For enthusiasts of aquatic vehicles, understanding the intricacies of maintenance is crucial for ensuring optimal performance and longevity. Whether you are navigating calm lakes or tackling challenging waves, having a solid foundation in care and upkeep can enhance your experience on the water. This section aims to provide valuable insights into the essential procedures and common challenges faced by operators of personal watercraft.

Every machine requires attention, and watercraft are no exception. From engine diagnostics to routine checks, knowing the key aspects of preservation can prevent minor issues from escalating into major repairs. With the right knowledge, operators can feel confident in their ability to troubleshoot and perform necessary tasks, allowing them to enjoy their time on the water without unnecessary interruptions.

Moreover, acquiring the skills to handle maintenance tasks not only fosters a deeper connection with your vessel but also empowers you as a user. This guide will delve into various techniques and best practices, equipping you with the tools needed to ensure that your aquatic adventures remain thrilling and worry-free.

Overview of 2003 Seadoo GTX

This section provides a comprehensive look at a specific watercraft model known for its performance and reliability. Designed to deliver an exhilarating experience on the water, it combines advanced technology with user-friendly features, appealing to both enthusiasts and casual riders alike.

Key Features

The model is equipped with several standout characteristics that enhance its functionality and overall riding experience. Below is a summary of the essential features:

| Feature | Description |

|---|---|

| Engine | Powerful propulsion system designed for optimal performance and efficiency. |

| Hull Design | Aerodynamic shape that ensures stability and maneuverability in various water conditions. |

| Seating Capacity | Comfortable seating for multiple passengers, promoting a social riding experience. |

| Storage | Ample storage space to accommodate personal belongings and gear. |

Performance and Handling

Renowned for its agile handling and swift acceleration, this watercraft provides a thrilling ride. It is engineered to perform well in both calm and choppy waters, making it a versatile choice for various aquatic adventures.

Common Issues with Seadoo GTX

When operating personal watercraft, various challenges may arise that can hinder performance and safety. Understanding these frequent complications is crucial for maintaining optimal functionality and enjoying a smooth ride on the water.

Engine Troubles: One of the primary concerns owners face is engine-related problems. Symptoms such as unusual noises, stalling, or failure to start can indicate underlying issues that require attention. Regular checks of the fuel system and electrical components can prevent these situations.

Cooling System Failures: Overheating is another significant problem that can lead to severe engine damage. It’s vital to monitor the cooling system, ensuring that water intake and hoses are clear of debris. Periodic inspections can help identify leaks or blockages early on.

Electrical Malfunctions: Issues with the electrical system, including battery failures and faulty connections, can disrupt operation. Keeping connections clean and ensuring the battery is in good condition are essential preventive measures.

Wear and Tear on Components: With regular use, parts such as the impeller and pump may experience degradation. Routine maintenance, including inspections and replacements, can help extend the life of these crucial components.

Fuel System Issues: Fuel delivery problems, such as clogged filters or injector malfunctions, can severely impact performance. Regularly replacing filters and inspecting fuel lines can mitigate these risks.

Addressing these common issues proactively can lead to a more enjoyable experience on the water. Awareness and maintenance are key to preventing minor inconveniences from turning into significant repairs.

Essential Tools for Repairs

When it comes to maintaining aquatic vehicles, having the right set of instruments is crucial for effective upkeep and troubleshooting. A well-equipped toolkit not only facilitates smoother repairs but also enhances overall efficiency, ensuring that tasks are completed swiftly and accurately.

First and foremost, a quality set of wrenches is indispensable. They come in various sizes and types, allowing for the loosening and tightening of bolts and nuts found in numerous components. Additionally, screwdrivers, both flat-head and Phillips, are essential for accessing and securing various parts. These tools enable you to address minor adjustments and replacements with ease.

Another vital addition to your toolkit is a socket set, which offers versatility in dealing with different fasteners. Coupled with a ratchet, this combination can significantly reduce the time spent on more complex tasks. Pliers are also important, as they provide the grip needed for holding and manipulating small parts.

For those who might encounter electrical issues, a multimeter is an invaluable asset. This device allows for the testing of voltage, current, and resistance, helping to diagnose problems in the electrical system efficiently. Furthermore, a good quality torque wrench ensures that components are tightened to the manufacturer’s specifications, preventing future complications.

