Understanding the intricacies of equipment upkeep is essential for ensuring both reliability and longevity in agricultural operations. Machines that handle heavy workloads require consistent attention and specific knowledge to maintain their full functionality. This guide provides in-depth insights into various techniques and practical advice aimed at preserving your equipment’s peak performance.

Practical solutions are discussed, designed to assist users in diagnosing and addressing a range of operational issues. With step-by-step explanations, you’ll be able to identify potential sources of problems and perform effective adjustments, enabling smooth functioning and reducing the risk of unexpected breakdowns.

Additionally, this resource includes detailed preventive measures to help avoid frequent malfunctions, emphasizing routine care as a key factor in extending the life of your machine. These guidelines will serve as a valuable reference, ensuring your equipment remains an efficient and reliable partner in the field.

Ford 4000 Repair Manual

The section provides essential insights into maintaining and troubleshooting this reliable piece of machinery. Understanding the basic principles and procedures outlined here allows you to address common mechanical issues with ease and ensure the equipment operates smoothly.

Maintenance Guidelines: Consistent upkeep is key for optimal performance. Regular checks, fluid adjustments, and cleaning of critical components extend the lifespan and prevent potential issues. Always ensure that parts are in working condition to avoid wear and tear.

Troubleshooting Common Issues: When operational problems arise, diagnosing the root cause is crucial. Pay attention to symptoms such as unusual noises, decreased performance, or mechanical irregularities. This guide assists in identifying the source of these issues, offering a systematic approach to resolving them.

Tools and Safety Tips: Using appropriate tools is vital for successful repairs. Additionally, prioritizing safety by following recommended precautions minimizes risks during maintenance procedures, helping to complete tasks efficiently and safely.

Engine Diagnostics and Troubleshooting

Proper engine diagnostics is essential for identifying and addressing issues that may affect the functionality and performance of the machinery. This section provides guidance on pinpointing common signs of engine wear or malfunction, enabling timely interventions to ensure smooth and efficient operation. By following structured steps, users can detect issues early, potentially preventing costly repairs and maintaining reliability.

Common Symptoms to Watch For: Pay attention to indicators like unusual sounds, vibrations, or irregularities in temperature. These can signal potential issues in various components, from fuel systems to cooling mechanisms. Detecting these symptoms early can help in diagnosing the underlying cause effectively.

Basic Checks and Procedures: Start by inspecting accessible parts for visible signs of wear, loose connections, or residue build-up. Simple procedures, such as checking fluid levels and examining hoses, can reveal clues to common issues. Remember, regular upkeep often minimizes the risk of major breakdowns.

Advanced Diagnostic Steps: When basic inspections don’t resolve issues, more detailed diagnostics are necessary. Using specialized tools, monitor pressure, temperature, and output levels across the engine’s systems. These measurements can help identify malfunctioning parts, allowing for precise repairs and enhanced performance.

Transmission Maintenance Essentials

Regular upkeep of the transmission system is vital to ensure long-lasting and efficient performance. By following a set maintenance schedule, you can help avoid common issues that may affect smooth gear shifts and reduce the risk of larger, costly repairs. This section outlines essential maintenance practices that contribute to optimal operation and reliability of the transmission.

Fluid Check and Replacement

Monitoring and replacing transmission fluid at recommended intervals is one of the primary steps in preserving the system’s health. Fresh fluid keeps the components well-lubricated, reducing wear and preventing overheating. Always ensure the fluid level is within the specified range and pay attention to any changes in color or odor, which can indicate potential issues.

Inspecting for Leaks and Wear

Regularly inspecting the transmission system for leaks and signs of wear is critical. Over time, seals, gaskets, and other parts may degrade, leading to fluid leaks that compromise performance. Identifying and addressing these issues early can prevent them from escalating into more serious problems, helping to maintain the transmission’s longevity.

Electrical System Repairs and Upgrades

The electrical system plays a crucial role in vehicle performance and reliability, impacting everything from engine start-up to efficient lighting. Enhancing and maintaining the electrical components can prevent common issues, improve efficiency, and extend the lifespan of vital parts.

Battery Maintenance and Replacement: Regularly assessing the battery condition ensures optimal power flow and avoids unexpected breakdowns. It’s essential to check for corrosion on terminals and monitor the charge to keep the vehicle starting smoothly, especially during cold weather.

