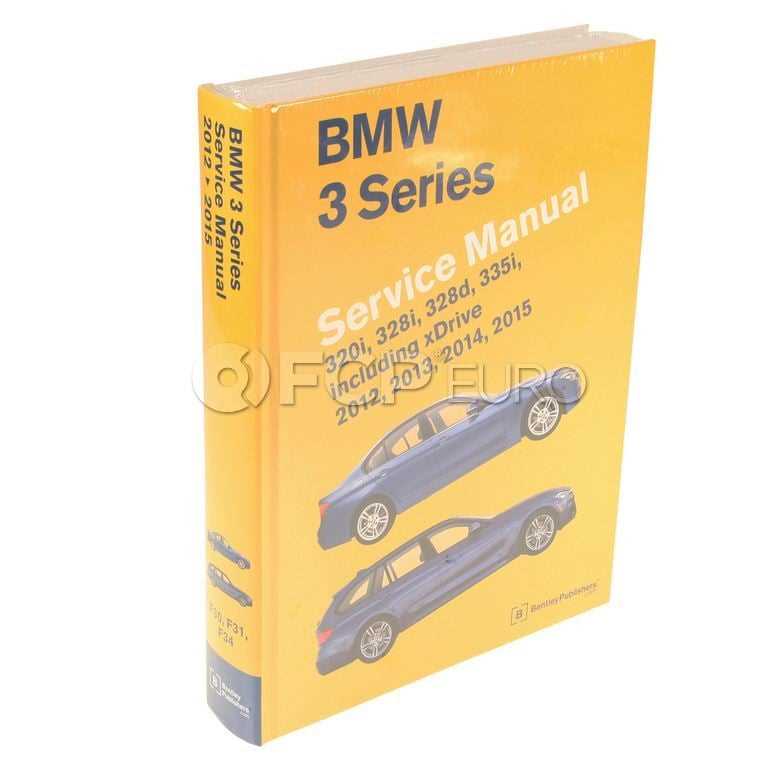

When it comes to ensuring optimal performance of your vehicle, understanding the intricacies of its engine system is essential. This section offers insights into various aspects of engine upkeep, providing valuable knowledge for enthusiasts and professionals alike. With proper guidance, any individual can delve into the specifics of their engine’s functionality, enhancing both efficiency and longevity.

Within this guide, readers will find comprehensive information regarding common issues and effective solutions. From identifying symptoms of wear and tear to implementing maintenance strategies, this resource aims to empower users with the tools they need for successful engine management. Each segment is designed to facilitate a deeper comprehension of your automobile’s inner workings, ultimately leading to more informed decisions.

Whether you are a seasoned mechanic or a novice seeking to expand your understanding, this section serves as a reliable reference point. By familiarizing yourself with the essentials of engine maintenance, you can contribute to the reliability and performance of your vehicle, ensuring a smoother and more enjoyable driving experience.

