Understanding the intricacies of vehicle rehabilitation is essential for both enthusiasts and professionals in the automotive field. This guide provides a thorough exploration of the techniques and resources needed to address various challenges encountered during the rejuvenation of damaged vehicles. With a focus on best practices, it empowers readers to achieve high-quality results.

Every automobile has unique specifications and characteristics that influence the restoration process. This resource delves into essential methodologies, covering everything from basic assessments to advanced corrective actions. By familiarizing oneself with these approaches, individuals can ensure that their efforts yield optimal outcomes.

Furthermore, the significance of utilizing authoritative references cannot be overstated. These resources serve as invaluable tools, offering insights into proper techniques and recommended standards. Emphasizing the importance of knowledge and preparation, this guide aims to equip readers with the information necessary for successful automotive enhancement.

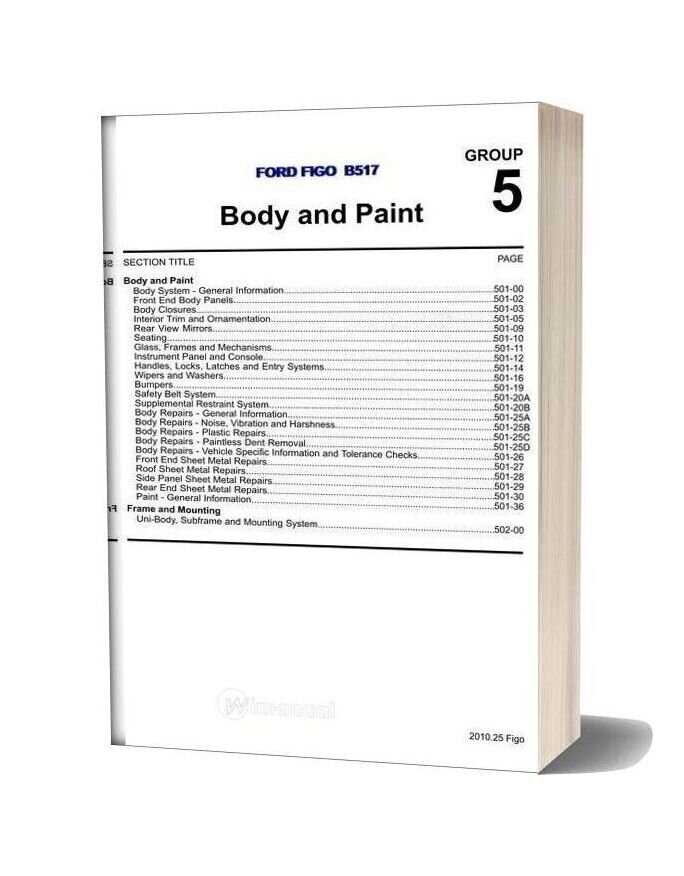

Understanding the Ford Collision Repair Manual

This section delves into the essential guidance provided for restoring vehicles to their original state after damage. It encompasses various techniques, specifications, and recommendations aimed at ensuring optimal performance and safety.

Key Components

The document includes several critical elements that facilitate the restoration process:

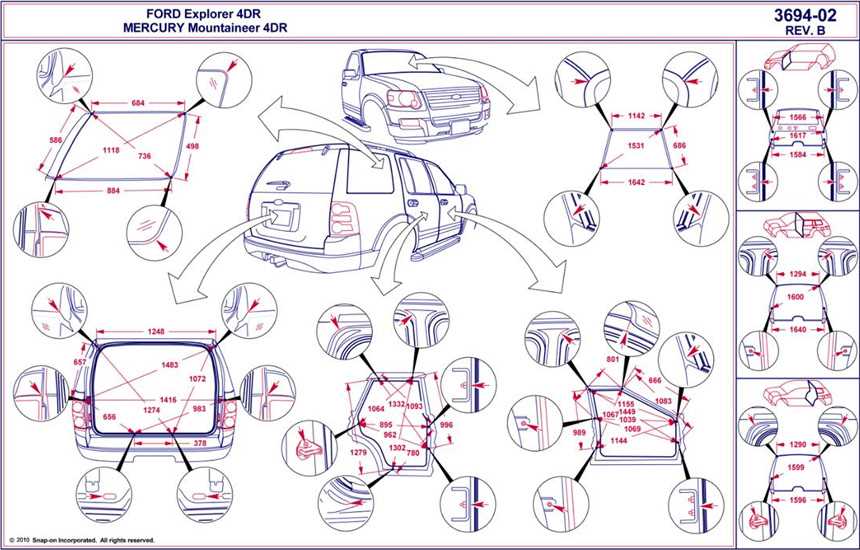

- Technical Specifications: Detailed measurements and standards required for different vehicle parts.

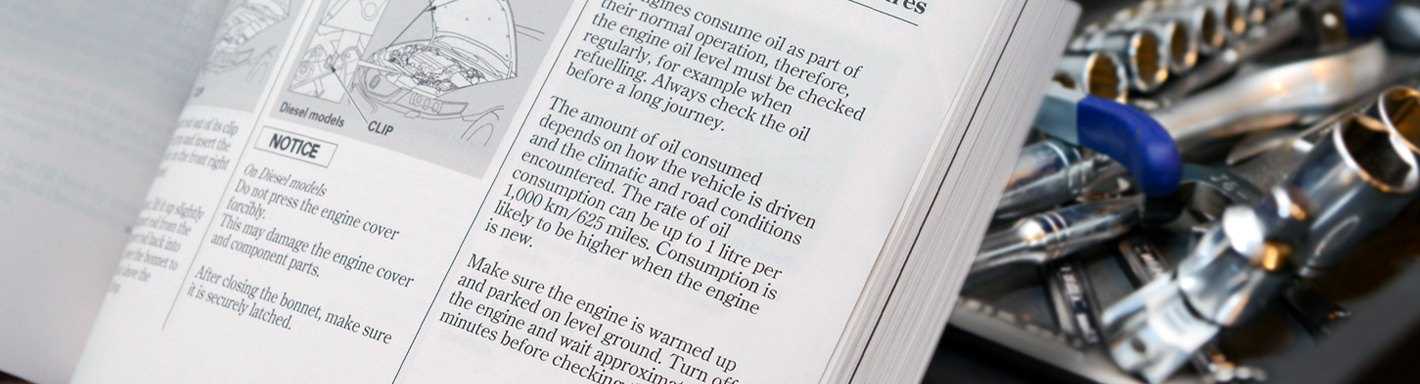

- Procedure Guidelines: Step-by-step instructions on how to approach various restoration tasks.

- Diagnostic Tools: Recommendations on equipment needed to assess and address issues accurately.

Benefits of Using the Guide

Utilizing this resource offers numerous advantages:

- Increased Efficiency: Streamlined processes reduce time spent on repairs.

- Enhanced Safety: Ensures all fixes meet safety standards, protecting drivers and passengers.

- Expert Insights: Access to industry knowledge and best practices.

Importance of Accurate Repair Documentation

Maintaining precise records during the restoration process is crucial for ensuring quality and accountability. These documents serve as a detailed account of the procedures undertaken, materials used, and the specific issues addressed. Such thorough documentation not only aids in maintaining consistency but also provides valuable insights for future reference, enhancing overall efficiency.

Benefits for Professionals

For technicians, meticulous records enable easier troubleshooting and facilitate communication within teams. When each step is documented accurately, it reduces the likelihood of errors and ensures that every aspect of the job meets industry standards. Furthermore, this information can be instrumental in training new employees, as it offers real-world examples of various challenges and solutions.

Impact on Customers

Clients benefit significantly from detailed documentation as well. It fosters transparency, allowing customers to understand the work performed and the rationale behind specific decisions. This not only builds trust but also enhances customer satisfaction, as they can be assured that their vehicle is in capable hands, backed by a comprehensive account of all actions taken.

