This section aims to provide essential insights and instructions for maintaining and servicing a specific type of two-wheeled vehicle. The focus is on ensuring optimal performance, longevity, and safety through regular checks and appropriate repairs.

Understanding the intricacies of your vehicle’s components is crucial. Each part plays a significant role in overall functionality, and recognizing how to address common issues can lead to more efficient and cost-effective solutions. This guide will equip you with the knowledge needed to tackle various challenges that may arise during your ownership experience.

From basic upkeep to more advanced troubleshooting techniques, the information presented here is designed to enhance your ability to manage your vehicle effectively. Whether you’re a seasoned enthusiast or a novice, these resources will empower you to make informed decisions and ensure your vehicle remains in excellent condition.

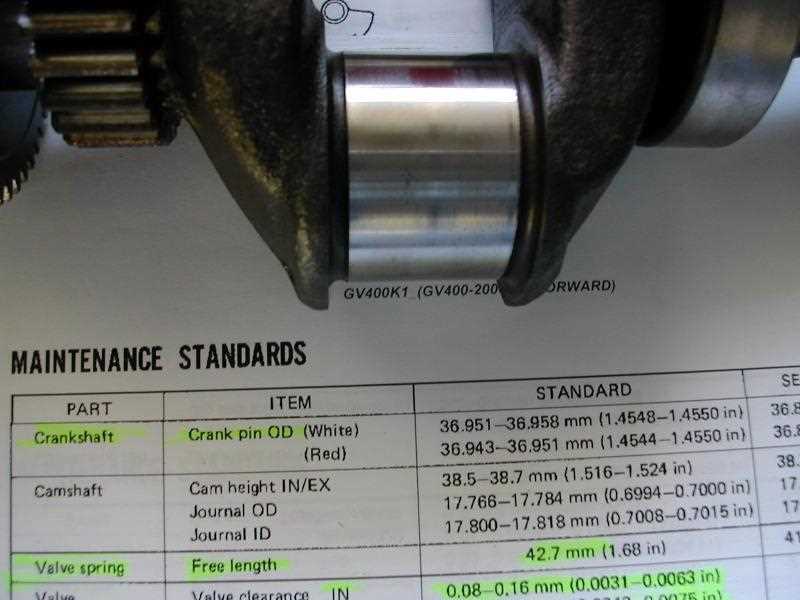

Overview of Gv400 Maintenance Procedures

Regular upkeep is essential for ensuring the longevity and optimal performance of any vehicle. This section outlines fundamental tasks and strategies that are vital for maintaining a reliable and efficient ride. Understanding these procedures helps owners enhance their experience and prevent common issues.

Essential Maintenance Tasks

Adhering to a systematic maintenance schedule is crucial. Below are the core activities to focus on:

| Task | Frequency |

|---|---|

| Oil Change | Every 3,000 miles |

| Air Filter Replacement | Every 12,000 miles |

| Tire Rotation | Every 6,000 miles |

| Brake Inspection | Every 15,000 miles |

Tips for Effective Upkeep

Implementing these strategies can significantly improve the reliability of your vehicle:

- Keep a detailed log of all maintenance activities.

- Use high-quality replacement parts to ensure performance.

- Stay informed about any recalls or service bulletins.

Essential Tools for Effective Repairs

Having the right equipment is crucial for successful maintenance tasks. A well-equipped workspace not only enhances efficiency but also ensures precision in every procedure. Below are some fundamental instruments that can significantly improve your repair experience.

Basic Hand Tools

- Wrenches: Essential for loosening and tightening fasteners.

- Screwdrivers: Available in various sizes and types for diverse screws.

- Pliers: Useful for gripping, twisting, and cutting wire.

- Hammers: Necessary for assembling parts or dislodging components.

Specialized Equipment

- Torque Wrench: Ensures fasteners are tightened to the correct specifications.

- Multimeter: Helps in diagnosing electrical issues by measuring voltage and resistance.

- Jack and Stands: Required for safely lifting and supporting a vehicle during work.

- Diagnostic Scanner: Useful for retrieving error codes and assessing performance metrics.

Troubleshooting Common Issues

When dealing with performance problems or operational faults, a systematic approach can help identify and resolve issues effectively. Understanding typical symptoms and their potential causes is crucial for efficient diagnostics.

Below are some prevalent challenges encountered and suggested steps to address them:

- Starting Difficulties:

- Check the battery charge and connections.

- Inspect the ignition system for wear or faults.

- Examine fuel supply for clogs or leaks.

- Overheating:

- Verify coolant levels and check for leaks.

- Inspect the radiator and cooling fans for proper operation.

- Look for any obstructions in the airflow.

- Unusual Noises:

- Identify the source of the sound–engine, transmission, or suspension.

- Check for loose components or damaged parts.

- Listen for changes in sound during acceleration or braking.

- Poor Handling:

- Examine tire pressure and tread condition.

- Inspect suspension components for wear or damage.

- Evaluate alignment and balancing settings.

By methodically addressing these common concerns, users can enhance reliability and extend the lifespan of their vehicle.

Step-by-Step Repair Techniques

This section focuses on systematic approaches to restoring functionality and ensuring optimal performance of your vehicle. Each technique outlined here is designed to guide you through various procedures, enabling efficient troubleshooting and maintenance.

Essential Tools Required

Before embarking on any restoration tasks, ensure you have the following tools at your disposal:

| Tool | Purpose |

|---|---|

| Socket Set | For loosening and tightening fasteners |

| Screwdriver Set | For removing screws in various sizes |

| Pliers | For gripping and bending components |

| Torque Wrench | For applying specific torque to fasteners |

Common Procedures

Follow these steps for typical tasks involved in maintenance:

- Begin by disconnecting the battery to ensure safety.

