The pursuit of effective vehicle maintenance is a crucial aspect of ensuring longevity and optimal performance. Accessing comprehensive documentation can significantly aid individuals in troubleshooting and resolving issues that may arise during the lifecycle of a vehicle. This section serves as a valuable resource, designed to equip readers with the necessary knowledge and skills to address common challenges.

Within this framework, users will discover a wealth of information covering various aspects of vehicle care. From step-by-step instructions to detailed explanations of complex systems, the content is curated to foster a deeper understanding of automotive functionalities. By empowering individuals with this expertise, we aim to enhance their confidence in handling repairs and enhancements.

Moreover, this collection of insights emphasizes the importance of preventative measures. Engaging with these materials not only helps in rectifying existing problems but also encourages proactive approaches to vehicle upkeep. Embracing this knowledge ultimately leads to a more satisfying and trouble-free driving experience.

Kiatechinfo Com Repair Manual

This section provides a comprehensive guide designed to assist users in troubleshooting and maintaining their vehicles. It aims to facilitate a deeper understanding of the various systems and components, enabling effective solutions to common issues. The resource is essential for both enthusiasts and professionals seeking reliable information.

Accessing the Resource

Utilizing the Information

Implementing the guidelines found within this platform can significantly enhance the efficiency of vehicle upkeep. By following the suggested procedures, users can confidently address problems and perform necessary adjustments, ultimately leading to better performance and longevity.

Understanding Repair Manuals

Documentation for vehicle maintenance and troubleshooting serves as an essential resource for both professionals and enthusiasts. It provides comprehensive insights into the intricacies of automotive systems, guiding users through various procedures and specifications. Such resources not only enhance knowledge but also facilitate effective problem-solving strategies.

Components of Maintenance Documentation

These resources typically encompass several key elements that aid users in their endeavors:

| Element | Description |

|---|---|

| Specifications | Detailed information regarding the technical aspects and requirements of the vehicle. |

| Troubleshooting Guides | Step-by-step instructions to identify and resolve common issues. |

| Diagrams | Visual aids that illustrate the layout and components of systems, enhancing comprehension. |

| Service Procedures | Detailed methods for performing maintenance tasks effectively and safely. |

The Importance of Accessing Accurate Resources

Utilizing reliable documentation not only streamlines the maintenance process but also reduces the risk of errors. Accurate resources empower users to make informed decisions, ensuring that all aspects of the vehicle are addressed appropriately. This leads to improved performance, safety, and longevity of the automobile.

Accessing Online Resources

In today’s digital age, obtaining information and support for automotive needs has become more accessible than ever. Various platforms provide users with a wealth of resources, enabling them to troubleshoot issues and enhance their knowledge about vehicle systems. These online tools serve as invaluable assets for both novice and experienced individuals seeking guidance.

To effectively navigate these platforms, users should be familiar with the types of resources available. Below is a table outlining common online resources that can assist in understanding and resolving automotive challenges:

| Resource Type | Description |

|---|---|

| Forums | Community-driven platforms where enthusiasts share experiences and solutions. |

| Tutorials | Step-by-step guides that help users perform specific tasks or repairs. |

| Videos | Visual content demonstrating procedures and techniques related to vehicle maintenance. |

| Technical Specifications | Detailed information regarding components and systems, aiding in accurate diagnostics. |

| Software Tools | Applications designed to assist in diagnostics and repairs through data analysis. |

By exploring these resources, individuals can enhance their understanding and effectively address various automotive issues. Engaging with online communities and utilizing available tools can lead to improved outcomes and greater confidence in handling vehicle maintenance tasks.

Types of Repair Documentation

The documentation related to vehicle maintenance and troubleshooting is essential for ensuring efficient and effective service. These resources serve as guides for technicians, providing vital information on various procedures, specifications, and diagnostics required for proper upkeep. Understanding the different types of such literature can enhance the overall repair process, leading to improved performance and longevity of vehicles.

Service Guides

Service guides are comprehensive resources that outline the step-by-step processes for performing specific tasks. They often include detailed illustrations, technical specifications, and recommended tools, making them invaluable for both novice and experienced technicians. These guides are designed to cover a wide range of maintenance activities, from basic inspections to complex overhauls.

