Understanding the intricacies of automotive upkeep is essential for any car enthusiast or owner. This section serves as a valuable resource, providing insights into the essential processes required to ensure optimal performance and longevity of your vehicle. With the right knowledge and tools, tackling various tasks becomes manageable and even rewarding.

In this guide, readers will find detailed instructions and helpful tips on addressing common issues that may arise in their vehicle. From routine inspections to more complex procedures, each aspect is covered comprehensively, enabling individuals to approach maintenance with confidence. By following the outlined steps, owners can enhance their understanding of their vehicle’s mechanics and achieve successful outcomes.

Equipped with this information, car owners will be better prepared to handle challenges that may come their way. Emphasizing practicality and clarity, the guide aims to empower users to take charge of their automotive experience. Whether you’re a seasoned mechanic or a novice, the content is structured to facilitate learning and application.

Understanding the 1996 Jeep Cherokee

The 1996 model year marks an important phase in the evolution of a well-known off-road vehicle. This particular version is celebrated for its durability, versatility, and the unique blend of ruggedness with everyday usability. Whether traversing rough terrains or navigating city streets, this vehicle offers a reliable driving experience.

Several key features and characteristics define this model:

- Engine Options: The vehicle comes equipped with a variety of powertrains, providing drivers with choices that suit different performance needs.

- Transmission: Available with both automatic and manual transmission options, catering to diverse driving preferences.

- Interior Space: The cabin is designed to maximize comfort and utility, making it suitable for both daily commutes and adventurous trips.

- Safety Features: Equipped with essential safety systems to ensure passenger protection and enhance overall driving confidence.

When considering ownership, it’s crucial to understand maintenance practices that can enhance longevity:

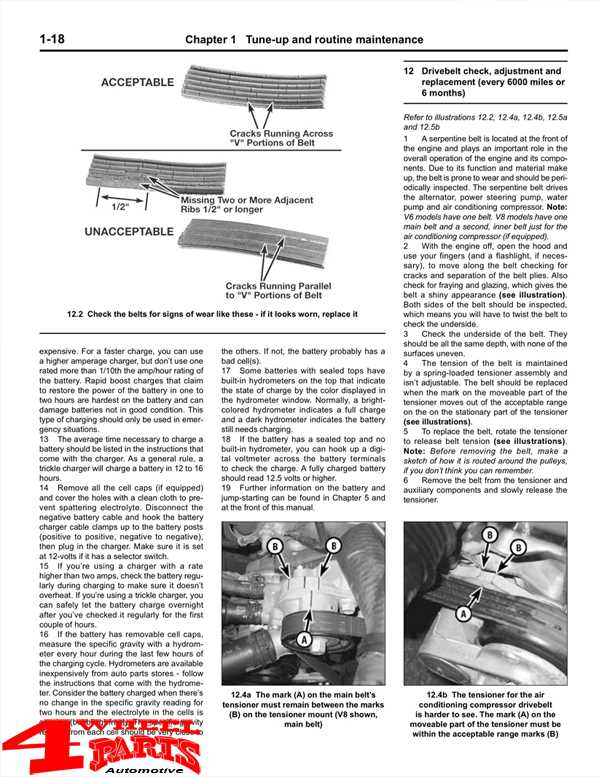

- Regular Checks: Conduct routine inspections of fluids, filters, and belts to maintain optimal performance.

- Tire Maintenance: Keep tires properly inflated and rotated to ensure even wear and improve handling.

- Brake System: Regularly check brake pads and discs to ensure safety and responsiveness.

- Electrical System: Monitor battery condition and connections to prevent starting issues.

In summary, comprehending the specifications and maintenance needs of this iconic vehicle will lead to a more enjoyable and dependable driving experience.

