Understanding the intricacies of machinery operation is essential for optimal performance. This section focuses on providing essential insights and instructions for effectively managing equipment challenges. With a detailed approach, users can navigate through various aspects of machinery upkeep and find solutions to common issues.

Every machine has its unique characteristics and operational requirements. Familiarity with the components and functions enables operators to identify potential problems early on, leading to improved efficiency. Emphasizing proactive maintenance strategies ensures longevity and reliability in daily operations.

Whether you are a seasoned operator or new to the field, having access to structured information can enhance your experience. This resource aims to empower users by offering step-by-step guidance and practical tips, ensuring that you are well-equipped to handle any task related to equipment care.

Overview of Bobcat 773 Models

This section provides an insight into a specific line of compact construction equipment, highlighting their key features, specifications, and applications. The models discussed are known for their versatility and efficiency in various tasks, making them a popular choice among operators and contractors alike.

Key Features

The machinery in this range is designed with several important characteristics that enhance performance and usability. These features include robust engines, intuitive controls, and a variety of attachments that cater to different work environments.

| Model Year | Engine Power (HP) | Operating Weight (lbs) | Lift Capacity (lbs) |

|---|---|---|---|

| 1990 | 50 | 3,150 | 1,300 |

| 1995 | 60 | 3,400 | 1,500 |

| 2000 | 70 | 3,600 | 1,600 |

Applications

Common Issues with Skid Steer

When operating compact machinery, various challenges may arise that can affect performance and efficiency. Understanding these potential problems is essential for maintaining optimal functionality and ensuring the longevity of the equipment. This section highlights some frequent complications encountered during use, along with insights into their causes and solutions.

Hydraulic System Failures

One of the primary concerns involves the hydraulic system, which plays a crucial role in the operation of the machinery. Common symptoms include sluggish movement, unusual noises, or complete failure to respond. These issues may result from low fluid levels, leaks, or worn-out components. Regular maintenance and timely fluid checks can help prevent such problems.

Engine Performance Issues

Another frequent dilemma pertains to the engine, which may exhibit a range of performance problems such as stalling, rough idling, or reduced power output. These complications can stem from fuel contamination, air filter obstructions, or ignition system malfunctions. Conducting routine inspections and ensuring clean fuel supply can mitigate these risks.

Essential Tools for Repairs

Effective maintenance of machinery requires a selection of indispensable instruments that facilitate both diagnostics and restoration tasks. Utilizing the right equipment not only enhances the efficiency of the work but also ensures the longevity of the equipment being serviced. Understanding the various tools at your disposal is crucial for performing tasks accurately and safely.

Basic Hand Tools

Among the primary instruments needed for servicing heavy machinery are basic hand tools. These include wrenches, screwdrivers, and pliers. Each of these tools plays a vital role in various tasks, from tightening bolts to replacing components. Investing in high-quality hand tools can significantly impact the outcome of your work.

Diagnostic Equipment

In addition to hand tools, having access to diagnostic devices is essential for identifying issues effectively. Multimeters and pressure gauges are examples of tools that help in troubleshooting electrical and hydraulic systems. Utilizing such equipment allows for a thorough analysis of machinery performance, leading to more informed decision-making during the service process.

Step-by-Step Maintenance Procedures

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. Following systematic protocols can prevent unexpected breakdowns and enhance functionality. This section outlines essential tasks that should be performed periodically to maintain the machine in excellent condition.

- Check Fluid Levels:

- Inspect hydraulic fluid levels and top up as needed.

- Examine engine oil and change it according to the manufacturer’s recommendations.

- Monitor coolant levels and ensure the cooling system is functioning properly.

- Inspect Filters:

- Replace air filters to maintain optimal air quality for the engine.

- Change fuel filters to prevent impurities from affecting performance.

- Check hydraulic filters and clean or replace as necessary.

- Examine Belts and Hoses:

- Look for signs of wear, fraying, or damage on all belts.

- Inspect hoses for leaks or cracks, replacing them if necessary.

- Grease Fittings:

- Locate all grease points and apply lubricant as per the maintenance schedule.

- Ensure all moving parts are adequately lubricated to prevent wear.

- Test Electrical Systems:

- Check the battery condition and clean terminals to ensure a good connection.

- Inspect lights and indicators for proper functionality.

