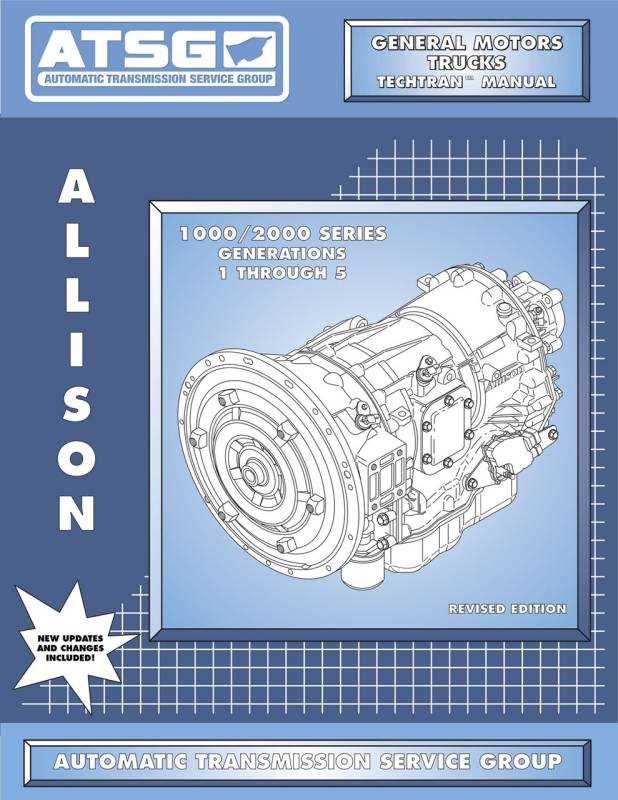

This section aims to provide essential insights into the upkeep and troubleshooting of high-performance diesel engines. Understanding the intricacies of these powerful machines is crucial for ensuring their longevity and efficiency.

In-depth knowledge about various components and their functions will empower enthusiasts and professionals alike. By following systematic procedures and utilizing appropriate techniques, users can effectively address common issues and enhance overall performance.

Equipping oneself with the right information is vital in navigating the complexities of engine service. This resource serves as a valuable reference for anyone looking to deepen their understanding and skills in engine care.

This section provides a comprehensive overview of a popular diesel engine model, highlighting its key characteristics and advantages. Understanding these features is crucial for effective maintenance and optimal performance.

Key Characteristics

- Powerful torque output for heavy-duty applications

- Advanced fuel injection system for improved efficiency

- Robust construction designed for durability

- Emissions control technologies that meet regulatory standards

Advantages of the Engine

- Enhanced towing capabilities, ideal for trucks and commercial vehicles

- Fuel-efficient operation, reducing overall running costs

- Smooth performance with minimal vibrations, contributing to driver comfort

Common Issues and Troubleshooting Tips

When working with high-performance diesel engines, several challenges may arise that require careful attention. Understanding typical problems can facilitate efficient diagnostics and solutions, ensuring optimal engine performance.

- Fuel System Problems: Issues with fuel delivery can lead to decreased efficiency. Regularly check for clogged filters or air leaks in the fuel lines.

- Overheating: Monitor engine temperatures closely. Insufficient coolant levels or a malfunctioning thermostat can cause overheating.

- Oil Leaks: Inspect seals and gaskets for signs of leakage. Address any oil loss promptly to prevent further damage.

Implementing basic troubleshooting techniques can also help diagnose and resolve issues quickly:

- Conduct regular maintenance checks to catch potential problems early.

- Use diagnostic tools to identify error codes and underlying issues.

- Consult with experienced professionals when in doubt to avoid costly repairs.

Maintenance Practices for Longevity

Ensuring the durability and efficiency of your engine requires a proactive approach to upkeep. Regular maintenance not only enhances performance but also extends the lifespan of critical components. By adopting effective practices, you can prevent premature wear and ensure your vehicle operates at its best.

One key aspect of maintenance involves consistent fluid checks and changes. Monitoring oil levels and quality helps maintain optimal lubrication, reducing friction and heat. Additionally, replacing coolant at recommended intervals prevents overheating and protects against corrosion.