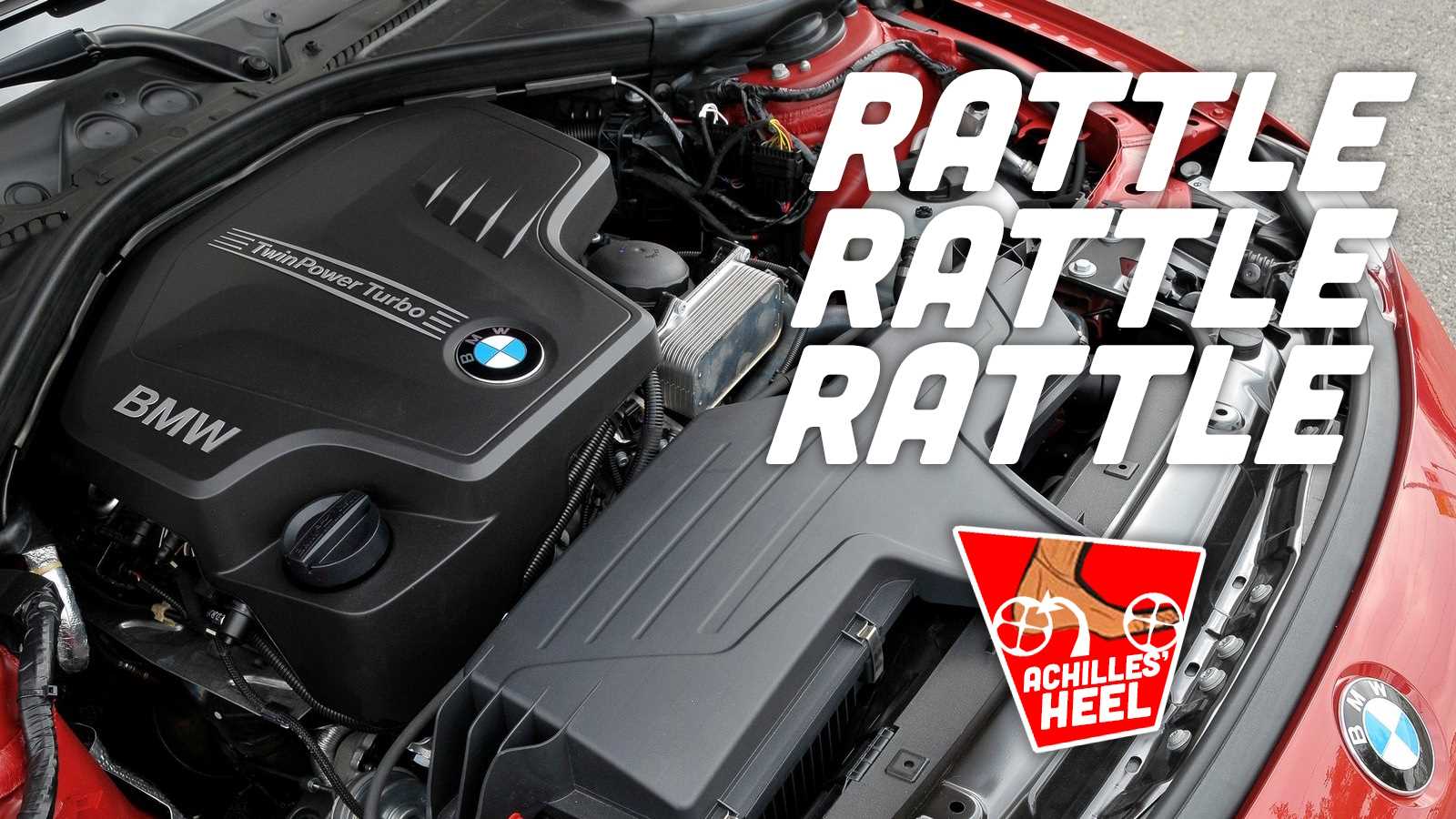

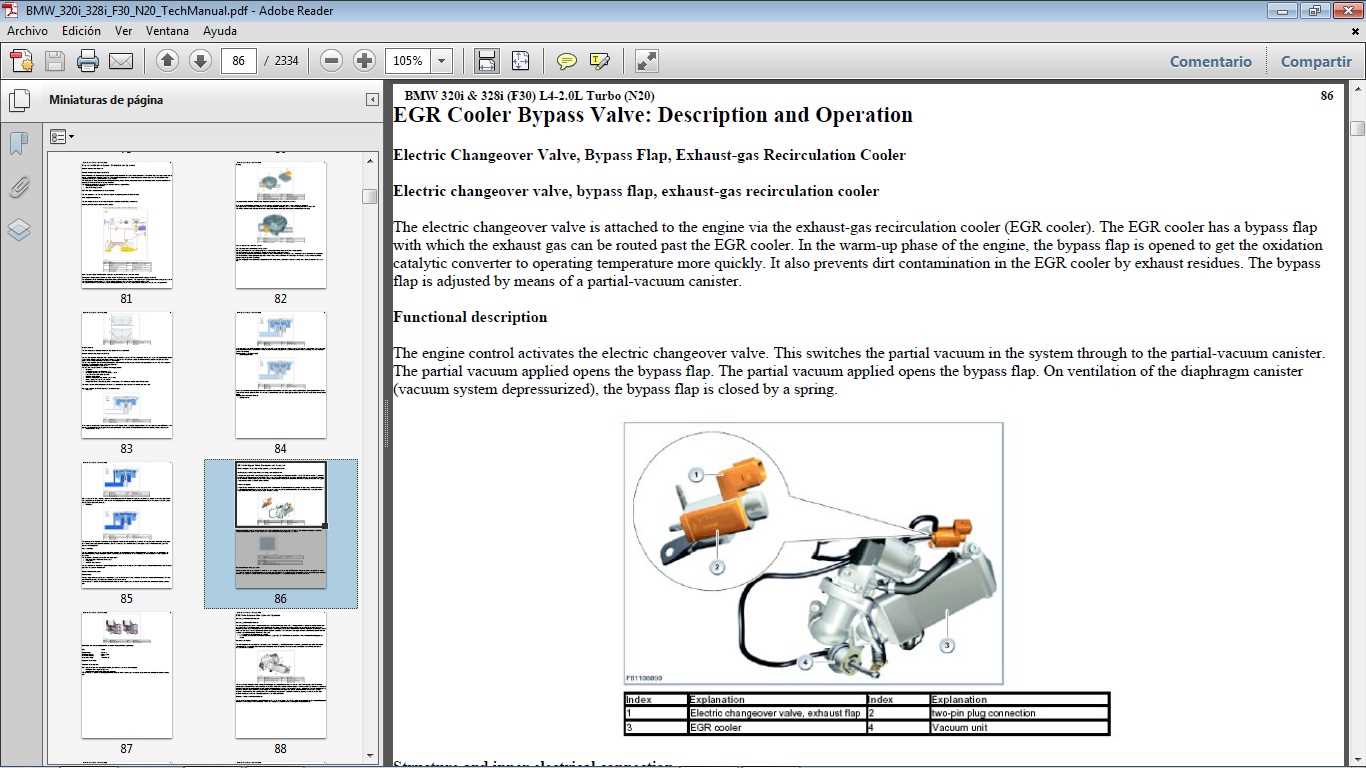

Understanding the BMW N20 Engine

The powertrain in question is a modern marvel of engineering, designed to deliver exceptional performance and efficiency. This advanced unit features a robust architecture that balances power output with fuel economy, making it suitable for a range of vehicles. Its design incorporates innovative technologies that enhance overall driving experience.

Key Features

This engine is characterized by several notable attributes that contribute to its reputation. The integration of turbocharging plays a pivotal role in achieving high torque across a wide RPM range, enabling swift acceleration and responsiveness.

Specifications Overview

| Specification | Details |

|---|---|

| Engine Type | Inline 4-cylinder |

| Displacement | 2.0 liters |

| Power Output | Up to 240 hp |

| Torque | Up to 258 lb-ft |

| Fuel Type | Premium unleaded |

