Engines are vital components in various machinery, ensuring optimal performance and efficiency. Understanding how to maintain and troubleshoot these power units is crucial for longevity and reliability.

In this section, we will explore comprehensive insights into upkeep and common issues that may arise with small engines. By following detailed instructions and guidelines, users can enhance the functionality and extend the lifespan of their equipment.

Equipping yourself with the right knowledge and tools will enable you to address challenges effectively. This approach not only minimizes downtime but also ensures that your engine operates at peak efficiency.

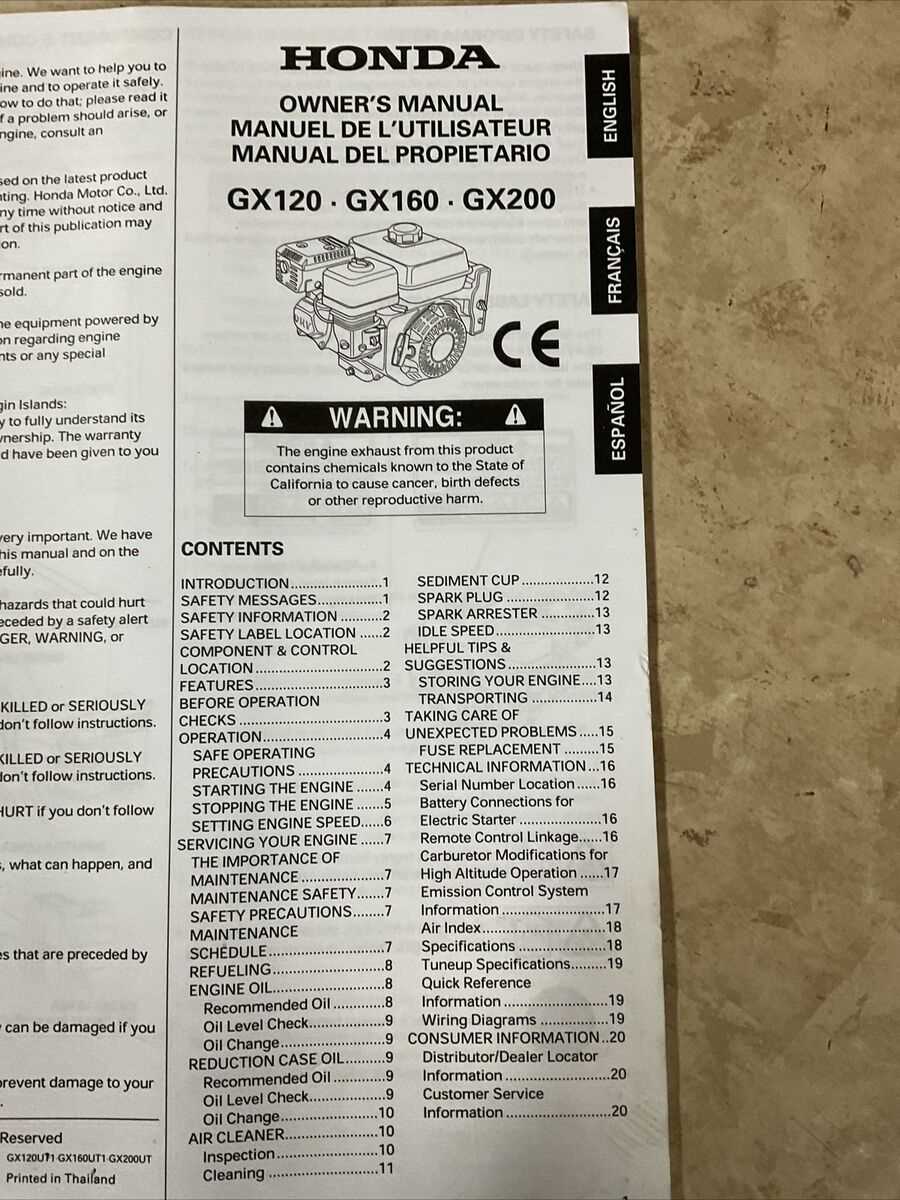

This section aims to provide a comprehensive overview of a popular small engine, focusing on its components, functionality, and maintenance practices. Understanding the inner workings of this power unit is essential for anyone looking to optimize its performance or troubleshoot issues effectively.