Common Issues Faced by Owners

Many vehicle enthusiasts encounter a variety of challenges with their automobiles over time. Understanding these prevalent concerns can assist in better preparation and maintenance. Below is a summary of frequent issues experienced by owners of a certain model, highlighting the importance of regular inspections and timely interventions.

| Issue | Description | Possible Solutions |

|---|---|---|

| Electrical Problems | Malfunctions in wiring or battery systems may lead to starting issues or power failures. | Inspect connections, replace fuses, and check battery health. |

| Engine Overheating | Engines may overheat due to coolant leaks or radiator issues, leading to performance concerns. | Regularly check coolant levels and inspect the radiator for leaks. |

| Transmission Issues | Shifting difficulties or slipping may occur, impacting drivability and safety. | Change transmission fluid regularly and inspect for leaks. |

| Suspension Wear | Worn-out suspension components can cause handling problems and an uncomfortable ride. | Replace worn parts and perform alignment checks periodically. |

| Brake System Failures | Decreased braking efficiency can lead to safety hazards. | Regularly inspect brake pads, rotors, and fluid levels. |

Essential Tools for Repairs

When embarking on any maintenance task, having the right instruments at hand is crucial for achieving optimal results. Whether you are conducting routine upkeep or addressing more complex issues, a well-equipped toolkit can make all the difference. Understanding which tools are essential will not only facilitate the process but also enhance your overall efficiency.

Basic Hand Tools: A selection of screwdrivers, wrenches, and pliers forms the foundation of any toolkit. These versatile items allow for easy access to various components and fasteners, ensuring that even the most stubborn parts can be managed with ease. It’s advisable to have both metric and standard sizes available.

Power Tools: For more extensive projects, power tools such as drills and impact wrenches can significantly reduce the time and effort required. These tools provide the necessary torque and speed to tackle larger tasks effectively, making them invaluable for any enthusiast.

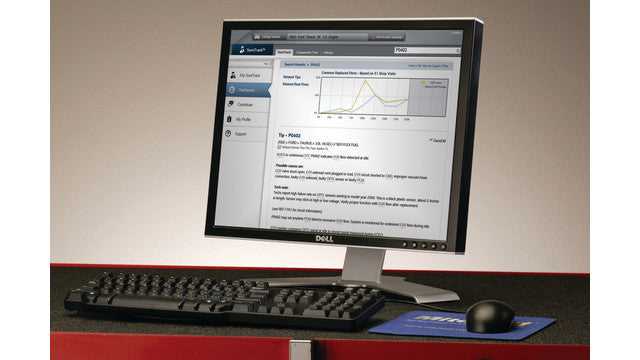

Diagnostic Equipment: To identify issues accurately, having diagnostic tools like OBD-II scanners is essential. These devices can help decipher error codes and offer insights into the functionality of various systems, making troubleshooting much more straightforward.

Safety Gear: Never underestimate the importance of safety equipment. Gloves, goggles, and other protective wear are essential to ensure your well-being while working on any task. Proper safety measures can prevent injuries and create a secure working environment.

In summary, assembling a comprehensive toolkit tailored to your needs will streamline your maintenance activities. With the right instruments, tackling any challenge becomes a more manageable and rewarding experience.

Step-by-Step Maintenance Guide

This guide aims to provide a comprehensive approach to ensuring your vehicle remains in optimal condition. By following these detailed steps, you can effectively perform essential upkeep tasks that will enhance performance and longevity.

Regular Inspections

Conducting routine inspections is vital for identifying potential issues early. Check fluid levels regularly, including oil, coolant, and brake fluids. Inspect filters to ensure they are clean and functioning properly, as this can significantly impact engine efficiency.

Preventive Care

Implementing preventive measures can save time and money in the long run. Regularly replace worn components, such as belts and hoses, and adhere to the recommended service intervals for parts like the battery and tires. This proactive approach not only enhances safety but also improves the overall driving experience.

Engine Troubleshooting Techniques

When faced with performance issues in an automobile’s power unit, it is essential to employ systematic approaches to identify and resolve the underlying problems. Understanding the symptoms and causes can significantly enhance the effectiveness of diagnostics, ensuring that appropriate solutions are implemented swiftly.

Common Symptoms of Engine Problems

- Unusual noises, such as knocking or ticking sounds

- Loss of power during acceleration

- Excessive exhaust smoke or unusual color

- Frequent stalling or difficulty starting

- Overheating and rising temperature gauge readings

Diagnostic Techniques

- Visual Inspection: Begin by examining the engine for obvious signs of damage, leaks, or disconnections.

- Check Fluid Levels: Ensure that all essential fluids, including oil and coolant, are at appropriate levels.

- Scan for Error Codes: Utilize a diagnostic scanner to retrieve trouble codes from the vehicle’s onboard computer.

- Perform a Compression Test: Assess the pressure within each cylinder to evaluate the engine’s internal condition.

- Inspect Spark Plugs: Examine the condition of spark plugs for wear or fouling, indicating potential ignition issues.

