For owners of classic vehicles, understanding the intricacies of upkeep and addressing technical challenges is essential to preserving functionality and longevity. Maintaining an older model demands attention to detail and knowledge of common mechanical areas that may require careful adjustments or replacement parts over time. With the right approach, even older vehicles can perform reliably and efficiently.

This guide provides insights into fundamental upkeep techniques, offering clarity on system maintenance and step-by-step guidance to help you diagnose potential issues with confidence. By exploring key areas like engine components, electrical configurations, and bodywork integrity, enthusiasts can gain a deeper understanding of how each part works together to deliver optimal performance.

From foundational checks to more advanced troubleshooting, this guide aims to equip you with the tools and knowledge needed to maintain your classic vehicle in excellent condition. Emphasizing practical solutions, it seeks to empower drivers with the confidence to handle mechanical challenges and enhance their vehicle’s lifespan.

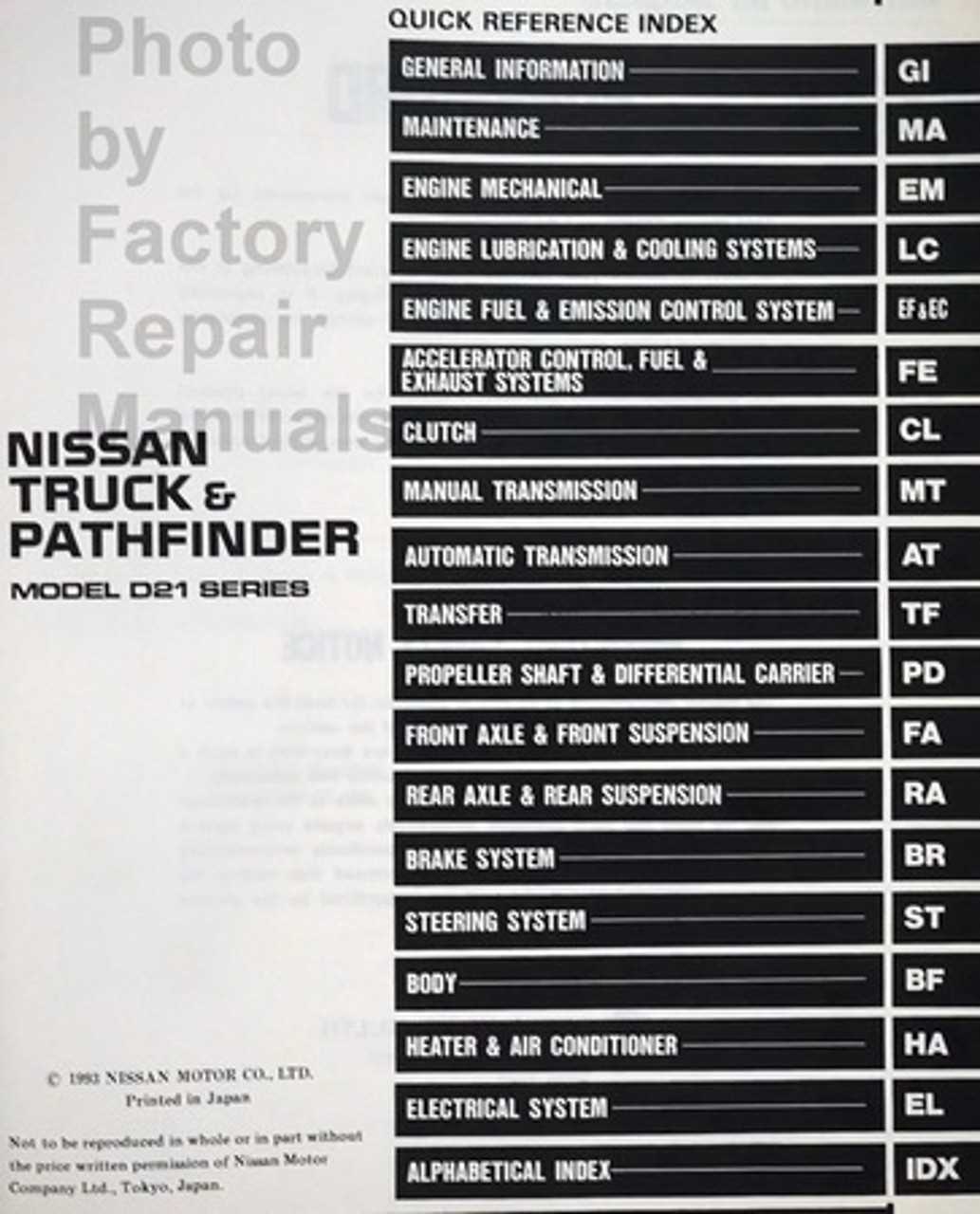

Nissan D21 Repair Guide

This section provides a comprehensive approach to the upkeep and servicing procedures required for a dependable and long-lasting operation of this vehicle type. Here, you’ll find instructions on handling key components to maintain performance and reliability on the road.

Engine Maintenance Essentials

To ensure optimal operation of your vehicle’s engine, regular upkeep is essential. This involves consistent checks and adjustments to the various mechanical elements, including the cooling, lubrication, and fuel systems. Routine inspections help in identifying any early signs of wear, minimizing the chance of unexpected breakdowns.

| Maintenance Task | Recommended Interval |

|---|---|

| Oil Change | Every 3,000 miles |

| Coolant Level Check | Monthly |

| Spark Plug Replacement | Every 12,000 miles |

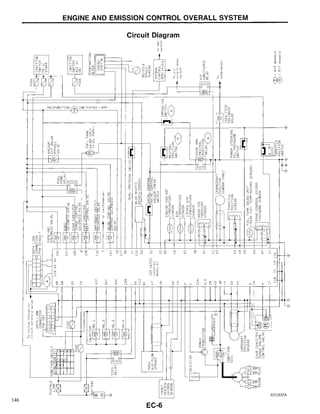

Electrical System Care