The innovative aspects of this engine also extend to its construction materials, which contribute to weight reduction and improved efficiency. Such a blend of performance-oriented features makes this powerplant a popular choice among enthusiasts and everyday drivers alike.

Common Issues with N20 Engines

Engines of this type are known for their performance and efficiency, but they can encounter several recurring problems that owners should be aware of. Understanding these issues can help in early detection and maintenance, ultimately extending the lifespan of the unit.

Oil Leaks

One of the most prevalent concerns involves oil leaks, which can stem from various sources, such as valve cover gaskets or oil filter housings. Regular inspections can help identify leaks early, preventing potential damage to surrounding components.

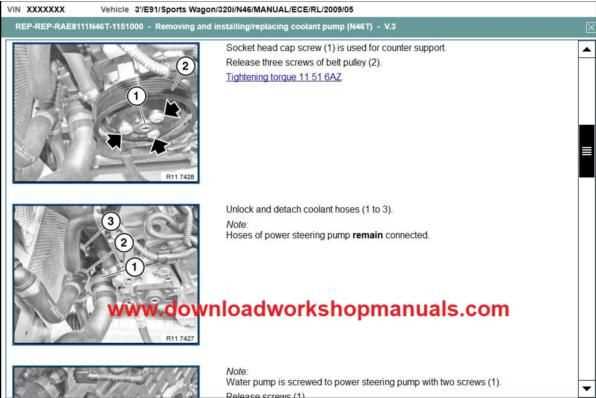

Cooling System Failures

Another significant issue pertains to the cooling system. Components such as the water pump and thermostat may fail, leading to overheating and subsequent engine damage. Timely replacements and routine checks are essential to ensure optimal operation.

