In the realm of farming, the functionality of heavy machinery is paramount. Ensuring optimal performance requires a comprehensive understanding of the equipment’s workings and the ability to address any issues that may arise. This guide aims to provide insights and procedures that can help owners keep their machines in peak condition, thereby enhancing productivity on the field.

Understanding your machinery is crucial for effective maintenance. Recognizing the signs of wear and tear, as well as knowing the recommended upkeep practices, can prevent minor problems from escalating into significant failures. This resource will delve into various aspects of machine care, from basic inspections to more intricate troubleshooting techniques.

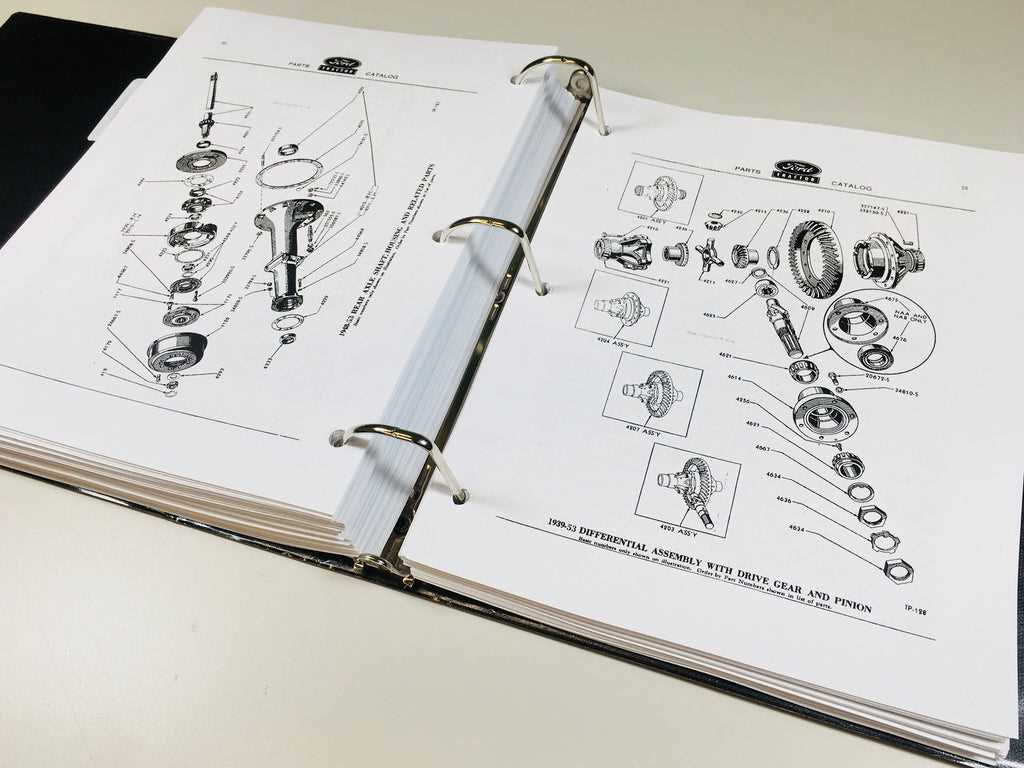

Furthermore, access to detailed resources can empower users to tackle repairs confidently. With a wealth of information available, individuals can learn how to replace parts, adjust settings, and perform essential services that prolong the life of their equipment. Emphasizing knowledge and preparation, this guide serves as a valuable companion for all who rely on their machines for agricultural success.

Understanding the Ford 8N Tractor

This section provides an in-depth look at a specific model of agricultural machinery that has become iconic over the years. Known for its reliability and simplicity, this equipment is often a favorite among enthusiasts and those engaged in farming. Its robust design and ease of use make it a staple in various tasks, from plowing fields to transporting materials.