Electrical System Diagnostics

The evaluation of the electrical system is crucial for maintaining optimal performance in any vehicle. This section focuses on identifying issues related to the power distribution, wiring integrity, and component functionality, ensuring that all electrical elements work harmoniously.

To effectively diagnose electrical problems, follow these key steps:

- Visual Inspection:

- Check for damaged wires or connectors.

- Inspect the battery for corrosion or loose connections.

- Examine fuses for signs of failure.

- Testing Components:

- Use a multimeter to measure voltage and continuity.

- Test switches and relays for proper operation.

- Verify that all sensors are functioning correctly.

- Scan for Codes:

- Utilize a diagnostic scanner to retrieve error codes.

- Interpret codes to determine specific electrical issues.

- Follow Wiring Diagrams:

- Refer to schematic diagrams to understand the electrical layout.

- Trace circuits to locate potential faults.

By systematically following these diagnostic procedures, one can pinpoint and resolve electrical faults effectively, ensuring reliable operation and longevity of the vehicle’s electrical system.

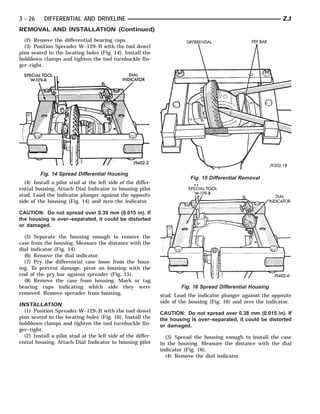

Transmission Repair Procedures

This section outlines the essential steps for addressing issues related to the shifting mechanism of a vehicle. Proper handling of the components involved ensures optimal functionality and extends the lifespan of the system.

Before beginning any work, it is crucial to gather the necessary tools and materials:

- Socket set

- Wrench set

- Torque wrench

- Fluid for transmission

- Sealant

The following procedures should be followed for effective maintenance:

- Fluid Check: Begin by inspecting the fluid level. Low levels can lead to operational failures.

- Leak Inspection: Look for any signs of leakage around the seals and gaskets. Replace damaged components as necessary.

- Filter Replacement: Change the filter to ensure that contaminants do not hinder performance. Consult specifications for correct part numbers.

- Adjusting Bands: If applicable, adjust the bands according to manufacturer guidelines to improve shifting precision.

- Fluid Replacement: Drain the old fluid and refill with new fluid. Ensure that the correct type is used for the specific model.

- Final Testing: Once all procedures are completed, start the engine and check for any irregularities in operation.

Following these steps will help maintain the integrity of the shifting system, promoting a smoother driving experience.