Another vital practice is the inspection of filters. Regularly replacing air and fuel filters keeps contaminants from entering the engine, promoting better combustion and efficiency. Similarly, examining belts and hoses for signs of wear can prevent breakdowns and costly repairs down the line.

Moreover, following a scheduled maintenance plan that includes periodic checks of electrical systems, tire pressure, and brake performance contributes to overall safety and reliability. Investing time in these practices not only protects your investment but also enhances driving experience.

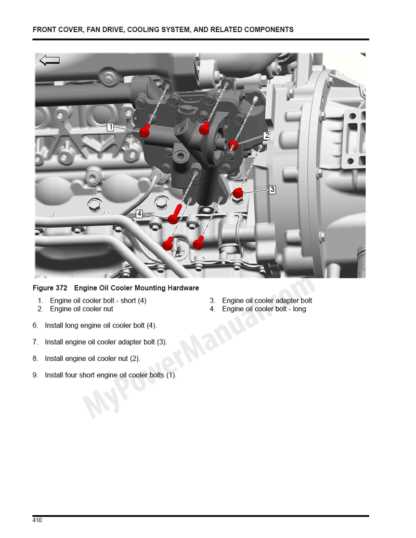

Step-by-Step Repair Procedures

This section outlines the detailed methodology for conducting maintenance and troubleshooting tasks. Following a systematic approach ensures accuracy and efficiency while addressing issues effectively.

Preparation and Safety

- Gather necessary tools and equipment.

- Ensure a clean working environment.

- Wear appropriate safety gear to prevent accidents.

Inspection Process

- Begin with a visual examination of components.

- Check for leaks, corrosion, or damage.

- Test the functionality of critical systems.

Following these steps helps identify potential problems early, allowing for timely interventions and ensuring optimal performance of the system.

Essential Tools for Repairs

Having the right equipment is crucial for effective maintenance and troubleshooting. A well-equipped toolkit not only facilitates the repair process but also enhances the overall efficiency of the work. Below are key instruments and supplies that every technician should consider having on hand.

Basic Hand Tools

- Wrenches: Various sizes for different fasteners.

- Screwdrivers: Flathead and Phillips types in multiple sizes.

- Socket Set: A complete set with different drive sizes.

- Pliers: Needle-nose, slip-joint, and cutting pliers.

Diagnostic Equipment

- OBD-II Scanner: For reading error codes and diagnosing issues.

- Multimeter: To measure voltage, current, and resistance.

- Pressure Gauges: For checking fluid pressures.

Upgrading Components for Performance

Enhancing the capabilities of your vehicle can significantly improve its overall efficiency and driving experience. By focusing on specific parts, you can achieve a noticeable boost in power, responsiveness, and reliability. This section explores the various options available for optimizing performance through component upgrades.

Key Areas for Improvement

One of the primary areas to consider is the air intake system. Upgrading to a high-flow intake can enhance airflow, resulting in better combustion and increased horsepower. Additionally, exhaust modifications can facilitate improved airflow out of the engine, reducing back pressure and further boosting performance.

Boosting Power with Tuning

Another effective way to elevate performance is through electronic tuning. By recalibrating the engine’s control unit, you can unlock additional power and torque. This adjustment ensures that all components work in harmony, maximizing the potential of your upgraded parts.

Fuel System Specifications and Care

The efficiency and longevity of a vehicle’s powertrain heavily depend on the proper functioning of its fuel system. Understanding the specifications and maintenance requirements is crucial for optimal performance and reliability. This section outlines essential aspects of the fuel system, emphasizing the importance of regular care and adherence to guidelines.

Key Specifications

The fuel system encompasses several critical components, including the fuel tank, pump, injectors, and filtration system. Each of these parts must operate within specific parameters to ensure efficient combustion and minimize emissions. Regular checks of fuel pressure and flow rates are vital, along with monitoring the condition of filters and injectors to prevent performance issues.

Maintenance Recommendations

Cooling System Troubleshooting Techniques

Addressing issues within the cooling system is essential for maintaining optimal engine performance. Effective diagnostics can prevent severe damage and ensure longevity. Understanding common problems and their symptoms allows for timely interventions, which can significantly enhance the efficiency of the system.

