Owning a two-wheeled vehicle is an exciting experience, yet it comes with responsibilities that every enthusiast should embrace. Understanding how to maintain and troubleshoot your machine can enhance its performance and longevity. This resource aims to provide valuable insights into the nuances of vehicle upkeep, empowering riders with the knowledge to tackle various challenges.

In this section, we will explore essential techniques and guidelines that enable you to effectively handle common issues. From routine inspections to more intricate repairs, grasping these concepts will help you optimize your vehicle’s functionality. By the end of this guide, you’ll be well-equipped to ensure your ride remains in top-notch condition.

Delving into the intricacies of mechanical systems may seem daunting, but with the right approach, it becomes manageable. Embracing a proactive mindset will not only save time and money but also lead to a more enjoyable riding experience. Get ready to embark on the ultimate journey of maintenance and problem-solving!

Understanding the Honda Helix CN250

This section aims to provide insights into a unique two-wheeled vehicle designed for urban commuting and leisure riding. With its distinctive features and engineering, this model offers both performance and comfort, making it a popular choice among enthusiasts and casual riders alike.

Key characteristics that define this scooter include:

- Efficient engine design that balances power and fuel economy.

- Streamlined bodywork that enhances aerodynamics and visual appeal.

- Comfortable seating arrangement suited for long-distance travel.

- Advanced suspension system that improves handling on various terrains.

- Ample storage capacity for personal belongings and essentials.

For those looking to maintain or enhance their riding experience, understanding the technical aspects and maintenance requirements is crucial. Here are some fundamental components to consider:

- Engine: Familiarize yourself with the specifications and operational characteristics.

- Transmission: Learn about the automatic system and how it contributes to ease of use.

- Braking System: Ensure you know the types and their maintenance needs for safety.

- Electrical System: Understand the basics of wiring and components like lights and indicators.

- Chassis: Recognize the importance of frame integrity and component alignment.

By grasping these elements, riders can enhance their understanding of this innovative scooter, leading to a more enjoyable and reliable riding experience.

Common Issues with the CN250

Many enthusiasts encounter specific challenges with their two-wheeled vehicles over time. Understanding these prevalent problems can help in maintaining optimal performance and enhancing the riding experience. Below are some frequent concerns that riders may face.

Electrical System Failures: One of the most reported issues involves the electrical components. Riders often experience problems with the battery, starter motor, or wiring, leading to difficulties in starting the machine or intermittent electrical malfunctions.

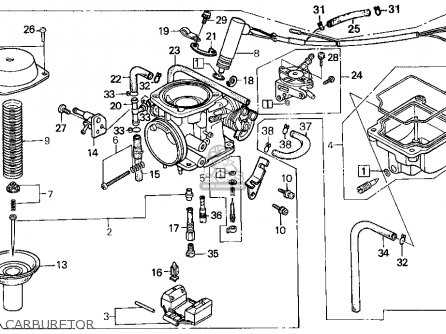

Fuel Delivery Problems: Another common concern relates to the fuel system. Clogs in the fuel filter or issues with the carburetor can result in poor engine performance, causing the vehicle to sputter or stall unexpectedly.

Brake Wear: Regular usage can lead to brake pads wearing down quicker than anticipated. This can compromise safety and requires timely inspection and replacement to ensure effective stopping power.

Suspension Issues: Riders may notice a decline in ride quality due to worn-out shock absorbers or forks. This can lead to an uncomfortable experience and may affect handling and stability.

Engine Overheating: Overheating is another significant concern, often caused by low coolant levels or a malfunctioning radiator. Monitoring engine temperatures and addressing leaks promptly is essential to avoid severe damage.

Being aware of these typical issues can aid in proactive maintenance and enhance the longevity of the vehicle. Regular check-ups and attentive care are key to ensuring a smooth and enjoyable ride.

Essential Tools for Repairs

When embarking on maintenance or restoration tasks, having the right set of instruments is crucial for efficiency and effectiveness. The proper tools not only streamline the process but also ensure that the work is performed safely and accurately. Whether you are a novice or a seasoned mechanic, understanding which implements are essential can significantly enhance your experience.

Basic Hand Tools: A reliable collection of hand tools forms the backbone of any workshop. Essential items include wrenches, screwdrivers, and pliers. Each tool serves a specific purpose, allowing you to tighten, loosen, or manipulate various components with ease.

Socket Set: A comprehensive socket set is invaluable for dealing with bolts and nuts of varying sizes. This tool provides versatility, enabling you to tackle a wide range of fasteners without hassle.

