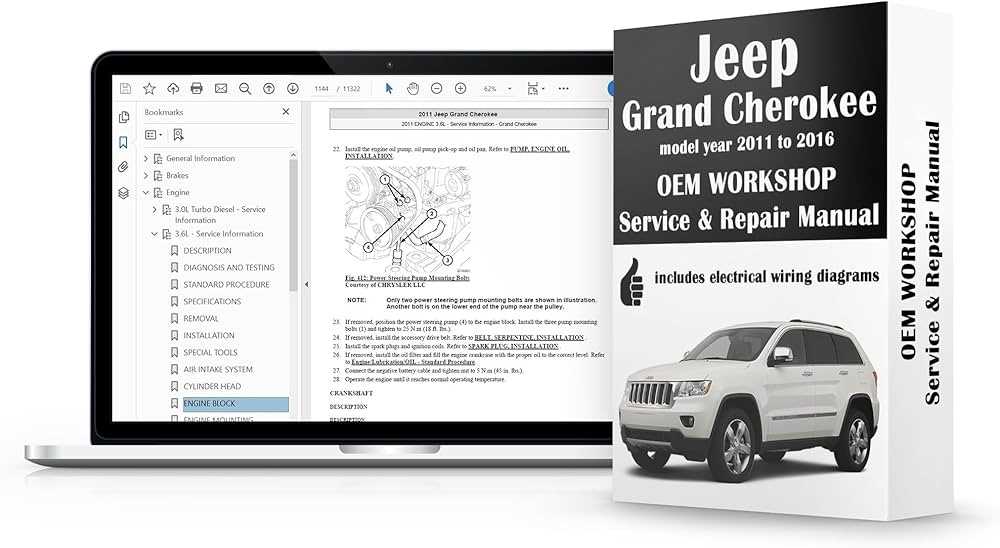

Understanding the intricacies of automobile upkeep is essential for any owner. A well-documented resource can significantly enhance the experience of maintaining and troubleshooting issues in your vehicle. This guide serves as a detailed companion, providing insights and instructions that empower enthusiasts and everyday drivers alike.

From routine checks to complex repairs, this resource covers a wide range of topics. It aims to demystify the processes involved in ensuring optimal performance and longevity. Whether you’re facing minor inconveniences or major challenges, having access to structured information can make a considerable difference.

As you navigate through various sections, you will find valuable tips, step-by-step procedures, and crucial safety information. Equipped with this knowledge, you can approach each task with confidence, ensuring your vehicle remains in peak condition for years to come.

Overview of 2012 Jeep Grand Cherokee

This section provides a comprehensive look at a versatile sport utility vehicle known for its blend of performance, luxury, and capability. The model stands out in its class for delivering a robust driving experience, sophisticated features, and a spacious interior designed for both comfort and utility.

Key highlights of this vehicle include:

- Powerful engine options that ensure excellent performance on various terrains.

- A well-appointed interior that combines modern technology with high-quality materials.

- Advanced safety features aimed at enhancing driver and passenger protection.

- Impressive towing capacity, making it suitable for hauling trailers and equipment.

Additionally, this vehicle is equipped with:

- All-wheel drive systems for improved traction in challenging conditions.

- Infotainment options that keep occupants connected and entertained during travels.

- Ample cargo space, offering flexibility for both daily use and long trips.

In summary, this model represents a well-rounded choice for those seeking a blend of rugged capability and refined comfort, making it suitable for a wide range of lifestyles and adventures.

Common Issues and Troubleshooting Tips

When it comes to maintaining a vehicle, certain problems tend to arise more frequently than others. Understanding these common issues can help owners address them promptly, ensuring safety and performance. This section provides a detailed overview of typical challenges along with practical solutions to help diagnose and resolve them effectively.

- Electrical System Failures:

- Check battery connections for corrosion and tightness.

- Inspect fuses for any blown components.

- Test the alternator to ensure it’s charging properly.

- Transmission Problems:

- Monitor fluid levels and check for leaks.

- Pay attention to unusual sounds during shifting.

- Ensure the transmission fluid is clean and at the correct temperature.

- Suspension Issues:

- Listen for knocking noises while driving over bumps.

- Inspect shocks and struts for wear or leakage.

- Check alignment regularly to avoid uneven tire wear.

- Engine Performance:

- Observe for warning lights on the dashboard.