Key Components

- Engine Block

- Piston Assembly

- Crankshaft

- Fuel System

- Ignition System

Functionality Overview

The small engine operates on the principles of internal combustion, where fuel is mixed with air, ignited, and converted into mechanical energy. This energy drives the crankshaft, enabling various applications.

Maintenance Practices

- Regular oil changes

- Air filter inspections

- Fuel quality checks

Common Issues with Honda GX120

Various small engines often encounter specific challenges that can affect their performance and longevity. Identifying these issues early can help maintain optimal functioning and prevent further complications.

Engine Starts but Stalls

This problem may arise due to fuel-related issues or air supply restrictions. Ensuring proper fuel quality and checking the air filter can resolve this common malfunction.

Noisy Operation

Excessive noise can indicate mechanical wear or loose components. Regular maintenance checks can help identify and fix these problems before they escalate.

| Issue | Possible Cause | Solution |

|---|---|---|

| Engine starts but stalls | Poor fuel quality or air filter blockage | Replace fuel and clean or replace air filter |

| Noisy operation | Mechanical wear or loose parts | Perform maintenance checks and tighten components |

Step-by-Step Repair Process

This section provides a comprehensive overview of the procedure for fixing common issues with small engines. By following a systematic approach, users can efficiently diagnose and resolve problems, ensuring optimal performance of their equipment.

Initial Assessment

Begin by conducting a thorough examination of the engine. Look for visible signs of wear, damage, or leaks. Ensure that all components are properly secured and free from debris. This initial evaluation is crucial for identifying the root cause of any malfunction.

Disassembly and Inspection

Once the assessment is complete, carefully disassemble the necessary parts for a closer inspection. Take note of any worn or broken components that may require replacement. Keep track of all screws and small parts to ensure a smooth reassembly process.

| Component | Common Issues | Recommended Action |

|---|---|---|

| Fuel System | Clogs, Leaks | Clean or replace fuel lines and filters |

| Ignition System | Failure to Start | Inspect spark plug, replace if necessary |

| Air Filter | Blockage | Clean or replace air filter |

Tools Needed for Repairs

When undertaking maintenance tasks, having the right equipment is essential for ensuring efficiency and effectiveness. This section outlines the various instruments and devices necessary for handling common issues.

Essential Instruments

- Wrenches

- Screwdrivers

- Socket set

- Pliers

Additional Equipment

- Torque wrench

- Multimeter

- Oil filter wrench

- Fuel line clamps

Having these tools on hand will greatly facilitate the troubleshooting process and ensure that all tasks are completed smoothly.

Safety Precautions During Repairs

Ensuring safety during maintenance tasks is crucial for both the individual performing the work and the equipment involved. Adopting appropriate measures can prevent accidents and enhance the effectiveness of the task at hand.

Essential Safety Measures

- Always wear protective gear such as gloves, goggles, and ear protection.

- Work in a well-ventilated area to avoid inhaling harmful fumes.

- Ensure that the equipment is turned off and disconnected from any power source before beginning work.

- Keep your workspace tidy to minimize hazards and improve focus.

Emergency Preparedness

- Familiarize yourself with the location of emergency exits and equipment.

- Keep a first aid kit readily accessible in case of accidents.

- Know how to shut off power and fuel supply in emergencies.

Replacing Engine Components

Maintaining optimal performance of an engine often involves the timely replacement of its various parts. This process is crucial for ensuring reliability and longevity, as worn or damaged components can significantly impact functionality.

Before starting the replacement, it is essential to gather the necessary tools and materials. Ensure that you have a clean workspace to facilitate the task. Disassembly of the engine will require careful attention to detail, as each component plays a vital role in overall operation.

Begin by removing the outer casing to access internal parts. Carefully detach components such as the cylinder head, crankshaft, or carburetor, noting the orientation and connection of each piece. This will aid in accurate reassembly.

Once the old parts are removed, inspect them for wear. Install new components with precision, following manufacturer specifications to guarantee proper fit and function. Reassemble the engine in reverse order, ensuring all connections are secure.

Regular Maintenance Tips

Proper upkeep of your engine is essential for optimal performance and longevity. Adhering to routine maintenance practices can prevent potential issues and ensure smooth operation over time.

Essential Maintenance Practices

- Check and replace the oil regularly to keep the engine lubricated.

