When it comes to keeping agricultural machinery in optimal condition, having access to comprehensive resources is essential. This section aims to provide invaluable insights into the upkeep and restoration of specific models, ensuring that users can effectively manage issues and enhance performance.

Understanding the intricacies of machinery operation not only facilitates better maintenance but also extends the lifespan of vital equipment. From diagnosing common problems to implementing step-by-step procedures, a well-structured resource serves as a reliable companion for both novices and seasoned operators.

By familiarizing yourself with essential techniques and best practices, you can navigate challenges with confidence. The following information will empower you to tackle various tasks, ensuring that your equipment remains efficient and reliable in the demanding world of agriculture.

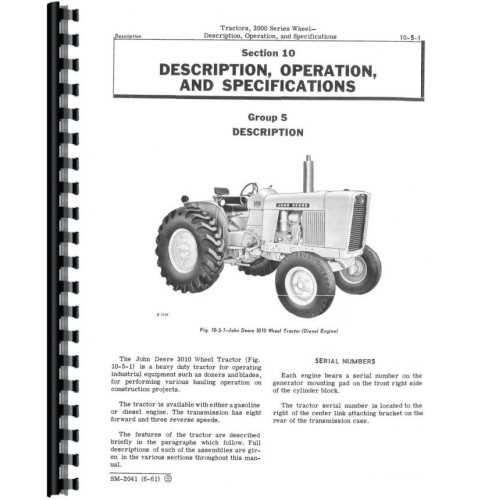

Overview of John Deere 3010 Model

This section provides a comprehensive look at a notable agricultural machine, highlighting its design, functionality, and historical significance. Known for its versatility and durability, this model has played a crucial role in enhancing productivity on farms.

Manufactured during a pivotal era in agricultural machinery development, this tractor features a robust engine and advanced transmission systems. Its engineering emphasizes ease of operation, making it accessible for both seasoned farmers and newcomers alike.

The model is equipped with various attachments and implements, allowing it to perform a wide range of tasks, from plowing to hauling. This adaptability has contributed to its lasting popularity among users seeking reliable performance in diverse farming conditions.

In addition to its mechanical attributes, the model’s legacy is marked by a community of enthusiasts and collectors. Many appreciate not only its operational capabilities but also its historical context, representing a significant advancement in farm technology during its time.

Common Issues with John Deere 3010

When operating a classic agricultural machine, it’s essential to be aware of typical challenges that may arise. Understanding these common problems can help owners maintain optimal performance and prolong the life of their equipment. Below are some frequently encountered issues and their implications.

Engine Performance Problems

One of the most prevalent concerns involves the engine’s ability to start or run smoothly. Starting difficulties can often stem from battery issues or fuel system malfunctions. Additionally, engine stalling during operation may be attributed to air intake restrictions or ignition failures. Regular inspection of these components can prevent major disruptions in productivity.

Hydraulic System Failures

The hydraulic system plays a critical role in the functionality of various implements. Common symptoms of trouble include leaking hydraulic fluid and reduced lifting capacity. These issues can be caused by worn seals or damaged hoses. Timely detection and replacement of faulty parts are vital to maintaining effective hydraulic performance.

Tools Required for Effective Repairs

To achieve successful maintenance and troubleshooting, having the right equipment is essential. Proper tools not only enhance efficiency but also ensure safety during the process. Below is a list of necessary items to consider for optimal performance when addressing machinery issues.

Essential Hand Tools

- Wrenches: A variety of sizes will be needed for loosening and tightening fasteners.

- Screwdrivers: Both flat-head and Phillips types are crucial for various screws.

- Pliers: Needle-nose and adjustable pliers help with gripping and bending components.

- Socket set: A complete set allows for quick removal and installation of nuts and bolts.

Power Tools and Equipment

- Impact wrench: Useful for loosening stubborn bolts with ease.

- Drill: Essential for making precise holes or driving screws quickly.

- Bench grinder: Ideal for sharpening tools and cleaning metal parts.

- Multimeter: A vital tool for diagnosing electrical issues and measuring voltage, current, and resistance.

