In the realm of automotive care, having a detailed resource can significantly enhance the experience of both novice and seasoned enthusiasts. This section delves into the essential aspects of vehicle upkeep, focusing on troubleshooting techniques, component replacements, and best practices to ensure optimal performance.

Understanding the intricacies of your automobile is paramount. This guide serves as a valuable asset, providing step-by-step instructions and insightful tips that cater to various skill levels. From routine checks to more complex tasks, every detail is crucial in maintaining the longevity and efficiency of the vehicle.

Emphasizing the importance of regular service, this section offers a structured approach to various procedures, ensuring that individuals can navigate each task with confidence. Whether addressing common issues or performing preventative maintenance, knowledge is key to preserving the functionality and reliability of your automobile.

Overview of 2006 Volkswagen Jetta TDI

This section provides a comprehensive examination of a compact vehicle known for its impressive efficiency and performance. Renowned for its robust engineering, this model has garnered attention for its blend of style and practicality, making it a popular choice among drivers seeking reliability.

Key Features

One of the standout aspects of this automobile is its fuel-efficient engine, which offers remarkable mileage, making it an economical option for daily commuting. The design showcases a sleek exterior complemented by a comfortable interior, ensuring a pleasant driving experience. Advanced technology features enhance safety and convenience, appealing to a broad range of consumers.

Maintenance Considerations

Proper upkeep is essential to maintain the vehicle’s performance and longevity. Regular inspections and timely servicing can prevent common issues, ensuring the engine runs smoothly. Understanding the specifications and recommended practices for care can help owners maximize the lifespan and efficiency of their investment.

Common Issues with 2006 Jetta TDI

This section highlights prevalent problems that may arise with certain vehicle models from this era. Understanding these issues can aid owners in maintaining performance and ensuring longevity. Below are some frequently encountered challenges:

- Fuel System Troubles: Inadequate fuel delivery can lead to stalling or reduced acceleration. Regular checks of the fuel filter and pump are essential.

- Electrical Failures: Malfunctions in the electrical system may cause dashboard lights to illuminate unexpectedly or accessories to fail. It’s advisable to inspect wiring and fuses periodically.

- Transmission Concerns: Issues with shifting or slipping gears can occur, indicating a need for fluid replacement or system inspection.

- Cooling System Problems: Overheating can result from a malfunctioning thermostat or coolant leaks, which should be addressed promptly to avoid engine damage.

- Exhaust Emissions: Failing emission systems may lead to increased pollution and failed inspections. Regular maintenance can help identify issues early.

- Brake Wear: Premature wear on brake pads and rotors can affect stopping power. Regular checks and timely replacements are crucial for safety.

Addressing these common concerns proactively can enhance reliability and enhance the overall driving experience.

Essential Maintenance Tips for Owners

Proper upkeep is vital for ensuring the longevity and reliability of your vehicle. By adhering to a systematic maintenance routine, you can enhance performance and reduce the likelihood of unexpected issues. This section outlines crucial practices that every owner should incorporate into their regular schedule.

Regular Fluid Checks

Monitoring fluid levels is a fundamental aspect of vehicle care. Regularly check engine oil, coolant, transmission fluid, and brake fluid to maintain optimal performance. Top off any low levels and consider replacing fluids as recommended in your vehicle’s guidelines to avoid potential damage.

Scheduled Inspections

Conducting routine inspections can help identify problems early on. Pay attention to brakes, tires, and belts, as these components wear over time. Following a recommended timeline for professional assessments can save you from costly repairs down the road.

Step-by-Step Repair Procedures

This section offers a comprehensive guide to systematically address various maintenance tasks and troubleshoot common issues. By following the outlined sequences, individuals can ensure effective outcomes while enhancing their understanding of vehicle components and systems.

Begin by preparing the necessary tools and equipment. Gather all essential items to streamline the process and minimize interruptions. Ensure that the workspace is clean and organized, allowing for easy access to tools and parts.

Next, consult the vehicle’s specifications. Understanding the specific parameters will guide the entire procedure and assist in identifying appropriate parts or adjustments. Familiarize yourself with the engine layout and component locations to facilitate efficient work.