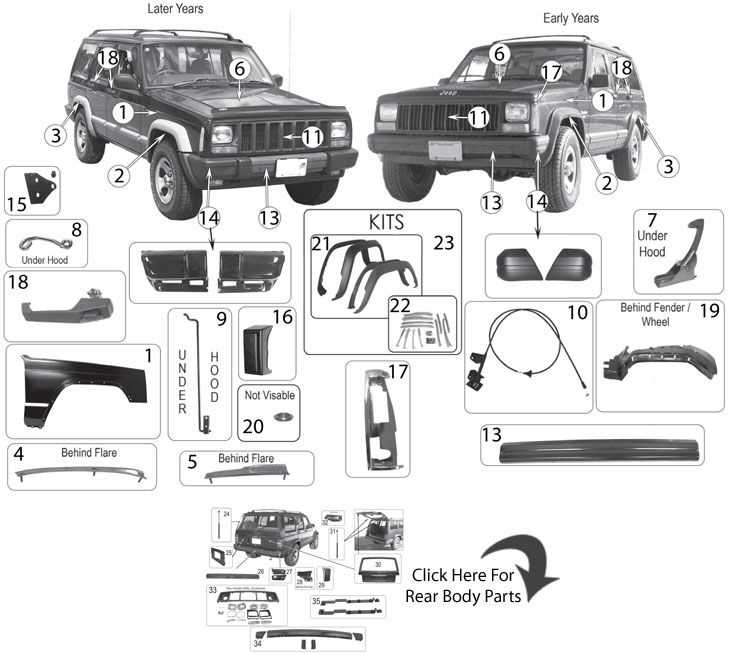

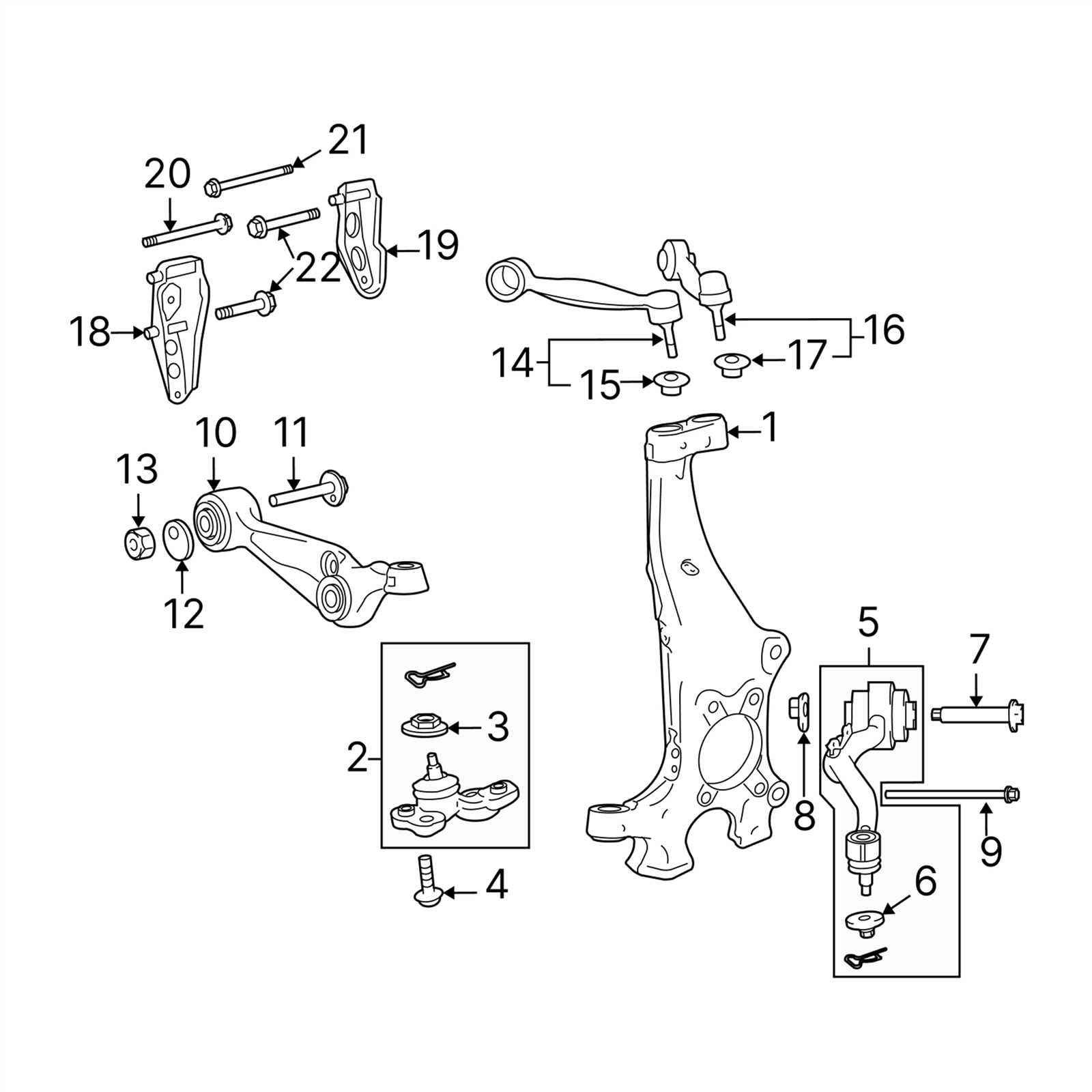

Suspension and Steering Adjustments

Proper alignment and configuration of the suspension and steering components are crucial for optimal handling and ride quality. Ensuring that these systems are correctly adjusted enhances vehicle stability and safety, while also improving tire longevity and performance.

