Maintaining specialized tools is essential for ensuring their longevity and optimal performance. Understanding the intricacies of these instruments can significantly enhance their functionality and reliability in various professional settings. Knowledge of troubleshooting techniques and best practices allows users to minimize downtime and maintain high standards of service.

Comprehensive documentation serves as a vital resource for users, providing step-by-step instructions for addressing common challenges. Such references empower individuals to tackle issues confidently, enabling a smoother workflow and reducing the need for external assistance. By familiarizing oneself with these resources, one can develop a deeper understanding of the devices, ultimately leading to improved outcomes.

Additionally, the incorporation of clear illustrations and detailed descriptions within these guides aids in the quick identification of components and functions. This clarity fosters a more effective approach to maintenance and enhances the user’s ability to perform routine checks and repairs. Thus, having access to well-structured references is crucial for anyone involved in the operation of these essential tools.

Understanding Dental Equipment Repair Manuals

This section delves into the critical documents that serve as guides for maintaining and troubleshooting various tools used in oral health practices. These resources are essential for ensuring optimal functionality and longevity of the instruments that professionals rely on daily.

Key aspects of these guides include:

- Comprehensive Instructions: Detailed procedures that outline step-by-step actions to address common issues.

- Diagnostic Techniques: Methods to identify problems quickly and efficiently, minimizing downtime.

- Parts Identification: Clear illustrations and descriptions of components to facilitate repairs and replacements.

Professionals who utilize these documents benefit from enhanced efficiency and reduced operational interruptions. By understanding the structure and content of these essential resources, users can navigate complex tasks with confidence.

In summary, these guides play a vital role in supporting practitioners by providing the necessary knowledge to maintain their tools effectively, ensuring that patient care remains uninterrupted and of the highest quality.

Importance of Repair Manuals in Dentistry

Guidelines for maintenance and troubleshooting play a crucial role in ensuring the longevity and efficiency of instruments used in oral health practices. These documents serve as essential resources for professionals, enabling them to address issues swiftly and effectively, minimizing downtime and maximizing patient care.

Proper documentation provides clear instructions and insights into the functioning of various tools, which is vital for maintaining high standards of service. Without these resources, practitioners may face challenges in diagnosing problems, leading to potential disruptions in workflow and increased costs.

| Benefits | Description |

|---|---|

| Efficiency | Streamlines the troubleshooting process, allowing for quicker resolutions. |

| Cost-Effectiveness | Reduces the need for external service calls by empowering staff to handle minor issues. |

| Training | Serves as a valuable educational tool for new team members learning about various devices. |

| Safety | Ensures proper usage and maintenance, promoting a safe environment for both staff and patients. |

In summary, the availability of comprehensive guides is vital for practitioners aiming to uphold operational excellence and provide top-notch care. Emphasizing the significance of these resources fosters a culture of preparedness and knowledge within the practice.

Common Types of Dental Equipment

In the realm of oral health care, various tools play a crucial role in ensuring effective treatment and patient comfort. These instruments range from basic hand tools to advanced technological devices, each designed to fulfill specific functions in the care process. Understanding the different categories of these tools can enhance both the efficiency of practitioners and the overall experience of patients.

| Type | Description |

|---|---|

| Hand Tools | Basic instruments used for examination and treatment, including mirrors, explorers, and scalers. |

| Imaging Devices | Technologies such as X-ray machines that allow for detailed visualization of oral structures. |

| Chairside Units | Comprehensive setups that provide necessary tools and support during patient procedures. |

| Operative Instruments | Specialized tools used for restorative procedures, including drills and filling instruments. |

| Surgical Instruments | Equipment utilized for surgical interventions, ranging from extraction tools to suturing devices. |

| Cleaning Tools | Instruments designed for hygiene maintenance, such as ultrasonic cleaners and sterilization units. |

