This section serves as an invaluable resource for enthusiasts and professionals alike, providing in-depth insights into the upkeep and troubleshooting of your automobile. Whether you’re a seasoned mechanic or a curious owner, understanding the intricacies of vehicle care is essential for ensuring optimal performance and longevity.

Within these pages, you’ll discover detailed instructions, essential tips, and troubleshooting strategies tailored to enhance your knowledge and skills. This guide emphasizes a systematic approach to vehicle maintenance, empowering you to tackle various challenges with confidence.

From routine checks to complex repairs, this resource aims to simplify the process, making it accessible to all. With an emphasis on practical advice and user-friendly language, you will find the information you need to keep your vehicle running smoothly and efficiently.

Comprehensive Guide to 2009 Subaru Outback

This section provides an in-depth overview designed for enthusiasts and owners of a specific vehicle model, focusing on essential aspects such as maintenance, troubleshooting, and operational insights. The information aims to enhance understanding and facilitate effective management of the automobile.

Key features and specifications play a crucial role in ensuring optimal performance. Below is a detailed table highlighting significant characteristics of the vehicle:

| Feature | Description |

|---|---|

| Engine Type | Flat-six engine providing a balanced performance with smooth operation. |

| Transmission | Continuously variable transmission (CVT) for improved fuel efficiency. |

| Drivetrain | All-wheel drive (AWD) system for enhanced traction in various conditions. |

| Fuel Economy | Average mileage of approximately 20-30 miles per gallon. |

| Interior Space | Spacious cabin with ample cargo capacity for versatile usage. |

Maintaining this vehicle involves regular checks and adherence to recommended service schedules. This ensures longevity and reliability, providing a comfortable driving experience.

Understanding the Vehicle’s Specifications

Grasping the specifications of an automobile is crucial for ensuring optimal performance and longevity. These detailed descriptions provide insight into the various components and capabilities that define the vehicle’s characteristics, guiding users in making informed decisions regarding maintenance and modifications.

Key specifications typically encompass a range of features that affect the overall functionality and efficiency:

- Engine Performance: Information about horsepower, torque, and fuel efficiency.

- Transmission: Details regarding the type and number of gears, as well as the system’s responsiveness.

- Dimensions: Measurements of length, width, height, and wheelbase, which influence handling and interior space.

- Weight: Overall weight and distribution, impacting stability and acceleration.

- Suspension: Types of suspension systems used and their impact on ride comfort and handling.

These attributes serve as a foundation for understanding how the vehicle operates under various conditions, allowing owners to appreciate the engineering behind their automobile. Familiarity with these details also aids in troubleshooting issues and planning for enhancements, ensuring a more enjoyable driving experience.

Key Maintenance Procedures for Owners

Regular upkeep is essential for ensuring the longevity and efficiency of your vehicle. By adhering to systematic care routines, owners can prevent common issues, enhance performance, and maintain optimal safety standards. This section outlines vital practices that should be integrated into the ownership experience to support the health of the automobile.

Essential Fluid Checks

Monitoring and replacing fluids is crucial for the vehicle’s operation. Neglecting this aspect can lead to serious complications over time. Below is a table summarizing the key fluids to inspect and their recommended maintenance intervals.

| Fluid Type | Recommended Interval | Notes |

|---|---|---|

| Engine Oil | Every 5,000 miles | Use high-quality oil to enhance engine performance. |

| Coolant | Every 30,000 miles | Ensure proper levels to prevent overheating. |

| Brake Fluid | Every 2 years | Check for contamination to maintain braking efficiency. |

| Transmission Fluid | Every 30,000 miles | Replace to ensure smooth shifting. |

Routine Inspections

Conducting regular inspections can identify potential issues before they escalate. Focus on the following areas during each evaluation:

- Brake components

- Tire tread depth and pressure

- Battery terminals and connections

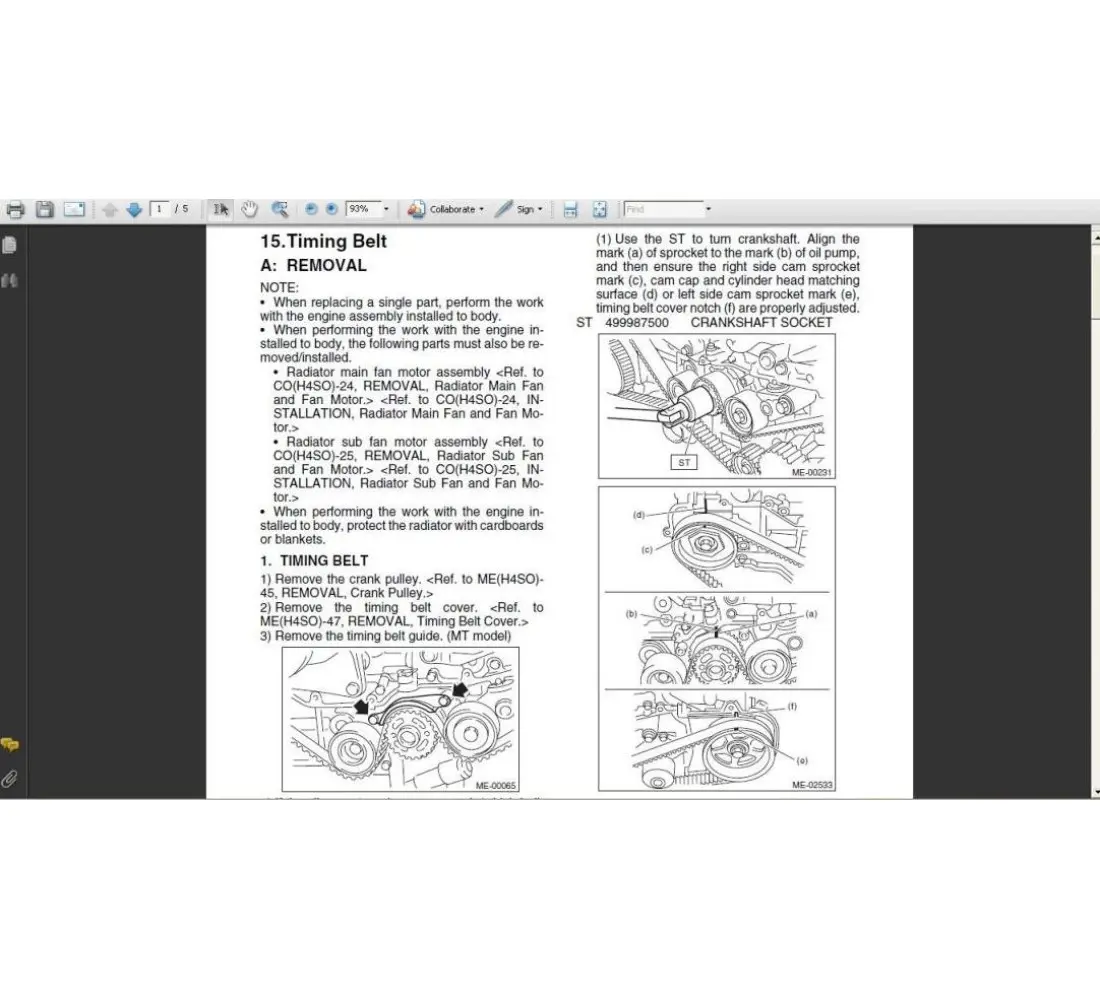

- Belts and hoses for signs of wear

Troubleshooting Common Mechanical Issues

Identifying and resolving frequent mechanical problems can significantly enhance the longevity and performance of your vehicle. By understanding the typical signs and symptoms of issues, owners can take proactive steps to rectify them before they escalate.

Here are some common mechanical problems and their potential causes:

- Engine Stalling:

- Fuel delivery issues

- Faulty ignition system

- Vacuum leaks

- Unusual Noises:

- Worn bearings

- Loose components

- Exhaust system problems

- Overheating:

- Coolant leaks

- Clogged radiator

- Faulty thermostat

- Braking Issues:

- Worn brake pads

- Fluid leaks

- Faulty brake lines

When experiencing any of these issues, it is crucial to perform a systematic examination to pinpoint the root cause. Regular maintenance and timely interventions can prevent further damage and ensure the vehicle operates smoothly.

Electrical System Diagnostics Explained

Understanding the intricacies of an automobile’s electrical framework is essential for identifying issues that may hinder optimal performance. Effective evaluation of the electrical components ensures that the vehicle operates smoothly, preventing potential breakdowns and enhancing safety. This segment delves into key concepts related to troubleshooting electrical anomalies.

Diagnostic procedures typically encompass the following stages:

- Preliminary Checks: Begin with visual inspections to identify obvious signs of wear or damage.

- Utilizing Diagnostic Tools: Employ specialized equipment to read fault codes and monitor system performance.

- Component Testing: Isolate and examine individual parts, such as fuses, relays, and sensors, to determine their functionality.

Key elements to consider during diagnostics include:

- Battery Condition: Ensure the power source is charged and connections are secure.

- Wiring Integrity: Inspect for frayed or corroded wires that could disrupt current flow.

- Ground Connections: Verify that grounding points are clean and tightly secured to maintain effective electrical pathways.

By systematically addressing these areas, one can effectively diagnose and resolve electrical issues, ensuring reliable vehicle operation.