Wiring and Connections: Faulty connections or aging wiring can lead to inconsistent power distribution and even short circuits. Inspect wires for signs of wear and ensure that connections are clean and secure. Replacing outdated or frayed wires can prevent potential hazards and boost system reliability.

Alternator Efficiency: The alternator’s function is to charge the battery while the engine is running and to power various electrical systems. Testing its output and replacing worn components can help maintain the charging system, ensuring consistent electrical support for all essential functions.

Lighting Upgrades: Upgrading lights not only improves visibility but also reduces the strain on the electrical system. Installing energy-efficient bulbs or modern LED lights can enhance brightness and lower power consumption, making the system more efficient.

Routine maintenance of the electrical setup ensures smooth operations and improves the safety of the vehicle on the road. Proper care and timely upgrades reduce the chances of electrical failures, contributing to a safer and more reliable driving experience.

Fuel System Inspection Guide

In this section, we cover essential aspects of examining the fuel system to ensure optimal engine performance. This guide emphasizes preventive measures and systematic checks that can help detect issues early and maintain smooth operation. Proper inspection of the system enhances efficiency, prevents common issues, and extends the engine’s life.

Visual Examination of Components

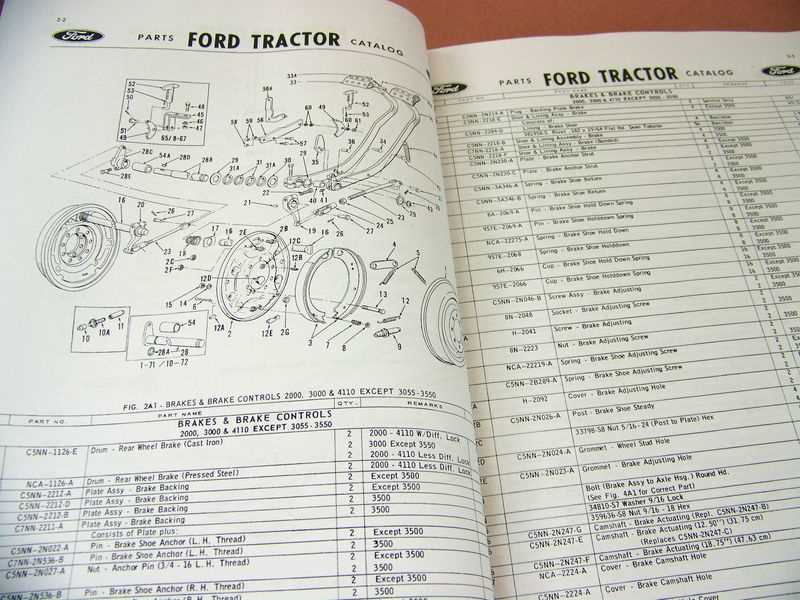

Start by visually inspecting the main parts of the fuel system, including fuel lines, connectors, and the filter. Look for signs of wear, cracks, or leaks that may compromise the system’s integrity. Ensure that all hoses are secure and free from obstruction. Regular checks of these components can help identify potential risks before they become serious problems.

Functional Checks and Measurements

For a more in-depth inspection, it’s necessary to test various components to confirm they function correctly. Use a pressure gauge to verify that the fuel pressure aligns with the recommended levels. Inaccurate pressure can lead to performance issues, so it’s essential to address any deviation promptly.

| Component | Inspection Step | Condition | ||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fuel Lines | Check for cracks, leaks, or wear | Secure and damage-free | ||||||||||||||||||||||

| Fuel Filter | Inspect for blockage or debris | Clean and unobstructed | ||||||||||||||||||||||

| Fuel Pump |

| Issue | Symptoms | Solution |

|---|---|---|

| Fluid Leaks | Visible puddles, reduced fluid levels | Inspect hoses and fittings; replace damaged components |

| Unresponsive Actuation | Slow or no movement in cylinders | Check for air in the system; bleed air and refill fluid |

| Overheating | High fluid temperature, system shutdown | Clean or replace filters; ensure adequate fluid levels |

Maintenance Best Practices

To prolong the life of hydraulic systems, regular upkeep is essential. Implementing the following practices can help maintain optimal functionality:

- Regularly check fluid levels and top off as necessary.