Common Types of Collision Damage

Understanding the various forms of damage that vehicles may sustain in an accident is crucial for assessing the extent of the impact and planning subsequent actions. Each type of harm can vary significantly, influencing the approach to restoration and the resources required.

Types of Damage

- Body Damage: This involves dents, scratches, and bent panels that affect the outer structure of the vehicle.

- Frame Damage: Structural integrity may be compromised, leading to misalignment of the chassis.

- Paint Damage: Scrapes and chips can occur, requiring touch-ups or complete repainting.

- Glass Damage: Windshields and windows may crack or shatter, necessitating replacement.

- Mechanical Damage: Internal components, including the engine and transmission, might be affected, leading to performance issues.

Assessment and Repair Considerations

- Inspection: A thorough evaluation is necessary to identify all affected areas.

- Estimation: Costs should be estimated based on the type and extent of the damage.

- Action Plan: Develop a clear strategy for addressing each type of damage efficiently.

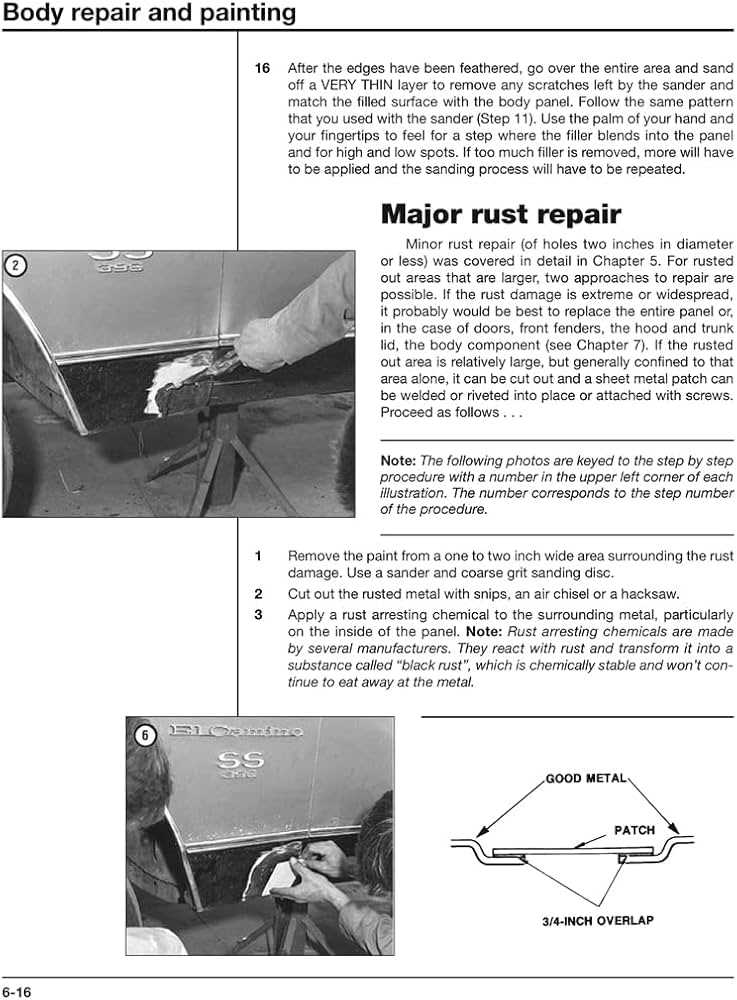

Step-by-Step Repair Process Overview

This section outlines a comprehensive approach to addressing vehicle damage, ensuring that each phase is methodically executed. Understanding the sequential tasks involved can enhance efficiency and lead to successful outcomes.

Initial Assessment

- Examine the vehicle thoroughly for visible damage.

- Document findings with photographs and notes.

- Identify all components that require attention.

Preparation for Restoration

- Gather necessary tools and materials.

