When it comes to ensuring the longevity and optimal performance of your vehicle, having access to detailed information is crucial. A well-structured resource can provide insights into various aspects of maintenance, troubleshooting, and essential repairs. This guide serves as a valuable tool for individuals seeking to enhance their knowledge and skills in automotive care.

Equipped with a wealth of information, this document aims to assist enthusiasts and owners alike in navigating common challenges. From understanding the intricacies of engine components to mastering the nuances of electrical systems, the content offers clear explanations and step-by-step instructions. Whether you’re tackling minor adjustments or major overhauls, having the right information at your fingertips makes all the difference.

Furthermore, the guide emphasizes safety and efficiency, ensuring that every task can be approached with confidence. By familiarizing yourself with the various systems and procedures outlined, you can enhance your capability to address issues proactively and maintain your vehicle in top-notch condition.

Essential Features of the 2013 Jeep Grand Cherokee

This exceptional vehicle showcases a blend of comfort, performance, and advanced technology, making it a standout choice for drivers seeking versatility and style. Designed for both urban environments and rugged terrains, it boasts a refined interior and a powerful engine lineup, catering to various preferences and needs. With a commitment to safety and convenience, this model incorporates features that enhance the driving experience, ensuring peace of mind on every journey.

Powerful Performance and Versatility

The robust powertrain options available provide an impressive balance of strength and efficiency. Drivers can choose from a selection of engines, each delivering optimal performance whether navigating city streets or exploring off-road trails. The sophisticated suspension system contributes to a smooth ride, enhancing stability and control across various conditions.

Innovative Technology and Comfort

Equipped with cutting-edge technology, this vehicle ensures connectivity and entertainment for all passengers. Features such as an intuitive infotainment system, smartphone integration, and premium sound systems elevate the driving experience. Moreover, the spacious and well-appointed cabin offers luxurious seating and ample cargo space, making long trips more enjoyable and accommodating.

Understanding Common Repair Issues

Vehicle maintenance can often unveil a variety of challenges that drivers may encounter over time. Recognizing these typical problems is essential for ensuring longevity and optimal performance. By familiarizing oneself with frequent complications, owners can take proactive steps to address concerns before they escalate into more significant dilemmas.

One prevalent concern involves the electrical system. Faulty wiring, poor connections, and malfunctioning components can lead to a host of issues, from dimming lights to complete electrical failure. Regular checks and timely replacements can mitigate these problems.

Another common area of difficulty is the suspension system. Wear and tear on components such as shock absorbers and bushings can result in a bumpy ride and compromised handling. Monitoring these elements can improve comfort and safety while driving.

Additionally, braking issues are frequently reported. Signs like squeaking noises or reduced stopping power often indicate that brake pads or rotors need attention. Ensuring these components are in good condition is critical for maintaining vehicle safety.

Overall, staying informed about these typical complications can empower owners to maintain their vehicles more effectively, enhancing both safety and driving experience.

Step-by-Step Maintenance Guidelines

Proper upkeep of your vehicle is essential to ensure longevity and optimal performance. Following a structured approach to maintenance can help you identify potential issues before they escalate, ultimately saving time and money.

Begin with regular inspections of vital components, such as the engine oil, coolant levels, and brake fluid. Replacing fluids at the recommended intervals is crucial for the smooth operation of various systems. Additionally, checking the air filters and replacing them when necessary will promote better airflow and fuel efficiency.

Another important aspect is the examination of tires. Ensure they are inflated to the correct pressure and rotate them periodically to achieve even wear. Maintaining the proper alignment and balance will also contribute to a smoother driving experience and prolong the life of your tires.

Don’t overlook the importance of battery health. Regularly cleaning the terminals and checking the charge level will prevent unexpected failures. Furthermore, inspect belts and hoses for signs of wear or damage to avoid breakdowns on the road.

Finally, adhere to the service schedule outlined by the manufacturer. Routine check-ups by a qualified technician will guarantee that all systems are functioning correctly and that any necessary adjustments or replacements are made in a timely manner.

Tools Needed for Efficient Repairs

Having the right equipment is essential for performing maintenance tasks effectively. Proper instruments not only simplify the process but also enhance safety and accuracy during operations. This section outlines the necessary implements that facilitate various service activities, ensuring a smooth experience for any technician.

Essential Equipment

When tackling service jobs, specific tools are indispensable. These instruments vary based on the type of task but typically include items for diagnostics, mechanical adjustments, and general upkeep. Below is a list of commonly used tools that aid in achieving optimal results.

| Tool | Purpose |

|---|---|

| Socket Set | Used for loosening and tightening bolts and nuts. |

| Wrench Set | Essential for gripping and turning fasteners. |

| Screwdriver Set | Required for various screw types and sizes. |

| Torque Wrench | Ensures accurate tightening of bolts to specified settings. |

| Diagnostic Scanner | Facilitates the identification of issues within electronic systems. |

| Fluid Pump | Aids in changing oils and other fluids efficiently. |

Additional Tools

In addition to the primary instruments, certain supplementary tools enhance the efficiency of maintenance tasks. These may include specialized equipment designed for specific functions or tasks. Investing in a comprehensive toolkit can greatly improve the effectiveness of any maintenance routine.

