In the realm of small engines, understanding the intricacies of their upkeep is crucial for longevity and optimal performance. This section aims to equip enthusiasts and technicians alike with essential knowledge, ensuring that every component operates smoothly and efficiently. Regular maintenance not only enhances functionality but also minimizes the risk of unexpected failures.

From common issues to advanced troubleshooting techniques, this guide offers a comprehensive overview of how to address typical challenges faced by engine owners. Whether you’re a seasoned professional or a novice, having access to detailed insights can significantly improve your skills in diagnosing problems and implementing effective solutions.

Additionally, practical tips on maintenance practices are included to help maintain peak performance and extend the lifespan of your equipment. By following these recommendations, users can enjoy a more reliable and efficient engine, enhancing their overall experience and productivity.

Understanding the Honda GX160 Engine

This section aims to provide an in-depth exploration of a popular small engine, often utilized in various applications ranging from gardening equipment to industrial machines. Recognized for its reliability and performance, this engine model serves as a critical component in many devices, delivering the power needed for efficient operation.

Engine mechanics are fundamental to understanding how this power unit functions. Key features contribute to its durability and efficiency, making it a preferred choice among users seeking dependable machinery. Familiarity with the components and their interactions is essential for anyone working with this type of engine.

| Feature | Description |

|---|---|

| Displacement | Approximately 163 cc, providing a balance of power and fuel efficiency. |

| Power Output | Produces around 5.5 horsepower, suitable for various applications. |

| Cooling System | Air-cooled design that maintains optimal operating temperatures. |

| Fuel Type | Runs on regular gasoline, making it accessible for users. |

| Starting System | Recoil starter mechanism for easy ignition. |

Understanding these attributes not only aids in effective usage but also facilitates troubleshooting and maintenance. Grasping the operational principles behind this engine ensures that users can maximize its capabilities and extend its lifespan.

Common Issues with Honda GX160

Engines designed for various applications often encounter typical problems that can affect their performance and longevity. Understanding these common challenges is essential for effective maintenance and troubleshooting. Below are some frequent issues that users may experience with this type of small engine.

Starting Difficulties

One prevalent issue is trouble starting the unit. This can stem from several factors, including a drained battery, clogged fuel lines, or issues with the ignition system. Ensuring that the fuel is fresh and that the spark plug is in good condition can often resolve these difficulties. Regular checks on the battery and electrical connections are also recommended to maintain optimal functionality.

Overheating Concerns

Overheating is another common problem that can arise due to inadequate airflow or low oil levels. If the engine is frequently shutting down due to excessive heat, it is crucial to inspect the cooling system, including the air filter and fins. Keeping the oil at the appropriate level and using the right type can help prevent overheating, ensuring smoother operation.

Tools Needed for Repairs

When tackling maintenance tasks, having the right equipment is essential for ensuring efficiency and effectiveness. A well-equipped workspace not only facilitates smoother operations but also enhances safety during the process. Below are key instruments and supplies that will assist in carrying out various servicing activities.

Basic Hand Tools: A reliable set of hand tools is fundamental. This typically includes wrenches, screwdrivers, and pliers. These items are necessary for loosening and tightening fasteners, making adjustments, and performing minor fixes.

Diagnostic Equipment: For accurate troubleshooting, investing in diagnostic devices can be beneficial. Multimeters and compression testers help in identifying electrical issues and assessing engine performance, respectively.

Safety Gear: Personal protective equipment is crucial for safeguarding oneself during maintenance. This includes gloves, goggles, and ear protection. Proper gear minimizes the risk of injury and ensures a safer working environment.

Cleaning Supplies: Keeping components clean is vital for optimal functionality. Brushes, cloths, and solvents assist in removing dirt and debris, promoting better performance and longevity of parts.

Specialized Tools: Depending on the specific tasks, certain specialized tools may be required. Items such as torque wrenches and valve adjustment tools can enhance precision during adjustments and repairs.

