Maintaining marine engines is crucial for ensuring optimal performance and longevity. Understanding the intricacies of these powerful machines allows users to address common issues effectively. This section delves into essential procedures and techniques to keep your engine running smoothly.

Regular maintenance not only enhances the efficiency of your vessel but also prevents costly breakdowns. Familiarizing yourself with the various components and their functions is vital for any boat enthusiast. Here, we explore the necessary steps to troubleshoot and service your engine, ensuring a reliable and enjoyable experience on the water.

The knowledge gained from this guide empowers users to take proactive measures. From routine inspections to more in-depth servicing, mastering these skills will contribute to a safer and more enjoyable boating experience. Dive into the world of engine care and discover the benefits of being hands-on with your marine equipment.

Common Issues with 50 HP Engines

Understanding the typical challenges faced by 50 HP motors can greatly assist in maintaining optimal performance. These issues can range from mechanical malfunctions to fuel system complications, each requiring attention to ensure reliability and efficiency.

Mechanical Problems

- Overheating due to insufficient coolant flow.

- Wear and tear on components leading to decreased efficiency.

- Engine misfires caused by faulty ignition systems.

Fuel System Complications

- Clogged fuel filters affecting power delivery.

- Old or contaminated fuel causing starting difficulties.

- Fuel line leaks leading to pressure loss.

Essential Tools for Repairs

When tackling maintenance tasks on a marine engine, having the right equipment is crucial. A well-equipped workspace not only streamlines the process but also ensures safety and efficiency. Whether you are a novice or an experienced technician, understanding the necessary instruments can make all the difference.

Basic Hand Tools: A selection of wrenches, pliers, and screwdrivers is fundamental for disassembling and reassembling components. Ensure that you have a range of sizes to accommodate different fasteners.

Diagnostic Equipment: Multimeters and compression testers are essential for diagnosing electrical issues and assessing engine performance. These tools help identify problems early, preventing more extensive damage.

Safety Gear: Never underestimate the importance of safety equipment. Gloves, goggles, and protective clothing are vital when working with machinery, as they shield against injuries and hazardous materials.

Cleaning Supplies: Keeping your workspace tidy is important. Having brushes, cloths, and suitable solvents will help maintain components and ensure a clean environment for repairs.

Step-by-Step Maintenance Procedures

This section outlines essential tasks to ensure optimal performance and longevity of your marine engine. Following these systematic steps will help you maintain the unit in good working condition, reducing the likelihood of unexpected issues and enhancing overall efficiency.

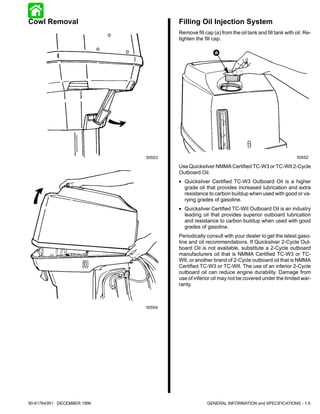

Routine Inspection and Cleaning

Begin with a thorough examination of the exterior for any signs of wear or damage. Clean the casing and components regularly to prevent the buildup of dirt and debris. Pay special attention to the cooling system, ensuring that it is free from obstructions to promote proper airflow and functionality.

Fluid Changes and System Checks

Regularly replace the essential fluids, such as oil and fuel, according to the manufacturer’s recommendations. Check the integrity of hoses and connections, looking for any leaks or deterioration. Ensure that all filters are clean and replace them as necessary to maintain efficiency and performance.

Troubleshooting Engine Starting Problems

Addressing issues with engine ignition can often be a straightforward process. Understanding common symptoms and following systematic steps can help identify the root cause of starting difficulties.

Common Symptoms

- Engine cranks but does not start

- No response when the ignition is turned

- Intermittent starting issues

Steps to Diagnose Starting Issues

- Check the fuel supply: Ensure there is enough fuel and that it is reaching the engine.

- Inspect the battery: Confirm that the battery is charged and the connections are secure.

- Examine the ignition system: Look for damaged wires or faulty components in the ignition setup.

- Verify safety switches: Ensure that any safety features are not preventing engine start.

- Assess the starter motor: Listen for unusual sounds or lack of operation from the starter unit.

Following these steps will help isolate the issue and guide necessary repairs, ensuring reliable engine performance.