- Examine wiring for any signs of corrosion or damage.

Following these procedures will help maintain the machinery’s efficiency and reliability. Always refer to the specific guidelines for your model for detailed instructions.

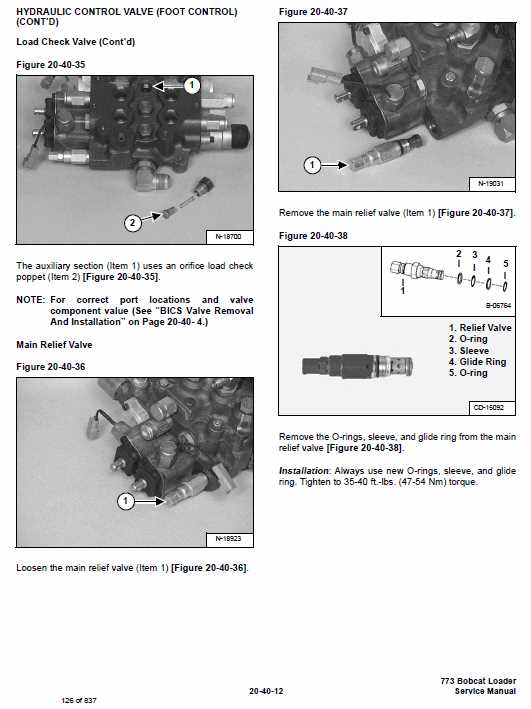

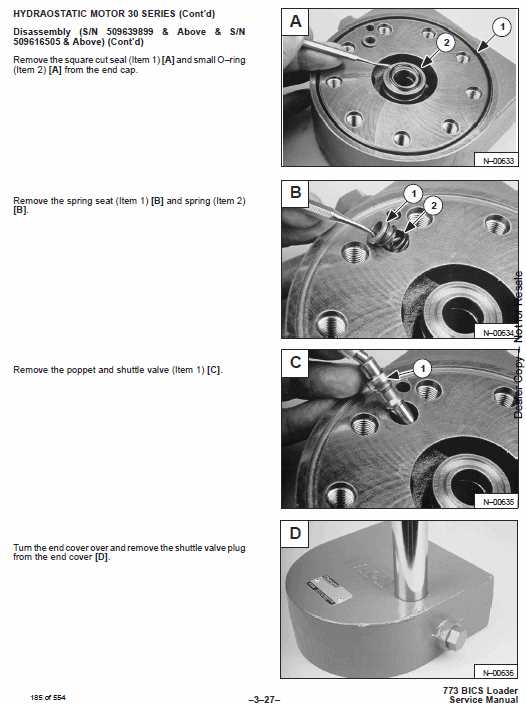

Understanding the Hydraulic System

The hydraulic system is a vital component in various machinery, providing the necessary power and control for operations. This system utilizes fluid under pressure to transmit energy, allowing for precise movements and functionalities. Understanding its workings is essential for effective maintenance and troubleshooting.

Key Components of the Hydraulic System

- Pump: Responsible for generating flow and pressure within the system.

- Actuators: These convert hydraulic energy into mechanical movement.

- Valves: Control the flow and direction of the hydraulic fluid.

- Reservoir: Stores the hydraulic fluid and provides a source for the pump.

- Hoses and Fittings: Facilitate the movement of fluid between components.

Common Issues and Maintenance Tips

- Check for leaks regularly, as they can lead to pressure loss and inefficiency.

- Inspect hoses and fittings for wear or damage, replacing them as necessary.

- Monitor fluid levels and quality to ensure optimal performance.

- Service the pump and actuators periodically to maintain their functionality.

