This section provides essential insights into the upkeep and troubleshooting of a specific automobile model. Understanding the intricacies of this vehicle will enhance your ability to address common issues and ensure its longevity. Whether you are a seasoned mechanic or a novice enthusiast, having access to reliable information is crucial for successful maintenance.

Equipped with knowledge about various components and systems, you can tackle a wide range of challenges that may arise during ownership. This guide aims to empower you with the skills necessary to perform essential tasks effectively. Emphasizing practical advice and step-by-step instructions, the content is designed to assist you in navigating the complexities of vehicle care.

By familiarizing yourself with the technical aspects outlined here, you can develop a deeper appreciation for automotive craftsmanship. Regular maintenance not only improves performance but also enhances safety, ultimately leading to a more enjoyable driving experience. Dive into the details and discover how to keep your automobile running smoothly and efficiently.

This section discusses frequently encountered problems and their corresponding signs that may indicate underlying issues with the vehicle. Understanding these symptoms can help in diagnosing and addressing concerns effectively.

Engine Performance Problems

- Unusual noises during operation

- Loss of power while accelerating

- Increased fuel consumption

- Check engine light activation

Transmission Difficulties

- Slipping or jerking during gear shifts

- Delayed engagement when shifting from park to drive

- Unusual vibrations felt while driving

- Fluid leaks under the vehicle

Engine Specifications and Maintenance

This section provides essential information regarding the powertrain components and their upkeep for optimal performance. Understanding the specifications and maintenance requirements is crucial for ensuring longevity and reliability of the engine.

The following points outline key specifications and maintenance practices:

- Engine Type: V6 or V8 configuration depending on the model variant.

- Displacement: Typically ranges from 3.0 to 4.0 liters.

- Horsepower: Output varies, generally between 150 to 280 horsepower.

- Torque: Peak torque often lies between 180 to 300 lb-ft.

Regular maintenance is vital to ensure peak performance. Recommended practices include:

- Oil Changes: Conduct every 5,000 to 7,500 miles or as per the manufacturer’s guidelines.

- Coolant System Inspection: Check and replace coolant every 30,000 miles to prevent overheating.

- Air Filter Replacement: Change the air filter every 15,000 to 30,000 miles to maintain airflow efficiency.

- Spark Plug Replacement: Replace spark plugs every 100,000 miles to ensure smooth ignition.

Adhering to these specifications and maintenance routines will enhance engine performance and reliability over time.

Transmission Troubleshooting Guide

This section provides essential information for diagnosing common issues related to the vehicle’s gearbox system. Understanding these problems can help identify underlying faults and facilitate appropriate solutions, ensuring smooth operation and reliability.

Common Symptoms of Transmission Issues

Drivers may experience a variety of symptoms indicating potential gearbox problems. Some common signs include:

- Slipping Gears: This occurs when the transmission unexpectedly changes gears or fails to engage properly.

- Unusual Noises: Grinding, whining, or clunking sounds can indicate mechanical failure within the gearbox.

- Fluid Leaks: Spotting fluid under the vehicle may suggest a leak, which can severely impact transmission performance.

- Delayed Engagement: Hesitation or a noticeable delay when shifting from park to drive can signal an internal issue.

Troubleshooting Steps

To effectively diagnose gearbox problems, follow these steps:

- Check Fluid Levels: Ensure that the transmission fluid is at the recommended level and inspect its condition. Low or dirty fluid can lead to performance issues.

- Inspect for Leaks: Examine the undercarriage and transmission components for any signs of leaking fluid.

- Test Drive: Pay attention to the vehicle’s behavior during a short drive. Note any irregularities in shifting or performance.

- Scan for Error Codes: Use a diagnostic scanner to check for any trouble codes that may provide insight into the issue.

By following these guidelines, drivers can gain a clearer understanding of potential transmission challenges and seek appropriate resolutions to maintain their vehicle’s performance.

Electrical System Diagnostics

Diagnosing issues within the electrical framework of a vehicle is crucial for ensuring optimal performance and reliability. A systematic approach helps in identifying malfunctions, which can range from simple wiring faults to complex component failures. By understanding the intricacies of the electrical network, technicians can effectively troubleshoot problems and implement solutions.

Common Symptoms of Electrical Issues

Drivers may notice several signs indicating potential electrical malfunctions. These symptoms often include:

- Dim or Flickering Lights: A clear indication of inadequate power supply or faulty connections.

- Starting Problems: Difficulty in starting the engine can point towards battery or starter motor issues.

- Electrical Accessories Malfunction: Failure of components such as power windows or radio may suggest wiring problems.

Diagnostic Tools and Techniques

Utilizing appropriate diagnostic tools is essential for effective troubleshooting. Common instruments include:

- Multimeter: For measuring voltage, current, and resistance, providing insight into circuit conditions.

- Scan Tool: This device can retrieve fault codes from the vehicle’s computer, aiding in identifying specific problems.

- Visual Inspection: Regular checks of wiring harnesses and connectors can reveal wear and tear or corrosion.