- Inspect air filters and clean or replace them as needed for optimal airflow.

- Ensure spark plugs are in good condition for efficient ignition.

- Monitor fuel levels and use fresh fuel to prevent clogging.

- Examine belts and hoses for wear and tear, replacing them when necessary.

Seasonal Preparations

- Before winter, drain any old fuel and replace it with new to avoid sediment buildup.

- Store the engine in a dry place to protect it from moisture.

- Conduct a thorough cleaning to remove dirt and debris from exterior parts.

- Check battery health and charge if necessary to ensure reliability.

Troubleshooting Engine Performance

When facing issues with engine functionality, it is crucial to identify potential causes that may affect overall performance. Understanding the symptoms can lead to effective solutions, ensuring optimal operation and longevity of the machine.

Common indicators of performance problems include unusual noises, difficulty starting, or a lack of power during operation. Each of these symptoms may stem from various sources such as fuel supply issues, air intake restrictions, or ignition system failures.

To begin troubleshooting, check the fuel system for blockages or leaks. Ensure that the fuel is clean and free of contaminants. Next, inspect the air filter and intake system for any obstructions that may hinder airflow. Additionally, examining the ignition components can help determine if the spark plug or ignition coil needs replacement.

By systematically addressing each of these areas, you can pinpoint the root cause of performance issues and implement appropriate corrective actions to restore functionality.

Identifying Electrical Problems

Electrical issues can manifest in various forms, impacting the performance of machinery. Recognizing these problems early is crucial for maintaining efficiency and preventing further damage. Common signs include unusual noises, intermittent functionality, and failure to start, which may indicate underlying electrical faults.

To accurately diagnose these issues, one should first inspect all wiring and connections for signs of wear or corrosion. Loose or damaged wires can disrupt power flow, leading to malfunctions. Additionally, checking fuses and circuit breakers is essential, as blown fuses or tripped breakers can prevent equipment from operating correctly.

Utilizing a multimeter can help test voltage levels and continuity in circuits. This tool allows for identifying breaks in connections or components that may not be functioning as intended. Regularly monitoring electrical systems can help catch problems before they escalate, ensuring smooth operation.

Fuel System Repair Techniques

Addressing issues within the fuel delivery system is essential for optimal engine performance. This section explores various methods to troubleshoot and enhance the components responsible for fuel supply.

Identifying Common Issues

Recognizing signs of malfunction is the first step in resolving fuel system challenges. Look for symptoms such as irregular engine performance, difficulty starting, or abnormal fuel consumption. These indicators often point to clogged filters or failing pumps.

Maintenance Procedures

Regular upkeep can prevent many fuel system complications. Cleaning the fuel filter and inspecting the fuel lines are crucial tasks that help maintain efficiency. Ensure all connections are secure to avoid leaks and ensure proper fuel flow.

Effective Cleaning Methods

Maintaining the optimal performance of small engines requires regular cleaning. Implementing proper cleaning techniques not only extends the lifespan of the equipment but also ensures efficient operation. This section will explore several effective methods for cleaning components thoroughly.

Recommended Cleaning Supplies

To achieve the best results, it’s essential to use the right cleaning materials. Here are some commonly recommended supplies:

| Item | Purpose |

|---|---|

| Soft Brush | Removes dirt and debris from surfaces |

| Degreaser | Dissolves oil and grease |

| Rags | Wipes off excess cleaner and residues |

Step-by-Step Cleaning Process

Follow these steps for effective cleaning:

- Ensure the engine is cool and turned off.

- Use a soft brush to remove loose dirt.

- Apply degreaser to oily areas and let it sit for a few minutes.

- Scrub gently with the brush and wipe with a rag.

- Inspect for any remaining debris and repeat as necessary.

When to Seek Professional Help

Understanding when to consult an expert can save time and ensure proper functioning of equipment. While many issues can be resolved independently, certain situations require specialized knowledge and experience.

Consider reaching out to a professional in the following cases:

- If the problem persists after following standard troubleshooting steps.

- When unfamiliar noises or vibrations occur that may indicate a serious issue.

- In cases where the equipment has sustained physical damage.

- If there are signs of fluid leaks or other hazardous conditions.

- When routine maintenance tasks exceed personal skills or tools available.

Seeking assistance from a qualified technician can ensure safety and restore performance effectively.