Step-by-Step Brake System Overhaul

This section outlines a comprehensive approach to rejuvenating the braking apparatus of your vehicle. Proper maintenance of the braking system is crucial for ensuring safety and optimal performance. The following steps will guide you through the essential procedures involved in overhauling this critical component.

Before beginning the process, gather all necessary tools and replacement parts. Familiarize yourself with the vehicle’s specifications to ensure compatibility. The focus will be on inspecting, cleaning, and replacing worn components, which is vital for restoring functionality.

| Step | Description |

|---|---|

| 1 | Lift the vehicle using a jack and secure it with jack stands to ensure stability during the overhaul. |

| 2 | Remove the wheel to access the braking components. Take note of the configuration for reassembly. |

| 3 | Inspect brake pads for wear and tear. If they are below the recommended thickness, replace them. |

| 4 | Examine the brake rotors for any signs of damage or uneven wear. Resurface or replace as necessary. |

| 5 | Check brake lines for leaks or corrosion. Replace any compromised lines to ensure fluid integrity. |

| 6 | Clean all components thoroughly to remove dust and debris, which can affect performance. |

| 7 | Reassemble the braking system, ensuring that all parts are secured correctly and torqued to specifications. |

| 8 | Reinstall the wheel and lower the vehicle. Test the braking system by applying pressure to the pedal and checking for responsiveness. |

Completing this procedure will help ensure that your vehicle’s braking system operates effectively, enhancing safety and driving experience.

Engine Performance Enhancement Tips

Improving engine efficiency and power output can significantly enhance the overall driving experience. This section offers practical advice on modifications and adjustments that can lead to better throttle response, increased horsepower, and improved fuel economy.

Upgrading Components

Investing in high-quality components can greatly influence engine performance. Consider the following upgrades:

| Component | Benefits |

|---|---|

| Cold Air Intake | Increases airflow, leading to improved combustion and power. |

| High-Performance Exhaust System | Enhances exhaust flow, reducing back pressure and increasing horsepower. |

| ECU Remapping | Optimizes fuel delivery and timing for better performance. |

Regular Maintenance

Routine upkeep is crucial for maintaining optimal performance. Focus on these key areas:

- Change engine oil regularly to ensure smooth operation.

- Replace air filters to maintain proper airflow.

- Check and replace spark plugs to ensure efficient ignition.

Cooling System Maintenance and Repair

The effective functioning of a vehicle’s cooling apparatus is crucial for maintaining optimal engine performance and longevity. Regular upkeep and timely interventions can prevent overheating and ensure that all components operate smoothly. This section will explore essential practices and troubleshooting techniques for maintaining this vital system.

Routine Inspections

Conducting periodic evaluations of the cooling system can identify potential issues before they escalate. Check the coolant level, inspect hoses for any signs of wear or leaks, and ensure that the radiator is free from debris. Monitoring the temperature gauge during operation also helps in detecting anomalies early.

Fluid Replacement and System Flushing

Over time, coolant can become contaminated or lose its effectiveness. It is important to replace the fluid according to the manufacturer’s recommendations. Flushing the system removes any buildup of deposits and ensures that the cooling passages remain clear, promoting efficient heat dissipation.

Transmission Fluid Replacement Guidelines

Maintaining the appropriate level and condition of transmission fluid is crucial for ensuring optimal performance and longevity of the vehicle’s transmission system. Regular checks and timely replacements can prevent potential issues and enhance the overall driving experience. This section provides essential instructions for effectively replacing the transmission fluid, helping to safeguard the integrity of the drivetrain.

Recommended Tools and Materials

Before beginning the fluid replacement process, gather the necessary tools and materials to ensure a smooth operation. The following items are typically required:

- Wrench set

- Transmission fluid pump

- Fluid catch pan

- Funnel

- New transmission fluid

- Clean rags

Replacement Procedure

The fluid replacement procedure can vary slightly based on the specific transmission type. Follow these general steps for a successful fluid change:

- Start by safely lifting the vehicle and securely supporting it on jack stands.

- Locate the transmission pan and place the catch pan underneath to collect the old fluid.

- Remove the transmission pan bolts using the wrench set and carefully lower the pan.

- Drain the old fluid completely into the catch pan and clean any debris from the pan.

- Replace the transmission filter if applicable.

- Reinstall the pan and tighten the bolts to the manufacturer’s specifications.

- Using a funnel, pour the new transmission fluid into the fill tube. Refer to the vehicle’s specifications for the correct type and quantity of fluid.

- Start the engine and allow it to reach operating temperature, then check the fluid level and add more if necessary.