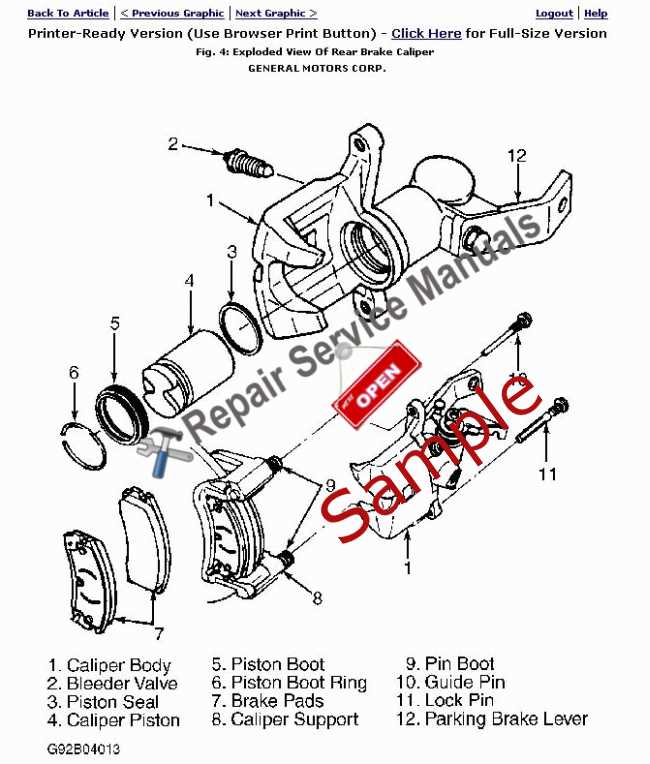

Brake System Inspection Procedures

The examination of the braking mechanism is crucial for ensuring optimal performance and safety. This section outlines the necessary steps to effectively assess the components involved in the braking process. Regular checks can help identify wear and tear, which is vital for maintaining the integrity of the vehicle’s stopping capabilities.

Begin by visually inspecting the brake pads for any signs of deterioration or uneven wear. Look for cracks, chips, or excessive thinning, which may indicate that they need replacement. Next, assess the brake rotors for warping or scoring. Any noticeable grooves or irregularities can compromise braking efficiency and should be addressed promptly.

Check the brake fluid level in the reservoir. Low fluid levels can lead to air entering the brake lines, causing a spongy brake pedal. If necessary, top up the fluid with the appropriate type as specified in the vehicle guidelines. Additionally, examine the brake lines for leaks or damage, ensuring they are securely attached and free from corrosion.

Finally, conduct a road test to evaluate the braking performance. Listen for any unusual noises, such as squeaking or grinding, which may indicate issues with the brake system. Pay attention to how the brakes respond; they should engage smoothly and effectively without pulling to one side. If any irregularities are detected during the inspection, further investigation and repairs are warranted to ensure safe operation.

Suspension and Steering Insights

The suspension and steering systems are crucial components that significantly influence vehicle handling and ride comfort. Understanding their functionality and maintenance can enhance performance and prolong the lifespan of these systems. Properly maintained suspension and steering not only ensure a smooth ride but also contribute to safety and control on various terrains.

Importance of Regular Maintenance

Regular maintenance of suspension and steering systems is vital for optimal vehicle performance. Inspecting components such as shocks, struts, and control arms can prevent issues that may arise from wear and tear. Additionally, ensuring that the alignment is properly set helps in enhancing tire longevity and improving handling characteristics.

Common Issues and Solutions

Common problems associated with these systems include excessive bouncing, uneven tire wear, and steering difficulties. Identifying these issues early can save time and costs associated with repairs. For instance, replacing worn-out bushings or adjusting the steering components can often resolve handling problems. Proactive maintenance is key to avoiding more extensive damage.

Cooling System Maintenance Tips

The cooling system plays a crucial role in maintaining the optimal temperature of your vehicle’s engine. Proper upkeep of this system can enhance performance, increase longevity, and prevent overheating. Here are some essential practices to ensure your engine stays cool and functions efficiently.

Regular Fluid Checks

Consistently monitor the coolant level in your vehicle. Ensure that the fluid is at the recommended level, as low coolant can lead to overheating. Additionally, check for any signs of leaks in the hoses, radiator, and connections. If you notice a decrease in fluid, investigate the cause and address it promptly.

Cooling System Flush

Perform a cooling system flush periodically to remove any buildup of contaminants and rust. This process helps maintain the efficiency of the radiator and prevents blockages. Use the appropriate coolant type as specified by the manufacturer, and follow the recommended intervals for flushing to keep the system in optimal condition.

By adhering to these maintenance tips, you can ensure the cooling system operates effectively, ultimately contributing to a smoother and more reliable driving experience.

Exhaust System Repairs Explained

The exhaust system is a critical component in maintaining a vehicle’s performance and efficiency. It plays a vital role in directing harmful gases away from the engine and reducing noise levels. Over time, various elements of this system may require attention due to wear and tear, leaks, or damage from road conditions. Understanding the common issues and the necessary procedures for addressing them can greatly enhance the lifespan of the vehicle.