Lastly, don’t overlook safety equipment. Goggles and gloves should always be on hand to protect against debris and potential hazards during maintenance activities. By assembling a comprehensive set of tools and safety gear, you set yourself up for successful and secure operations.

Step-by-Step Maintenance Guide

Proper upkeep of your watercraft is essential for ensuring its longevity and optimal performance. Regular maintenance not only enhances reliability but also prevents potential issues from escalating into costly repairs. This guide outlines essential steps to keep your vessel in peak condition throughout the seasons.

1. Inspect the Engine: Begin by examining the engine compartment for any signs of wear or damage. Check hoses, belts, and connections for cracks or fraying. Ensuring that everything is securely attached is crucial for safe operation.

2. Change the Oil: Regular oil changes are vital for engine health. Drain the old oil and replace it with fresh lubricant, following the manufacturer’s recommended specifications. Always replace the oil filter during this process to maintain clean oil circulation.

3. Clean the Fuel System: Over time, fuel can accumulate debris that may hinder performance. Use a fuel system cleaner to remove deposits, and ensure that the fuel lines and filter are free of blockages. Regularly check the fuel level and quality to prevent issues.

4. Examine the Battery: A well-functioning battery is essential for reliable starts. Clean the terminals and ensure connections are tight. Check the electrolyte levels and recharge or replace the battery if necessary.

5. Inspect the Hull: Thoroughly check the exterior for cracks, scratches, or any signs of damage. Repair any issues promptly to prevent water infiltration. A clean hull also improves performance, so wash it regularly to remove dirt and algae.

6. Test the Safety Equipment: Verify that all safety gear, including life jackets, fire extinguishers, and signaling devices, are in good condition and easily accessible. Replace any expired items to ensure compliance with safety regulations.

7. Prepare for Storage: If not in use, proper storage is key to preserving your watercraft. Drain the fuel system, flush the engine with antifreeze, and cover it to protect against environmental elements. Regularly check on the vessel during the off-season to maintain its condition.

Following these steps will help you maintain your watercraft effectively, allowing for enjoyable and trouble-free adventures on the water.