Fluid Change Interval

It is advisable to follow the recommended service intervals for fluid replacement, typically outlined in the vehicle’s specifications. Regular maintenance contributes significantly to the smooth operation and durability of the transmission system.

| Fluid Type | Capacity | Change Interval |

|---|---|---|

| Automatic Transmission Fluid | 6-8 quarts | 30,000 – 60,000 miles |

| Manual Transmission Fluid | 2-4 quarts | 30,000 – 50,000 miles |

Safety Features and Their Maintenance

Ensuring the safety of a vehicle involves understanding its protective attributes and implementing regular upkeep. These systems play a critical role in preventing accidents and minimizing injuries. Regular inspection and servicing of these features are essential to guarantee optimal performance and reliability.

Key Safety Components

Several vital safety elements contribute to the overall security of the vehicle. Below is a table highlighting these components along with their maintenance requirements:

| Safety Feature | Maintenance Requirements |

|---|---|

| Antilock Braking System (ABS) | Inspect brake fluid levels, check for warning lights, and examine brake pads regularly. |

| Airbags | Ensure the airbag system is functioning properly and has no warning indicators lit on the dashboard. |

| Traction Control | Test the system during regular driving and ensure the warning light functions correctly. |

| Electronic Stability Control (ESC) | Regularly assess the system’s performance during various driving conditions to confirm effectiveness. |

Regular Checks and Inspections

Conducting periodic evaluations of safety features is paramount. Engaging professional services for thorough inspections can help identify any underlying issues early. Additionally, owners should remain vigilant for any irregularities in vehicle behavior that may indicate a malfunction in safety systems.

Body and Frame Repair Techniques

Maintaining the integrity of a vehicle’s structure is essential for safety and performance. This section explores various methods to address issues related to the outer shell and supporting framework of automobiles. Proper techniques ensure that any damage is effectively managed, enhancing both aesthetics and functionality.

Assessment is the first step in addressing any structural concerns. Technicians should meticulously examine the body for dents, rust, or misalignment. Identifying the extent of damage allows for informed decisions regarding the necessary interventions.

Once the assessment is complete, the next phase involves straightening and alignment. Using specialized equipment, professionals can restore bent frames to their original specifications. This process often requires precise measurements and adjustments to maintain the vehicle’s intended handling and safety characteristics.

In cases where sections of the structure are compromised, welding and reinforcement may be necessary. High-quality materials and techniques are vital to ensure lasting strength and durability. Proper preparation and execution during these procedures can significantly impact the vehicle’s overall resilience.

Finally, a thorough finish process, including painting and coating, protects the surface from environmental elements. This not only enhances appearance but also prolongs the lifespan of the outer shell. Effective application techniques are essential for achieving a seamless and attractive result.

Interior Systems: Troubleshooting and Fixes

The functionality of a vehicle’s interior systems is essential for ensuring a comfortable and enjoyable driving experience. Common issues may arise in areas such as climate control, audio systems, and dashboard displays. Addressing these problems promptly can enhance the overall performance and usability of the vehicle.

Climate Control Issues

Malfunctions in the climate control system can lead to discomfort during travel. If the air conditioning fails to cool or the heating system is ineffective, checking the coolant levels and inspecting the fuses is a good starting point. Additionally, the cabin air filter should be examined for blockages, as this can impede airflow.

Audio System Troubleshooting

If the sound system is not functioning correctly, the first step is to verify that all connections are secure. Loose wires can result in intermittent sound issues. Furthermore, resetting the audio unit may resolve software glitches that could affect performance. If the problem persists, consider checking the speakers for damage.

Recommended Tools for DIY Repairs

Embarking on automotive maintenance and enhancements requires a well-equipped workspace and the right instruments. Having the appropriate tools not only simplifies the tasks but also enhances safety and efficiency. Below is a list of essential items that can significantly aid in various automotive projects.

- Socket Set: A versatile socket set allows for easy loosening and tightening of fasteners in different sizes.

- Wrenches: Adjustable and fixed wrenches are crucial for handling various bolt types and sizes.

- Screwdriver Set: A variety of screwdrivers, including flathead and Phillips, will cover most screws found in vehicles.

- Pliers: Needle-nose and standard pliers assist in gripping and manipulating small components.

- Torque Wrench: This tool ensures that bolts are tightened to the manufacturer’s specifications, preventing damage from overtightening.

In addition to the basic tools, several specialized instruments can enhance your capability:

- OBD-II Scanner: Useful for diagnosing and troubleshooting electronic issues.

- Jack and Jack Stands: Essential for lifting the vehicle safely for undercarriage access.

- Multimeter: A valuable tool for electrical diagnostics and troubleshooting.

- Fluid Extractor: Makes it easier to change fluids without spills.

Equipping yourself with these tools will enable you to tackle various tasks with confidence, ensuring a more enjoyable and successful experience.