Torque Wrench: Precision is key in many tasks, and a torque wrench helps ensure that fasteners are tightened to the manufacturer’s specifications. This tool is especially important for maintaining the integrity of critical components.

Diagnostic Tools: Modern vehicles often require specialized diagnostic equipment to identify issues. OBD-II scanners and multimeters are excellent choices for troubleshooting electrical problems and reading error codes.

Safety Equipment: No task is complete without considering safety. Invest in protective gloves, goggles, and a sturdy work apron to safeguard against potential hazards.

Equipping yourself with these fundamental tools will not only improve your efficiency but also enhance your confidence when tackling various projects. A well-prepared workspace sets the stage for successful maintenance endeavors.

Step-by-Step Maintenance Guide

Regular upkeep is essential for ensuring the longevity and optimal performance of your two-wheeled vehicle. This guide provides a comprehensive approach to routine care, helping you identify key tasks that will keep your ride in excellent condition. By following these steps, you can enhance both safety and efficiency while enjoying every journey.

Routine Checks

Begin with a thorough inspection of your vehicle before every ride. Look for signs of wear and tear, paying particular attention to the following areas:

- Tires: Check for proper inflation and tread depth.

- Fluids: Ensure that oil, coolant, and brake fluid levels are adequate.

- Lights: Test all lights to ensure visibility and safety.

Scheduled Maintenance Tasks

Adhere to a maintenance schedule to keep your vehicle running smoothly. Key tasks include:

- Oil Change: Replace the oil and filter every few thousand miles to maintain engine health.

- Brake Inspection: Examine brake pads and fluid regularly to ensure responsive braking.

- Chain Adjustment: Check and adjust the chain tension as needed for optimal power transfer.

By incorporating these practices into your routine, you can enjoy a safer and more reliable riding experience.

Electrical System Troubleshooting

The electrical system is crucial for the overall performance of any two-wheeled vehicle. Diagnosing issues in this system can prevent minor problems from escalating into major failures. This section provides guidance on identifying common electrical faults and offers steps for resolution.

Common Issues

- Battery Failure

- Faulty Wiring Connections

- Blown Fuses

- Malfunctioning Lights

- Starter Motor Issues

Troubleshooting Steps

- Check the Battery: Ensure the battery is fully charged and terminals are clean. Use a multimeter to measure voltage.

- Inspect Wiring: Look for frayed or damaged wires. Tighten loose connections and replace any compromised components.

- Test Fuses: Remove and inspect each fuse. Replace any that are blown with the correct rating.

- Evaluate Lighting: If lights are dim or not functioning, check the bulbs and wiring connections.

- Starter Function: Listen for clicking sounds when starting. If absent, check the starter motor and relay.

By following these steps, you can effectively diagnose and address electrical issues, ensuring a reliable and safe riding experience.