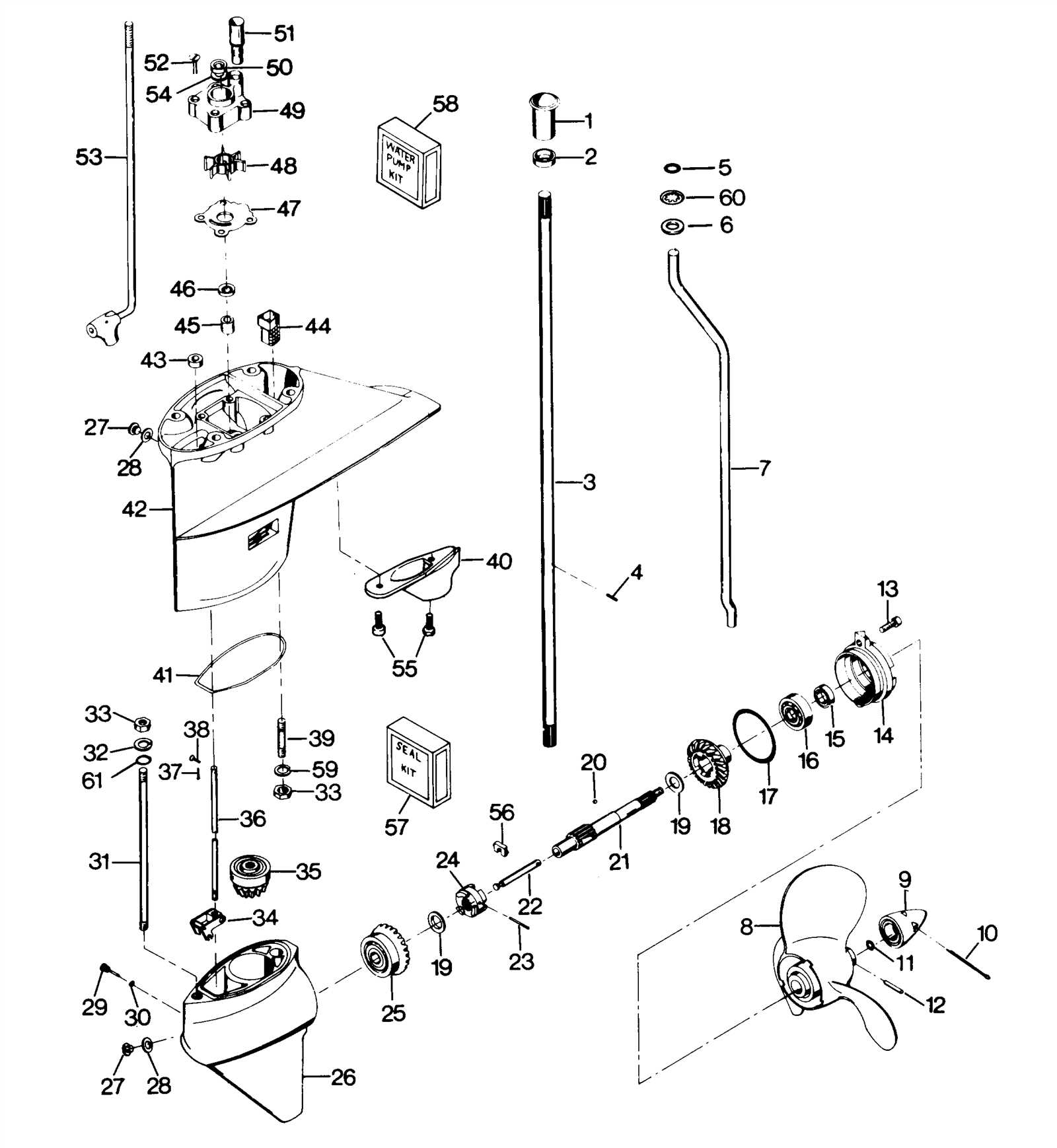

Replacing Key Components Effectively

Maintaining optimal performance requires the careful exchange of vital parts in your marine engine. Understanding the process can enhance longevity and reliability. This section provides insights into the best practices for swapping essential elements, ensuring a seamless transition.

Identifying Components: Begin by pinpointing the parts that are most prone to wear. Regular inspections will help you recognize which components need attention and replacement.

Preparation Steps: Before initiating the swap, gather all necessary tools and replacement pieces. Ensure you have a clean workspace to facilitate an efficient process.

Careful Removal: When taking out the old components, proceed with caution. Use appropriate techniques to avoid damaging surrounding areas, which can lead to additional complications.

Installation Process: When installing new elements, follow the manufacturer’s specifications closely. Proper alignment and secure fastening are crucial to avoid future issues.

Testing and Adjustment: After installation, conduct thorough tests to confirm functionality. Make necessary adjustments to ensure everything operates smoothly.

By following these guidelines, you can effectively replace key components, enhancing the performance and reliability of your marine engine.

Fuel System Care and Maintenance

Proper upkeep of the fuel system is essential for optimal performance and longevity of your marine engine. Regular attention to this component ensures efficient operation and minimizes the risk of complications that could lead to costly repairs.