Equipped with a powerful engine and a straightforward transmission system, this machine is well-suited for a variety of farming applications. Understanding its components and functions is essential for anyone looking to maximize efficiency and performance.

| Component | Description |

|---|---|

| Engine | A four-cylinder unit that provides ample power for numerous tasks. |

| Transmission | Simple gear system allowing for easy operation in different conditions. |

| Hydraulics | Efficient lifting system that supports various implements and attachments. |

| Chassis | Sturdy frame designed for durability and stability on rough terrain. |

By exploring these features, users can better appreciate the capabilities and historical significance of this remarkable piece of machinery.

History of the Ford 8N Model

The evolution of this iconic agricultural machine marks a significant milestone in the realm of farming equipment. Introduced in the early 1940s, it quickly gained recognition for its innovative features and reliability, becoming a favorite among farmers across the United States. The design focused on enhancing productivity and ease of use, which contributed to its lasting legacy in the agricultural community.

Innovations and Features

One of the most remarkable aspects of this model was its incorporation of a three-point hitch system, which revolutionized the way implements were attached and used. This advancement allowed for greater versatility in the field, enabling farmers to switch between tasks with minimal effort. Additionally, the introduction of a more powerful engine and improved hydraulics set a new standard in performance, making it a highly sought-after piece of equipment during its production years.

Legacy and Impact

Over the decades, this machine has left an indelible mark on farming practices. Its robust construction and user-friendly design have led to a strong following among collectors and enthusiasts. Many vintage units continue to operate in fields today, a testament to the quality and durability of its engineering. The impact of this model can still be felt in modern machinery, with many contemporary designs drawing inspiration from its pioneering features.

Common Issues Faced by Owners

Owning an agricultural machine often comes with a set of challenges that can affect performance and reliability. Many individuals encounter specific problems that can hinder productivity and require attention. Understanding these common difficulties can help owners maintain their equipment more effectively.

Engine Problems: One of the frequent issues involves the engine not starting or stalling unexpectedly. This can result from a variety of factors, such as fuel delivery problems or electrical failures. Regular checks on the ignition system and fuel lines can mitigate these risks.

Hydraulic Failures: Owners may also experience issues with the hydraulic system, including leaks or loss of pressure. These malfunctions can severely impact the functionality of attachments. Routine inspections and timely fluid changes are essential to prevent such occurrences.

Transmission Difficulties: Shifting gears can become problematic over time, leading to delays in operation. This may stem from worn components or inadequate lubrication. Addressing transmission issues early can save time and resources in the long run.

Electrical System Issues: Electrical malfunctions, such as faulty wiring or dead batteries, are another common concern. Ensuring that connections are clean and secure can help avoid these headaches and keep the machinery running smoothly.

By being aware of these prevalent challenges, owners can take proactive steps to maintain their equipment and enhance its longevity.

Essential Tools for Repairs

When it comes to maintaining heavy machinery, having the right instruments at your disposal is crucial. These tools not only streamline the process but also enhance efficiency and ensure safety during work. Whether you are a seasoned mechanic or a beginner, understanding which implements to use can make a significant difference in the outcome of your tasks.

Basic Tool Set

A solid foundation of essential instruments is the first step towards effective maintenance. Here are some of the must-have tools that every technician should consider:

| Tool | Purpose |

|---|---|

| Wrenches | For loosening or tightening bolts and nuts. |

| Screwdrivers | Used for fastening or removing screws. |

| Socket Set | For working on various sizes of fasteners quickly. |

| Pliers | Useful for gripping, twisting, and cutting wire. |

Advanced Equipment

In addition to basic tools, some specialized equipment can enhance your capabilities. Consider the following items for more complex tasks:

| Tool | Purpose |

|---|---|

| Torque Wrench | Ensures bolts are tightened to the correct specifications. |

| Hydraulic Jack | For lifting heavy components safely. |

| Multimeter | To diagnose electrical issues effectively. |

| Impact Driver | Helps in driving screws with high torque. |

Step-by-Step Maintenance Procedures

Regular upkeep of machinery is essential to ensure optimal performance and longevity. Following systematic procedures can prevent costly repairs and enhance efficiency. This section outlines detailed steps to keep your equipment in top condition.

Routine Inspection

Conducting frequent inspections is crucial. Pay attention to the following areas:

- Fluid levels: Check oil, coolant, and fuel.

