Maintaining a vehicle can often seem daunting, especially for those who are unfamiliar with its inner workings. This guide aims to empower enthusiasts and everyday drivers alike by providing detailed insights into the upkeep of their automobiles. With the right information at hand, anyone can tackle various issues, ensuring their ride remains in optimal condition.

Understanding the mechanics of your vehicle is crucial for effective maintenance. From troubleshooting minor glitches to performing major overhauls, knowing the specifics can save both time and money. Each car has its unique characteristics, and familiarity with these elements can enhance your confidence as you work on your vehicle.

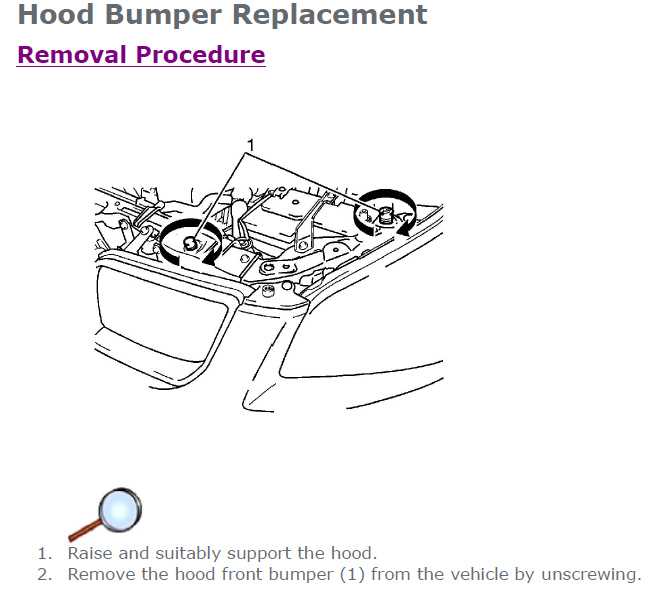

Resourceful approaches can make a significant difference when addressing car-related challenges. Whether it’s following step-by-step instructions or utilizing helpful diagrams, having access to reliable information simplifies the process. This section will provide essential tools and tips for anyone looking to enhance their mechanical knowledge and skills.

Essential Tools for Chevy Blazer Repair

When it comes to maintaining and fixing your vehicle, having the right equipment is crucial for efficiency and success. A well-equipped workspace can make the difference between a smooth project and a frustrating experience. Here are some of the key instruments that will assist you in your automotive endeavors.

Basic Hand Tools

- Wrenches: A variety of sizes, including adjustable and socket wrenches, are necessary for loosening and tightening bolts.

- Screwdrivers: Both flathead and Phillips types are essential for working on various components.

- Pliers: Needle-nose and locking pliers can help in gripping and manipulating smaller parts.

Specialized Equipment

- Jack and Jack Stands: Vital for lifting the vehicle safely when accessing the undercarriage.

- Torque Wrench: Ensures that fasteners are tightened to the manufacturer’s specifications.

- Diagnostic Scanner: Helps in identifying issues by reading error codes from the vehicle’s computer system.

Equipping yourself with these fundamental and specialized tools will greatly enhance your ability to address various tasks and challenges that may arise while working on your vehicle. Being prepared not only saves time but also ensures that you maintain a high standard of quality in your work.

Common Issues in Chevy Blazer Models

Various models from this well-known American automotive brand have faced specific challenges over the years. Understanding these prevalent issues can aid in maintaining the vehicle’s performance and longevity. Below is a summary of the most frequently encountered problems.

| Issue | Description | Possible Solution |

|---|---|---|

| Electrical Problems | Inconsistent power delivery to various systems, often linked to faulty wiring or connectors. | Inspect wiring harnesses and replace damaged components. |

| Transmission Slippage | Difficulty in shifting gears or unexpected slipping during operation. | Check fluid levels and quality; consider a transmission service or replacement. |

| Suspension Wear | Premature wear on suspension components, leading to a rough ride and handling issues. | Regularly inspect and replace worn parts like shocks and struts. |

| Fuel System Issues | Problems with fuel delivery can result in poor performance and reduced efficiency. | Clean or replace fuel injectors and check the fuel filter. |

| Overheating | Engine temperature exceeding normal levels, potentially causing serious damage. | Inspect the cooling system, including radiator, hoses, and thermostat. |

Step-by-Step Guide to Engine Maintenance

Regular upkeep of your vehicle’s powerplant is crucial for optimal performance and longevity. This guide outlines essential tasks that will help ensure your engine runs smoothly and efficiently.