- Prepare a clean workspace to ensure safety and efficiency.

- Remove damaged parts carefully to avoid further issues.

By following these steps, one can ensure a structured approach to rejuvenating the vehicle, leading to satisfactory results for both the technician and the owner.

Tools and Equipment for Repairs

Effective restoration requires a diverse array of implements and devices tailored for various tasks. Understanding the right tools and their specific functions is crucial for achieving optimal outcomes in any repair situation. The selection of proper equipment not only enhances efficiency but also ensures safety and precision throughout the process.

Hand Tools: A variety of hand tools, such as wrenches, screwdrivers, and pliers, are essential for performing detailed work. These tools allow technicians to execute precise adjustments and dismantle components with ease. Investing in high-quality hand tools can significantly improve durability and reliability.

Power Tools: For more demanding tasks, power tools like drills, grinders, and sanders are indispensable. These machines expedite processes that would otherwise take considerable time and effort, providing consistent results. Familiarity with their operation and safety precautions is vital for effective usage.

Measuring Instruments: Accurate measurements are fundamental in any restoration endeavor. Tools such as calipers, tape measures, and laser measuring devices ensure that all components fit together perfectly. Employing these instruments minimizes errors and enhances the overall quality of the work.

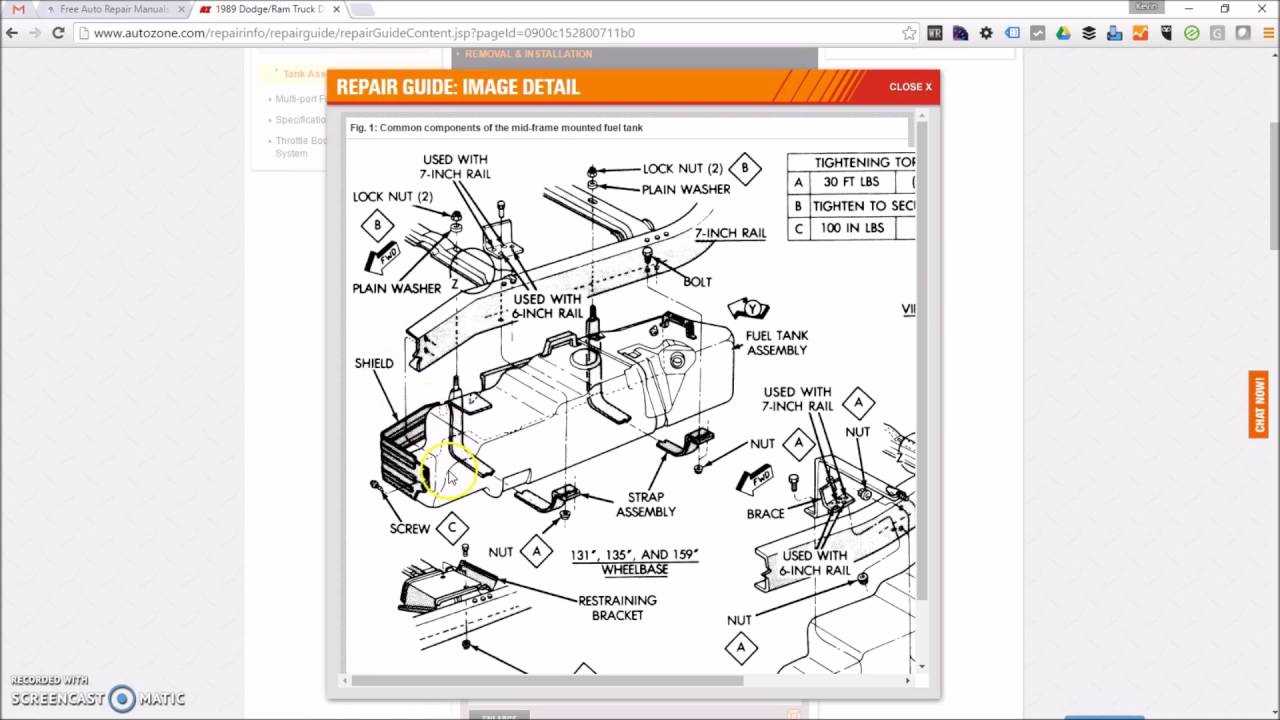

Diagnostic Equipment: To identify issues effectively, diagnostic devices such as scanners and multimeters are crucial. These tools help technicians assess problems accurately, facilitating informed decision-making for subsequent actions. Regular updates and maintenance of diagnostic equipment are essential to ensure their reliability.

Safety Gear: Personal protective equipment (PPE) should never be overlooked. Items like gloves, goggles, and masks are vital for safeguarding health during any repair task. Adhering to safety protocols not only protects the technician but also contributes to a more efficient working environment.

In conclusion, equipping oneself with the right array of tools and equipment is essential for any successful restoration project. Prioritizing quality, safety, and functionality will yield better results and foster a more efficient workflow.

Safety Protocols in Collision Repair

Ensuring a secure environment during vehicle restoration is essential for both technicians and clients. Adhering to specific guidelines can significantly reduce risks and promote efficiency in the workplace. By implementing comprehensive safety measures, professionals can protect themselves and others while maintaining high-quality standards in their work.

Key Safety Measures

- Wear appropriate personal protective equipment (PPE) including gloves, goggles, and masks to safeguard against harmful substances.

