When it comes to maintaining robust trucks, having a detailed reference can make all the difference. These vehicles are designed to withstand the rigors of demanding tasks, and understanding their mechanics is essential for any owner or enthusiast. A thorough guide serves as a valuable resource, providing insights into various systems and components that ensure optimal performance.

From routine check-ups to more extensive troubleshooting, this resource empowers you with the knowledge needed to tackle any issue that may arise. Each section is crafted to enhance your understanding of the vehicle’s inner workings, making it easier to identify problems before they escalate. Whether you’re a seasoned mechanic or a first-time user, the information presented here is tailored to meet diverse needs.

Equipped with this knowledge, you can approach maintenance with confidence. By familiarizing yourself with the intricacies of your vehicle, you’ll not only save time and money but also prolong its lifespan. Dive into this guide to discover practical tips and techniques that will keep your truck running smoothly for years to come.

Understanding the 2002 Ford F250

This section aims to explore the essential features and characteristics of a robust heavy-duty vehicle that has captured the attention of enthusiasts and professionals alike. By examining its design, performance, and utility, one can appreciate what makes this model a reliable choice for various tasks.

Key attributes include:

- Powerful engine options that enhance performance.

- Durable build designed for heavy loads and tough conditions.

- Versatile configurations catering to different needs.

Moreover, understanding maintenance practices is crucial for ensuring longevity:

- Regular fluid checks and changes.

- Routine inspections of key components like brakes and suspension.

- Timely replacement of worn-out parts to prevent larger issues.

Common Issues with the F250

Vehicles of this model year often experience several recurring problems that owners should be aware of. Understanding these common issues can help in maintaining optimal performance and longevity.

- Engine Problems:

- Oil leaks, particularly around gaskets and seals.

- Overheating due to coolant leaks or thermostat failures.

- Rough idling or stalling, often linked to fuel delivery issues.

- Transmission Difficulties:

- Slipping gears or delayed engagement when shifting.

- Fluid leaks, which may lead to low transmission fluid levels.

- Electrical System Issues:

- Faulty battery connections causing starting problems.

- Malfunctioning alternator resulting in charging issues.

- Issues with dashboard warning lights, often due to sensor failures.

- Suspension Wear:

- Worn shock absorbers leading to a rough ride.

- Ball joint failures causing steering instability.

- Uneven tire wear, often indicating alignment issues.

Regular maintenance and timely inspections can significantly reduce the risk of these issues. Being proactive can enhance the driving experience and ensure the vehicle remains reliable.

Importance of a Repair Manual

Having a comprehensive guide for vehicle maintenance and troubleshooting is essential for any owner. Such resources provide detailed information that helps ensure proper handling and care of the automobile. Understanding the significance of these guides can enhance both the longevity and performance of the vehicle.

Here are several key reasons why utilizing a maintenance guide is beneficial:

- Enhanced Knowledge: Users gain insights into the various components and systems of their vehicle, fostering a deeper understanding of how everything operates.

- Improved Safety: Regular upkeep and informed repairs reduce the risk of accidents caused by mechanical failures.

- Cost Efficiency: Having access to troubleshooting tips can help identify minor issues before they escalate, saving money on major repairs.

- Increased Resale Value: Well-maintained vehicles often command higher prices, making attention to detail crucial for potential future sales.

In summary, the value of a detailed resource cannot be overstated. It empowers owners to take control of their vehicle’s maintenance, ensuring reliability and safety on the road.

Basic Maintenance Tips for Your Truck

Ensuring the longevity and reliability of your vehicle requires consistent care and attention. Regular upkeep not only enhances performance but also helps prevent costly repairs down the line. Here are some essential practices to keep your truck in top shape.

Check Fluid Levels: Regularly inspect and top off fluids such as engine oil, coolant, brake fluid, and transmission fluid. Maintaining appropriate levels is crucial for optimal operation.

Inspect Tires: Monitor tire pressure and tread depth frequently. Properly inflated tires improve fuel efficiency and provide better handling. Rotate them as recommended to promote even wear.

Replace Filters: Air and oil filters play a significant role in maintaining engine health. Change these components as per the manufacturer’s schedule to ensure clean airflow and lubrication.

Examine Belts and Hoses: Periodically inspect belts and hoses for signs of wear, such as cracks or fraying. Replacing them before they fail can prevent unexpected breakdowns.

Battery Care: Keep the battery terminals clean and ensure connections are tight. Testing the battery’s charge regularly can help avoid starting issues, especially in extreme weather.