Essential Tools for N20 Repairs

When undertaking maintenance tasks on a specific engine type, having the right equipment is crucial for ensuring efficiency and accuracy. A well-prepared toolkit can make the difference between a smooth process and potential setbacks, allowing for effective troubleshooting and adjustments.

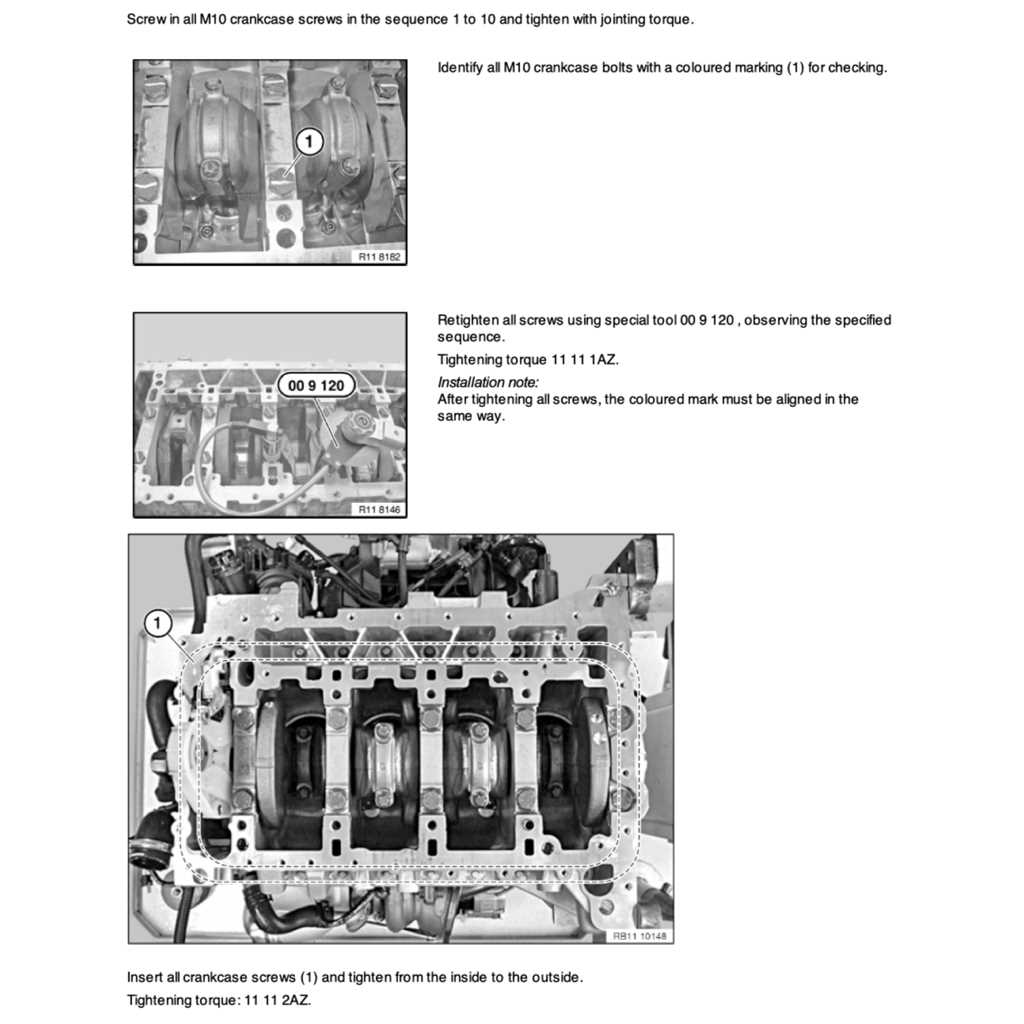

Key instruments include socket sets and wrenches, which are fundamental for loosening and tightening components. Torque wrenches are particularly important for achieving the correct specifications, preventing over-tightening that could lead to damage. Additionally, screwdrivers of various sizes will be necessary for accessing different fasteners throughout the assembly.