Step-by-Step Maintenance Procedures

Regular upkeep of agricultural machinery is essential for optimal performance and longevity. This section outlines a series of systematic tasks designed to ensure that your equipment remains in peak operating condition. Following these steps will help prevent common issues and extend the lifespan of your machinery.

1. Routine Inspections

Conducting periodic assessments is vital. Focus on the following areas:

- Fluid levels: Check oil, coolant, and hydraulic fluid.

- Belts and hoses: Look for wear, cracks, or leaks.

- Tires: Inspect for proper inflation and tread wear.

2. Cleaning Procedures

Keeping your machinery clean helps maintain efficiency. Follow these cleaning guidelines:

- Remove debris from the exterior, particularly around the engine and cooling systems.

- Flush the radiators to prevent overheating.

- Clean air filters regularly to ensure proper airflow.

Engine Troubleshooting Techniques

Identifying issues within an engine requires a systematic approach and keen observation. By understanding common symptoms and employing effective diagnostic methods, operators can efficiently pinpoint problems, ensuring optimal performance and longevity of the machinery.

Begin with a thorough visual inspection. Check for signs of leaks, loose connections, and worn components. A clear assessment can reveal immediate issues that may need addressing. Next, listen for unusual noises during operation. Sounds such as knocking or grinding can indicate internal complications that warrant further investigation.

Utilize diagnostic tools to analyze engine performance. Instruments like multimeters and pressure gauges can provide valuable data on electrical systems and compression levels, respectively. Cross-referencing these measurements with manufacturer specifications will help in identifying discrepancies.

Pay attention to the exhaust. Excessive smoke, unusual colors, or odors can signal various issues ranging from fuel mixture problems to internal wear. Conducting tests on fuel quality and ensuring proper air intake can also aid in diagnosing inefficiencies.

Finally, if problems persist, consulting technical documentation or seeking professional assistance may be necessary. A comprehensive understanding of engine mechanics will empower operators to tackle issues effectively and maintain peak performance.

Hydraulic System Care Guidelines

Proper maintenance of the hydraulic system is crucial for ensuring optimal performance and longevity of machinery. Regular attention to this component can prevent costly repairs and downtime, enhancing overall productivity. Adhering to specific care practices will help maintain the efficiency and reliability of the hydraulic functions.

Routine Inspection: Regularly check for leaks, loose connections, and signs of wear on hoses and fittings. Early detection of issues can prevent major failures.

Fluid Quality: Always use the recommended hydraulic fluid and ensure it is clean. Contaminated or degraded fluid can cause significant damage to the system.

Fluid Level Monitoring: Keep an eye on fluid levels and top up as necessary. Low fluid levels can lead to insufficient lubrication and overheating.

Filter Maintenance: Replace filters according to the manufacturer’s guidelines. Clogged filters can restrict flow and lead to increased wear on hydraulic components.

Temperature Checks: Monitor the operating temperature of the hydraulic system. Overheating can result in reduced efficiency and premature component failure.

System Testing: Periodically conduct performance tests to ensure that all hydraulic functions are operating as intended. This includes checking pressure levels and response times.

By following these guidelines, operators can ensure the hydraulic system remains in excellent condition, thereby enhancing the overall functionality and lifespan of the equipment.

Electrical System Diagnostics Explained

The evaluation of electrical systems in machinery is crucial for maintaining optimal performance and preventing malfunctions. Understanding the diagnostic process can help identify issues efficiently, ensuring that components function harmoniously. This section delves into the essential techniques and tools used to assess the electrical network of your equipment.

Effective diagnostics involve several steps, starting with the inspection of wiring and connections. Identifying visible damage or corrosion can often reveal potential problems. Following this, utilizing specialized tools allows for deeper analysis of circuit integrity and component functionality.

| Diagnostic Step | Description | Tools Required |

|---|---|---|

| Visual Inspection | Check for physical damage or loose connections. | Flashlight, Magnifying Glass |

| Voltage Testing | Measure voltage levels across components to ensure proper operation. | Multimeter |

| Continuity Testing | Verify that electrical pathways are uninterrupted. | Multimeter |

| Component Testing | Assess individual components for functionality. | Component Tester |

By following these steps and utilizing appropriate tools, operators can pinpoint issues effectively, reducing downtime and enhancing reliability. Regular diagnostics not only prolong the lifespan of electrical components but also contribute to overall operational efficiency.