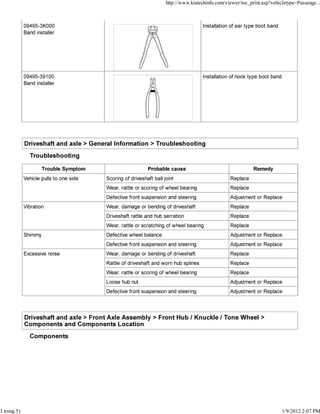

Diagnostic Manuals

Diagnostic manuals focus on troubleshooting and identifying issues within a vehicle’s systems. They provide systematic approaches to diagnosing problems, often featuring flowcharts and error code explanations. These documents help technicians efficiently pinpoint malfunctions, enabling quicker resolutions and minimizing downtime for the vehicle.

Common Repair Procedures Explained

This section delves into various typical methods employed for addressing vehicle issues, providing insights into standard techniques that technicians utilize. Understanding these processes can greatly enhance the ability to diagnose and resolve problems effectively.

One of the most frequently applied methods involves the systematic inspection of components. This approach ensures that all potential sources of malfunction are evaluated, facilitating accurate identification of faults. Additionally, employing diagnostic tools can aid in pinpointing specific areas requiring attention, streamlining the overall assessment.

Another prevalent technique is the replacement of faulty parts. This often includes sourcing high-quality components to ensure durability and performance. Proper installation procedures must be adhered to, as incorrect fittings can lead to further complications.

Maintenance checks also play a crucial role in preserving vehicle integrity. Regular servicing helps prevent minor issues from escalating into major concerns, ultimately prolonging the lifespan of various systems within the vehicle.