Follow these steps to maintain your engine effectively:

-

Check Engine Oil Level:

- Park the vehicle on a level surface.

- Remove the dipstick, wipe it clean, and reinsert it.

- Pull it out again to check the oil level; add oil if necessary.

-

Replace Engine Oil:

- Warm up the engine for a few minutes.

- Turn off the engine and let it cool slightly.

- Drain the old oil into a suitable container.

- Replace the oil filter and refill with new oil.

-

Inspect Air Filter:

- Locate the air filter housing.

- Remove the filter and check for dirt and damage.

- Clean or replace the filter as necessary.

-

Examine Belts and Hoses:

- Look for cracks, fraying, or signs of wear.

- Ensure that belts are properly tensioned.

- Replace any damaged belts or hoses immediately.

-

Check Coolant Level:

- Open the hood and locate the coolant reservoir.

- Inspect the level; top up with the appropriate coolant if needed.

-

Inspect Spark Plugs:

- Remove spark plugs using a socket wrench.

- Check for wear and carbon buildup.

- Replace old plugs with new ones if necessary.

By following these maintenance steps, you can significantly improve your engine’s performance and extend its lifespan. Regular checks and timely replacements are key to a healthy vehicle.

How to Troubleshoot Electrical Problems

Identifying issues within the electrical system of a vehicle can be challenging yet crucial for ensuring optimal performance. A systematic approach to diagnostics can help pinpoint the source of malfunctions, ranging from faulty wiring to component failures.

Begin by gathering essential tools, including a multimeter, wiring diagrams, and basic hand tools. This preparation will streamline the troubleshooting process and enhance accuracy in identifying issues.

| Step | Description |

|---|---|

| 1 | Inspect Fuses |

| 2 | Check Wiring Connections |

| 3 | Test Components |

| 4 | Measure Voltage |

| 5 | Consult Wiring Diagrams |

Start with a visual examination of fuses and relays, as these are often the first points of failure. Replace any blown fuses and ensure connections are secure. Next, check wiring for signs of wear, corrosion, or damage that could lead to shorts or open circuits.

Use a multimeter to test individual components such as switches, sensors, and motors, confirming they function within specified parameters. Measuring voltage at various points in the system will reveal whether power is reaching critical components. If all else fails, refer to wiring diagrams for guidance in tracking circuits and isolating issues.

Braking System: Inspection and Repair

The braking mechanism is a crucial component for vehicle safety and performance. Regular examination and maintenance of this system ensure reliable operation and can prevent potential failures. This section provides guidance on how to effectively assess and address issues within the braking system, emphasizing the importance of timely interventions.

Inspection Procedures

Begin the evaluation by checking the brake pads and rotors for signs of wear. Worn pads can lead to reduced stopping power and increased rotor damage. Inspect the brake fluid level and condition, as low or contaminated fluid can compromise braking efficiency. Additionally, examine the brake lines for leaks or cracks, which could indicate a potential hazard.

Common Repairs

Addressing worn pads involves replacing them with new components to restore optimal function. If rotors are damaged, resurfacing or replacing them may be necessary. For fluid issues, flushing the brake system ensures that all contaminants are removed, allowing for better performance. Regularly servicing the entire system not only enhances safety but also prolongs the lifespan of the braking components.

Transmission Troubles: Diagnosis and Solutions

Issues with the transmission can manifest in various ways, leading to frustrating experiences for vehicle owners. Identifying the root cause of these problems is crucial for effective resolution. This section outlines common symptoms, diagnostic steps, and potential remedies.