Parts Replacement Best Practices

Effective component replacement is crucial for maintaining the longevity and efficiency of machinery. By adhering to best practices, operators can ensure that their equipment runs smoothly and minimizes downtime. This section outlines essential guidelines to follow when replacing parts to achieve optimal performance and reliability.

Choosing the Right Components

Selecting high-quality parts is the foundation of successful replacements. Always opt for components that meet or exceed the original specifications. OEM parts are often recommended as they are designed specifically for the equipment, ensuring compatibility and performance. In some cases, high-quality aftermarket options may also suffice, but it’s vital to research and confirm their reliability.

Proper Installation Techniques

Installation plays a significant role in the effectiveness of new components. Follow these tips for successful integration:

- Refer to manufacturer guidelines for installation procedures.

- Use the appropriate tools to avoid damage during the replacement process.

- Inspect surrounding areas for wear or damage before installing new parts.

- Ensure all connections are secure and correctly aligned to prevent future issues.

By implementing these practices, operators can enhance the performance of their machinery and extend its operational life.

Finding Quality Replacement Parts

When it comes to maintaining machinery, sourcing high-quality components is essential for ensuring optimal performance and longevity. Choosing the right parts can significantly impact the efficiency and reliability of your equipment. In this section, we will explore various strategies to identify and procure superior alternatives for your machinery needs.

Understanding Compatibility

Before making any purchases, it’s crucial to confirm that the parts you are considering are compatible with your specific model. Thoroughly reviewing the specifications and consulting with knowledgeable sources can help you avoid costly mistakes. Utilize manufacturer documentation or reputable online forums to gather insights into what will work best for your equipment.

Reputable Suppliers

Establishing relationships with trusted vendors is vital. Look for suppliers who specialize in machinery components and have a proven track record. Read reviews and seek recommendations from fellow users to ensure you are dealing with reliable sources. Investing time in finding reputable suppliers will pay off by providing you access to quality products that meet your requirements.

Utilizing the Repair Manual Effectively

Harnessing the guidance provided in a comprehensive technical document can significantly enhance your ability to troubleshoot and maintain machinery. This resource serves as a vital tool, offering detailed insights into various components and their functionalities, ensuring that you can perform tasks with precision and confidence.

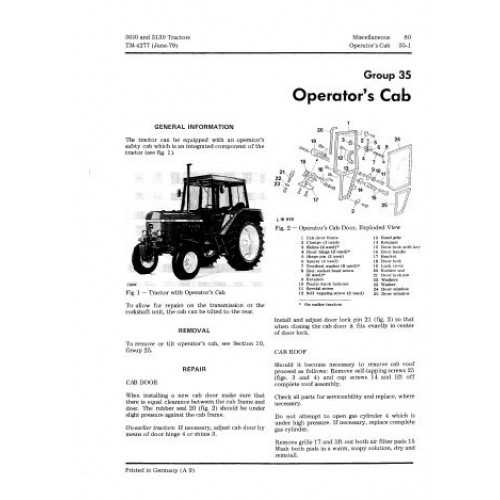

Understanding the Structure

Familiarize yourself with the layout of the resource. Typically, it is organized into sections that cover specific systems, parts, and procedures. By navigating through these sections systematically, you can locate relevant information quickly. Pay attention to the diagrams and illustrations; they are invaluable for visualizing complex assemblies and repairs.

Practical Application of Guidelines

Once you have identified the relevant section, it is essential to apply the provided instructions carefully. Always follow the steps in order, and take note of any precautions highlighted in the text. This approach minimizes the risk of errors and maximizes efficiency during maintenance tasks. If a certain procedure seems unclear, refer back to earlier sections for clarification. Document your findings and progress for future reference, ensuring that your experience builds a knowledge base for subsequent projects.