Proceed with the disassembly of relevant components. Carefully remove parts while taking note of their arrangement. Utilize storage solutions, such as labeled containers, to keep track of screws and small items, preventing any loss during reassembly.

Inspect all parts thoroughly. Look for signs of wear, damage, or malfunction. This evaluation is crucial for determining whether components need replacement or repair, ultimately influencing the overall effectiveness of the service performed.

Follow up with the reinstallation process. Ensure that all parts are fitted correctly and securely, adhering to the manufacturer’s guidelines. Double-check connections and fastenings to maintain vehicle integrity and safety.

Finally, conduct a comprehensive test. After completing the tasks, it’s essential to evaluate the vehicle’s performance. Listen for any unusual sounds and monitor for leaks or irregularities. This final step confirms the success of the procedures undertaken and ensures the vehicle operates optimally.

Tools Needed for Effective Repairs

Having the right equipment is essential for achieving successful outcomes during maintenance and troubleshooting tasks. This section outlines the necessary instruments that ensure efficiency and precision, contributing to overall performance and longevity.

First and foremost, a comprehensive set of hand tools is crucial. Wrenches and screwdrivers in various sizes enable you to tackle a wide range of components effectively. Additionally, a socket set will provide the versatility needed for different fasteners.

Moreover, utilizing specialized instruments can greatly enhance the process. Torque wrenches ensure that bolts are tightened to the correct specifications, preventing potential damage. A multimeter is invaluable for diagnosing electrical issues, allowing for precise measurements of voltage and resistance.

Finally, investing in quality safety gear, such as gloves and goggles, cannot be overlooked. These items protect you from potential hazards and contribute to a safe working environment.

Understanding the Engine Components

The internal combustion engine is a complex assembly of various parts that work together to convert fuel into motion. Each component plays a crucial role in the overall efficiency and performance of the vehicle. Understanding these elements can help owners and enthusiasts appreciate the intricacies of engine functionality.

Key components include:

- Engine Block: The core structure housing the cylinders and providing support for other engine components.

- Pistons: Moving parts that convert the energy from combustion into mechanical work.

- Cylinders: Chambers where the combustion process occurs, housing the pistons.

- Crankshaft: A rotating shaft that translates the up-and-down motion of the pistons into rotational motion.

- Camshaft: Controls the opening and closing of the engine’s intake and exhaust valves.

- Timing Belt/Chain: Ensures the synchronization of the crankshaft and camshaft to maintain proper timing.

Additionally, various auxiliary systems contribute to the engine’s performance:

- Fuel System: Responsible for delivering the right amount of fuel to the combustion chamber.

- Ignition System: Produces the spark needed to ignite the fuel-air mixture.

- Cooling System: Maintains optimal operating temperature, preventing overheating.

- Lubrication System: Reduces friction between moving parts, ensuring smooth operation.

Each of these components must work harmoniously to ensure optimal performance and longevity of the engine. Regular maintenance and understanding of these parts can lead to better decision-making regarding care and upgrades.

Electrical Systems and Diagnostics

The efficient functioning of a vehicle relies heavily on its electrical framework, encompassing everything from power distribution to diagnostic capabilities. Understanding these systems is crucial for identifying issues and ensuring optimal performance. This section will delve into the fundamental aspects of electrical components, their interactions, and troubleshooting techniques.

Key Electrical Components

- Batteries: Store electrical energy and supply power to various systems.

- Alternators: Recharge the battery and power the vehicle’s electrical systems while the engine runs.

- Fuses: Protect circuits by breaking the connection in case of overload.

- Wiring Harness: Facilitate electrical connections throughout the vehicle.

Diagnostic Procedures

Accurate diagnosis of electrical issues is essential for effective resolution. Here are some common methods:

- Visual Inspection: Check for damaged wires, loose connections, or corroded terminals.

- Multimeter Testing: Measure voltage, current, and resistance to assess component functionality.

- Scan Tool Utilization: Use diagnostic equipment to retrieve fault codes and analyze system performance.