- Maintain a clean and organized workspace to minimize hazards and enhance visibility.

- Ensure proper ventilation in the area to disperse harmful fumes and particles.

- Regularly inspect tools and equipment for damage or wear to prevent accidents.

- Follow manufacturer guidelines for the use of chemicals and tools to avoid misuse.

Emergency Preparedness

- Have first aid kits readily available and ensure all staff are trained in basic first aid procedures.

- Establish and communicate emergency protocols, including evacuation routes and procedures for chemical spills.

- Conduct regular safety drills to ensure readiness in case of emergencies.

- Designate safety officers to oversee compliance with safety regulations and address concerns.

By prioritizing these protocols, professionals can create a safer atmosphere that ultimately benefits everyone involved in the restoration process.

Assessing Vehicle Damage Effectively

Evaluating the extent of harm to a vehicle is a crucial process that ensures safety and guides the subsequent actions for restoration. An accurate assessment not only identifies visible issues but also uncovers underlying concerns that may not be immediately apparent. This approach helps in making informed decisions about repairs and maintaining the vehicle’s integrity.

Key Steps in Damage Assessment

- Conduct a visual inspection to identify external issues.

- Examine the interior for any hidden damages.

- Utilize diagnostic tools to uncover electronic malfunctions.

- Document all findings for reference.

Considerations for a Thorough Evaluation

- Look for signs of structural integrity compromise.

- Check for fluid leaks that may indicate system failures.

- Assess tire condition and alignment.

- Engage with a professional if extensive damage is suspected.

By following these steps, one can ensure a comprehensive evaluation, paving the way for effective restoration and safety on the road.

Replacement Parts and Their Specifications

When it comes to restoring a vehicle, understanding the various components and their specific requirements is crucial. Each part plays a vital role in ensuring optimal performance and safety. This section delves into the essential characteristics of replacement items, guiding users through the selection and implementation processes.

| Part Type | Material | Specifications | Compatibility |

|---|---|---|---|

| Bumper | Polypropylene | Thickness: 3mm, Weight: 5kg | Model Year: 2015-2020 |

| Headlight Assembly | Polycarbonate | Voltage: 12V, Lumens: 1000 | Fitment: Left/Right Side |

| Fender | Steel | Gauge: 18, Finish: Primer | Model Compatibility: All Models 2018 |

| Windshield | Tempered Glass | Thickness: 6mm, UV Protection | Applicable: All Trim Levels |

Selecting the right components involves thorough consideration of the specifications to ensure functionality and safety standards are met. Using high-quality materials and adhering to defined characteristics significantly enhances the longevity and reliability of the vehicle.