Identifying Common Problems is the first step in ensuring proper functionality. Frequent signs of issues include unusual noises, reduced fuel efficiency, or visible damage to exhaust pipes. These symptoms can indicate problems such as rust, cracks, or loose fittings, which may necessitate further investigation.

Repair Techniques vary depending on the specific issue encountered. For instance, if a leak is detected, sealing methods may be employed, while more severe damage might require replacement of entire sections. Proper tools and techniques are essential to perform these tasks effectively. Additionally, ensuring all connections are tight and secure is crucial to prevent future complications.

Regular maintenance and timely repairs can lead to improved performance and reduced emissions. Taking proactive steps can help avoid costly replacements and enhance the overall driving experience.

Body and Interior Repair Strategies

This section explores effective methods for addressing issues related to the external and internal components of vehicles. Ensuring the integrity and aesthetic appeal of both the body and interior is essential for maintaining value and safety.

Exterior Maintenance Techniques

Proper care of the vehicle’s exterior involves several strategies:

- Regular Washing: Keep the surface clean to prevent rust and corrosion.

- Paint Protection: Use wax or sealants to shield the paint from UV rays and environmental contaminants.

- Minor Dents and Scratches: Address small imperfections promptly using tools or kits designed for such repairs.

Interior Upkeep Tips

Maintaining the interior enhances comfort and extends the lifespan of components:

- Vacuuming: Regularly clean carpets and upholstery to remove dirt and debris.

- Conditioning: Use appropriate products for leather or fabric to prevent cracking and fading.

- Dashboard Care: Wipe down surfaces with suitable cleaners to avoid dust accumulation and maintain appearance.

Tools Needed for Repairs

When undertaking maintenance or fixing issues in a vehicle, having the right equipment is crucial for successful outcomes. Various tools cater to different tasks, ensuring efficiency and safety during the process. Proper preparation with the appropriate instruments not only simplifies the job but also enhances the overall experience.

Essential items include a comprehensive set of wrenches and sockets, which are vital for loosening and tightening bolts and nuts. A torque wrench is particularly important for applying precise pressure to fasteners, preventing damage. Additionally, pliers and screwdrivers in multiple sizes facilitate a wide range of adjustments and repairs.

For those more involved in electrical components, a multimeter is indispensable for diagnosing electrical issues. A jack and jack stands are necessary for lifting the vehicle safely when working underneath. Moreover, keeping a reliable flashlight on hand can greatly assist in illuminating dark areas during inspections.

Finally, investing in a quality tool organizer can help keep all equipment neatly arranged and easily accessible, streamlining the repair process and promoting a more effective workspace.

Routine Maintenance Checklist

Regular upkeep is essential for ensuring the longevity and optimal performance of your vehicle. Following a consistent schedule of checks and tasks can help prevent major issues and enhance safety. The following checklist outlines key activities to maintain your automobile in excellent condition.

1. Engine Oil Change: Check the oil level monthly and replace it as recommended by the manufacturer to ensure proper lubrication and engine health.

2. Tire Inspection: Examine tire pressure and tread depth regularly. Rotate tires every 5,000 to 7,500 miles to promote even wear.

3. Brake System Check: Inspect brake pads and fluid levels at least twice a year. Listen for unusual sounds while braking, as they can indicate wear.

4. Battery Maintenance: Check battery terminals for corrosion and ensure a secure connection. Test battery health annually, especially before winter.

5. Fluid Levels: Regularly monitor coolant, transmission fluid, brake fluid, and windshield washer fluid levels, topping off as needed.

6. Air Filter Replacement: Replace the engine air filter every 15,000 to 30,000 miles to maintain optimal airflow and engine efficiency.

7. Wiper Blades: Inspect wiper blades for wear and replace them if they are leaving streaks or not functioning effectively.

8. Light Functionality: Regularly check all exterior lights, including headlights, taillights, and turn signals, to ensure they are functioning properly.

By adhering to this routine checklist, you can help ensure that your automobile remains reliable and efficient for years to come.

Safety Precautions During Repairs

When undertaking maintenance or servicing of vehicles, it is crucial to prioritize safety to prevent accidents and injuries. Adhering to established guidelines and being aware of potential hazards can significantly enhance the safety of the work environment.

Always ensure that you are equipped with the proper personal protective equipment (PPE) such as gloves, safety glasses, and steel-toed boots. These items serve as a first line of defense against unexpected incidents. Additionally, it is essential to work in a well-ventilated area to minimize exposure to harmful fumes and chemicals.

Before starting any task, thoroughly inspect the workspace for potential dangers, including clutter or improper lighting. It is advisable to have a fire extinguisher nearby, especially when dealing with flammable materials. Furthermore, make sure to follow all manufacturer instructions and guidelines to ensure safe handling of tools and components.

Lastly, keep a first aid kit on hand in case of minor injuries. Regularly review safety procedures and encourage others in the workspace to remain vigilant about their own safety as well as that of their colleagues. By fostering a culture of safety, everyone can contribute to a safer and more efficient working environment.