By mastering these elements, vehicle owners and technicians can enhance reliability and extend the lifespan of their automobiles.

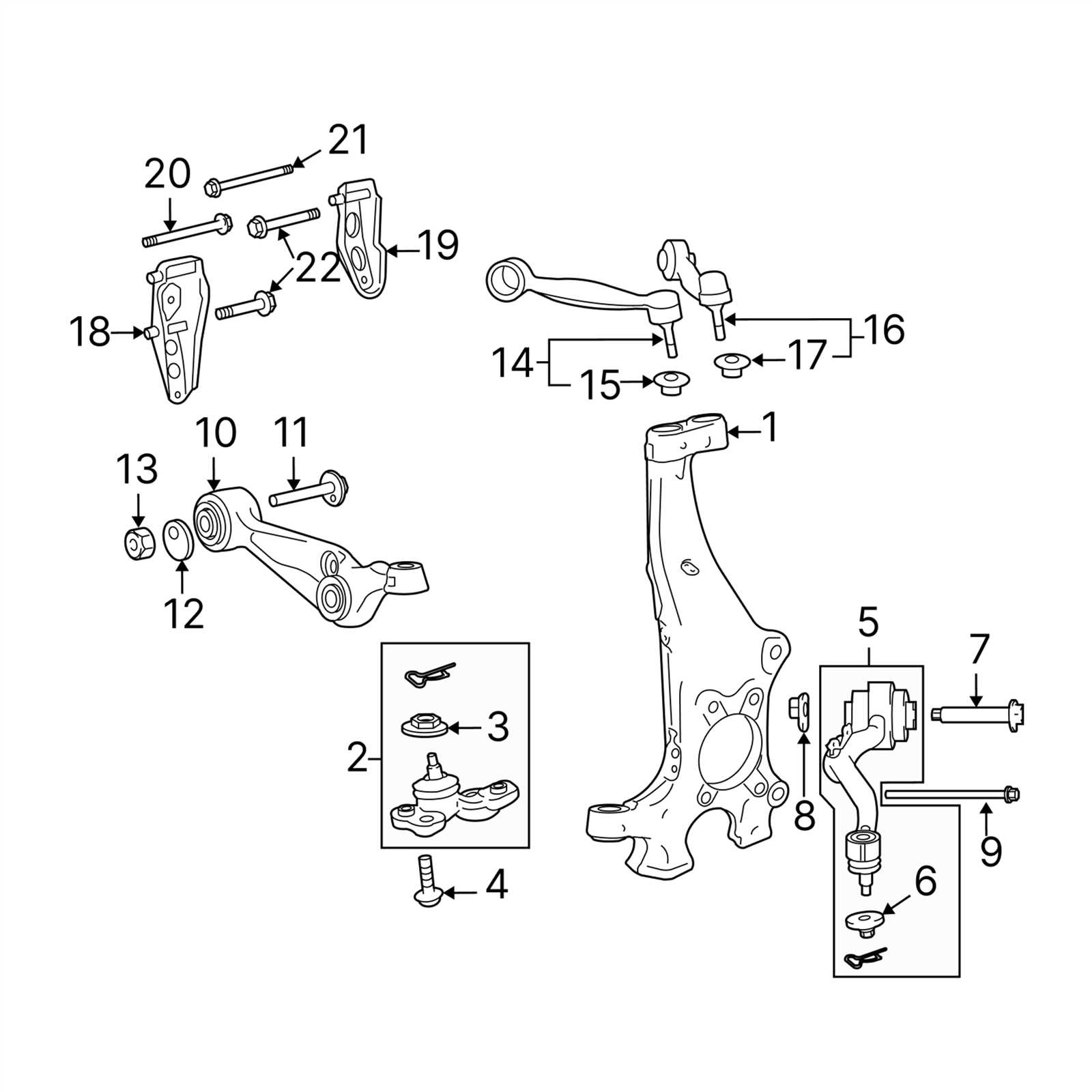

Suspension and Steering Maintenance

Proper upkeep of the suspension and steering systems is essential for ensuring optimal performance and safety in any vehicle. Regular inspections and maintenance not only enhance driving comfort but also prolong the lifespan of key components. Addressing wear and tear promptly can prevent more extensive repairs in the future.