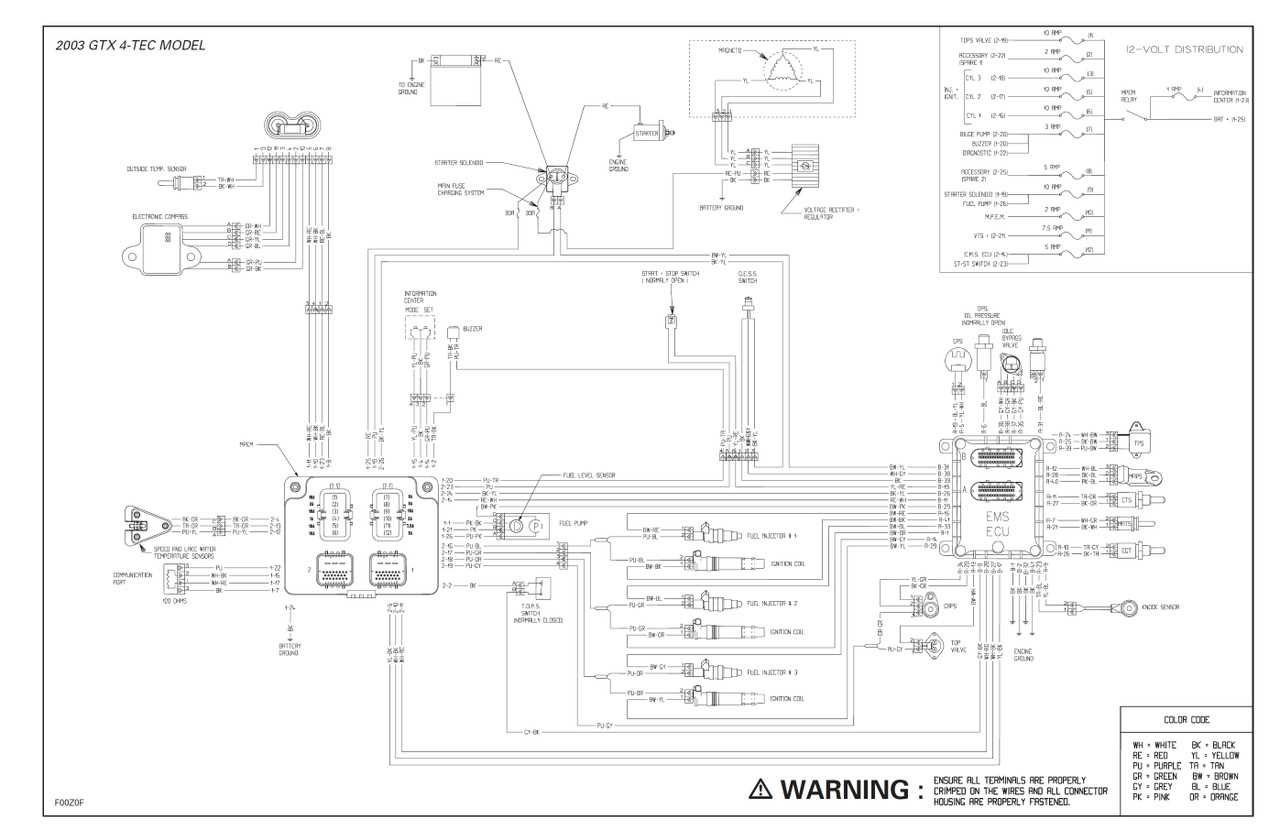

Electrical System Troubleshooting

Troubleshooting electrical components is essential for maintaining optimal performance and reliability of watercraft. Identifying issues within the electrical system can help prevent more significant failures and ensure a smooth operation on the water. This section provides a systematic approach to diagnosing and resolving common electrical problems.

Common Issues and Symptoms

- Inconsistent starting or no response when attempting to start.

- Electrical accessories not functioning properly.

- Flickering lights or gauges that are not displaying correctly.

- Unusual noises or smells indicating electrical shorts or overloads.

Troubleshooting Steps

- Check the battery voltage using a multimeter. Ensure it meets the recommended specifications.

- Inspect all wiring connections for corrosion, fraying, or loose connections.

- Test fuses and relays to determine if they are functioning correctly; replace if necessary.

- Examine the ground connections to ensure they are secure and free of rust.

- Verify the operation of switches and controls for proper function.

By systematically addressing these areas, you can effectively identify and rectify electrical issues, ensuring a safe and enjoyable experience on the water.

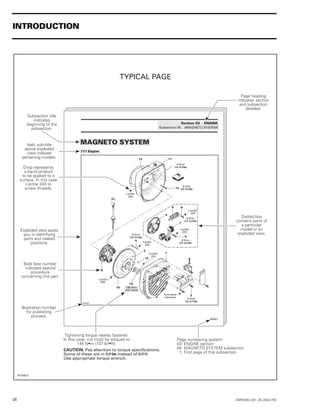

Engine Repair Techniques

Effective techniques for addressing engine issues are crucial for maintaining optimal performance and longevity. A thorough understanding of various methods allows for efficient diagnosis and resolution of common problems. This section outlines key approaches to ensure the internal workings of the powerplant remain in peak condition.

Diagnostics is the first step in the repair process. Utilizing specialized tools to assess engine performance can help identify underlying issues. Regularly monitoring parameters such as compression and fuel delivery is essential for early detection of potential failures.

Disassembly of engine components requires meticulous attention. Carefully removing parts while documenting their arrangement ensures accurate reassembly. Keeping a clean workspace minimizes the risk of contamination and damage to sensitive components.

Inspection involves scrutinizing parts for wear, cracks, or other forms of damage. Employing precise measuring tools can help evaluate tolerances and ensure each piece meets the required specifications. Replacing worn components with high-quality alternatives is vital to restore functionality.

Reassembly should follow a systematic approach, adhering to manufacturer guidelines. Proper torque specifications and sealant application prevent future leaks and failures. This step is crucial for ensuring the reliability of the engine after repairs.

Testing the engine post-repair is necessary to confirm successful interventions. Running the unit under various conditions allows for observation of performance metrics and identification of any lingering issues. Documenting results provides valuable insights for future maintenance.

In conclusion, mastering these techniques not only enhances the understanding of engine mechanics but also contributes to the longevity and efficiency of the system. Regular practice and attention to detail are key to becoming proficient in engine restoration.