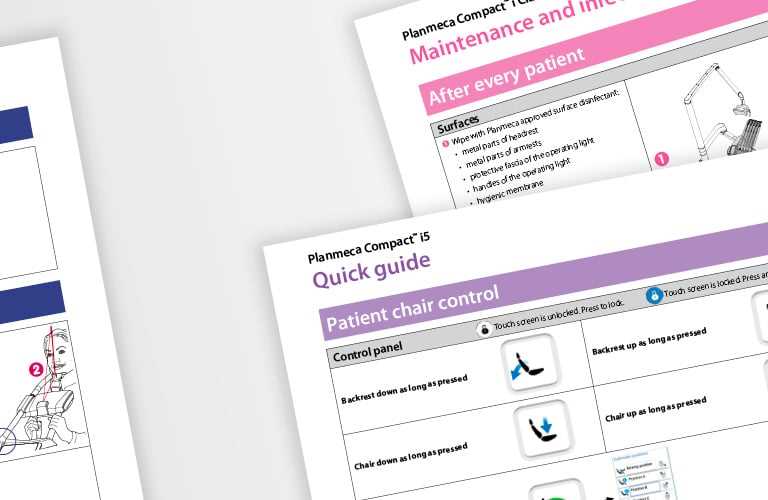

Essential Components of Repair Manuals

When addressing the maintenance and troubleshooting of specialized tools, a comprehensive guide is crucial for ensuring proper function and longevity. These documents serve as an invaluable resource for technicians, providing detailed insights into the structure, operation, and common issues that may arise.

Key elements typically include a thorough introduction that outlines the scope of the guide, alongside detailed specifications for each tool. Clear diagrams and illustrations enhance understanding, making it easier to visualize components and their interactions. Step-by-step instructions for assembly and disassembly are essential for effective servicing, while a troubleshooting section addresses potential malfunctions and their solutions.

Furthermore, a glossary of terms can aid users in navigating technical jargon, ensuring clarity. Safety precautions are also vital, guiding users on best practices to prevent accidents. Lastly, maintenance schedules and parts replacement information help in prolonging the life of the tools, making these guides indispensable for any professional in the field.

How to Access Repair Manuals

Obtaining detailed guidance for maintenance and troubleshooting is essential for ensuring optimal performance of tools used in various professions. Accessing these resources can significantly enhance efficiency and prolong the lifespan of your devices. This section outlines effective methods to locate and utilize these invaluable documents.

Online Resources

The internet is a treasure trove of information. Numerous websites host a variety of documents that can be easily downloaded. Start by searching for specific brands or models to find dedicated sites or forums where professionals share their insights. Utilize keywords related to your tools to improve search results.

Manufacturer Support

Contacting the original creators of your tools is often the most reliable method. Many manufacturers provide access to comprehensive documentation on their official websites. Additionally, customer support can direct you to relevant materials or even send them directly to you. Keeping a record of serial numbers can facilitate this process.

Remember: Utilizing these resources not only aids in maintenance but also ensures safe operation and compliance with industry standards.

Step-by-Step Repair Guides

This section provides detailed procedures for troubleshooting and restoring functionality to various tools used in clinical settings. By following these organized instructions, users can effectively address common issues and extend the lifespan of their devices. Each guide is designed to be straightforward, ensuring that even those with limited experience can confidently undertake the tasks.

Common Issues and Solutions

| Issue | Solution |

|---|---|

| Inconsistent Performance | Check power connections and ensure all components are securely attached. |

| No Power | Inspect the power source and replace any faulty fuses. |

| Excessive Noise | Lubricate moving parts and check for loose components. |

| Temperature Issues | Clean cooling vents and ensure proper airflow around the device. |

Tools Needed

To effectively carry out the maintenance tasks, gather the following tools:

- Screwdriver set

- Lubricant

- Multimeter

- Cleaning supplies

Safety Considerations During Repairs

Ensuring a secure environment while conducting maintenance on tools and machinery is crucial. Proper precautions help prevent accidents and injuries, safeguarding both the technician and the devices involved. Awareness of potential hazards and adherence to safety protocols can significantly mitigate risks associated with the task.

Personal Protective Equipment

Wearing appropriate protective gear is essential. Items such as gloves, goggles, and masks provide a barrier against harmful substances and debris. It is important to select gear that suits the specific tasks at hand, ensuring maximum protection while maintaining comfort and mobility.

Workspace Organization

A well-organized workspace minimizes the likelihood of accidents. Keeping tools and components arranged and within reach prevents unnecessary movement and distractions. Additionally, ensuring that the area is well-lit and free of clutter promotes a safer and more efficient working environment.

Tools Required for Dental Equipment Repairs

In order to effectively address issues with various apparatus used in oral care, specific instruments are essential. These tools facilitate troubleshooting, adjustment, and maintenance, ensuring optimal performance and longevity of the devices.

Essential Instruments

- Screwdrivers – Various sizes and types for different fasteners.

- Wrenches – To secure or loosen components.

- Pliers – For gripping, bending, or cutting wires.

- Multimeters – To measure voltage, current, and resistance.

- Calipers – For precise measurements of components.

Safety Equipment

- Gloves – To protect hands from chemicals and sharp edges.

- Safety goggles – To shield eyes from debris and fluids.

- Face masks – To prevent inhalation of harmful particles.