Diagnostic tools, such as OBD-II scanners, can provide valuable insights into the system’s health, helping identify any issues before they escalate. Moreover, a good quality multimeter is essential for electrical diagnostics, allowing for accurate measurement of voltage, current, and resistance.

Lastly, safety gear, including gloves and goggles, should not be overlooked. Ensuring personal protection while working with machinery contributes to a safe and efficient workspace, ultimately enhancing the overall experience of working on this particular engine configuration.

Step-by-Step Maintenance Procedures

This section outlines essential tasks to ensure optimal performance and longevity of your vehicle’s engine. Regular upkeep is crucial to prevent potential issues and maintain efficiency.

-

Fluid Checks

- Inspect oil levels and quality.

- Examine coolant levels and ensure proper mix.

- Check brake fluid for clarity and levels.

-

Filter Replacement

- Replace engine air filter to enhance airflow.

- Change fuel filter to prevent contamination.

- Swap out cabin air filter for improved interior air quality.

-

Belts and Hoses Inspection

- Check serpentine belt for signs of wear.

- Inspect hoses for leaks or cracks.

- Ensure all connections are secure and free of corrosion.

-

Tire Maintenance

- Monitor tire pressure regularly.

- Inspect tread depth and look for uneven wear.

- Rotate tires to promote even wear patterns.

-

Battery Care

- Check battery terminals for corrosion.

- Test battery charge and replace if necessary.

- Ensure proper connections and secure placement.

Following these procedures diligently will help maintain your engine’s reliability and performance over time.

Diagnosing Engine Performance Problems

Identifying issues related to engine efficiency is crucial for maintaining optimal functionality. Problems may manifest as reduced power, irregular idling, or unusual noises. A systematic approach to diagnosis can help pinpoint the underlying cause and facilitate timely intervention.

Common Symptoms of Engine Trouble

Symptoms such as decreased acceleration, rough idling, or increased fuel consumption often indicate that something is amiss. Pay attention to warning lights on the dashboard, as these can provide valuable clues about the engine’s condition. Monitoring these signs early can prevent more severe damage and costly repairs.

Step-by-Step Diagnostic Process

Begin the assessment by checking the onboard diagnostic system for error codes. Next, inspect key components such as the fuel system, ignition system, and air intake for any irregularities. Conducting a visual inspection can reveal leaks, loose connections, or signs of wear. Utilizing specialized tools for deeper analysis will enhance accuracy in identifying the issue.

Replacement Parts and Specifications

This section focuses on the essential components and their technical details crucial for maintaining optimal vehicle performance. Understanding the specifications of various parts aids in selecting suitable replacements, ensuring reliability and efficiency.

| Part Name | Specification | Recommended Replacement |

|---|---|---|

| Engine Oil Filter | High-efficiency, compatible with 5W-30 oil | Replace every 10,000 miles |

| Air Filter | Flow rate: 250 CFM, pleated design | Replace every 15,000 miles |

| Spark Plug | Iridium type, gap: 0.032 inches | Replace every 30,000 miles |

| Fuel Injector | Multi-port, flow rate: 300 cc/min | Inspect every 20,000 miles, replace as needed |

Safety Precautions During Repairs

When engaging in maintenance tasks on your vehicle, it is essential to prioritize safety. Proper precautions not only protect you but also enhance the efficiency of the work being performed. Understanding potential hazards and implementing effective measures can significantly reduce risks associated with automotive service.

Firstly, always ensure that you are working in a well-ventilated area. Fumes and chemicals can be harmful, so adequate airflow is crucial. Additionally, wearing personal protective equipment, such as gloves and safety glasses, is recommended to shield against injuries.

Moreover, it is vital to utilize appropriate tools and equipment. Ensure that all tools are in good condition and suited for the tasks at hand. This reduces the likelihood of accidents caused by faulty instruments.

Finally, familiarize yourself with the specific systems of your vehicle. Understanding their functions and common issues can help you identify problems early and work safely. Always consult relevant literature for guidance when unsure about any process.