Common symptoms of transmission issues include:

- Slipping gears

- Delayed or rough shifting

- Unusual noises during operation

- Fluid leaks beneath the vehicle

- Warning lights on the dashboard

To accurately diagnose the problem, follow these steps:

- Check fluid levels and condition. Low or dirty fluid can cause various issues.

- Inspect for leaks. Look for fluid stains on the ground where the vehicle is parked.

- Listen for unusual sounds. Grinding or whining noises may indicate internal damage.

- Monitor performance. Pay attention to how the vehicle responds during acceleration and deceleration.

Once the symptoms are identified and diagnosed, consider these solutions:

- Change the transmission fluid and filter to improve performance.

- Repair or replace damaged components, such as solenoids or clutches.

- Consult a professional technician for complex issues that require specialized knowledge.

- Regular maintenance checks can prevent future complications.

By understanding the signs of transmission troubles and implementing proper diagnostic techniques, vehicle owners can ensure their vehicles remain in optimal condition.

Understanding the Blazer’s Suspension System

The suspension framework plays a crucial role in ensuring a smooth ride and maintaining vehicle stability. It consists of various components that work together to absorb shocks from the road, manage weight distribution, and enhance handling characteristics. A well-functioning system is essential for both safety and comfort during travel.

Components of the Suspension System

The main elements of the suspension include springs, shock absorbers, control arms, and struts. Springs support the vehicle’s weight and help manage weight transfer during maneuvers. Shock absorbers dampen oscillations caused by road irregularities, improving overall ride quality. Control arms facilitate the movement of the wheels while maintaining proper alignment.

Importance of Regular Maintenance

Regular checks and maintenance of the suspension system can prevent premature wear and ensure optimal performance. Symptoms of issues may include uneven tire wear, excessive bouncing, or difficulty in steering. Addressing these problems early can save time and resources, providing a more enjoyable driving experience.

Tips for DIY Oil Changes

Performing oil changes at home can save time and money while providing a sense of accomplishment. With the right knowledge and tools, you can ensure your engine runs smoothly and efficiently. Here are some practical suggestions to help you through the process.

Essential Tools and Materials

- Wrench set

- Oil filter wrench

- Oil catch pan

- Funnel

- New oil and filter

- Gloves and rags

Step-by-Step Process

- Gather all necessary tools and materials before starting.

- Warm up the engine for a few minutes to help the oil drain out smoothly.

- Secure the vehicle on a level surface and raise it with jack stands if needed.

- Remove the drain plug and let the old oil flow into the catch pan.

- Replace the oil filter using the wrench and apply a small amount of new oil to the gasket.

- Reinstall the drain plug and refill the engine with new oil through the funnel.

- Check the oil level with the dipstick and add more if necessary.

- Run the engine for a few minutes and check for leaks.

By following these steps and using the right tools, you can successfully perform oil changes yourself, contributing to the longevity and performance of your vehicle.

