The process of restoring a vehicle to its optimal condition involves a series of meticulous steps aimed at ensuring both functionality and aesthetics. This segment provides essential insights into techniques and considerations necessary for effectively addressing any form of exterior damage.

Understanding the components and structure of an automobile is crucial for anyone involved in enhancement tasks. By familiarizing oneself with various parts, one can better assess the specific needs of a vehicle, leading to more informed decisions during the restoration process.

Moreover, utilizing appropriate tools and methods is vital to achieving satisfactory results. With a focus on practical guidance, this section emphasizes best practices, ensuring that each action taken contributes positively to the overall rejuvenation of the vehicle.

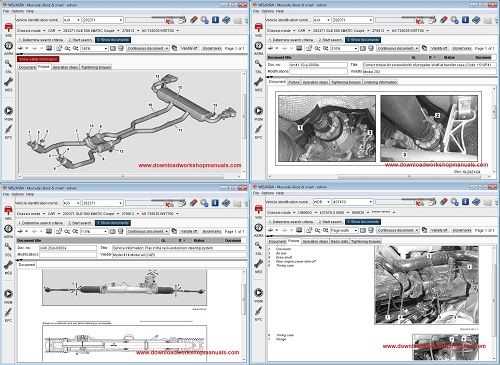

Essential Tools for Body Repairs

When it comes to restoring and maintaining vehicle exteriors, having the right equipment is crucial. The tools used in this process can significantly affect the quality of the work and the efficiency of the repairs. From simple hand tools to specialized devices, a well-equipped workshop is essential for achieving professional results.

Fundamental Equipment

A variety of basic implements are indispensable for any restoration task. Commonly used items include wrenches, hammers, and pliers. These tools facilitate the manipulation of components and ensure that everything is securely fastened. Additionally, measuring devices are necessary for precise alignment and fit during the restoration process.

Advanced Instruments

For more intricate tasks, advanced machinery plays a vital role. Tools such as pneumatic sanders, welding machines, and paint sprayers are essential for finishing touches. These instruments not only enhance the aesthetic appeal but also ensure durability and protection against environmental factors. Proper training in using these tools is equally important to maximize their potential.

Understanding Mercedes Body Components

In the realm of automotive design, the various structures and elements that make up a vehicle are crucial for both aesthetics and functionality. Each part plays a significant role in ensuring safety, performance, and visual appeal, contributing to the overall integrity of the vehicle.

Main Structural Elements

The primary frameworks of a vehicle are engineered to withstand various forces while providing a solid foundation for all other components. Understanding these foundational elements helps in recognizing their importance in the vehicle’s longevity and performance.

Exterior Features

The outer components not only enhance the visual attractiveness of a vehicle but also serve essential purposes such as aerodynamics and protection against environmental elements. Each feature is designed with both form and function in mind, contributing to the overall driving experience.

| Component | Function | Importance |

|---|---|---|

| Chassis | Support and frame for the vehicle | Ensures stability and safety |

| Fenders | Protect wheels and enhance aerodynamics | Reduce drag and improve efficiency |

| Bumpers | Absorb impacts and protect vital components | Critical for safety during collisions |

| Hoods | Cover the engine compartment | Protect engine and improve airflow |

Common Damage Types and Solutions

Understanding the various forms of damage that vehicles can sustain is crucial for effective maintenance and restoration. This section outlines typical issues encountered and suggests appropriate methods for addressing them, ensuring optimal functionality and aesthetics.

Types of Common Damage

- Dents and Dings: Often caused by minor collisions or hail, these imperfections can detract from the vehicle’s appearance.

- Scratches: Surface abrasions from everyday use or accidents can lead to rust if left untreated.

- Corrosion: Rusting can occur in areas exposed to moisture, particularly in older models.

- Frame Damage: More serious issues resulting from major collisions that can affect the vehicle’s alignment and safety.

Suggested Solutions

- Paintless Dent Removal: An effective method for minor dents that preserves the original paint finish.

- Touch-Up Paint: Useful for addressing small scratches, preventing further damage.

- Rust Treatment: Involves removing rust and applying protective coatings to prevent recurrence.

- Frame Straightening: A specialized process that realigns the structure to restore safety and performance.

Techniques for Straightening Panels

Restoring the shape of damaged surfaces requires a blend of skill and appropriate tools. This process often involves methods that manipulate the material back to its original contour, ensuring structural integrity and visual appeal. Understanding various techniques can greatly enhance the effectiveness of the repair process.

Heat Treatment Method

Utilizing controlled heat can facilitate the reshaping of metal components. By applying heat to specific areas, the metal becomes malleable, allowing for careful adjustments. It is crucial to monitor temperatures to avoid compromising the material’s strength. Once the desired shape is achieved, the area should be cooled rapidly to set the new form.

Hammer and Dolly Technique

This traditional approach employs a combination of a hammer and a backing tool, known as a dolly. The hammer is used to tap the damaged area while the dolly supports the reverse side, promoting even pressure. This method is particularly effective for minor dents and requires precision to avoid further distortion.