The electrical framework is a critical aspect of your vehicle, influencing everything from ignition to lighting. Regularly inspecting the wiring and battery connections ensures these components remain in top shape, reducing the likelihood of

Understanding Nissan D21 Engine Components

The engine system in this model is composed of various integral parts that work together to deliver efficient and consistent power. Each component plays a unique role in ensuring smooth operation and longevity of the vehicle’s performance. This section covers essential elements, helping owners and mechanics gain a deeper appreciation of their interrelated functions and maintenance needs.

Key Parts of the Engine System

Understanding the principal elements of the engine system provides insight into how power is generated and maintained. From the ignition to the exhaust, each component has a distinct purpose, forming a chain of processes that sustains vehicle functionality. Here is a breakdown of key components:

| Component | Description | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cylinder Block | The foundation of the engine, housing the cylinders where fuel combustion occurs, generating power. | ||||||||||||||

| Cylinder Head | Sits atop the cylinder block, containing passages for air and fuel and houses valves and spark plugs. | ||||||||||||||

| Pistons | Move within the cylinders to compress fuel and air, aiding in the combustion process and transferring energy. | ||||||||||||||

| Crankshaft | Converts the pistons’ linear movement into rotational energy, which powers the vehicle. |

| Component | Inspection Notes |

|---|

| Technique | Description |

|---|---|

| Body Repair | Fixing dents, scratches, and rust to restore the original shape and finish of the vehicle. |

| Paint Restoration | Polishing, buffing, or repainting to rejuvenate the exterior surface and protect against future damage. |

| Upholstery Repair | Replacing or reupholstering seats and interior panels to ensure comfort and visual appeal. |

| Dashboard Restoration | Refurbishing or replacing the dashboard components to restore functionality and aesthetics. |

| Trim and Molding Replacement | Replacing worn or damaged trim and moldings to enhance the overall interior look. |