Identifying Common Symptoms

Begin by observing indicators such as unusual temperature readings, fluid leaks, or strange noises. High engine temperatures may suggest insufficient coolant circulation, while visible leaks could point to worn hoses or a damaged radiator. Recognizing these signs early can prevent further complications.

Conducting System Checks

Perform routine checks on coolant levels and inspect for contaminants. Ensure that the radiator and hoses are free of blockages. Testing the thermostat and water pump functionality is crucial, as failures in these components can severely disrupt the cooling process. Regular maintenance can aid in identifying potential issues before they escalate.

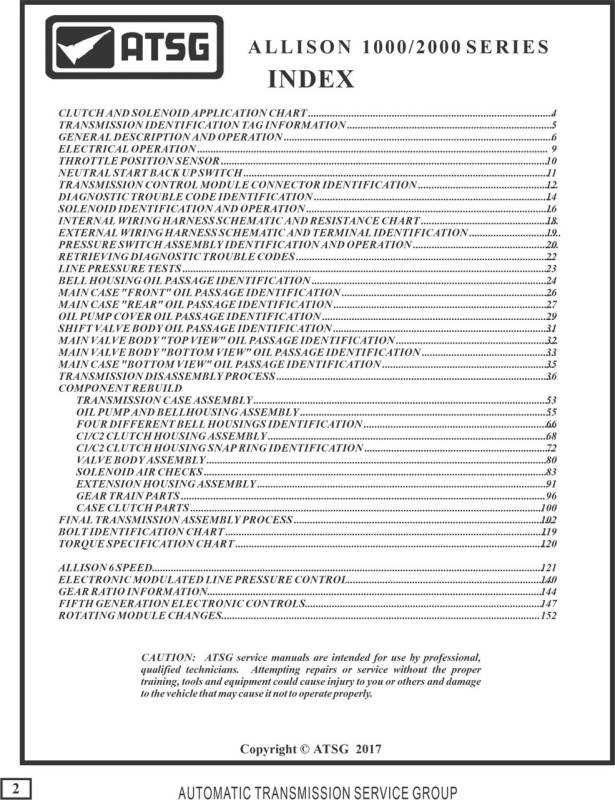

Electrical System Diagnostics Explained

Understanding the intricacies of an electrical system is crucial for effective troubleshooting and maintenance. This segment delves into the methodologies employed to identify and resolve issues within the electrical framework of vehicles. By grasping the principles behind diagnostics, technicians can efficiently pinpoint faults and implement appropriate solutions.

One of the fundamental aspects of electrical system analysis involves the use of specialized tools to measure voltage, current, and resistance. Multimeters and oscilloscopes serve as essential instruments, allowing for real-time data collection and assessment. These devices facilitate a deeper understanding of the system’s performance, revealing anomalies that may indicate underlying problems.

Additionally, a systematic approach is vital. Technicians often start by reviewing wiring diagrams and schematics to gain insight into the system’s layout. This preliminary step is crucial for tracing circuits and identifying potential areas of concern. Visual inspections of connectors and wiring can also uncover issues such as corrosion or damage, which may compromise functionality.

Moreover, understanding the interaction between various components is essential for accurate diagnostics. Each element of the electrical system, from sensors to relays, plays a specific role. By analyzing these relationships, technicians can identify the root cause of malfunctions more effectively, ensuring a comprehensive resolution.

Best Practices for Engine Rebuilding

Rebuilding an engine is a meticulous process that requires attention to detail and a thorough understanding of the components involved. Adhering to best practices not only enhances the longevity of the engine but also optimizes its performance. This section outlines key strategies that should be followed during the rebuilding process.

Thorough Inspection of Components

Before any assembly begins, it is essential to conduct a comprehensive inspection of all engine parts. This includes checking for wear, damage, or corrosion. Using precise measurement tools will ensure that each component meets the required specifications, allowing for a seamless rebuild.

Proper Cleaning Techniques

Ensuring that all parts are free of contaminants is crucial for a successful rebuild. Utilizing appropriate cleaning agents and techniques will remove any old oil, debris, or residue. This step prevents potential issues during operation and promotes better performance once the engine is reassembled.