Regular checks should include inspecting various parts such as struts, shocks, tie rods, and bushings. Maintaining correct alignment and ensuring proper fluid levels in the steering system are equally important for achieving smooth handling and stability.

| Component | Maintenance Tip | Frequency |

|---|---|---|

| Struts and Shocks | Inspect for leaks and physical damage. | Every 30,000 miles |

| Ball Joints | Check for wear and lubrication. | Every 15,000 miles |

| Tie Rods | Examine for play and corrosion. | Every 15,000 miles |

| Power Steering Fluid | Check level and top off as needed. | Every 5,000 miles |

By adhering to these maintenance practices, owners can ensure their vehicle’s suspension and steering systems remain in peak condition, providing a safe and enjoyable driving experience.

Braking System Repair Techniques

Maintaining optimal functionality in a vehicle’s deceleration mechanism is essential for safety and performance. This section will delve into methods and practices that can enhance the efficiency and reliability of this critical component.

Common Issues and Diagnostic Procedures

Identifying problems within the stopping system is the first step toward effective solutions. Below are frequent complications encountered:

- Unusual noises during operation

- Vibration or pulsation when engaging the brake

- Inconsistent braking force

- Fluid leaks from the braking assembly

To diagnose these issues, follow these steps:

- Conduct a visual inspection for any visible wear or damage.

- Test the braking response at varying speeds to evaluate performance.

- Check fluid levels and inspect for contamination.

Maintenance and Replacement Techniques

Once issues are identified, proper maintenance and part replacement are vital. Consider the following methods:

- Regularly inspect brake pads and rotors for wear and tear.

- Replace worn components with high-quality alternatives.

- Bleed the brake system to remove air pockets and ensure proper fluid pressure.

- Apply anti-seize compound to prevent corrosion on hardware.

Implementing these techniques can significantly improve the performance and lifespan of the braking system, ensuring a safer driving experience.

Replacing Fluids and Filters

Maintaining optimal performance requires regular attention to essential liquids and filtration systems. Ensuring these components are replaced at appropriate intervals helps prolong the lifespan of the vehicle and enhances its efficiency.

To achieve effective maintenance, follow these key steps:

- Gather necessary tools and materials, including new fluids, filters, and any required equipment.

- Identify the specific locations for fluid reservoirs and filter components.

The following fluids and filters should be considered for replacement:

- Engine oil and oil filter: Change regularly to ensure proper lubrication.

- Fuel filter: Replace to maintain fuel system integrity and performance.

- Air filter: Check and replace to ensure optimal airflow to the engine.

- Coolant: Inspect and refresh to prevent overheating and protect engine components.

- Transmission fluid: Monitor and replace as needed for smooth gear operation.

Always consult the vehicle’s guidelines for recommended replacement intervals and specifications to maintain peak performance.

DIY Troubleshooting for Common Problems

When encountering issues with your vehicle, understanding basic diagnostic techniques can be immensely beneficial. This section aims to provide guidance on identifying and resolving frequent malfunctions that drivers may face. By following these steps, you can efficiently address concerns without the need for professional assistance.

Identifying Engine Performance Issues

Engine-related problems are often evident through unusual sounds or decreased efficiency. Here are steps to help pinpoint the issue:

- Check for warning lights on the dashboard, which may indicate a malfunction.

- Inspect fluid levels, including oil, coolant, and fuel.

- Listen for strange noises during operation, which could suggest mechanical failure.

- Monitor for vibrations or irregular performance while driving.

Tackling Electrical System Concerns

Electrical issues can manifest as failure of lights, dashboard indicators, or other electronic components. Consider the following troubleshooting tips:

- Examine the battery terminals for corrosion and ensure a secure connection.

- Test fuses for any blown components and replace as necessary.

- Inspect wiring for signs of wear or damage that may interrupt power flow.

- Utilize a multimeter to check voltage at key electrical points in the system.