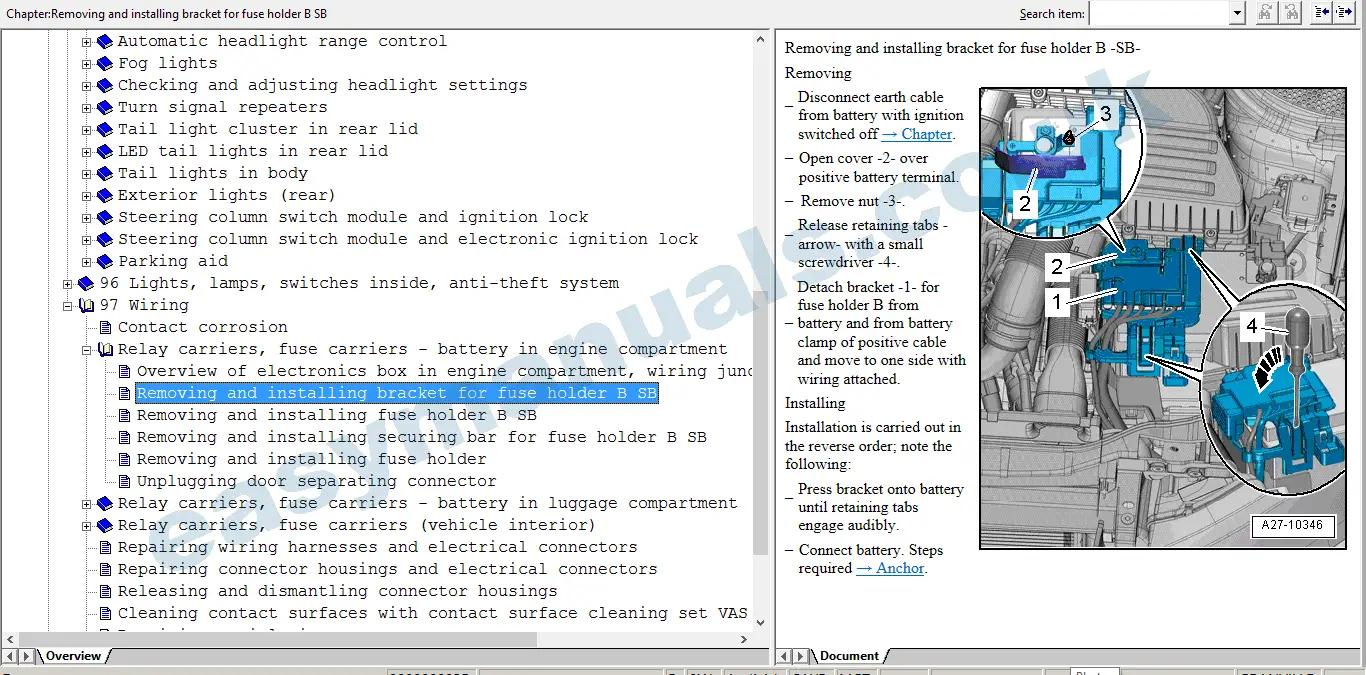

How to Read Repair Manuals Effectively

Understanding technical documentation is crucial for successful vehicle maintenance and troubleshooting. Familiarizing yourself with the layout and terminology can significantly enhance your ability to follow the provided instructions and perform tasks correctly.

Here are some strategies to maximize your comprehension of these documents:

- Familiarize with the Structure: Most guides have a standard format that includes sections such as specifications, procedures, and diagrams. Knowing what to expect will help you navigate more easily.

- Utilize the Index and Table of Contents: These features allow you to quickly find specific topics or procedures. Refer to them often to save time.

- Read Thoroughly: Take your time to read each section carefully. Skimming can lead to misunderstandings and errors.

When tackling a specific task, consider these tips:

- Follow Steps Sequentially: Adhere to the outlined procedures step by step to avoid missing critical actions.

- Refer to Diagrams: Visual aids can clarify complex procedures. Ensure you understand what each illustration represents.

- Take Notes: Jot down important points or reminders as you read. This practice can reinforce your understanding and provide quick references later.

By implementing these techniques, you can enhance your efficiency and accuracy in performing maintenance and repairs on your vehicle.

Preventive Maintenance for Longevity

Regular upkeep is essential for ensuring the extended life of your vehicle. By proactively addressing potential issues before they escalate, you can enhance performance, improve safety, and ultimately save on costly repairs. Establishing a consistent maintenance routine is crucial for vehicle reliability and longevity.

Key components of a comprehensive maintenance strategy include fluid checks, filter replacements, and periodic inspections. Below is a table outlining essential maintenance tasks along with their recommended intervals:

| Maintenance Task | Recommended Interval |

|---|---|

| Oil Change | Every 5,000 to 7,500 miles |

| Tire Rotation | Every 6,000 to 8,000 miles |

| Brake Inspection | Every 10,000 miles |

| Coolant Flush | Every 30,000 miles |

| Air Filter Replacement | Every 15,000 to 30,000 miles |

By adhering to these guidelines and maintaining an awareness of your vehicle’s needs, you can foster its durability and optimize your driving experience. A little effort in preventive care goes a long way in preserving your automobile’s health and performance.