Fuel System Inspection Tips

Maintaining the integrity of the fuel delivery system is crucial for optimal performance and reliability. Regular examination of this system can prevent issues that may arise from contamination, wear, or improper function. A thorough inspection ensures that the engine receives the right amount of fuel, facilitating smooth operation and longevity.

Start by visually checking the fuel lines for any signs of leaks, cracks, or deterioration. Ensure that all connections are secure and free of corrosion. Additionally, inspect the fuel filter for clogs or debris that could impede fuel flow. Replacing a dirty filter can significantly enhance engine performance.

Next, evaluate the fuel pump’s functionality. Listen for any unusual noises during operation, which could indicate potential failure. Testing the pump’s pressure with a gauge will provide insight into its performance; specifications can usually be found in relevant guidelines.

Finally, examine the fuel tank for cleanliness. Remove any sediment or water that may have accumulated at the bottom, as these contaminants can lead to engine damage. Regular maintenance and inspections of the fuel system not only enhance performance but also extend the lifespan of the entire engine.

Replacing the Impeller and Wear Ring

Maintaining optimal performance in personal watercraft requires periodic replacement of critical components, particularly the propulsion system parts. Among these, the impeller and wear ring are essential for ensuring efficient water flow and preventing damage to the engine. This section will guide you through the steps necessary to replace these components effectively.

Tools and Materials Needed

- Socket set

- Wrench set

- Screwdriver set

- Replacement impeller

- New wear ring

- Grease

- Cleaning cloth

Step-by-Step Instructions

- Begin by disconnecting the battery to ensure safety during the process.

- Remove the jet pump assembly from the watercraft. This typically involves unscrewing several bolts and carefully detaching any attached hoses.

- Once the jet pump is removed, take out the old impeller by unscrewing it from its housing.

- Inspect the wear ring for any signs of damage. If it’s worn or cracked, proceed to remove it.

- Clean the housing area thoroughly to eliminate debris and old grease.

- Install the new wear ring by pressing it into place, ensuring a snug fit.

- Attach the new impeller, ensuring it is properly aligned and securely fastened.

- Reassemble the jet pump and reattach it to the watercraft, reversing the disassembly steps.

- Reconnect the battery and perform a test run to ensure everything is functioning correctly.

Following these steps will help you maintain the efficiency of your watercraft, prolonging its lifespan and enhancing your overall riding experience.

Winterizing Your Seadoo GTX

Preparing your watercraft for the colder months is essential to ensure its longevity and optimal performance. This process involves taking specific steps to protect the internal components and exterior from the damaging effects of freezing temperatures and moisture. By properly winterizing, you can prevent costly repairs and ensure a smooth start when the warm weather returns.

Start by thoroughly cleaning the exterior and interior of the vessel to remove any dirt, debris, and contaminants. This will help prevent corrosion and other damage during the off-season. After cleaning, ensure that the fuel system is treated with a stabilizer to keep the fuel fresh and prevent gumming or varnishing.

Next, it’s crucial to drain any water from the engine and cooling system. This can be done by running the engine for a short period while ensuring that the water intake is above the surface. Afterward, add antifreeze to the cooling system to protect it from freezing. Don’t forget to lubricate all moving parts and check the battery; storing it in a warm place will extend its life.

Finally, cover your vessel with a breathable tarp or cover designed for this purpose to shield it from dust and moisture. Taking these steps will ensure that your craft remains in excellent condition and is ready for use when the boating season begins again.

Where to Find Replacement Parts

Locating suitable components for your watercraft can be a straightforward process if you know where to look. Whether you are aiming for original equipment or aftermarket options, several resources are available to help you find what you need efficiently.

Online marketplaces and specialized retailers often provide a wide range of parts. Additionally, local shops and forums can offer valuable insights and recommendations. Below is a table summarizing the most effective sources for replacement components:

| Source | Description |

|---|---|

| Online Retailers | Websites specializing in marine parts often have extensive inventories and competitive prices. |

| Manufacturer Websites | Directly visiting the manufacturer’s site can ensure you find original parts designed specifically for your model. |

| Local Dealerships | Authorized dealers can provide parts and expert advice, though prices may be higher. |

| Marine Salvage Yards | These facilities often have used components at lower prices, which can be a cost-effective option. |

| Online Forums and Communities | Engaging with fellow enthusiasts can lead to tips on sourcing parts and recommendations on reliable suppliers. |