Having these essential tools at your disposal will empower you to address various tasks effectively, ensuring that everything operates smoothly and efficiently.

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to keeping your engine in optimal condition. Regular upkeep not only enhances performance but also extends the lifespan of the machinery. By following a systematic process, you can ensure that every crucial component is well cared for.

Below is a structured outline of maintenance tasks to perform regularly:

- Inspect Oil Levels:

- Check the oil level using the dipstick.

- Add oil if necessary, using the recommended type.

- Change the oil according to the manufacturer’s guidelines.

- Clean or Replace Air Filter:

- Remove the air filter cover.

- Inspect the filter for dirt and debris.

- Clean or replace it as needed to ensure proper airflow.

- Examine Spark Plug:

- Remove the spark plug using a socket wrench.

- Check for wear or carbon buildup.

- Replace if necessary, ensuring correct gap settings.

- Inspect Fuel System:

- Check fuel lines for cracks or leaks.

- Ensure the fuel filter is clean.

- Replace stale fuel to prevent engine issues.

- Check Belts and Hoses:

- Inspect belts for signs of wear or fraying.

- Check hoses for leaks or damage.

- Replace any faulty components to maintain efficiency.

By adhering to this maintenance routine, you can significantly enhance the performance and reliability of your engine, ensuring it operates smoothly for years to come.