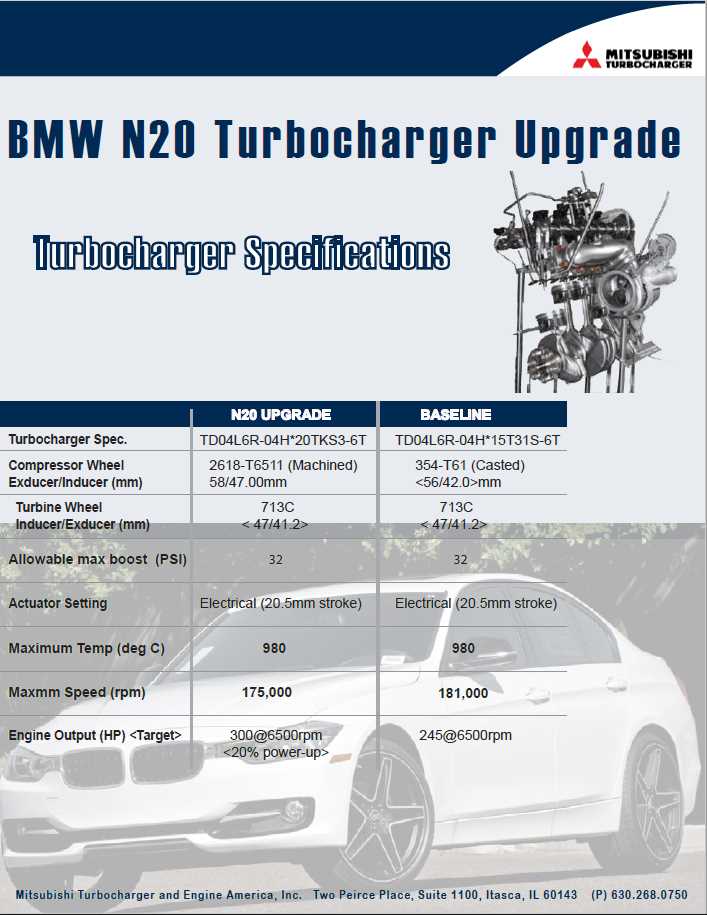

Tuning and Upgrades for N20

Enhancing the performance of your engine can significantly improve the overall driving experience. By implementing various modifications, you can unlock additional power and efficiency while tailoring the vehicle to your specific preferences. This section explores popular enhancements and upgrades to consider for optimal results.

Performance Enhancements

One of the most effective ways to boost engine output is through performance chips or tuning software. These solutions optimize fuel mapping and ignition timing, resulting in improved throttle response and increased horsepower. Additionally, upgrading the exhaust system can reduce back pressure, allowing for better airflow and further performance gains.

Suspension and Handling Upgrades

To complement the increased power, improving the vehicle’s handling is essential. Consider installing upgraded suspension components such as coilovers or sway bars. These modifications enhance stability and cornering performance, providing a more engaging driving experience. Furthermore, high-performance tires can offer superior grip and traction, making a noticeable difference on the road.

| Upgrade Type | Benefits |

|---|---|

| Performance Chips | Improved horsepower and throttle response |

| Exhaust System | Reduced back pressure, enhanced airflow |

| Coilovers | Better handling and ride quality |

| High-Performance Tires | Increased grip and traction |

Fuel System Troubleshooting Techniques

The fuel delivery system is critical for optimal engine performance, and diagnosing issues effectively can prevent more severe damage. Understanding the common symptoms and utilizing systematic methods can help identify problems and facilitate repairs.

Identifying Symptoms

Begin by observing any irregularities during operation. Signs such as difficulty starting, rough idling, or decreased power can indicate fuel system malfunctions. Listening for unusual noises from the fuel pump or detecting a fuel odor can also provide valuable clues. Keep an eye on the fuel gauge and monitor fuel consumption for inconsistencies.

Diagnostic Procedures

Utilize a fuel pressure gauge to check the pressure levels against the manufacturer’s specifications. Inspect fuel filters for clogs and replace them as necessary. A thorough examination of the fuel injectors for leaks or blockages is essential. Additionally, verifying electrical connections and testing the fuel pump operation can lead to quick resolutions of performance issues. Regular maintenance and timely diagnostics will prolong the life of the fuel delivery system.