Brake Inspection: Regularly assess the braking system for any signs of wear or reduced effectiveness. Timely replacement of brake pads and fluid is essential for safety.

By adhering to these basic maintenance guidelines, you can enhance the performance and reliability of your vehicle, ensuring it serves you well for years to come.

Engine Specifications and Repair Insights

This section provides a comprehensive overview of engine characteristics and essential guidance for maintenance. Understanding these elements is crucial for ensuring optimal performance and longevity of the vehicle. Key details include specifications, common issues, and tips for effective troubleshooting.

Key Engine Specifications

- Engine Type: V8 configuration

- Displacement: Approximately 5.4 liters

- Horsepower: Around 300 hp

- Torque: Peak torque output of 365 lb-ft

- Fuel System: Multi-point fuel injection

Maintenance and Troubleshooting Tips

- Regularly check and replace engine oil to maintain smooth operation.

- Inspect the air filter frequently to ensure optimal airflow.

- Monitor coolant levels and replace coolant at recommended intervals to prevent overheating.

- Keep an eye on ignition system components for wear and tear.

- Utilize diagnostic tools to identify and address error codes promptly.

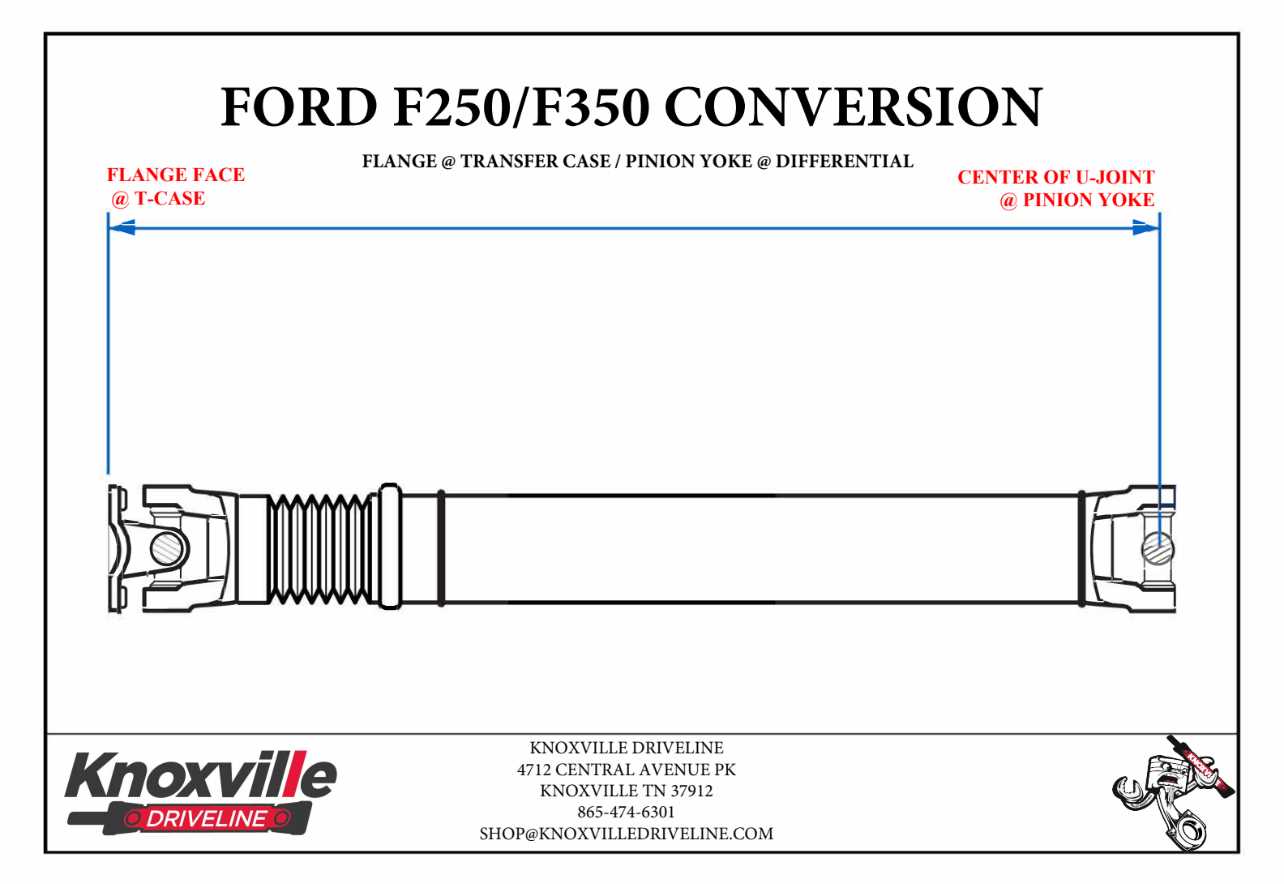

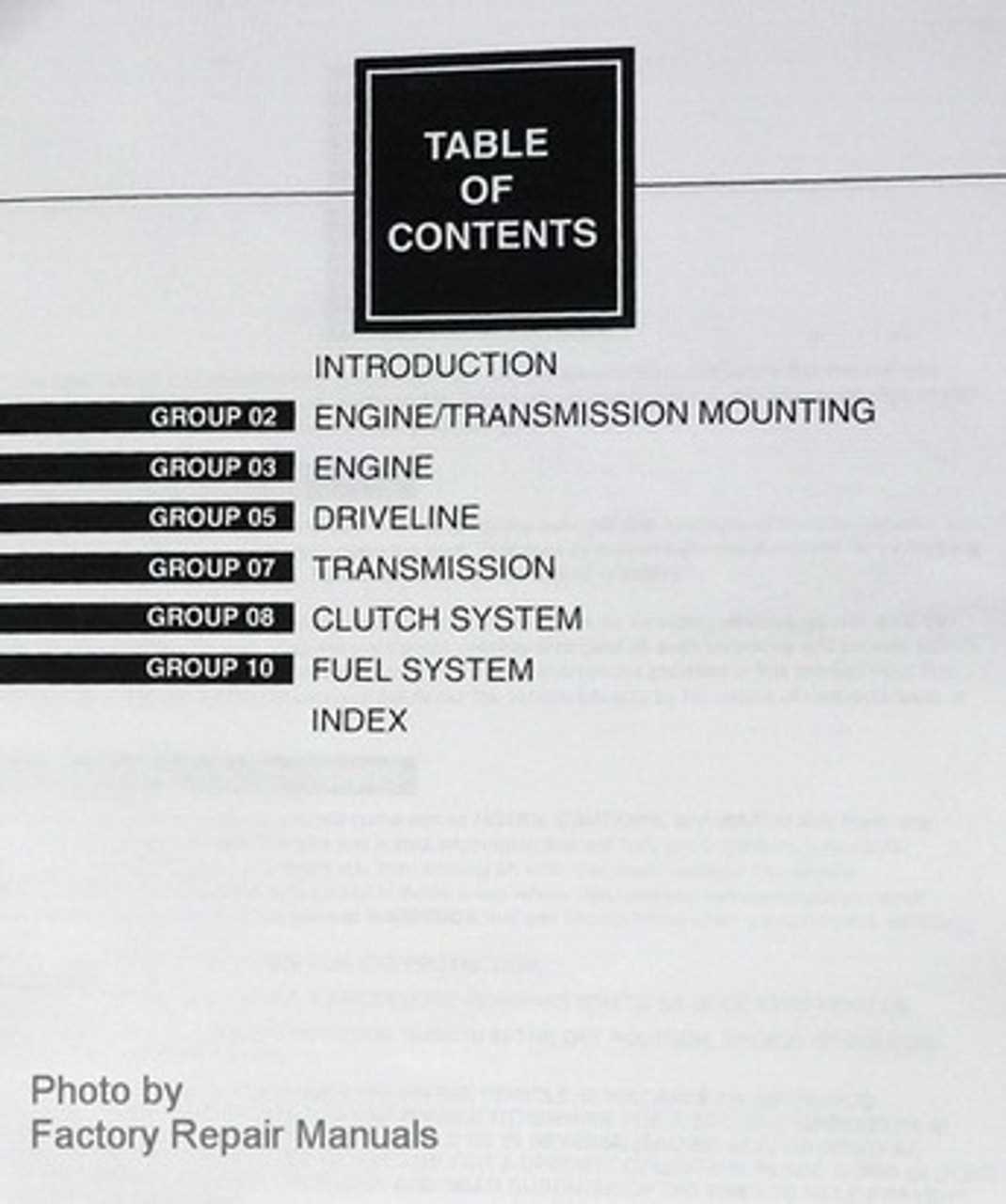

Transmission Troubleshooting Techniques

Addressing issues with a vehicle’s transmission requires a systematic approach to identify and resolve potential problems. By understanding the common signs of malfunction and employing effective diagnostic methods, one can efficiently determine the root cause of transmission-related challenges.