Choosing the Right Paint Products

When it comes to achieving a flawless finish, selecting the appropriate coating materials is crucial. Various factors, such as the type of surface, desired durability, and environmental conditions, play a significant role in this decision-making process.

Types of Paints: There are several varieties of coatings available, including acrylic, enamel, and polyurethane. Each type offers unique characteristics that can affect adhesion, gloss, and resistance to wear. It is essential to evaluate the specific requirements of your project to determine which option will yield the best results.

Compatibility: Ensure that the chosen products are compatible with the underlying material. Using the wrong type can lead to poor adhesion and may result in peeling or chipping over time. Always consult the manufacturer’s guidelines for compatibility information.

Finishing Touches: The application technique can also influence the final appearance. Spraying may provide a smoother finish compared to brushing, but it requires more skill and equipment. Consider the method that aligns with your experience and desired outcome.

By taking the time to research and select the right coating products, you can enhance the longevity and aesthetic appeal of your project.

Preparation for Painting Surfaces

Achieving a flawless finish requires meticulous preparation of the surfaces involved. This process ensures that the paint adheres properly and lasts for an extended period. Properly preparing the area not only enhances the visual appeal but also contributes to the durability of the final coating.

Cleaning and Degreasing

The first step involves thoroughly cleaning the surfaces to remove any dirt, grease, or contaminants. Utilizing a suitable cleaner ensures that all residues are eliminated, providing a pristine foundation for painting. Following this, rinsing and drying the area is crucial to prevent any moisture from interfering with the adhesion of the coating.

Sanding and Priming

Next, sanding the surface helps to create a rough texture, promoting better bonding between the paint and the substrate. After sanding, applying a primer is essential, as it acts as a barrier and enhances the overall finish. This primer layer not only improves adhesion but also prevents any underlying materials from affecting the appearance of the topcoat.

Safety Precautions During Repairs

Ensuring a safe environment is crucial when undertaking maintenance or restoration tasks. Proper safety measures help prevent accidents and injuries, allowing for efficient work on vehicles.

- Always wear appropriate personal protective equipment (PPE), such as gloves, goggles, and steel-toed boots.

- Ensure the workspace is well-ventilated to avoid inhaling harmful fumes or dust.

- Use proper lifting equipment to avoid injuries when raising vehicles for access.

- Keep a fire extinguisher nearby, especially when working with flammable materials.

- Maintain a clean and organized workspace to minimize trip hazards and maintain focus.

Prioritizing these precautions can significantly enhance safety and effectiveness during maintenance tasks, leading to successful outcomes.

Maintenance of Repair Equipment

Proper upkeep of tools and machinery is crucial for ensuring optimal performance and longevity. Regular maintenance not only enhances efficiency but also minimizes the risk of unexpected breakdowns. Establishing a routine inspection schedule can help identify potential issues before they escalate, allowing for timely interventions.

Routine cleaning of equipment prevents the accumulation of debris and contaminants that can interfere with functionality. Lubricating moving parts reduces friction and wear, ensuring smoother operation. Additionally, replacing worn components promptly is essential to maintain the reliability and safety of the equipment.

Keeping an organized workspace is equally important. A clutter-free environment enables easier access to tools and promotes efficient workflows. Implementing proper storage solutions for equipment helps protect it from damage and preserves its condition for future use.

Tips for Professional Finishing Touches

Achieving a polished look in automotive restoration requires attention to detail and the right techniques. Finishing touches can greatly enhance the overall appearance and longevity of the vehicle, ensuring that the work done stands the test of time.

- Surface Preparation: Properly prepare surfaces before applying any coatings. Sanding and cleaning are crucial steps to ensure good adhesion and a smooth finish.

- Quality Materials: Invest in high-quality paints and sealants. These products provide better durability and a more professional look compared to cheaper alternatives.

- Techniques for Application: Use spray techniques for an even coat. Practice proper distance and angle to avoid runs and uneven spots.

- Layering: Apply multiple thin layers instead of one thick coat. This helps achieve a smoother finish and reduces the risk of drips.

- Buffing and Polishing: After the paint has cured, buffing and polishing the surface can bring out a brilliant shine. Use appropriate tools and compounds for the best results.

- Inspect for Imperfections: After finishing, inspect the work closely for any imperfections. Touch up as necessary to maintain a flawless appearance.

By following these guidelines, one can achieve results that not only look professional but also provide lasting protection and aesthetic appeal.

Evaluating Repair Costs Effectively

Assessing the expenses associated with vehicle restoration can be a complex task. Understanding various factors that influence pricing is essential for making informed decisions.

- Parts Quality: The choice between original and aftermarket components can significantly impact total costs.

- Labor Rates: Different service providers have varying hourly charges, which can affect overall pricing.

- Extent of Damage: Evaluating how much work is needed will provide a clearer picture of potential expenses.

To ensure a comprehensive understanding of financial requirements, consider obtaining multiple estimates from different service centers. This allows for comparison and can highlight areas where savings may be achievable.

Additionally, incorporating preventative measures can reduce future costs. Regular maintenance helps avoid extensive repairs down the line.