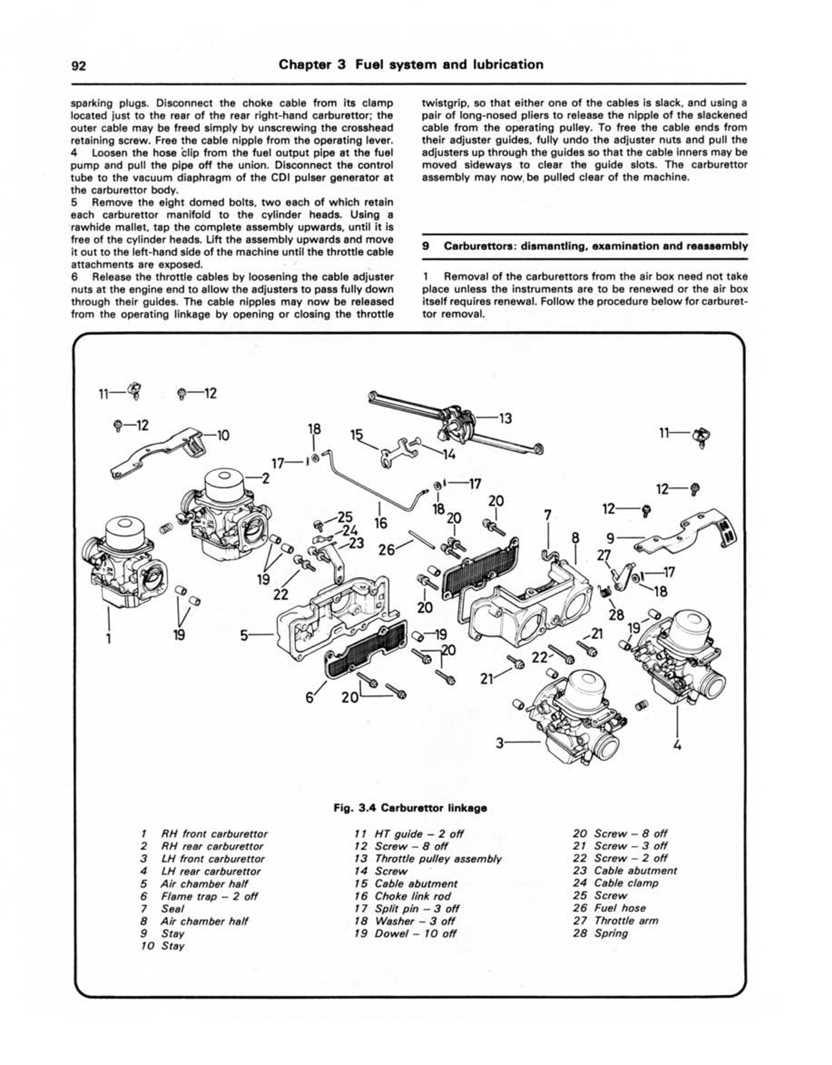

Identifying Engine Components

Understanding the various elements of an engine is essential for effective maintenance and troubleshooting. Each component plays a crucial role in the overall functionality, contributing to performance, efficiency, and reliability. Familiarity with these parts helps in identifying issues and implementing appropriate solutions.

Key Components to Recognize

- Fuel Tank: Stores the fuel required for engine operation.

- Air Filter: Cleans the air entering the engine, ensuring optimal combustion.

- Cylinder: The chamber where fuel and air mix for combustion.

- Piston: Moves within the cylinder to compress the fuel-air mixture and convert energy into mechanical motion.

- Crankshaft: Converts the linear motion of the piston into rotational motion, powering the engine.

- Exhaust System: Channels exhaust gases away from the engine and reduces noise.

Visual Identification Tips

- Use diagrams to familiarize yourself with the layout of the engine.

- Label parts during disassembly to avoid confusion during reassembly.

- Refer to part numbers when ordering replacements for precise matching.

- Take notes on the condition of each component to track wear over time.

Fuel System Troubleshooting Tips

Effective diagnosis of fuel delivery issues is essential for optimal engine performance. A thorough understanding of potential problems within the fuel system can help identify and resolve issues efficiently, ensuring smooth operation and longevity of the equipment.

Common Symptoms of Fuel System Issues

- Engine won’t start or has difficulty starting.

- Irregular or unstable idle.

- Engine stalling or losing power during operation.

- Excessive fuel consumption.

Troubleshooting Steps

- Check Fuel Quality: Ensure that the fuel is fresh and free from contaminants. Stale or contaminated fuel can lead to various issues.

- Inspect Fuel Lines: Look for cracks, leaks, or blockages in the fuel lines that could impede flow.

- Examine the Filter: A clogged fuel filter can restrict fuel flow. Replace it if necessary.

- Test the Fuel Pump: Verify that the fuel pump is functioning correctly by checking for proper pressure and operation.

- Inspect the Carburetor: Clean or rebuild the carburetor if it is dirty or malfunctioning, as it is crucial for proper fuel atomization.

By systematically addressing these areas, you can effectively troubleshoot and resolve fuel system problems, leading to improved engine performance and reliability.

Oil Change Procedure Explained

Regular maintenance of small engines is essential for optimal performance and longevity. One critical aspect of this upkeep is the timely replacement of lubrication fluid. This process not only helps to keep the engine components well-protected but also ensures smooth operation by reducing friction and heat buildup.

To perform an oil change, follow these simple steps to guarantee a thorough and effective job:

| Step | Description |

|---|---|

| 1 | Prepare the necessary tools and materials, including a wrench, oil container, and fresh lubricant. |

| 2 | Start the engine briefly to warm up the fluid, making it easier to drain. |

| 3 | Turn off the engine and allow it to cool for a few minutes. |

| 4 | Locate the drain plug and place an oil container underneath to catch the old fluid. |

| 5 | Remove the drain plug and let the used oil completely flow out. |

| 6 | Once drained, replace the drain plug securely. |

| 7 | Remove the oil filler cap and pour in the recommended type and amount of fresh lubricant. |

| 8 | Replace the filler cap and run the engine for a few minutes to circulate the new oil. |

| 9 | Check the oil level with the dipstick and add more if necessary. |

Following these steps ensures that the engine remains in peak condition, minimizing wear and extending its service life. Regularly changing the lubrication fluid is a straightforward yet vital task for anyone looking to maintain their small engine effectively.