- Remove any protective covers or components obstructing access.

- Carefully inspect each part for signs of wear or damage.

- Replace or repair components as necessary, following the specifications for installation.

- Reassemble all parts in reverse order, ensuring secure connections.

Understanding the Electrical System

The electrical framework of a vehicle plays a crucial role in its overall functionality and efficiency. This system comprises various components that work together to ensure smooth operation, from ignition to lighting. Understanding how these elements interact can greatly assist in troubleshooting and maintenance.

Key components include the battery, alternator, and wiring harness, each contributing to the effective distribution of power throughout the vehicle. Proper knowledge of this setup allows for better diagnostics and timely interventions when issues arise.

| Component | Function |

|---|---|

| Battery | Stores electrical energy and provides power for starting the engine and operating accessories. |

| Alternator | Generates electrical power while the engine is running, recharging the battery. |

| Wiring Harness | Connects various electrical components, ensuring proper communication and power distribution. |

| Fuses | Protect the electrical system by preventing overloads and short circuits. |

By familiarizing oneself with these elements, owners can enhance their ability to maintain and troubleshoot the vehicle effectively.

Engine Components and Their Functions

The functionality of an internal combustion engine relies on various integral elements that work cohesively to ensure optimal performance. Each part plays a distinct role in the overall operation, contributing to the efficiency and power of the engine.

The cylinder block serves as the main structure housing essential components like pistons and crankshaft. It provides the necessary strength to withstand combustion forces while enabling effective heat dissipation.

Pistons convert the pressure from combustion into mechanical energy, moving up and down within the cylinders. This movement drives the crankshaft, which translates the linear motion into rotational energy that powers the vehicle.

The camshaft controls the timing of valve openings and closings, allowing for the precise intake of air-fuel mixture and exhaust gases. Synchronization with the crankshaft is crucial for maintaining engine performance.

Valves, including intake and exhaust types, regulate airflow into and out of the combustion chamber. Their precise operation ensures that the engine breathes efficiently, affecting overall power output and fuel consumption.

Finally, the ignition system ignites the air-fuel mixture at the correct moment, initiating combustion. A well-functioning ignition system is vital for smooth engine operation and responsiveness.

Routine Checks for Optimal Performance

Regular maintenance is essential to ensure the longevity and efficiency of any vehicle. By adhering to a systematic approach, owners can identify potential issues early and maintain peak functionality. This section outlines key checks that contribute to the overall health of the machine.

Fluid Levels and Quality

Monitoring fluid levels is crucial. Regularly inspect the engine oil, coolant, and brake fluid to ensure they are at appropriate levels and free from contaminants. Changing fluids at recommended intervals not only protects engine components but also enhances performance.

Tire Condition and Pressure

The state of the tires directly impacts handling and safety. Check for worn treads and maintain the correct air pressure. Proper inflation improves fuel efficiency and extends tire lifespan, ensuring a smoother ride.

Safety Precautions During Repairs

When working on machinery, ensuring safety is paramount. Taking the necessary precautions not only protects the individual but also enhances the efficiency of the task at hand. Understanding potential hazards and implementing measures to mitigate risks is essential for a successful outcome.

Personal Protective Equipment

Utilizing appropriate gear is crucial when undertaking any maintenance work. Items such as gloves, goggles, and sturdy footwear help shield against potential injuries. Ensure that all equipment is in good condition and fits properly to maximize protection.

Workspace Organization

Maintaining a tidy area is vital for preventing accidents. Keep tools organized and within reach to avoid unnecessary movements that could lead to mishaps. Clear any clutter and ensure that the workspace is well-lit, allowing for better visibility and reducing the likelihood of errors.

Parts Replacement and Upgrades

Maintaining the optimal performance of a vehicle often requires the timely replacement of components and thoughtful upgrades. This section delves into various strategies for enhancing functionality and longevity, ensuring that each part operates effectively within the system.

Identifying Worn Components

Recognizing when parts are due for replacement is crucial. Regular inspections can help spot signs of wear, such as unusual noises, decreased efficiency, or visual damage. Essential components to monitor include the braking system, suspension elements, and powertrain parts. Proactive replacement can prevent further issues and maintain safety.

Upgrading for Improved Performance

In addition to replacing worn parts, upgrading components can significantly enhance a vehicle’s performance. Performance-enhancing upgrades such as improved exhaust systems, enhanced air intakes, or upgraded suspension kits can lead to better handling and increased power. Evaluating the compatibility of these upgrades with existing systems is vital for achieving desired results.

Finding Quality Replacement Parts

Locating high-grade components is essential for maintaining optimal performance and longevity of any vehicle. The right parts not only ensure proper functionality but also enhance safety and reliability. This section will guide you through the best practices for sourcing top-notch replacements.

Where to Look

Consider various sources for obtaining superior parts. Authorized dealers often provide original equipment manufacturer (OEM) options, while online retailers can offer a wider selection. Additionally, salvage yards may have functional components at a fraction of the cost.

Evaluating Quality

When assessing parts, consider factors such as warranty, customer reviews, and certifications. High-quality replacements often come with a guarantee, indicating the manufacturer’s confidence in their product. Checking feedback from previous buyers can also reveal insights about performance and durability.

| Source | Advantages | Considerations |

|---|---|---|

| Authorized Dealers | OEM Parts, Warranty | Higher Cost |

| Online Retailers | Wide Selection, Competitive Prices | Variable Quality |

| Salvage Yards | Cost-Effective Options | Limited Availability |