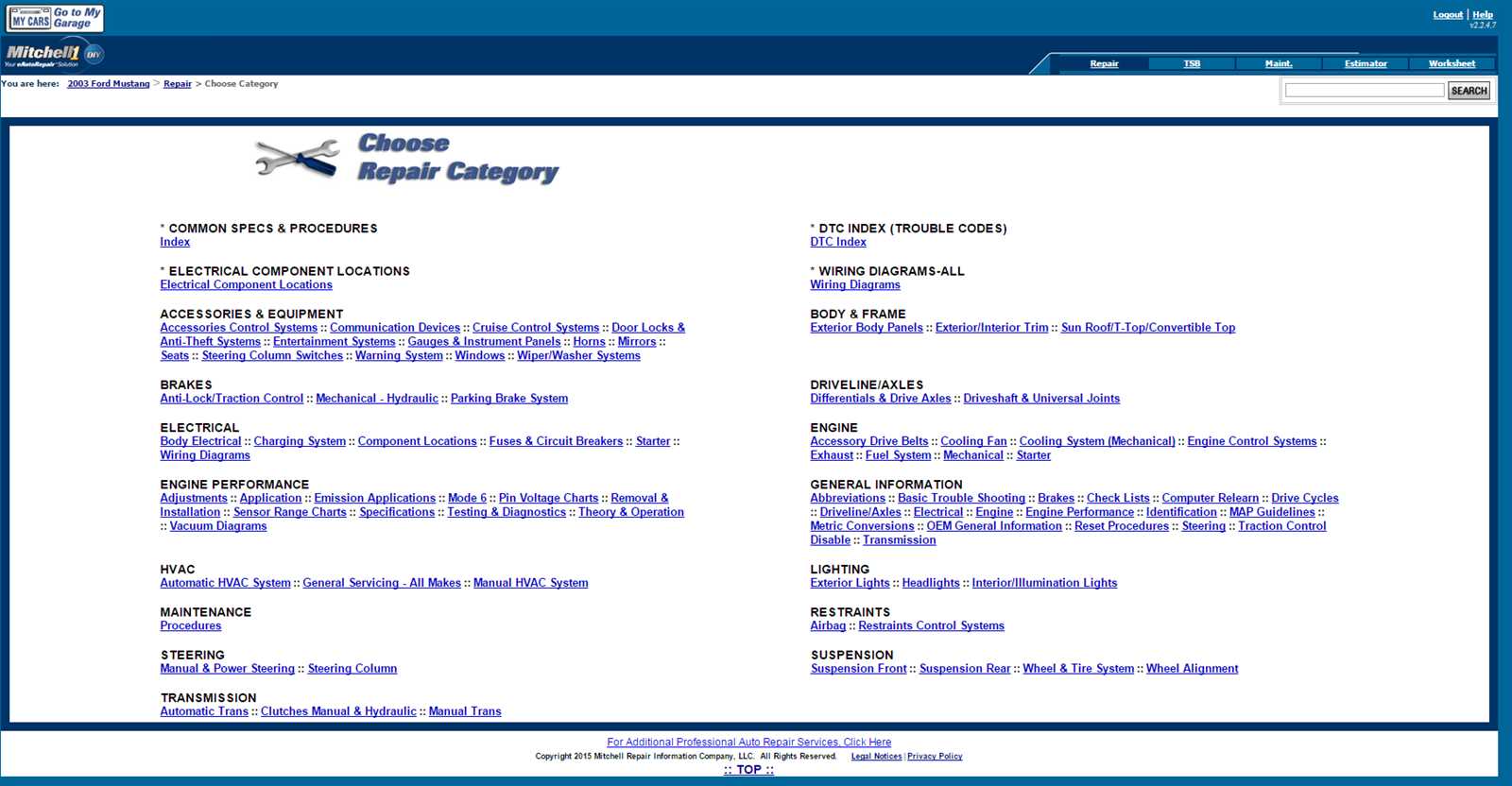

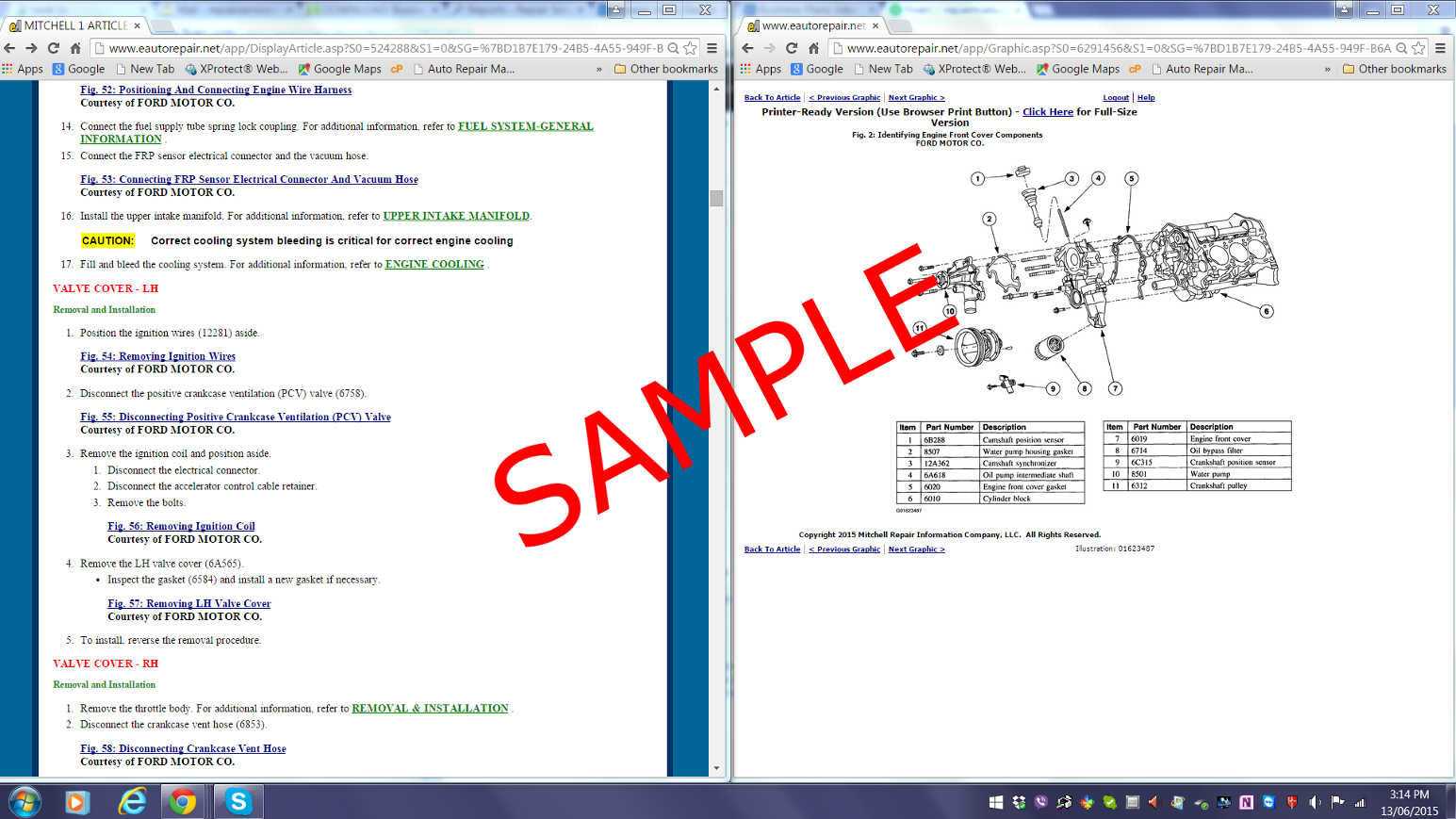

Electrical System Troubleshooting Techniques

Identifying and resolving issues within a vehicle’s electrical framework requires a systematic approach. This section provides guidance on effective strategies to diagnose problems, ensuring reliable operation of electronic components. Understanding common symptoms and employing methodical testing can significantly enhance the troubleshooting process.

Common Symptoms and Initial Assessment

Before delving into detailed diagnostics, it’s crucial to recognize prevalent signs of electrical malfunctions. Issues such as dimming lights, erratic instrument readings, or failure to start can indicate underlying problems. Begin with a thorough visual inspection of wiring harnesses and connectors. Look for signs of wear, corrosion, or loose connections, which can often be the root cause of many electrical failures.

Testing Procedures and Tools

Utilizing appropriate diagnostic tools is essential for effective troubleshooting. A multimeter can be employed to measure voltage, current, and resistance across various components. Start by checking the battery’s voltage and then proceed to test fuses and relays to ensure they function correctly. For more complex systems, employing an oscilloscope can help analyze signal patterns, allowing for a deeper understanding of potential faults.

By adhering to these techniques, vehicle owners and technicians can efficiently navigate the intricacies of electrical system challenges, promoting longevity and reliability.