Begin by observing the vehicle’s behavior. Look for symptoms such as unusual noises, slipping gears, or delayed engagement when shifting. These indicators can guide the troubleshooting process.

| Symptom | Possible Cause | Troubleshooting Steps |

|---|---|---|

| Slipping gears | Low fluid levels or worn components | Check fluid level, inspect for leaks, and examine clutches. |

| No response when shifting | Faulty transmission fluid or electrical issues | Inspect fluid condition, check for error codes. |

| Unusual noises | Damaged parts or low lubrication | Listen for sounds while driving; inspect components visually. |

| Overheating | Clogged cooler or low fluid | Check cooler operation, inspect fluid levels and condition. |

Utilizing these techniques can facilitate a more comprehensive understanding of transmission issues, leading to effective resolutions and enhanced vehicle performance.

Electrical System Diagnostics Explained

Diagnosing issues within an automotive electrical framework is crucial for ensuring optimal performance and longevity of the vehicle. Understanding how to systematically evaluate and troubleshoot electrical components can save time and resources while enhancing safety on the road.

The diagnostic process typically involves several key steps:

- Initial Assessment: Begin with a thorough inspection of visible wiring, connectors, and fuses.

- Utilizing Diagnostic Tools: Employ multimeters, oscilloscopes, and scan tools to gather data on voltage levels and circuit integrity.

- Identifying Symptoms: Record specific issues such as dim lights, failure to start, or erratic gauge readings.

- Systematic Testing: Test each component methodically, starting from the power source and moving towards the load.

- Interpreting Results: Analyze the collected data to pinpoint faults or irregularities within the system.

- Implementing Solutions: Once the issue is identified, apply the appropriate repair or replacement techniques.

Common areas to investigate include:

- Batteries and connections

- Alternators and charging systems

- Wiring harnesses and connectors

- Grounding points and circuits

- Control modules and sensors

By following these guidelines, one can effectively navigate the complexities of automotive electrical diagnostics, leading to timely repairs and improved vehicle functionality.

Braking System Maintenance and Repairs

The braking system is a crucial component of any vehicle, ensuring safety and control during operation. Regular upkeep and timely interventions can prevent issues that may lead to reduced performance or potential hazards on the road.

To maintain optimal functionality, consider the following key aspects:

- Inspection: Regularly check the brake pads, rotors, and fluid levels. Look for signs of wear or damage.

- Fluid Replacement: Brake fluid should be replaced periodically to maintain effective braking power and prevent moisture contamination.

- Pad and Rotor Replacement: Monitor the thickness of brake pads and the condition of rotors. Replace them as necessary to ensure efficient braking.

When addressing maintenance, follow these steps:

- Lift the vehicle and secure it on jack stands.

- Remove the wheel to access the braking components.

- Inspect the brake pads for uneven wear and the rotors for scoring.

- Replace any worn parts as needed, ensuring proper installation.

- Reassemble the wheel and lower the vehicle back to the ground.

By adhering to these guidelines, drivers can enhance their vehicle’s braking performance, ensuring safety and reliability on every journey.

Suspension System Overview and Tips

The suspension system plays a crucial role in ensuring a smooth ride and maintaining vehicle stability. Understanding its components and functionality can enhance performance and comfort while driving.

Key Components

- Shock Absorbers: Control the rebound of the springs.

- Coil Springs: Support the weight of the vehicle and absorb bumps.

- Control Arms: Allow for wheel movement while maintaining alignment.

- Sway Bars: Reduce body roll during cornering.

Maintenance Tips

- Regularly inspect all components for wear and damage.

- Ensure proper alignment to avoid uneven tire wear.

- Check and replace worn shock absorbers for optimal handling.

- Lubricate moving parts to prevent rust and ensure smooth operation.

Body and Frame Repair Essentials

Maintaining the integrity of a vehicle’s structure is crucial for performance and safety. This section explores the key aspects of restoring and reinforcing the outer shell and foundational framework of a vehicle, ensuring longevity and resilience against various challenges.

Understanding Structural Components

Every vehicle comprises several vital parts that contribute to its overall strength. The chassis provides support, while the body panels protect and enhance aesthetics. Familiarizing oneself with these components aids in effective troubleshooting and enhancements.