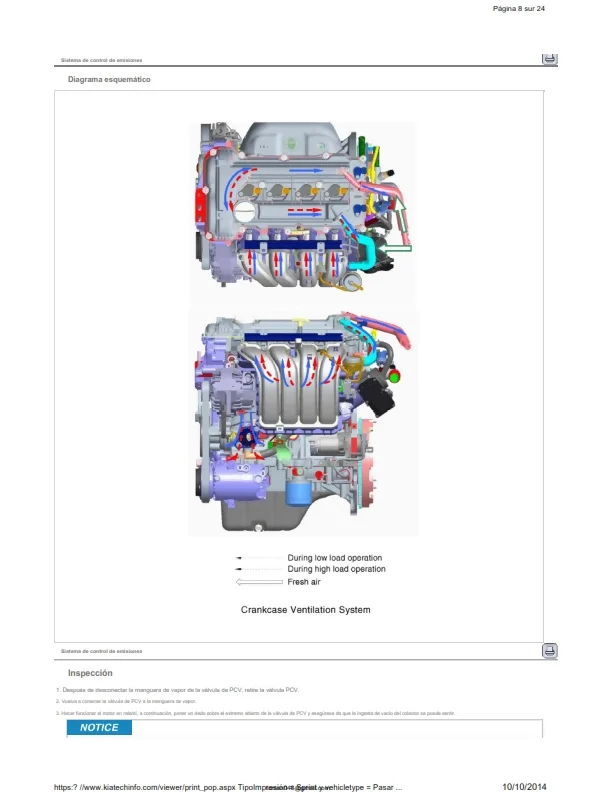

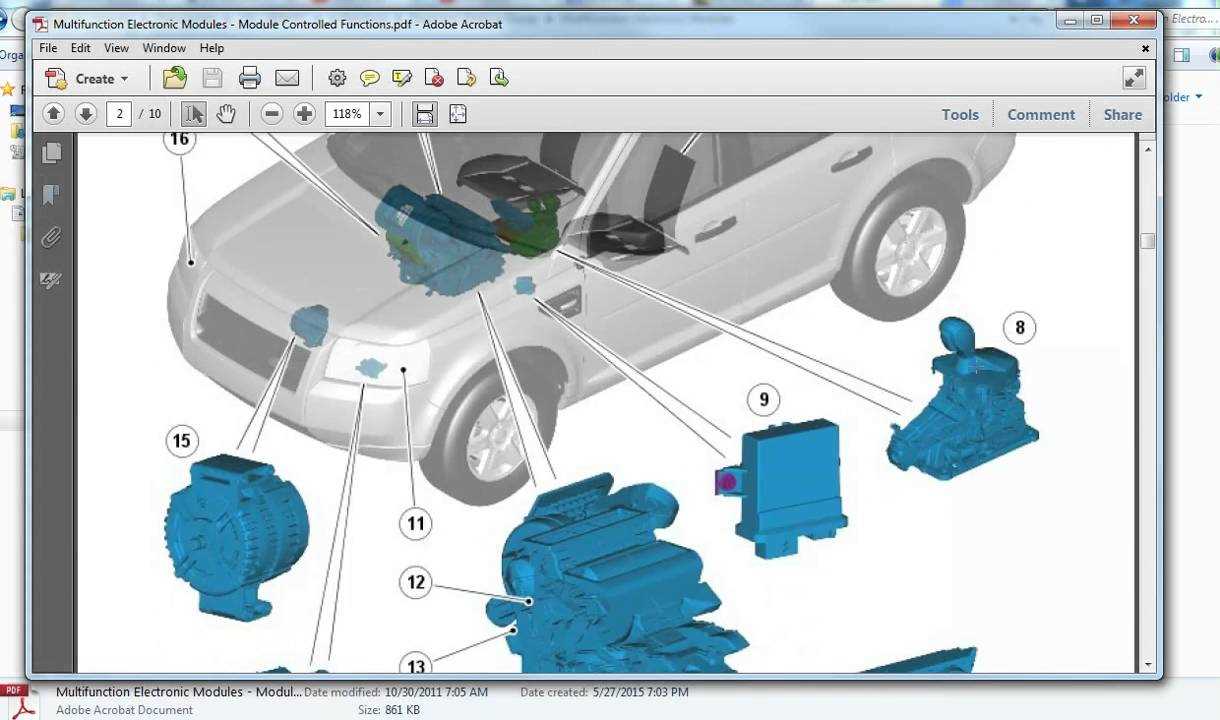

Navigating Technical Diagrams

Understanding intricate illustrations is crucial for anyone working in the field of maintenance and diagnostics. These graphical representations provide essential information about systems and components, allowing users to identify relationships and workflows effectively. Mastering the art of interpreting these visuals can greatly enhance problem-solving capabilities.

Familiarity with common symbols and conventions is vital. Each diagram typically employs standardized icons that represent various elements, such as connectors, circuits, or mechanical parts. By becoming accustomed to these symbols, individuals can quickly ascertain the purpose and function of each component within the diagram.

Additionally, following a logical path through the illustration is necessary. Many diagrams are organized in a sequential manner, guiding users from one element to another. Paying attention to directional arrows and numbering can facilitate a smoother navigation experience, ensuring that no critical detail is overlooked.

Moreover, utilizing color coding can further enhance comprehension. Different hues often indicate various statuses or types of connections, making it easier to differentiate between elements at a glance. This practice not only saves time but also minimizes the risk of errors during analysis.

Lastly, contextual knowledge of the system being depicted is beneficial. Understanding how components interact within a broader framework can provide deeper insights, enabling users to draw connections between the diagram and real-world applications. This holistic approach to navigating illustrations can significantly boost efficiency in troubleshooting and assembly tasks.

Identifying Tools and Equipment

Understanding the necessary instruments and apparatus for efficient maintenance tasks is crucial. Each task requires specific items that ensure precision and safety. Familiarizing oneself with these essentials can streamline the workflow and enhance the quality of the outcome.

Essential Hand Tools

Hand tools play a vital role in performing various tasks. Common items include wrenches, screwdrivers, pliers, and hammers. Each tool serves a unique purpose, making it imperative to select the right one based on the job at hand. For example, adjustable wrenches can accommodate different sizes of fasteners, while a Phillips screwdriver is specifically designed for cross-shaped screws.

Power Equipment

Power tools significantly improve efficiency and effectiveness in various tasks. Equipment such as drills, saws, and grinders allows for faster completion and more intricate work. It is essential to choose tools that match the requirements of the task, considering factors like power source, size, and functionality. Proper maintenance and safety measures must also be observed when using power equipment to prevent accidents and ensure longevity.

Safety Precautions During Repairs

When undertaking any maintenance or restoration work, prioritizing safety is essential to ensure a secure environment for both the individual performing the task and the equipment involved. Adhering to proper safety measures can help prevent accidents and injuries while extending the lifespan of tools and machinery.

Essential Safety Guidelines

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and masks, to safeguard against hazardous materials.

- Ensure the workspace is clean and organized, minimizing clutter to reduce the risk of slips, trips, and falls.

- Disconnect power sources before beginning any work to prevent electric shock or accidental activation of machinery.

- Use tools that are in good condition and suitable for the task at hand; avoid makeshift or damaged equipment.

- Follow all manufacturer instructions and guidelines to prevent misuse or misunderstanding of equipment.

Emergency Preparedness

- Keep a first aid kit readily accessible and ensure all individuals are aware of its location.

- Familiarize yourself with emergency procedures, including how to handle electrical shocks, chemical spills, or equipment failures.

- Maintain communication with others in the area to ensure support in case of an incident.

Troubleshooting Common Issues

Addressing frequent challenges in vehicle performance can enhance the driving experience and ensure longevity. This section outlines typical problems and effective strategies for resolving them, empowering users to tackle issues with confidence.