Regular checks and modifications may be necessary due to wear, environmental factors, or modifications made to the vehicle. This section provides guidance on how to approach these adjustments effectively.

| Adjustment Type | Procedure | Tools Required |

|---|---|---|

| Camber | Check with a camber gauge; adjust upper control arms if needed. | Camber gauge, wrench set |

| Toe | Measure toe angle; adjust tie rods to achieve desired alignment. | Toe gauge, adjustable wrench |

| Caster | Evaluate with a caster gauge; adjust control arm bushings as necessary. | Caster gauge, torque wrench |

| Steering Wheel Alignment | Center the steering wheel by adjusting tie rods; ensure wheels are straight. | Socket set, alignment tools |

Following these procedures will help maintain the integrity of the vehicle’s suspension and steering systems, ensuring a smooth and safe driving experience.

Brake System Inspection Tips

Ensuring optimal performance of your vehicle’s stopping mechanism is crucial for safety. Regular examination of the braking components can prevent potential failures and enhance the driving experience. Here are some essential tips to keep in mind during your inspection process.

Visual Checks

- Inspect brake pads for wear; they should not be thinner than the manufacturer’s specifications.

- Look for any signs of fluid leaks around the calipers and hoses.

- Examine the rotors for cracks, grooves, or excessive rust.

Functional Tests

- Press the brake pedal and assess its firmness; a spongy feel may indicate air in the system.

- Test the vehicle’s stopping distance at various speeds to ensure responsiveness.

- Listen for unusual noises during braking, such as grinding or squeaking, which can signal issues.

Adhering to these tips will help maintain a reliable stopping system and ensure your vehicle remains safe on the road.

Cooling System Maintenance Essentials

Maintaining the cooling mechanism of your vehicle is crucial for optimal performance and longevity. Regular attention to this system helps prevent overheating and ensures efficient operation under various driving conditions.

Regular Inspection: Routinely check the coolant level and inspect for leaks in hoses, fittings, and the radiator. Any signs of wear or damage should be addressed immediately to avoid potential failures.

Coolant Replacement: It is essential to change the coolant at recommended intervals to maintain its effectiveness. Old coolant can become acidic, leading to corrosion within the system.

Thermostat Functionality: Ensure the thermostat is functioning properly. A malfunctioning thermostat can disrupt the flow of coolant, leading to engine overheating or inefficient heating of the cabin.

Radiator Maintenance: Keep the radiator clean and free from debris. A blocked radiator can impair heat dissipation, reducing the overall efficiency of the cooling system.

Cooling Fan Operation: Regularly test the cooling fan to ensure it engages at the appropriate temperatures. A faulty fan can lead to overheating, especially during stop-and-go traffic.

By adhering to these maintenance essentials, you can enhance the reliability and efficiency of your vehicle’s cooling system, contributing to a smoother and safer driving experience.

Upgrading Parts for Performance

Enhancing the components of your vehicle can significantly improve its overall functionality and responsiveness. By focusing on specific areas such as the engine, suspension, and exhaust system, you can achieve a more dynamic driving experience.

Here are some key upgrades to consider:

- Engine Enhancements:

- High-performance air intake systems to increase airflow.

- Upgraded fuel injectors for better fuel delivery.

- Aftermarket engine tuning for optimal performance settings.

- Suspension Improvements:

- Performance shocks and struts for improved handling.

- Upgraded sway bars to reduce body roll during cornering.

- Adjustable coilovers for a customizable ride height.

- Exhaust Modifications:

- High-flow catalytic converters to reduce back pressure.

- Performance mufflers for a sportier sound.

- Mandrel-bent exhaust piping for smoother airflow.

These upgrades not only boost performance but also enhance the driving pleasure and overall efficiency of your vehicle. Choose components that align with your performance goals for the best results.

Resourceful Online Repair Communities

In today’s digital age, enthusiasts and DIYers have access to a wealth of knowledge through various online platforms. These virtual communities provide valuable insights, troubleshooting tips, and support for individuals seeking to resolve issues with their vehicles. The collaborative spirit of these groups fosters a sense of belonging and encourages members to share their experiences and solutions.

Benefits of Joining Online Communities

- Access to a vast repository of information

- Opportunities to connect with fellow enthusiasts

- Real-time advice from experienced members

- Step-by-step guides and tutorials

- Support during complex tasks

Popular Platforms to Explore

- Forums dedicated to automotive enthusiasts

- Social media groups focused on vehicle maintenance

- Video-sharing sites featuring instructional content

- Websites offering detailed troubleshooting articles

Engaging with these online resources can significantly enhance your knowledge and confidence when dealing with automotive challenges. By participating actively, you can contribute to the collective wisdom while gaining insights that may simplify your projects.