- Check for unusual smells or smoke from the engine compartment.

- Ensure regular oil changes and inspect for leaks.

By being aware of these common challenges and utilizing the troubleshooting tips provided, vehicle owners can maintain their automobiles in optimal condition and enhance their driving experience.

Maintenance Schedule for Optimal Performance

Regular upkeep is essential to ensure your vehicle operates smoothly and efficiently. A well-structured maintenance plan not only enhances performance but also prolongs the lifespan of various components. Adhering to specific intervals for inspections and servicing can prevent potential issues before they escalate.

Below is a suggested maintenance schedule to keep your vehicle in peak condition:

- Every 5,000 miles:

- Change engine oil and replace the oil filter.

- Inspect and top off all fluids (coolant, brake fluid, transmission fluid).

- Check tire pressure and tread depth.

- Every 15,000 miles:

- Rotate tires for even wear.

- Inspect brakes and replace worn components if necessary.

- Check battery terminals and connections.

- Every 30,000 miles:

- Replace air filter for optimal airflow.

- Flush and replace coolant to prevent overheating.

- Inspect and service the exhaust system.

- Every 60,000 miles:

- Replace spark plugs to maintain efficient combustion.

- Inspect the timing belt for wear and tear.

- Perform a full brake system inspection.

Staying on top of these tasks can significantly enhance reliability and performance. Always consult the manufacturer’s guidelines for any specific recommendations related to your vehicle model.

Essential Tools for DIY Repairs

Engaging in vehicle maintenance can be a rewarding experience, especially when equipped with the right instruments. Having a well-stocked toolkit not only simplifies tasks but also enhances the overall efficiency of the process. Here, we explore the must-have items for anyone looking to take on automotive projects with confidence.

Basic Hand Tools

- Wrenches: A set of combination wrenches in various sizes is essential for loosening and tightening bolts.

- Sockets and Ratchets: These allow for quick and easy access to hard-to-reach fasteners.

- Screwdrivers: A variety of flathead and Phillips screwdrivers will cover most needs.

- Pliers: Needle-nose and slip-joint pliers are invaluable for gripping and bending components.

Specialized Tools

- Torque Wrench: Ensures that bolts are tightened to the manufacturer’s specifications, preventing damage.

- Jack and Jack Stands: Vital for safely lifting the vehicle during maintenance tasks.

- OBD-II Scanner: Helps diagnose engine issues by reading error codes from the vehicle’s computer.

- Fluid Extractor: Useful for changing fluids without making a mess.

Investing in these tools not only prepares you for a wide range of maintenance tasks but also cultivates a sense of accomplishment as you take control of your vehicle’s upkeep.

Understanding Engine Specifications

Engine specifications provide crucial insights into the performance and efficiency of a vehicle. These details not only inform potential buyers but also assist owners in maintaining and optimizing their machines. A thorough understanding of these specifications can lead to better decision-making regarding repairs and upgrades.

Key specifications typically include the following:

- Displacement: The total volume of all the cylinders, indicating engine size and potential power output.

- Horsepower: A measurement of the engine’s power, influencing acceleration and overall performance.

- Torque: The twisting force produced by the engine, essential for towing capacity and driving feel.

- Compression Ratio: The ratio of the cylinder’s volume before and after compression, affecting efficiency and power.

- Fuel Type: The recommended fuel for optimal engine performance, impacting efficiency and emissions.

- Cooling System: Details about the cooling method, vital for maintaining operating temperature and preventing overheating.

Each of these factors plays a significant role in how the engine performs under various conditions. Understanding them is essential for anyone looking to enhance their vehicle’s capabilities or troubleshoot issues effectively.

When analyzing specifications, consider the following:

- Evaluate how each specification aligns with your driving needs.

- Research modifications that can improve specific aspects of engine performance.

- Stay informed about manufacturer recommendations and best practices for maintenance.

A comprehensive grasp of engine specifications not only enriches your knowledge but also empowers you to make informed choices about your vehicle’s future.

Transmission Problems and Solutions

Transmission issues can significantly impact vehicle performance, leading to various challenges for drivers. Understanding common problems and their remedies is essential for maintaining optimal function and ensuring safety on the road.

Common Transmission Issues

- Slipping Gears

- Delayed Engagement

- Fluid Leaks

- Overheating

Effective Solutions

- Regular Maintenance: Check and replace transmission fluid as recommended.