Below are some common concerns and suggested solutions:

- Engine Performance:

- Check for any unusual noises that may indicate mechanical failures.

- Inspect fluid levels and replace filters regularly to maintain optimal function.

- Electrical Systems:

- Verify that all connections are secure and free of corrosion.

- Test the battery and alternator to ensure adequate power supply.

- Braking Issues:

- Listen for squeaking or grinding sounds when applying brakes.

- Examine brake pads and discs for wear and replace if necessary.

- Transmission Problems:

- Check for fluid leaks and ensure the transmission fluid is at the correct level.

- Monitor shifting patterns for smooth transitions; address any delays.

By systematically addressing these common issues, vehicle owners can maintain better control over their automobiles and enjoy a more reliable driving experience.

Maintenance Tips for Longevity

Ensuring the extended lifespan of any vehicle involves consistent care and attention to various components. By following a systematic approach to upkeep, owners can avoid premature wear and enhance performance. Here are some essential strategies to consider for optimal longevity.

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Oil Change | Every 5,000 miles | Reduces engine wear and improves efficiency |

| Tire Rotation | Every 6,000 miles | Ensures even wear and extends tire life |

| Brake Inspection | Every 12,000 miles | Enhances safety and prevents costly repairs |

| Fluid Levels Check | Monthly | Prevents overheating and maintains performance |

| Battery Maintenance | Every 3 months | Ensures reliable starts and electrical system health |

Implementing these practices not only preserves the vehicle’s functionality but also contributes to a safer driving experience. Regular attention to these aspects is key to enjoying a reliable and enduring vehicle.

Using Forums for Assistance

Online discussion platforms provide a valuable resource for individuals seeking guidance and support for various issues. Engaging with a community of knowledgeable enthusiasts and professionals can enhance problem-solving efforts and offer new perspectives. These platforms facilitate the sharing of experiences, tips, and solutions, making them an essential tool for anyone looking to navigate challenges.

Many users turn to these platforms to ask questions or clarify doubts. By posting specific queries, individuals can tap into the collective expertise of the community. Active participation not only fosters a sense of camaraderie but also leads to quicker and more effective resolutions.

Additionally, forums often host a wealth of archived discussions. This repository of information allows users to search for similar issues and read through previous solutions. Browsing through past threads can save time and provide insights that may not be immediately apparent in new conversations.

Finally, contributing to these discussions can also enhance one’s own understanding. By sharing personal experiences or solutions, users not only help others but reinforce their own knowledge. Active involvement in community forums cultivates a collaborative environment that benefits everyone involved.

Upgrading Components Effectively

Enhancing various elements of a system can significantly boost performance and longevity. When executed thoughtfully, these improvements can lead to better functionality and efficiency. This process involves assessing current capabilities, selecting appropriate replacements, and implementing them seamlessly to achieve optimal results.

Assessment and Planning

Before initiating any upgrades, it is crucial to evaluate the existing components. Identifying strengths and weaknesses will guide your selection of new parts. Consider the following factors:

| Component | Current Status | Upgrade Potential |

|---|---|---|

| Processor | Average performance | High |

| Memory | Insufficient | Very High |

| Storage | Slower speed | High |

Implementation Tips

Once you have identified the components to upgrade, proceed with care. Ensure compatibility with the existing system and follow best practices during installation. Proper handling and configuration are essential to avoid issues that may arise from new components. Testing the system post-upgrade will confirm that the enhancements are functioning as intended.

Evaluating Repair Costs

Determining the expenses associated with vehicle restoration involves a comprehensive approach that considers various factors. Understanding the potential financial implications is crucial for making informed decisions and budgeting effectively. By assessing both direct and indirect costs, individuals can better prepare for necessary interventions.

Initial Estimates play a significant role in the evaluation process. It is essential to gather preliminary quotes from multiple service providers to establish a baseline for anticipated expenditures. These estimates should encompass labor, parts, and any additional services required to complete the task.

Another critical aspect is comparing parts prices. Costs can vary widely based on whether original components or aftermarket alternatives are chosen. Researching prices from different suppliers can lead to significant savings without compromising quality.

Labor Costs should not be overlooked. Different technicians and facilities may charge varying rates, which can impact the overall price. Additionally, understanding the time required for specific jobs helps in calculating labor expenses accurately.

Finally, it is wise to consider potential unexpected costs. Even with thorough assessments, unforeseen issues may arise during the process. Setting aside a contingency budget can alleviate financial strain if additional work becomes necessary.