Having the right assortment of tools not only aids in efficient diagnostics but also contributes to a safer working environment. Proper maintenance practices extend the lifespan of the apparatus, ensuring reliability and performance in clinical settings.

Identifying Common Equipment Issues

Recognizing frequent malfunctions is crucial for maintaining optimal functionality in any technical setup. Awareness of typical problems can help practitioners swiftly address concerns and minimize downtime. By familiarizing oneself with common signs of trouble, it becomes easier to implement effective solutions and ensure seamless operations.

One prevalent symptom is unusual noise during operation, which can indicate misalignment or wear in moving parts. Additionally, irregular performance, such as inconsistent output or slow response times, often points to underlying mechanical or electronic faults. In some cases, visual inspections reveal wear and tear, such as frayed cables or damaged connectors, which can compromise efficiency.

Another critical aspect to monitor is overheating, often caused by prolonged use or inadequate ventilation. This issue may lead to severe damage if not addressed promptly. Moreover, erratic behavior, like sudden shutdowns or error messages, typically signifies deeper systemic issues that require immediate attention.

Ultimately, staying vigilant and knowledgeable about these common indicators enables timely interventions, ensuring that all tools function at their best and supporting overall productivity.

Preventive Maintenance Tips for Equipment

Regular upkeep is crucial for ensuring longevity and optimal performance of various tools and devices. By implementing proactive measures, one can significantly reduce the likelihood of unexpected breakdowns and enhance the efficiency of operations. This section outlines essential strategies that can be adopted to maintain functionality and reliability.

Establish a Routine Inspection Schedule

Creating a timetable for routine assessments is vital. Regular inspections allow for early detection of potential issues, enabling timely interventions. Focus on checking for wear and tear, ensuring all components are functioning correctly, and cleaning any dust or debris that may affect performance. Document findings to track patterns over time.

Invest in Quality Supplies

Utilizing high-quality materials for maintenance tasks can make a significant difference in performance. Always opt for recommended products that enhance durability and reliability. Additionally, using the right tools for specific tasks prevents damage and prolongs the lifespan of components.

Manufacturer-Specific Repair Recommendations

When dealing with maintenance and restoration tasks, adhering to the guidelines provided by original producers is crucial for optimal performance and longevity. These suggestions not only ensure that components function correctly but also help in avoiding potential issues that could arise from improper handling. Each brand may have unique requirements and protocols that are essential to follow for effective outcomes.

Key Considerations

Understanding the specifications and requirements of each manufacturer can greatly enhance the reliability of tools. It is important to consult the resources provided by the brands, which often include troubleshooting tips, part specifications, and maintenance schedules. This tailored approach not only mitigates risks but also maximizes efficiency during servicing.

Common Manufacturer Guidelines

| Manufacturer | Recommendations |

|---|---|

| Brand A | Use only original parts; follow specific torque settings during assembly. |

| Brand B | Regular calibration is required; inspect seals every six months. |

| Brand C | Clean components with designated solvents; replace filters annually. |

By following these manufacturer-specific recommendations, users can ensure their tools remain in excellent working condition, ultimately leading to enhanced performance and reliability.

Digital vs. Printed Repair Manuals

The choice between electronic and physical guides can significantly influence the efficiency and ease of maintenance tasks. Each format offers distinct advantages and drawbacks, impacting user experience and accessibility.

| Aspect | Digital Guides | Printed Guides |

|---|---|---|

| Accessibility | Available on multiple devices, easy to share | Requires physical storage, less portable |

| Searchability | Quick keyword searches, hyperlinks for navigation | Manual index, more time-consuming to locate information |

| Updates | Can be updated instantly and frequently | Requires reprinting for new information |

| Usability | Interactive features, multimedia content available | Traditional format, limited to text and images |

| Cost | Often less expensive, sometimes free | Printing and binding costs can be high |

Ultimately, the decision hinges on individual preferences and specific needs, with both formats serving valuable purposes in different scenarios.

Benefits of Regular Equipment Maintenance

Routine upkeep of machinery plays a crucial role in ensuring optimal performance and longevity. By implementing a consistent maintenance schedule, facilities can significantly reduce the likelihood of unexpected breakdowns and enhance overall operational efficiency.

Cost Savings

- Minimized repair expenses due to early detection of issues.

- Extended lifespan of tools, leading to lower replacement costs.

- Reduced downtime, allowing for continuous productivity.

Enhanced Performance

- Improved functionality and reliability of tools.

- Consistent results, ensuring high standards in operations.

- Greater safety for personnel, reducing the risk of accidents.

In conclusion, prioritizing regular maintenance fosters a more effective and safe working environment while protecting investments in machinery.