- Adjustments: Ensure proper linkage adjustments to prevent slipping.

- Seal Replacement: Fix leaks by replacing worn-out seals.

- Cooling System Check: Inspect and repair the cooling system to prevent overheating.

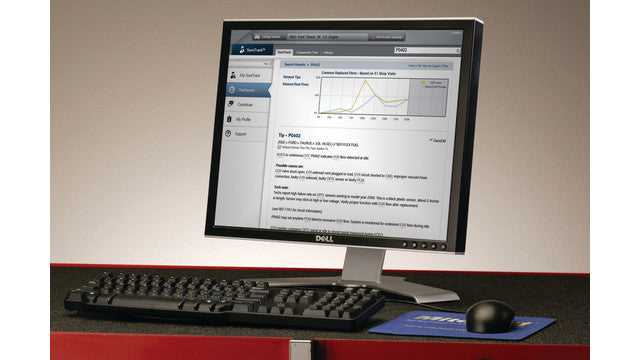

Electrical System Diagnostics

The evaluation of an automobile’s electrical framework is crucial for ensuring optimal performance and reliability. By systematically identifying and addressing issues within the circuitry, components, and connections, vehicle owners can prevent potential failures and enhance longevity. This section focuses on the essential procedures and techniques required for effective troubleshooting and resolution of electrical problems.

Common Electrical Issues

Many problems can arise within the electrical system, including faulty wiring, dead batteries, and malfunctioning sensors. Symptoms such as dimming lights, erratic behavior of electrical components, or failure to start often indicate underlying issues. Identifying these symptoms early can save time and resources.

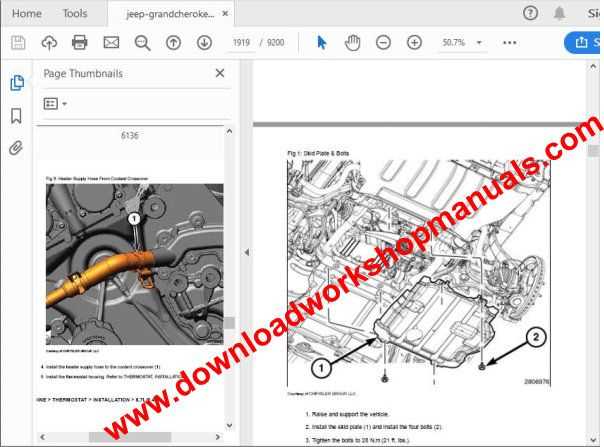

Diagnostic Procedures

To conduct thorough diagnostics, it is vital to employ specific tools and techniques. Utilizing a multimeter allows for the measurement of voltage, current, and resistance, providing insight into the health of various components. Additionally, checking for loose or corroded connections can reveal hidden problems. Regular inspections and systematic testing will help maintain the integrity of the electrical system and ensure safe operation of the vehicle.

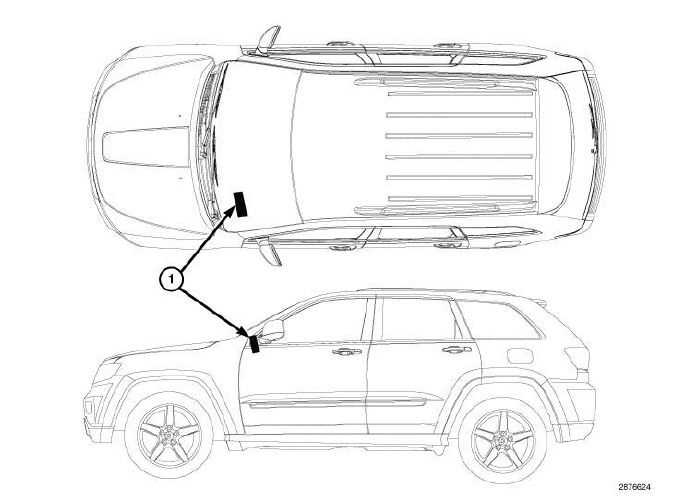

Suspension and Steering Repair Insights

The suspension and steering systems play a crucial role in the overall performance and safety of a vehicle. Proper maintenance and timely interventions are essential to ensure a smooth ride and responsive handling. Understanding the intricacies of these components can help owners address issues before they escalate into significant problems.