Common Issues and Solutions

Damage to the outer casing or frame can arise from impacts, corrosion, or wear over time. Employing proper techniques for straightening bent metal, addressing rust, and aligning misaligned structures can significantly improve functionality. Using high-quality materials ensures that any modifications will withstand the test of time.

How to Find Quality Parts

When it comes to maintaining your vehicle, sourcing high-quality components is essential for ensuring optimal performance and longevity. Selecting the right parts can significantly impact not only your vehicle’s reliability but also its overall efficiency. This guide outlines effective strategies to help you locate superior components for your automotive needs.

Research Reputable Suppliers

Start by identifying trusted suppliers known for their commitment to quality. Look for retailers with a strong reputation in the automotive community. Online reviews, ratings, and recommendations from fellow enthusiasts can provide valuable insights. Always check for warranties or guarantees, as these often indicate the level of confidence a supplier has in their products.

Consider OEM vs. Aftermarket Options

Understanding the difference between Original Equipment Manufacturer (OEM) parts and aftermarket alternatives is crucial. OEM components are designed specifically for your vehicle, ensuring a precise fit and performance akin to the original. On the other hand, aftermarket parts can offer more cost-effective solutions, but quality may vary. Research brands and read customer feedback to determine which option best meets your requirements.

Step-by-Step Repair Procedures

This section provides a comprehensive guide to performing various maintenance tasks and troubleshooting techniques. Following a systematic approach ensures effective results and enhances the longevity of your vehicle.

Preparation Steps

- Gather necessary tools and materials.

- Review safety precautions to ensure a safe working environment.

- Park the vehicle on a level surface and engage the parking brake.

Detailed Procedures

- Identify the issue you need to address.

- Access the relevant components based on the task.

- Perform the necessary adjustments or replacements.

- Test the system to ensure proper functionality.

- Clean up the workspace and store tools properly.

Resources for DIY Mechanics

For those who enjoy tackling automotive projects on their own, having the right resources at hand can make a significant difference. From online forums to detailed guides, there is a wealth of information available that can empower enthusiasts to diagnose issues, perform maintenance, and undertake complex repairs with confidence.

Online Communities

Connecting with fellow enthusiasts can provide invaluable support. Here are some popular platforms:

- Forums: Websites dedicated to automotive discussions often have sections for specific models where users share their experiences and solutions.

- Social Media Groups: Platforms like Facebook host groups where mechanics can ask questions, share tips, and showcase their projects.

- Video Channels: YouTube features countless channels dedicated to automotive repair, offering visual guidance for a variety of tasks.

Reference Materials

Having reliable reference materials can streamline the repair process. Consider the following:

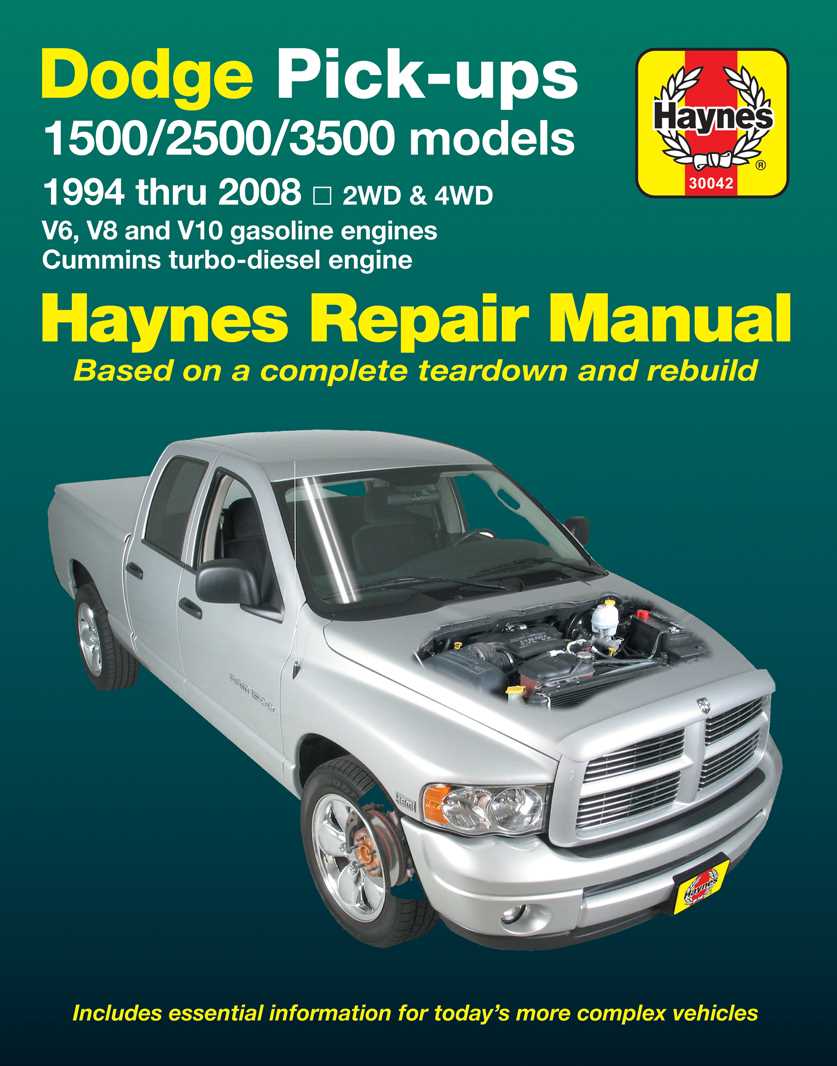

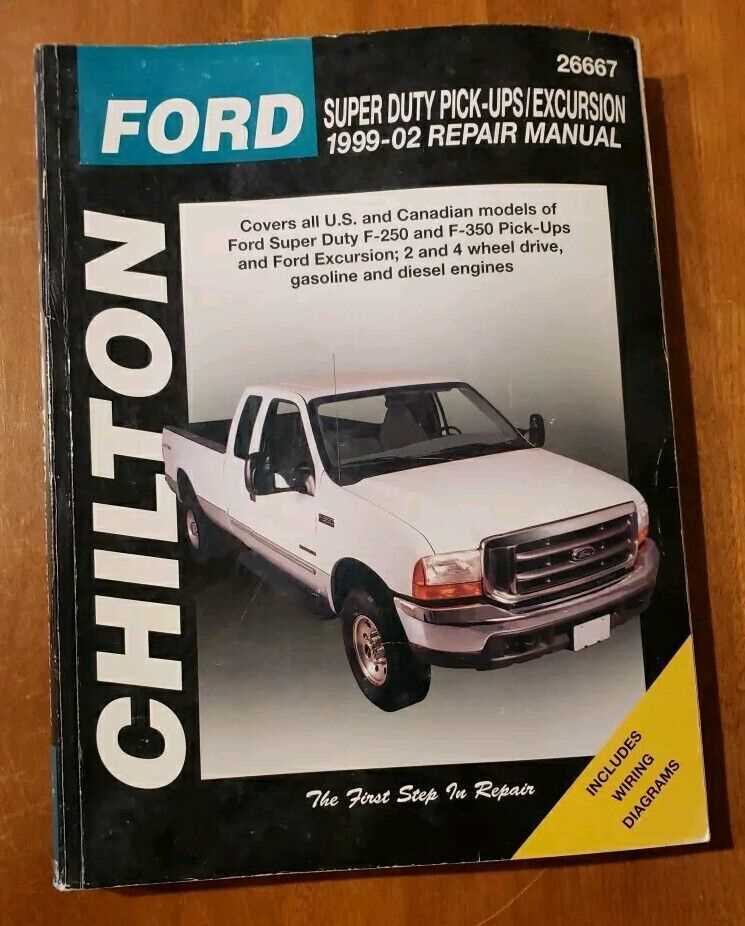

- Service Guides: Comprehensive guides provide step-by-step instructions, diagrams, and troubleshooting advice.

- Parts Catalogs: Knowing the correct parts needed for a repair can save time and money.

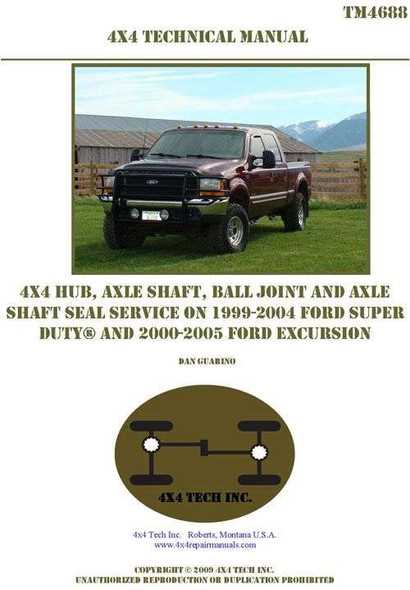

- Technical Manuals: Detailed documents often include specifications, wiring diagrams, and maintenance schedules.