Replacing the Engine Components

Maintaining optimal performance of the power unit is crucial for any vehicle. Over time, various parts may wear out or fail, necessitating their replacement. This section covers the essential steps and considerations for swapping out engine components, ensuring your vehicle runs smoothly and efficiently.

Identifying Worn Components

Before beginning the replacement process, it is vital to identify which parts require attention. Common signs of wear include unusual noises, decreased power, and poor fuel efficiency. Regular inspections can help pinpoint issues before they escalate, making it easier to determine the necessary replacements.

Steps for Component Replacement

Once you have identified the worn components, follow a systematic approach to remove and replace them. Start by disconnecting the battery to prevent any electrical mishaps. Next, drain any fluids associated with the components you plan to replace. Carefully remove the old parts, taking note of their orientation and connection points. When installing the new components, ensure they are securely fastened and properly aligned. Finally, refill any fluids and reconnect the battery before testing the engine to confirm proper operation.

Guidelines for Suspension Adjustments

Fine-tuning the suspension system is essential for optimizing vehicle handling and comfort. Proper alignment and adjustments can enhance driving stability, improve tire longevity, and contribute to a smoother ride. Understanding the key components involved and the adjustment procedures will help ensure a well-balanced suspension setup.

Key Considerations for Alignment

When adjusting the suspension, it is crucial to consider factors such as ride height, camber, toe angle, and caster. These elements significantly influence the vehicle’s performance and wear patterns. A thorough assessment of the current setup will provide insights into necessary adjustments. Regular checks are advisable, especially after significant repairs or modifications.

Adjustment Procedures

Begin the adjustment process by ensuring the vehicle is on a level surface. Utilize specialized tools to measure and adjust the suspension components accurately. Follow the manufacturer’s specifications for settings to achieve optimal alignment. After adjustments are made, take the vehicle for a test drive to evaluate handling and comfort before finalizing the setup.

Brake System Inspection and Repair

Ensuring the functionality of the braking mechanism is essential for vehicle safety and performance. Regular evaluation of this critical system can prevent issues that may compromise the vehicle’s handling and control. Proper inspection procedures and timely interventions can enhance longevity and reliability.

Inspection Procedures

Start by examining the brake pads and rotors for signs of wear or damage. Look for uneven surfaces, cracking, or excessive thickness reduction. Additionally, inspect the brake lines for any leaks or deterioration, as this can lead to decreased efficiency. Ensure that the brake fluid is at the appropriate level and free from contaminants, as this is vital for optimal performance.

Maintenance and Replacement

If any components show significant wear or damage, timely replacement is crucial. Utilize high-quality parts that meet or exceed manufacturer specifications to ensure longevity and performance. Regularly scheduled maintenance, including fluid changes and component adjustments, can significantly enhance the overall functionality of the braking system. Addressing minor issues promptly can prevent more severe problems and costly repairs in the future.

Cooling System Maintenance Strategies

Proper upkeep of the cooling mechanism is essential for the longevity and efficiency of any vehicle. Regular attention to this system helps in preventing overheating and ensures optimal performance. Understanding the key components and their care can lead to significant improvements in vehicle reliability and safety.

Key Components to Monitor

- Radiator: Ensure it is free from debris and leaks.

- Coolant: Check levels regularly and replace when necessary.

- Hoses: Inspect for cracks or wear and replace as needed.

- Water Pump: Listen for unusual noises that may indicate failure.

- Thermostat: Test for proper operation to maintain correct temperature.

Maintenance Tips

- Regularly flush and refill the coolant to prevent buildup of contaminants.

- Inspect the cooling fan for proper functionality to ensure efficient airflow.

- Monitor temperature gauges to catch issues before they escalate.

- Check for any signs of leaks under the vehicle, particularly after running.

- Consult with a professional for any complex repairs or inspections.

Transmission Fluid Change Procedures

Regularly replacing the fluid within your vehicle’s transmission is essential for maintaining optimal performance and longevity. This process helps ensure that the components remain lubricated, reducing wear and tear while enhancing the overall functionality of the transmission system.

Before starting the fluid exchange, gather the necessary tools and materials. Make sure to follow the recommended procedures to achieve a successful and efficient change.

| Step | Description |

|---|---|

| 1 | Park the vehicle on a level surface and engage the parking brake. |

| 2 | Locate the transmission dipstick and remove it to check the current fluid level. |

| 3 | Drain the old fluid using a suitable container, ensuring all fluid is removed. |

| 4 | Replace the transmission filter if necessary to ensure clean fluid circulation. |

| 5 | Refill the transmission with the appropriate type of fluid through the dipstick tube. |

| 6 | Start the engine and allow it to reach normal operating temperature while checking for leaks. |

| 7 | Verify the fluid level again and add more fluid if needed to achieve the correct level. |

Following these guidelines will help ensure that the transmission operates smoothly and efficiently. Regular fluid changes are a proactive measure to avoid costly repairs down the road.