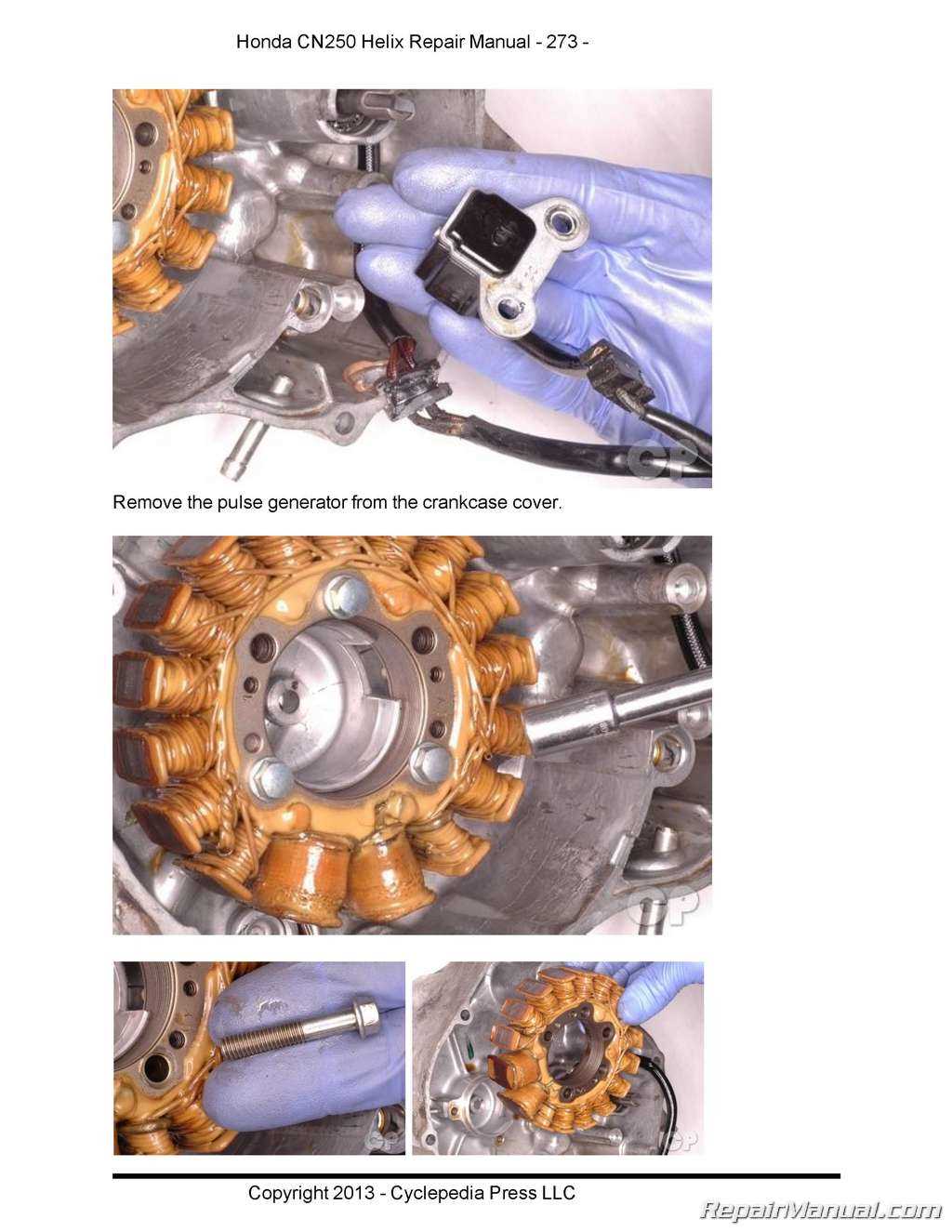

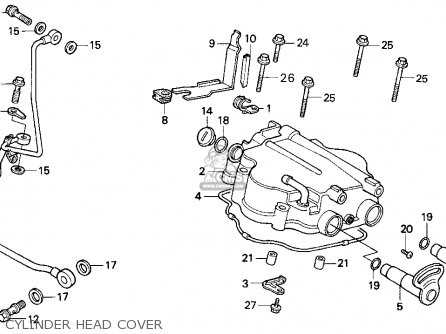

Engine Overhaul Procedures

Overhauling the engine is a crucial process for maintaining optimal performance and longevity. This comprehensive procedure involves a series of systematic steps to disassemble, inspect, and reassemble the power unit, ensuring that all components function harmoniously. Proper execution of these tasks can significantly enhance efficiency and reduce the likelihood of future issues.

Before beginning the overhaul, it’s essential to gather the necessary tools and components. Here’s a list of items you may need:

- Socket set

- Torque wrench

- Cleaning supplies

- Replacement gaskets

- Oil filter

- Engine oil

The following steps outline the essential procedures for an effective engine overhaul:

- Preparation: Ensure the work area is clean and organized. Disconnect the battery and drain fluids.

- Disassembly: Carefully remove external components such as the air intake, exhaust system, and electrical connections. Document the process to facilitate reassembly.

- Inspection: Examine all parts for wear and damage. Pay close attention to the cylinder head, pistons, and crankshaft.

- Cleaning: Clean all components thoroughly to remove carbon deposits and debris. Use appropriate cleaning solutions and tools.

- Replacement: Replace worn or damaged parts with high-quality components. Ensure that all gaskets and seals are new to prevent leaks.

- Reassembly: Follow the reverse order of disassembly, ensuring that all bolts are torqued to the manufacturer’s specifications.

- Final Checks: Once reassembled, check all fluid levels and reconnect the battery. Start the engine and monitor for any unusual sounds or leaks.

Completing an engine overhaul requires attention to detail and adherence to safety protocols. Following these guidelines will help ensure a successful rebuild and optimal engine function.

Replacing the CVT Belt

Replacing the continuously variable transmission belt is a crucial maintenance task for ensuring optimal performance and longevity of the vehicle. Over time, wear and tear can lead to slippage, decreased efficiency, and potential damage to other components. This guide outlines the essential steps to perform the belt replacement effectively.

Begin by ensuring the vehicle is parked on a level surface and the engine is turned off. Safety precautions are paramount; disconnect the battery to prevent accidental starts during the process. Once secured, remove the necessary panels to access the transmission case. This may involve unscrewing bolts and gently prying off covers.