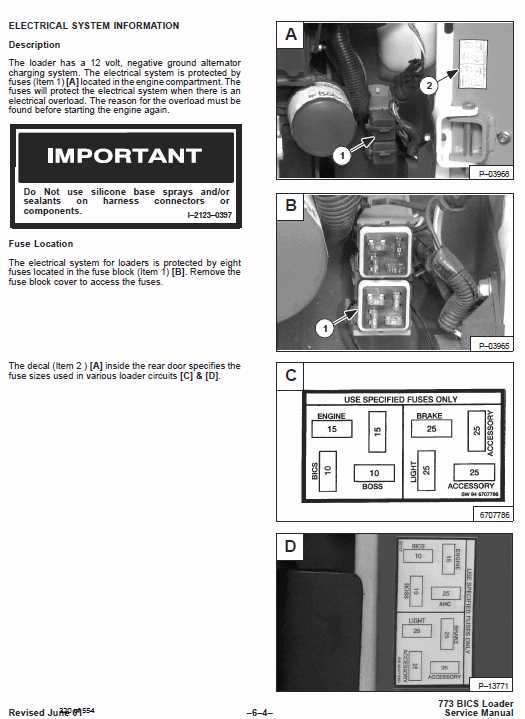

Electrical Components and Troubleshooting

This section focuses on the various electrical elements found in compact machinery and the common issues that may arise with them. Understanding these components is crucial for effective diagnostics and maintenance, ensuring optimal performance and longevity.

Key Electrical Elements: The electrical system typically consists of several critical parts, including batteries, wiring harnesses, switches, and relays. Each of these components plays a vital role in the overall functionality of the machine, facilitating power distribution and control.

Troubleshooting Common Issues: When faced with electrical malfunctions, it is essential to approach the problem systematically. Start by examining the battery and connections, as poor contact can lead to power failures. Next, check for any damaged wiring or corroded terminals that could disrupt the electrical flow. Additionally, verify the integrity of switches and relays, as faulty components can hinder operation.

Prevention Tips: Regular inspections and maintenance of electrical components can significantly reduce the likelihood of issues arising. Keeping connections clean and secure, along with replacing worn-out parts promptly, helps maintain a reliable electrical system.

Replacing Key Engine Parts

When it comes to maintaining optimal performance in heavy machinery, understanding the replacement of vital engine components is essential. Over time, wear and tear can lead to inefficiencies and potential failures. Proper identification and timely substitution of these elements can significantly enhance the longevity and functionality of the equipment.

Common components that may require attention include the following:

| Component | Signs of Wear | Replacement Procedure |

|---|---|---|

| Piston Rings | Oil consumption increases, loss of power | Remove cylinder head, replace rings, reassemble |

| Fuel Injectors | Uneven engine performance, rough idling | Detach fuel lines, replace injectors, reconnect |

| Timing Belt | Cracking, wear, abnormal noise | Remove covers, replace belt, reassemble covers |

| Water Pump | Overheating, coolant leaks | Drain coolant, detach pump, install new pump |

Regular inspection and prompt replacement of these key components will help maintain the machine’s efficiency and reliability, ultimately saving time and costs in the long run.

Proper Tire and Track Maintenance

Ensuring optimal performance of equipment requires careful attention to the components that provide traction and stability. Proper upkeep of these elements is essential for maximizing efficiency and prolonging the lifespan of the machinery. Regular maintenance not only enhances safety but also improves productivity.

Regular Inspections: Frequent evaluations of tires and tracks are crucial. Look for signs of wear, such as cracks, bulges, or uneven tread. Inspecting for loose components and ensuring proper tension can prevent costly repairs and downtime.

Pressure Management: Maintaining the correct air pressure in tires is vital. Under-inflated or over-inflated tires can lead to poor handling and increased wear. Refer to the manufacturer’s specifications for the ideal pressure range to ensure optimal performance.

Cleaning: Keeping the tread and track surfaces clean from debris, mud, and other contaminants is important. This practice not only improves traction but also prevents premature wear and damage. Regular cleaning routines can enhance overall equipment efficiency.

Rotation and Alignment: For tire maintenance, regular rotation helps achieve even wear across all tires. Additionally, ensuring proper alignment can prevent uneven tread wear and enhance handling. Track components should also be regularly checked for alignment to maintain optimal functionality.

Storage Considerations: When not in use, proper storage can significantly extend the life of tires and tracks. Avoid exposing them to direct sunlight for prolonged periods, as this can lead to degradation. Consider utilizing protective covers or storing in shaded areas.

Safety Tips for Operation

Ensuring a secure environment during machinery operation is crucial for preventing accidents and maintaining efficiency. Proper awareness and adherence to safety protocols can significantly reduce the risk of injuries and equipment damage. The following guidelines serve as essential reminders for anyone working with heavy equipment.

Pre-Operation Checks

Before starting any equipment, perform a thorough inspection to identify any potential issues. Check fluid levels, brakes, and steering functions. Ensure that all safety features, such as seat belts and alarms, are operational. Addressing any concerns before use helps maintain safety standards and enhances overall performance.