- Belts and hoses: Look for wear and tear or leaks.

- Filters: Replace air, fuel, and oil filters as needed.

- Tires: Inspect for proper inflation and tread wear.

Cleaning and Lubrication

Proper cleaning and lubrication ensure smooth operation. Follow these steps:

- Clean external surfaces with a damp cloth to remove dirt and debris.

- Inspect and clean the air intake system to avoid clogs.

- Lubricate moving parts according to the manufacturer’s specifications.

- Check and grease pivot points and joints to reduce friction.

Engine Overhaul Techniques Explained

The process of rejuvenating a power unit is essential for maintaining its performance and longevity. Understanding the various techniques involved can significantly enhance the efficiency and reliability of the machinery. This section delves into the critical methods employed during an overhaul, providing insights into the necessary steps and considerations.

Disassembly is the first crucial phase, where components are carefully removed to allow for inspection and cleaning. It is vital to document the disassembly process to ensure that every part can be reassembled correctly. Special attention should be paid to labeling and organizing parts, as this will streamline the subsequent stages.

Once disassembled, the next step is inspection. Each element must be thoroughly examined for signs of wear, damage, or corrosion. Commonly assessed parts include the cylinder head, pistons, and crankshaft. Identifying issues early on can prevent further complications and ensure that the necessary replacements or repairs are made.

Following inspection, cleaning is imperative. Utilizing appropriate solvents and techniques will remove carbon deposits and other contaminants. This process not only prepares the components for reassembly but also helps in identifying hidden defects that may not have been apparent during initial inspection.

After cleaning, replacement of worn or damaged parts is often necessary. It is important to select high-quality components to ensure optimal performance and compatibility. This step can significantly affect the overall durability and efficiency of the unit post-overhaul.

Finally, reassembly should be approached with care. Following the documented procedures ensures that each component is placed correctly and securely. Proper torque specifications and assembly techniques are vital to avoid future failures. After reassembly, thorough testing is recommended to confirm that the rejuvenated unit operates smoothly and efficiently.

By following these techniques, one can ensure a successful overhaul that not only restores functionality but also enhances the overall performance of the engine.

Electrical System Troubleshooting Guide

This section aims to assist users in diagnosing and resolving issues related to the electrical components of their equipment. By following a systematic approach, individuals can identify faults and implement effective solutions to ensure optimal performance.

Common Symptoms and Their Causes

Understanding the typical signs of electrical malfunction is crucial. Below is a table summarizing frequent issues along with potential causes:

| Symptom | Possible Cause |

|---|---|

| Engine won’t start | Dead battery, faulty starter, loose connections |

| Lights dim or flicker | Weak alternator, poor wiring, corroded terminals |

| Fuse keeps blowing | Short circuit, overloaded circuit, defective component |

| Instruments not functioning | Broken gauge, loose wires, bad ground connection |

Troubleshooting Steps

To effectively diagnose the issues, follow these steps:

- Inspect the battery condition and connections.

- Check fuses and replace any that are blown.

- Test the alternator output to ensure proper charging.

- Examine wiring for any signs of damage or corrosion.

- Verify the functionality of switches and controls.

By systematically checking these areas, users can pinpoint and address electrical concerns efficiently.

Hydraulic System Repair Insights

Understanding the intricacies of a hydraulic mechanism is essential for maintaining optimal functionality. This segment delves into the nuances of troubleshooting and restoring hydraulic components to ensure smooth operation and longevity. Proper attention to details can significantly enhance performance and prevent future issues.

Common Issues and Solutions

Several typical problems can arise within hydraulic systems. Leaks, often caused by worn seals or loose connections, are among the most frequent concerns. Identifying the source of a leak is crucial; a thorough inspection of hoses and fittings can reveal hidden damage. In many cases, replacing a compromised seal can restore full functionality.

Maintenance Tips for Longevity

Regular upkeep plays a vital role in sustaining hydraulic efficiency. Flushing the system periodically to remove contaminants is recommended, as dirt can lead to premature wear. Additionally, checking fluid levels and quality ensures that the system operates smoothly. Using the correct type of hydraulic fluid is equally important, as it affects performance and can prevent potential damage.