After exposing the transmission, carefully detach the old belt from the pulleys. It is advisable to inspect the pulleys for any signs of damage or debris before installing the new belt. Once everything is cleaned, position the new belt onto the primary and secondary pulleys, ensuring it sits properly in the grooves.

Reassemble the transmission casing and secure all covers. Reconnect the battery and perform a test run to verify that the new belt is functioning smoothly. Monitoring performance post-replacement is important to confirm that the installation was successful.

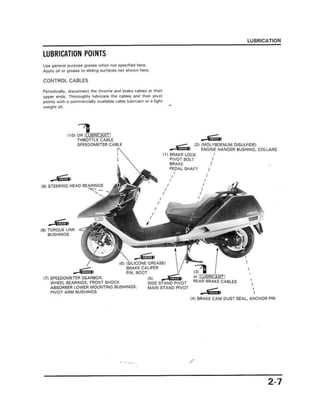

Brake System Maintenance Tips

Proper upkeep of the braking mechanism is essential for ensuring safety and optimal performance of any two-wheeled vehicle. Regular checks and maintenance can prevent issues, extend the lifespan of components, and provide a smoother riding experience. This guide offers practical advice for maintaining the braking system effectively.

Regular Inspections

Routine inspections are crucial for identifying wear and tear. Check the brake pads for thickness and replace them if they appear too thin. Inspect the rotors for any signs of scoring or warping. Additionally, ensure that the brake lines are free from leaks and damage, as these can severely compromise braking efficiency.

Fluid Maintenance

The condition of brake fluid is vital for optimal functionality. Regularly check the fluid level and look for any discoloration or debris, which may indicate contamination. Change the fluid according to the manufacturer’s recommendations, as old fluid can absorb moisture and reduce braking performance. Bleeding the brakes periodically helps remove air bubbles, ensuring a firm brake feel.

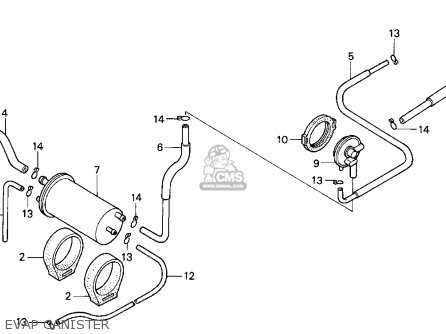

Handling Fuel System Problems

Addressing issues related to the fuel system is crucial for maintaining optimal performance and reliability of your vehicle. These problems can manifest in various ways, such as difficulty starting, poor acceleration, or unusual engine sounds. Understanding the underlying causes and knowing how to troubleshoot them can help ensure a smooth ride.

Common symptoms may include a clogged fuel filter, malfunctioning fuel pump, or dirty injectors. It is essential to conduct a thorough inspection of the fuel components, starting from the tank to the injectors. Regular maintenance, such as replacing filters and cleaning injectors, can prevent many issues from arising.

If you experience a drop in fuel pressure, consider checking the fuel lines for leaks or blockages. A damaged line can lead to decreased performance and fuel efficiency. Additionally, be mindful of any warning lights on the dashboard, as they can indicate fuel system malfunctions that require immediate attention.

For more complex problems, consulting a professional may be necessary. Technicians have the expertise and tools to diagnose and fix intricate fuel system issues effectively. By staying proactive and addressing problems as they arise, you can ensure your vehicle remains in top condition for years to come.

Finding Reliable Replacement Parts

When it comes to maintaining your vehicle, sourcing trustworthy components is crucial for ensuring optimal performance and longevity. Quality replacement parts not only enhance the reliability of your machine but also contribute to your safety on the road. In this guide, we will explore effective strategies to identify and procure dependable parts for your needs.

Researching Trusted Suppliers

Begin by identifying reputable suppliers who specialize in the components you require. Look for vendors with positive reviews and a solid reputation in the community. Online forums and enthusiast groups can provide valuable insights into which retailers are known for their integrity and product quality. Additionally, consider checking certifications and warranties offered by suppliers, as these can be indicators of reliability.

Evaluating Quality and Compatibility

Before making a purchase, assess the quality of the parts by examining materials and manufacturing standards. Genuine or OEM parts are often recommended for their precise fit and reliability, while aftermarket options may offer cost savings but vary in quality. Always verify compatibility with your specific model to avoid issues that could arise from improper fitment. Consulting with professionals or experienced users can also provide guidance on the best options available.