Operator Awareness

Maintain constant vigilance during operation. Be aware of your surroundings and any personnel in the vicinity. Use mirrors and cameras, if available, to monitor blind spots. Always communicate with team members to ensure everyone is aware of movements and actions being taken. This proactive approach is essential for creating a safe working atmosphere.

Identifying and Fixing Leaks

Detecting and addressing fluid escape in machinery is crucial for maintaining optimal performance and longevity. Leaks can lead to reduced efficiency, increased operational costs, and potential damage if left unattended. This section explores effective strategies for identifying and resolving these issues.

Recognizing Signs of Leakage

Common indicators of fluid loss include visible puddles beneath the equipment, changes in fluid levels, and unusual operational noises. Inspecting seals and hoses regularly can help pinpoint potential sources of leakage before they escalate. Vibrations during operation may also suggest compromised connections.

Effective Repair Techniques

Once a leak is identified, the next step is to implement a suitable solution. Tightening loose connections and replacing damaged hoses are often effective measures. Additionally, applying appropriate sealants can provide a temporary fix while more comprehensive repairs are scheduled. Regular maintenance and timely intervention are essential to prevent recurrence and ensure the machinery operates efficiently.

Best Practices for Storage

Proper storage of equipment is essential to ensure longevity and optimal performance. Following certain guidelines can prevent damage and maintain functionality, allowing for efficient use when needed. By implementing best practices, owners can protect their assets from environmental factors and deterioration.

Choose a Suitable Location: Select a dry, cool, and well-ventilated area for storage. This minimizes the risk of rust and corrosion. Avoid places with excessive humidity or temperature fluctuations that could harm sensitive components.

Clean Before Storing: Thoroughly clean the machinery before placing it in storage. Remove dirt, grease, and debris to prevent buildup that can lead to wear and tear. Ensuring that the surfaces are clean will also help identify any potential issues that need addressing.

Protect Moving Parts: Lubricate moving components to ensure they remain functional and free from rust during periods of inactivity. Apply appropriate oils or greases to joints and mechanisms to prevent seizing or damage.

Cover with Protective Tarps: Utilize covers or tarps to shield the equipment from dust and moisture. This simple measure can significantly reduce the risk of damage and extend the lifespan of various parts.

Regular Inspections: Periodically check on the stored equipment to ensure everything is in good condition. Look for signs of wear, rust, or other potential issues that may require attention. Early detection can save time and resources in the long run.

When to Seek Professional Help

Understanding the right moment to consult an expert can be crucial for maintaining equipment efficiency. While some issues may seem manageable, others require specialized knowledge and skills to ensure safe and effective resolution.

Complex Problems: If you encounter intricate mechanical failures or electronic malfunctions, it’s wise to reach out to a qualified technician. Their experience can save time and prevent further damage.

Safety Concerns: If any task raises safety alarms, seeking professional assistance is essential. Experts can ensure all safety protocols are followed, minimizing risks during repairs.

Warranty Considerations: If the equipment is still under warranty, attempting DIY fixes could void it. Consulting a professional can help preserve coverage while addressing the issue correctly.

Time Efficiency: In cases where immediate repairs are needed, professionals can expedite the process, ensuring the equipment returns to optimal performance without unnecessary delays.

Resources for Parts and Manuals

Accessing reliable sources for components and documentation is essential for maintaining and servicing equipment effectively. Various platforms offer a wealth of information and parts to ensure optimal performance and longevity of machinery.

- Manufacturer’s Website: The official site often provides technical documentation, parts lists, and service updates. It’s a primary resource for accurate information.

- Online Marketplaces: Platforms like eBay and Amazon host a range of vendors selling both new and used parts. Ensure to check seller ratings for reliability.

- Specialized Retailers: Websites dedicated to heavy machinery parts can be invaluable. They often carry OEM parts and may offer manuals for specific models.

- Forums and Community Groups: Online communities can be a treasure trove of shared experiences and recommendations for parts suppliers and maintenance tips.

- Local Dealerships: Authorized dealers typically have access to original parts and can provide guidance on compatible components.

Utilizing these resources will facilitate effective upkeep and enhancement of equipment functionality, ensuring that users have the necessary tools and information at their disposal.