Advanced Techniques in Collision Repair

The automotive restoration industry has evolved significantly, embracing innovative methodologies that enhance the precision and quality of vehicle refurbishment. These advancements not only improve efficiency but also ensure that vehicles return to the road in optimal condition, emphasizing safety and aesthetics.

One of the key strategies involves the use of laser technology for measuring and aligning structural components. This technique provides unparalleled accuracy, allowing technicians to restore original specifications with ease. Furthermore, adhesive bonding has emerged as a crucial method for joining materials, offering superior strength and flexibility compared to traditional welding.

Additionally, the integration of robotic systems in the painting process has transformed how surfaces are finished. These machines ensure consistent application of coatings, reducing human error and enhancing durability. The incorporation of 3D scanning technology further aids in assessing damage and planning repairs with exceptional detail.

Overall, these sophisticated approaches not only elevate the standards of automotive refurbishment but also pave the way for the future of vehicle maintenance, ultimately leading to a safer and more reliable driving experience.

Quality Control Measures to Implement

Ensuring excellence in automotive restoration requires a systematic approach to quality oversight. By establishing comprehensive measures, organizations can enhance the accuracy and durability of their services while fostering customer satisfaction and loyalty. The following strategies are essential for maintaining high standards throughout the entire process.

Standardized Procedures

Implementing standardized procedures is crucial for consistency. Documenting each step in the restoration process allows technicians to follow best practices, minimizing variations that can lead to defects. Regular training sessions should be held to ensure all personnel are well-versed in these protocols, which helps in maintaining uniformity across different projects.

Regular Inspections

Conducting frequent inspections during various stages of the project is vital. By incorporating checkpoints, managers can identify potential issues early, allowing for timely corrections. Utilizing both visual assessments and detailed measurements ensures that all aspects meet established criteria, ultimately enhancing the quality of the finished product.

Training for Technicians in Repairs

Effective training is essential for professionals in the automotive service industry, ensuring they possess the skills necessary to address various challenges encountered during the repair process. Ongoing education and practical experience empower technicians to enhance their proficiency, keeping them up-to-date with the latest technologies and methodologies.

Structured training programs provide a foundation for technicians to learn about advanced tools, safety protocols, and industry standards. These programs often include hands-on workshops, allowing individuals to practice their skills in a controlled environment. Additionally, certifications from recognized organizations can enhance a technician’s credibility and demonstrate their commitment to excellence.

As the automotive landscape continues to evolve, staying informed about new materials and techniques is vital. Regular seminars, online courses, and peer networking opportunities foster a culture of continuous improvement. By investing in comprehensive training, organizations can ensure their workforce is well-equipped to meet the demands of modern automotive challenges.

Future Trends in Collision Repair Technology

The landscape of vehicle restoration is evolving rapidly, driven by advancements in materials, processes, and technology. As the industry adapts to new challenges, the focus is shifting toward innovative solutions that enhance efficiency, safety, and sustainability. The following trends highlight the direction in which the field is heading, emphasizing a blend of traditional skills and modern methodologies.

| Trend | Description |

|---|---|

| Advanced Materials | Utilization of lightweight composites and high-strength steels to improve performance and reduce repair time. |

| Automation | Integration of robotics and automated systems for precise and consistent restoration tasks. |

| Digital Technologies | Implementation of augmented reality and 3D printing to streamline processes and enhance accuracy. |

| Eco-Friendly Practices | Adoption of sustainable materials and eco-conscious techniques to minimize environmental impact. |

| Data-Driven Solutions | Use of big data and analytics to optimize workflows and predict outcomes effectively. |

These emerging trends are not only transforming operational methodologies but also setting new standards for quality and customer satisfaction. As the industry embraces these innovations, the future looks promising, paving the way for enhanced vehicle maintenance practices.