By adopting these insights, one can foster a deeper understanding of hydraulic systems, promoting both efficiency and durability in the long run.

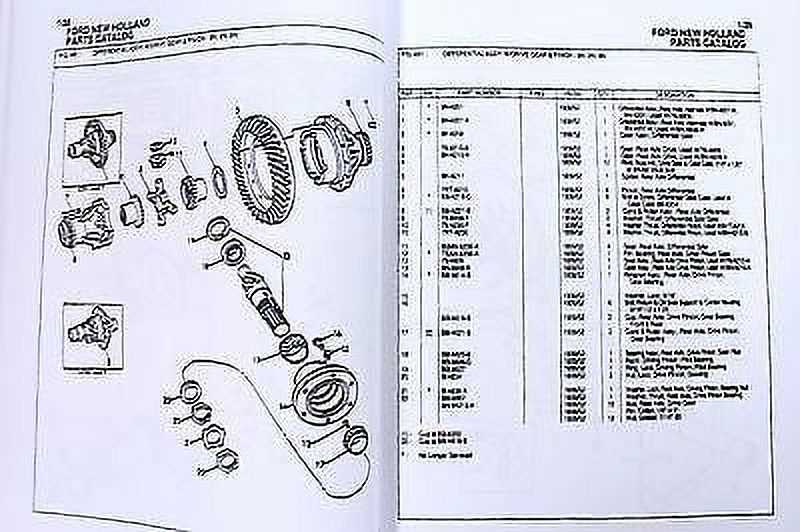

Parts Replacement and Upgrades

Maintaining and enhancing machinery often involves the replacement of worn components and the implementation of upgrades to improve performance. This process not only prolongs the life of the equipment but also optimizes its efficiency and functionality. Understanding the significance of each part and the benefits of potential enhancements can lead to better overall results in operation.

Common Component Replacements

Several key elements are frequently subject to replacement due to wear and tear. Engine components, such as filters and gaskets, are essential for maintaining optimal performance. Additionally, hydraulic systems may require new seals or hoses to ensure proper functioning. Regular inspections can help identify these needs early, preventing further damage and ensuring reliable operation.

Enhancing Performance with Upgrades

Upgrading specific parts can significantly enhance the capabilities of your equipment. For instance, swapping out a standard exhaust system for a high-performance variant can improve power output and fuel efficiency. Additionally, installing advanced ignition systems or modified air intakes can lead to smoother operation and increased responsiveness. These enhancements not only boost productivity but can also contribute to a more enjoyable experience for the operator.

Seasonal Maintenance Checklist

Regular upkeep is essential to ensure optimal performance and longevity of your equipment. A seasonal checklist can help identify necessary tasks and keep everything running smoothly throughout the year. Below is a comprehensive guide to help you stay on track with essential maintenance activities.