Key areas to focus on include:

- Components Overview: Familiarize yourself with essential parts such as control arms, shocks, struts, and tie rods.

- Symptoms of Wear: Look out for signs like unusual noises, vibrations, or changes in handling characteristics.

- Routine Checks: Regular inspections can identify problems early. Pay attention to the alignment, fluid levels, and any visible damage.

In terms of maintenance, consider the following:

- Lubrication: Ensure all moving parts are adequately lubricated to minimize friction and wear.

- Replacement Schedule: Adhere to the manufacturer’s guidelines for replacing worn components.

- Professional Assistance: Consult with qualified technicians for complex repairs to ensure safety and reliability.

By being proactive and informed, vehicle owners can enhance the lifespan of their suspension and steering systems, leading to improved driving experiences and safety on the road.

Brake System Maintenance Guidelines

Ensuring optimal performance of the braking mechanism is crucial for vehicle safety and reliability. Regular upkeep of this essential system helps prevent unexpected failures and extends its lifespan. Adhering to a structured maintenance routine allows drivers to maintain peak functionality, promoting both safety and comfort on the road.

1. Regular Inspection: Conducting frequent examinations of brake components is vital. Look for signs of wear on pads, rotors, and calipers. Any unusual noises or vibrations during braking should prompt immediate attention.

2. Brake Fluid Replacement: The hydraulic fluid plays a key role in the braking process. It is important to check its level and quality regularly. Replace the fluid according to the manufacturer’s recommendations, as old fluid can absorb moisture, leading to decreased performance.

3. Pad and Rotor Maintenance: Brake pads should be inspected for thickness and replaced when they reach the minimum recommended level. Rotors should be checked for scoring or warping; resurfacing or replacement may be necessary to maintain effective braking performance.

4. Cleaning Components: Dust and debris can accumulate on brake parts, affecting their efficiency. Regular cleaning of calipers, pads, and rotors can help maintain optimal contact and performance.

5. Professional Service: Engaging a qualified technician for comprehensive checks is advisable. They can provide insights into potential issues and perform complex repairs that may be beyond basic maintenance capabilities.

By adhering to these guidelines, vehicle owners can enhance the performance and longevity of their braking system, ensuring a safer driving experience.