Electrical System Diagnostics

Understanding the intricacies of an engine’s electrical framework is crucial for effective troubleshooting. This section provides insights into identifying and resolving common electrical issues that may arise.

- Check battery connections for corrosion or looseness.

- Inspect wiring harnesses for signs of wear or damage.

- Test fuses and relays to ensure they are functioning properly.

- Measure voltage at key points to detect any irregularities.

By following a systematic approach, one can delve deeper into potential faults and restore optimal performance.

- Start with a visual inspection of all electrical components.

- Use a multimeter to verify voltage levels.

- Replace any defective parts identified during the diagnostics.

- Conduct a final test to confirm that all systems are operational.

Ultimately, proper electrical diagnostics can prevent future issues and enhance the longevity of the machinery.

Replacing Spark Plugs Efficiently

Ensuring optimal performance of your engine often involves timely replacement of ignition components. This task, while straightforward, can greatly influence the efficiency and longevity of your equipment. In this section, we will outline the essential steps and considerations for replacing spark plugs effectively.

Necessary Tools and Materials

- New spark plugs

- Socket wrench with the appropriate size socket

- Torque wrench

- Spark plug gap tool

- Anti-seize compound (optional)

Step-by-Step Process

- Ensure the engine is cool to avoid burns.

- Disconnect the spark plug wire to prevent accidental ignition.

- Using the socket wrench, carefully remove the old spark plug by turning it counterclockwise.

- Inspect the old spark plug for wear and deposits to diagnose potential issues.

- Check the gap of the new spark plug with the gap tool, adjusting if necessary.

- Apply a small amount of anti-seize compound to the threads of the new spark plug (optional).

- Insert the new spark plug by hand to avoid cross-threading, then tighten with the socket wrench.

- Use the torque wrench to ensure the spark plug is tightened to the manufacturer’s specifications.

- Reconnect the spark plug wire securely.

Regularly checking and replacing ignition components can lead to smoother operation and better fuel efficiency. By following these steps, you can efficiently maintain your equipment and ensure its reliability.

Cleaning the Air Filter Properly

Maintaining optimal airflow is essential for the efficient operation of any engine. A clean air filter ensures that the engine receives an adequate supply of air, which enhances performance and prolongs its lifespan. Regularly inspecting and cleaning the air filter can prevent debris accumulation that may lead to engine inefficiency or damage.

Steps for Effective Cleaning

To begin the cleaning process, first, remove the air filter from its housing carefully. Depending on the type of filter, you may need to unscrew or unclip it. Once removed, tap it gently to dislodge any loose dirt or dust. For a more thorough clean, use a soft brush or compressed air to remove stubborn particles, ensuring not to damage the filter material.

Finalizing the Cleaning Process

After brushing or blowing away the debris, rinse the filter with soapy water if it is washable. Allow it to dry completely before reinstallation. If the filter shows signs of wear or significant damage, consider replacing it to maintain the engine’s efficiency. Regular maintenance will not only improve performance but also save on fuel consumption and reduce emissions.

When to Seek Professional Help

Determining when to consult an expert can significantly impact the longevity and functionality of your equipment. While many issues can be addressed with basic knowledge and tools, certain situations require specialized skills and experience.

Here are some indicators that it might be time to call in a professional:

- Persistent Issues: If problems continue despite your efforts to resolve them, it may indicate a deeper underlying issue.

- Complex Repairs: Tasks involving intricate components or systems often require expertise that goes beyond basic maintenance.

- Safety Concerns: If you’re unsure about the safety of a repair, especially those involving fuel or electrical systems, it’s best to consult a professional.

- Lack of Time: When your schedule is tight, relying on an expert can save you valuable time and ensure the job is done right.

- Warranty Issues: If your equipment is still under warranty, professional service may be required to avoid voiding it.

In summary, recognizing the limits of your capabilities is crucial. Seeking assistance from a qualified technician can prevent further damage and ensure safe operation.