| Season | Maintenance Tasks |

|---|---|

| Spring |

|

| Summer |

|

| Fall |

|

| Winter |

|

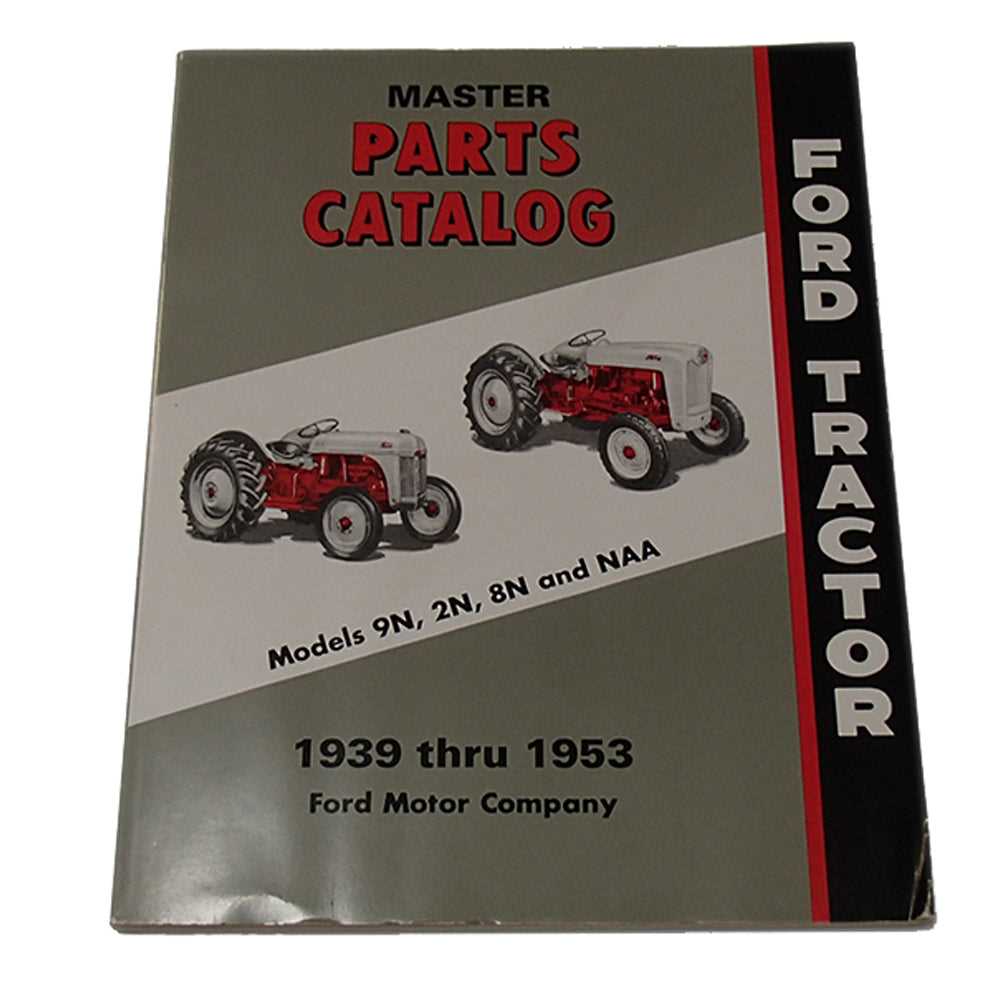

Finding Reliable Replacement Parts

Ensuring optimal performance of your equipment often hinges on sourcing trustworthy components. Identifying high-quality parts can significantly enhance longevity and efficiency, preventing unnecessary downtime. It is crucial to know where to look and how to assess the reliability of potential suppliers.

When seeking replacements, consider several avenues to guarantee that you are making a wise investment. Reliable suppliers typically offer a combination of authenticity, warranty options, and customer support. Evaluating these factors can lead to more informed purchasing decisions.

| Source | Pros | Cons |

|---|---|---|

| Authorized Dealers | Genuine parts, warranties, expert advice | Higher prices |

| Online Retailers | Convenience, variety, competitive pricing | Quality may vary, lack of personal support |

| Local Salvage Yards | Cost-effective, used parts | Uncertain condition, limited selection |

| Aftermarket Suppliers | Affordable options, innovative designs | Variable quality, limited warranty |

Thorough research and careful consideration of these options will lead you to dependable components that meet your needs and ensure the seamless operation of your machinery.

Safety Precautions During Repairs

When engaging in maintenance tasks, ensuring a safe environment is paramount. Adhering to safety protocols not only protects the individual performing the work but also preserves the integrity of the equipment. By taking the necessary precautions, one can prevent accidents and ensure a smoother process throughout the undertaking.

Before initiating any tasks, it is crucial to assess the workspace and gather the appropriate tools. Familiarity with the machinery’s components can significantly enhance safety measures. The following table outlines essential safety tips to consider:

| Precaution | Description |

|---|---|

| Wear Protective Gear | Always use safety glasses, gloves, and steel-toed boots to safeguard against injuries. |

| Ensure Stability | Make sure that the equipment is on a level surface and securely positioned before starting work. |

| Disconnect Power | Always disconnect the power source before performing any maintenance to avoid accidental starts. |

| Use Tools Properly | Utilize tools for their intended purposes and maintain them in good condition to prevent malfunctions. |

| Stay Alert | Remain focused and avoid distractions while working to minimize the risk of accidents. |

Implementing these safety measures will create a more secure working environment and enhance the overall effectiveness of maintenance tasks. Prioritizing safety is essential for anyone involved in hands-on activities with machinery.