- Inspect and replace filters at recommended intervals.

- Conduct routine inspections for wear and tear on components.

Replacing Worn Parts and Components

Maintaining optimal performance in machinery often involves the timely replacement of degraded elements. Addressing wear and tear not only enhances efficiency but also extends the lifespan of the equipment. Understanding the signs of deterioration and knowing when to act is crucial for any operator aiming to ensure reliable operation.

Identifying Signs of Wear

Recognizing the indicators of worn parts is essential for effective maintenance. Common signs include unusual noises, vibrations, reduced performance, and visual damage. Regular inspections can help pinpoint which components require attention, preventing more significant issues down the line.

Replacement Process

The process of substituting worn components typically involves several key steps. First, ensure that the equipment is powered off and safe to work on. Next, remove any covers or shields obstructing access to the components in question. Carefully detach the faulty parts, noting their orientation for proper installation of new pieces. Finally, install the new components, reassemble any covers, and conduct a thorough test to verify functionality.

| Component | Signs of Wear | Replacement Frequency |

|---|---|---|

| Belts | Fraying, cracking | Every 500 hours |

| Filters | Clogging, discoloration | Every 250 hours |

| Seals | Leaks, brittleness | Annually |

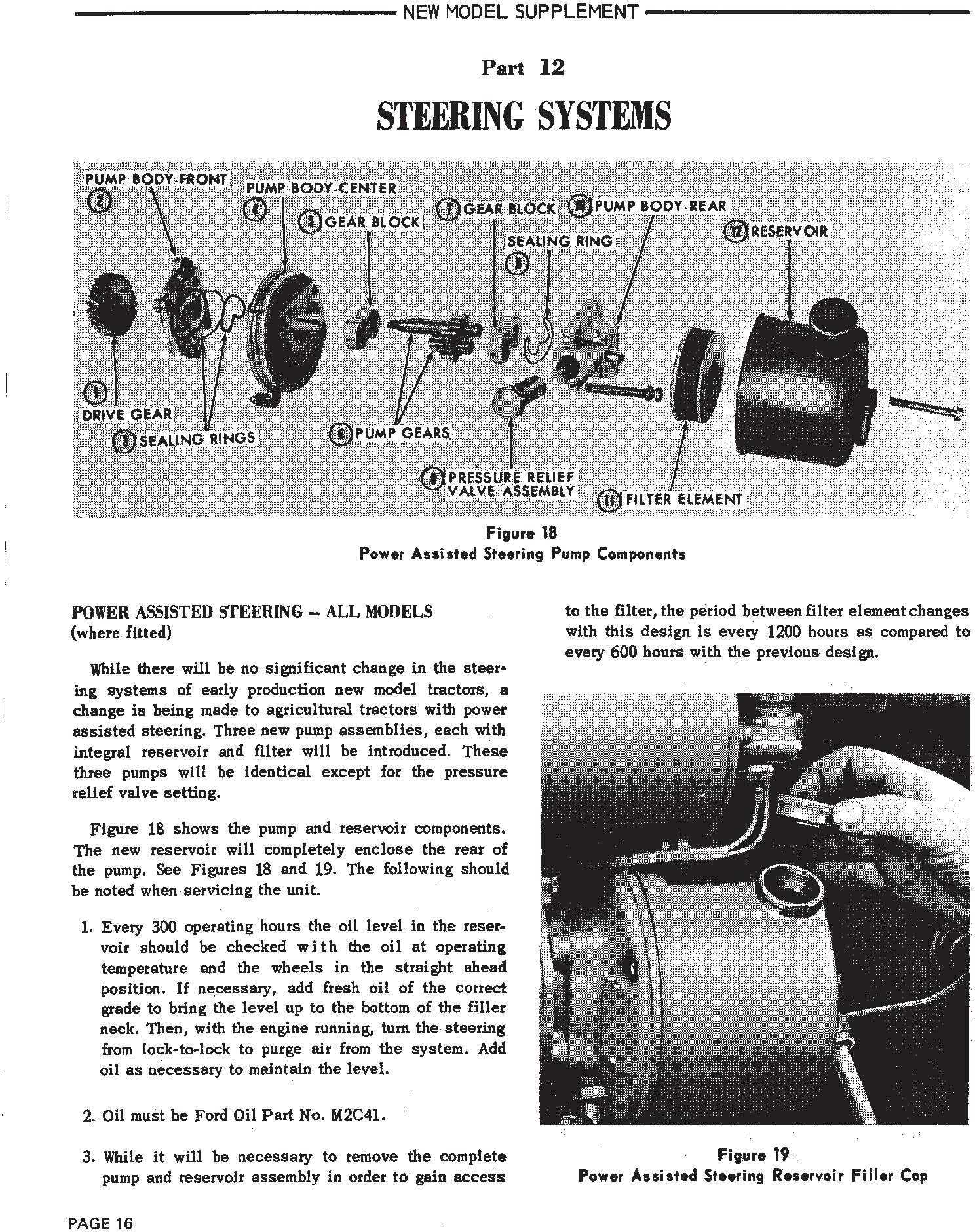

Steering and Suspension Adjustments

Proper alignment and calibration of steering and suspension components are crucial for optimal vehicle handling and comfort. Adjustments in these areas ensure that the vehicle responds effectively to driver inputs while maintaining stability and control on various terrains.

To achieve the best performance, it is essential to regularly inspect and fine-tune the following elements:

- Alignment: Ensures that the wheels are parallel to each other and perpendicular to the ground.

- Camber: Refers to the tilt of the wheels in relation to the vertical axis, affecting cornering stability.

- Toe: Involves adjusting the angle of the wheels to promote even tire wear and better handling.

- Steering Play: Checks for excessive movement in the steering wheel that can impact responsiveness.

- Shock Absorbers: Regular inspection of these components helps maintain ride quality and handling characteristics.

To perform adjustments effectively, follow these general steps:

- Inspect all components for wear or damage.

- Use appropriate tools to measure alignment angles.

- Adjust camber and toe settings according to manufacturer specifications.

- Test drive the vehicle to ensure proper handling.

- Recheck adjustments and make any necessary refinements.