Here are key practices to maintain the fuel system:

| Maintenance Task | Frequency | Details |

|---|---|---|

| Inspect Fuel Lines | Every 50 hours | Check for cracks, leaks, or wear and replace as needed. |

| Replace Fuel Filter | Every season | Ensure clean fuel supply and prevent clogging. |

| Check Fuel Quality | Monthly | Use fresh fuel and avoid contaminated sources. |

| Inspect Fuel Tank | Seasonally | Look for rust or debris; clean as necessary. |

| Use Fuel Stabilizer | As needed | Prevent fuel degradation during storage. |

By following these guidelines, you can enhance the reliability and efficiency of your engine, ensuring smooth sailing for years to come.

Electrical System Diagnostics and Fixes

This section focuses on evaluating and addressing issues related to the electrical components of your engine. Proper diagnostics are essential for identifying problems that may hinder performance and reliability.

Identifying Electrical Issues

Begin by examining the battery and connections. A weak or dead battery can lead to starting difficulties. Check for corrosion on terminals and ensure all connections are tight. Use a multimeter to measure voltage levels; a healthy battery should read around 12.6 volts when fully charged.

Testing Components

Next, test the alternator and voltage regulator to confirm they are functioning correctly. The alternator generates power while the engine runs, and the regulator ensures the voltage remains stable. If these components are faulty, they can lead to electrical failures.

Wiring Inspection

Inspect the wiring for signs of wear, damage, or fraying. Damaged wires can cause shorts or interruptions in the circuit. Replace any compromised wiring to maintain a reliable electrical system.

Final Steps

After diagnosing and fixing any issues, perform a thorough system check. Monitor the electrical performance during operation to ensure everything functions smoothly. Regular maintenance can prevent future problems and enhance overall reliability.

Propeller Selection and Installation Tips

Selecting the right propeller is crucial for optimizing performance and efficiency. The choice of propeller affects speed, handling, and fuel consumption. Understanding key factors such as pitch, diameter, and blade design will help ensure that the vessel operates smoothly and meets the desired performance criteria.

When installing a propeller, proper technique is essential to avoid damage and ensure safety. Follow these guidelines to achieve a successful installation:

| Step | Description |

|---|---|

| 1 | Ensure the drive shaft is clean and free of debris. |

| 2 | Apply a suitable lubricant to the splines of the drive shaft. |

| 3 | Align the propeller with the drive shaft and gently slide it into place. |

| 4 | Secure the propeller with the locking nut, ensuring it is tightened to the manufacturer’s specifications. |

| 5 | Check for any signs of misalignment or unusual noise before taking the vessel into the water. |

By carefully selecting and properly installing the propeller, the overall performance of the vessel can be greatly enhanced, leading to a more enjoyable and efficient experience on the water.

Safety Practices During Repairs

Ensuring safety while conducting maintenance on marine engines is essential to protect both the individual performing the work and the equipment itself. Adhering to specific guidelines can prevent accidents and promote a secure working environment.

Essential Safety Equipment

Utilizing appropriate safety gear is crucial during any maintenance task. Here are some items that should be worn:

| Safety Equipment | Description |

|---|---|

| Safety Goggles | Protects eyes from debris and chemicals. |

| Gloves | Prevents skin contact with harmful substances. |

| Ear Protection | Reduces noise exposure from tools and engines. |

| Steel-Toed Boots | Protects feet from heavy equipment. |

Work Environment Considerations

Maintaining a tidy and organized workspace can significantly reduce risks. Ensure proper ventilation to avoid the buildup of harmful fumes, and always have a fire extinguisher accessible. Additionally, securing tools and materials prevents accidents caused by tripping or falling objects.

Where to Find Replacement Parts

Locating suitable components for your marine engine can be essential for maintaining optimal performance. Various sources provide quality alternatives, ensuring that you can find exactly what you need to keep your vessel in top shape.

Authorized Dealers: One of the most reliable options is to visit authorized dealers who specialize in marine equipment. These establishments often stock original components and can offer expert advice on compatibility.

Online Retailers: Numerous online platforms cater to enthusiasts and professionals alike, featuring a wide selection of parts. Websites dedicated to marine supplies typically have user-friendly search functions that make it easy to find the specific items you require.

Local Marine Supply Stores: Don’t overlook local shops that focus on boating supplies. They may carry essential parts or be able to order them for you, providing a quick solution without the need for shipping delays.

Marine Forums and Communities: Engaging with online communities can also yield valuable information. Fellow boaters often share their experiences, including recommendations for where to purchase parts at competitive prices.

Salvage Yards: For those seeking cost-effective options, marine salvage yards can be a treasure trove of used components. While quality may vary, inspecting items closely can lead to significant savings.