Resources for Ford 8N Enthusiasts

For those passionate about classic machinery, having access to valuable resources can enhance the experience of ownership and maintenance. Whether you’re seeking advice on upgrades, troubleshooting issues, or connecting with fellow aficionados, there are numerous platforms and materials available to support your journey.

Online Communities and Forums

Engaging with online forums can be an excellent way to share knowledge and find answers to specific questions. Websites dedicated to vintage equipment often feature sections where enthusiasts discuss their experiences, offer tips, and provide support to one another. Participating in these communities allows you to tap into a wealth of collective wisdom and insights.

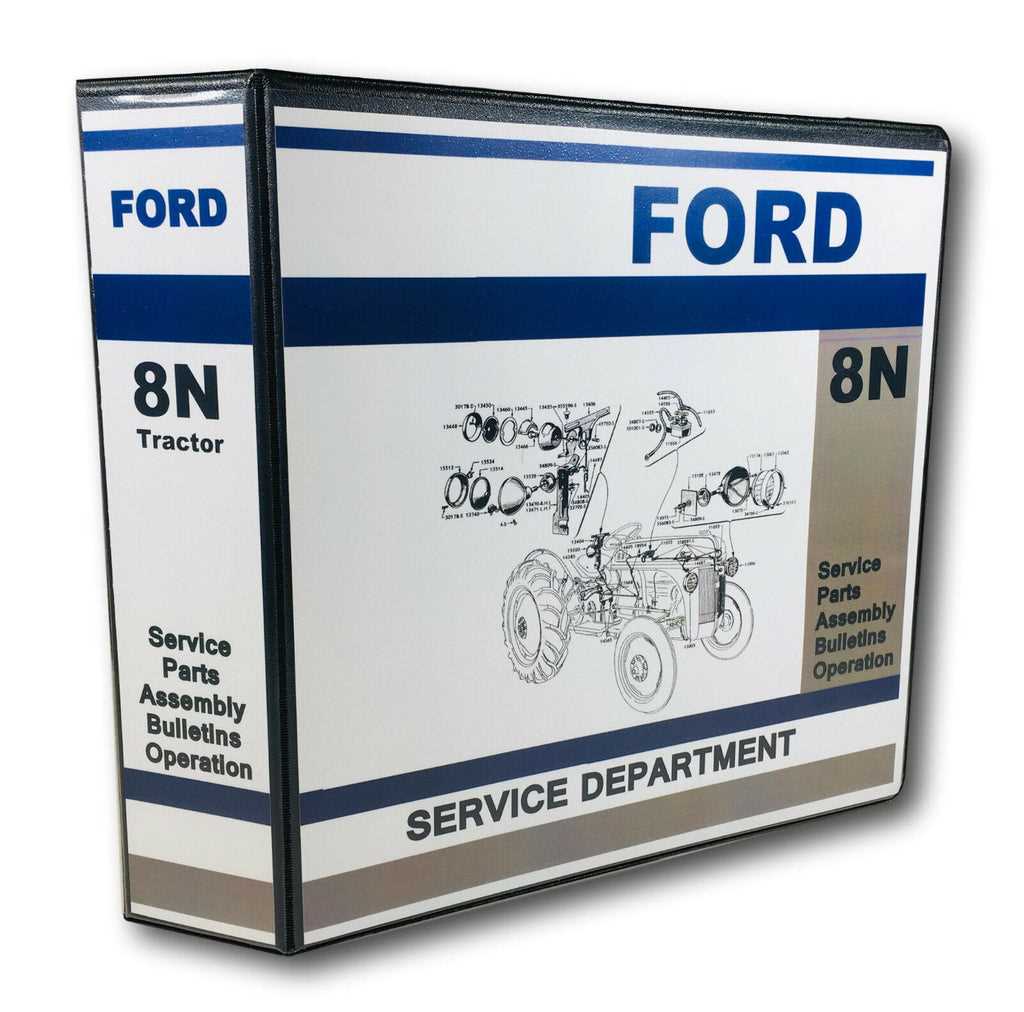

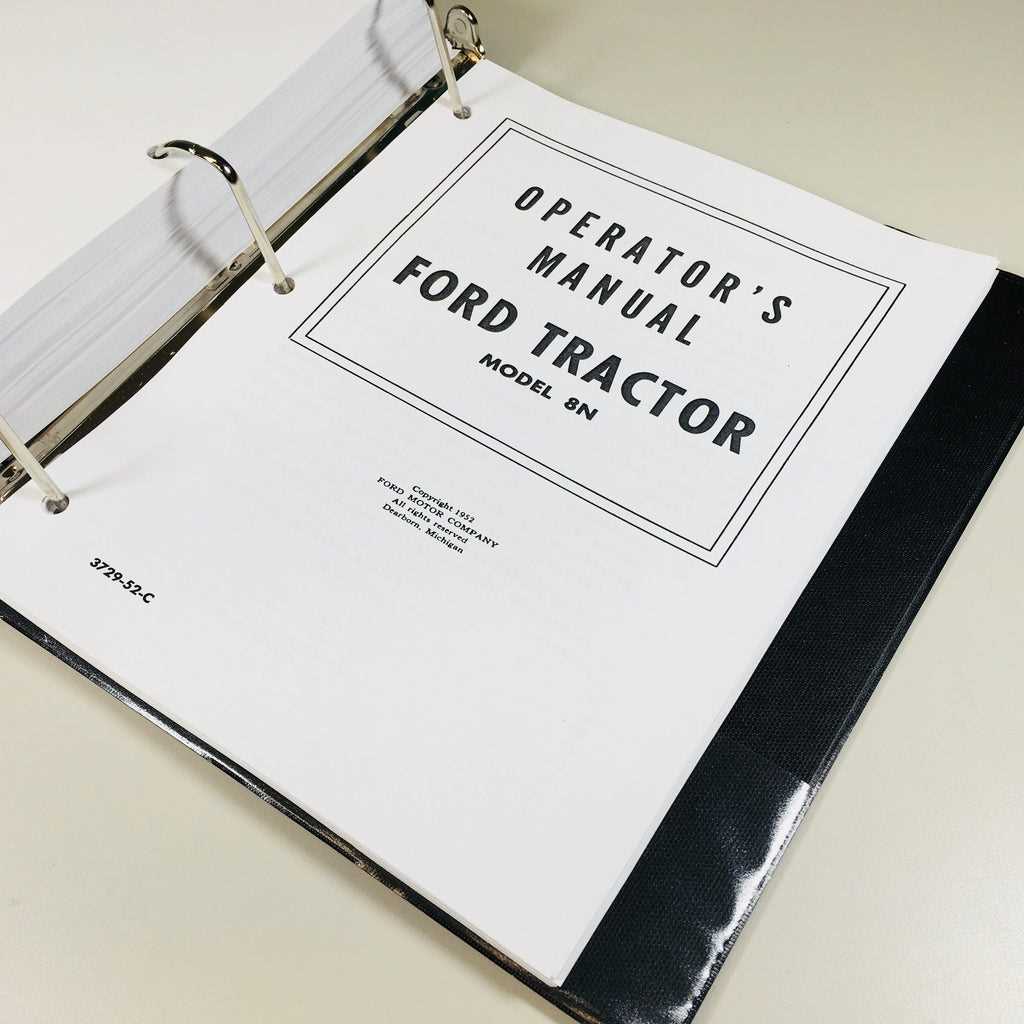

Books and Publications

Consider exploring books and magazines that focus on classic machinery maintenance and restoration. These publications frequently include detailed guides, practical tips, and stunning photography. Investing in literature that covers specific models can prove invaluable, offering comprehensive information that helps preserve the rich history and functionality of these beloved machines.