Regular maintenance of steering and suspension systems not only enhances driving comfort but also prolongs the lifespan of tires and related components.

Routine Lubrication and Oil Changes

Regular maintenance is essential for ensuring optimal performance and longevity of machinery. Consistent lubrication and timely oil replacements play a crucial role in minimizing wear and tear, enhancing efficiency, and preventing potential malfunctions. This section outlines best practices for maintaining your equipment through effective lubrication and oil management.

Importance of Regular Lubrication

Lubrication serves to reduce friction between moving parts, thereby decreasing the risk of overheating and damage. It is vital to monitor and maintain appropriate lubricant levels to ensure smooth operation. Regular checks and application of suitable lubricants not only protect components but also contribute to overall operational efficiency.

Oil Change Frequency and Guidelines

Changing the lubricant is a fundamental aspect of maintenance. It is advisable to follow a specific schedule based on usage and environmental conditions. Consultation with manufacturer guidelines will provide insight into the appropriate intervals for oil changes. Always use high-quality lubricants that meet the specifications required for your equipment, ensuring optimal protection and performance.

Tire Care and Replacement Procedures

Proper maintenance of tires is essential for ensuring optimal performance and safety of any vehicle. This section outlines essential practices for caring for tires, including inspection, maintenance, and guidelines for replacement. By following these procedures, you can extend the life of your tires and enhance overall driving experience.

Regular Inspection and Maintenance

Routine checks are crucial for identifying potential issues before they escalate. Inspect tires for signs of wear, such as uneven tread depth or visible damage. Check tire pressure regularly, as maintaining the correct inflation is vital for traction and fuel efficiency. If the pressure is too low or too high, it can lead to increased wear and decreased performance. Additionally, rotating tires according to the manufacturer’s recommendations can help ensure even wear across all tires.

Replacement Guidelines

Knowing when to replace tires is critical for maintaining safety. Look for indicators such as tread wear indicators, which become visible as tires wear down. If tread depth is less than 2/32 of an inch, it’s time for a replacement. Also, if you notice cracks, bulges, or blisters on the tire surface, these are signs that a replacement is necessary. Always consult a professional to ensure that new tires are installed correctly, and consider balancing and alignment services to maximize performance.