Cooling System Management Strategies

The effective management of the cooling system is crucial for maintaining optimal engine performance and longevity. This involves a comprehensive approach that includes regular monitoring, timely maintenance, and proactive measures to prevent overheating and related issues.

Monitoring Temperature Levels: Regularly checking the coolant temperature can help detect potential problems before they escalate. Utilizing advanced sensors and gauges allows for real-time data collection, which can be critical for preventing engine damage.

Routine Maintenance: Routine inspections of the cooling components, such as the radiator, hoses, and water pump, are essential. Replacing worn-out parts and ensuring proper fluid levels can significantly enhance system efficiency.

Cooling Fluid Quality: The choice of coolant is vital for effective thermal management. Using the recommended type of coolant and ensuring it is free from contaminants can improve heat transfer and prevent corrosion within the system.

Thermostat Functionality: The thermostat plays a key role in regulating engine temperature. Ensuring it operates correctly prevents overheating and maintains a stable operating temperature, enhancing overall performance.

Implementing these strategies can lead to improved engine efficiency and durability, ultimately contributing to a more reliable driving experience.

Electrical System Inspection Guidelines

This section provides essential recommendations for evaluating the electrical components of a vehicle. A thorough examination ensures the efficient operation of electrical systems, enhancing overall vehicle performance and safety.

Regular assessments can prevent potential issues, allowing for early identification and resolution of faults. Follow these steps to conduct a comprehensive inspection:

| Inspection Area | Recommended Action | Notes |

|---|---|---|

| Battery | Check terminals for corrosion and ensure secure connections. | Replace if voltage is below the recommended level. |

| Wiring Harness | Inspect for fraying, cracks, or wear. | Address any damage immediately to avoid short circuits. |

| Fuses | Examine all fuses for continuity and functionality. | Replace blown fuses with correct amperage ratings. |

| Ground Connections | Verify all ground points for tightness and corrosion. | Poor grounding can lead to electrical malfunctions. |

| Charging System | Test alternator output and inspect drive belts. | A malfunctioning alternator can lead to battery drain. |

By adhering to these guidelines, individuals can maintain the electrical system in optimal condition, thereby enhancing reliability and safety during operation.

Service Intervals and Recommendations

This section outlines the essential maintenance schedules and guidelines for optimal vehicle performance. Regular servicing ensures longevity and reliability, minimizing the risk of unexpected issues.

- Oil Change: It is advised to replace engine oil every 5,000 to 7,500 miles or as specified in the manufacturer’s guidelines.

- Filter Replacement: Air and oil filters should be changed during each oil service to maintain engine cleanliness.

- Fluid Checks: Regularly inspect coolant, brake fluid, and transmission fluid levels, topping off as necessary.

Additional recommendations include:

- Inspecting brake pads and rotors every 15,000 miles to ensure safety.

- Checking tire pressure and tread depth regularly to promote efficient handling and fuel economy.

- Performing a full inspection of belts and hoses every 30,000 miles to prevent breakdowns.

Following these intervals not only helps maintain performance but also enhances driving safety and comfort.

Finding Professional Repair Services

When it comes to maintaining your vehicle, seeking the assistance of skilled technicians can make all the difference. Choosing the right service provider ensures that your automobile receives the best care, extending its longevity and enhancing performance. This section offers guidance on how to identify qualified professionals who can handle your vehicle’s needs effectively.

Tips for Selecting the Right Service Provider

- Research local garages and workshops with strong reputations.

- Check online reviews and customer feedback to gauge service quality.

- Inquire about certifications and qualifications of the mechanics.

- Ask for recommendations from friends and family who have experience.

- Evaluate the range of services offered to ensure they can meet your specific needs.

Evaluating Service Quality

Before committing to a particular provider, it’s crucial to assess their level of service. Consider the following factors:

- Visit the facility to inspect cleanliness and organization.

- Observe customer interactions and how inquiries are handled.

- Request estimates for services to compare pricing structures.

- Ask about warranties or guarantees for the work performed.

- Ensure they use quality parts and adhere to industry standards.

Taking the time to find a competent service provider will help you maintain your vehicle in optimal condition, providing peace of mind for every journey.