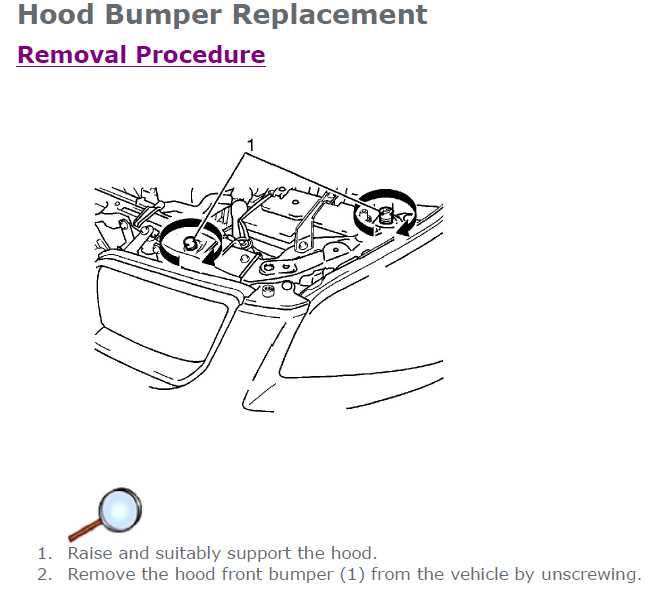

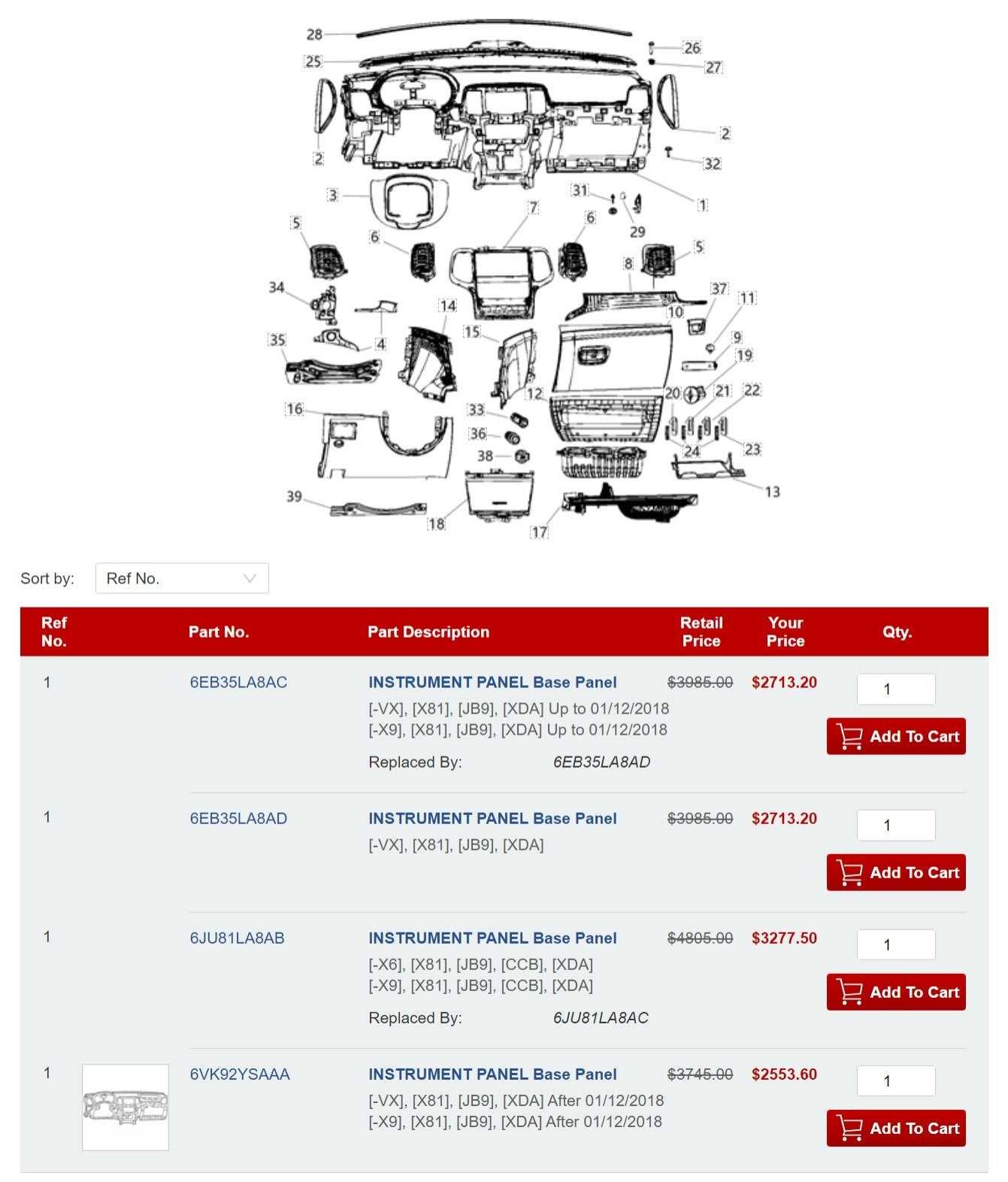

Replacing Key Components: A Guide

Maintaining a vehicle’s performance often involves the replacement of essential elements that may wear out over time. This guide offers insight into the process of substituting critical parts, ensuring the longevity and reliability of your automobile.

Understanding Component Replacement is vital for any car owner. Identifying which parts require attention is the first step. Common components include filters, belts, and fluid reservoirs, all of which can significantly impact functionality if neglected.

Before proceeding, it is important to gather the necessary tools and replacement parts. Ensure you have items such as wrenches, screwdrivers, and safety equipment readily available. Having everything on hand streamlines the process and minimizes disruptions.

Next, follow a systematic approach to remove the old component. Begin by consulting the vehicle’s specifications to locate the part and understand any specific removal instructions. Carefully detach the worn element, taking care to note how it is connected.

Once the old part is removed, install the new component with precision. Align it correctly, ensuring all connections are secure. After installation, double-check for any loose fittings that could lead to issues down the line.

Finally, test the vehicle after replacing the component. Start the engine and observe its performance. Listen for unusual sounds and monitor for any leaks. A successful replacement should enhance overall function and provide peace of mind.