In the realm of recreational equipment, ensuring optimal performance is essential for a seamless experience. This segment delves into the intricacies of a specific apparatus, emphasizing the importance of understanding its components and functionality. By familiarizing oneself with the underlying mechanisms, users can effectively address issues that may arise during operation.

Maintenance is not merely a task; it is an integral aspect of ownership that enhances longevity and reliability. Through systematic inspection and thoughtful intervention, one can prevent minor glitches from escalating into major concerns. This guide serves as a valuable resource, offering insights into common challenges and practical solutions.

Whether you are a novice seeking foundational knowledge or an experienced individual looking to refine your skills, the following information will equip you with the necessary tools to manage your device confidently. Embrace the opportunity to learn and empower yourself in the art of upkeep.

Overview of Atwood Model 8535 IV DCLP

This section provides a comprehensive understanding of a specific type of equipment designed for efficient performance in various applications. It encompasses essential features, operational principles, and key functionalities that enhance user experience and reliability.

Engineered for versatility, this unit is commonly utilized in recreational vehicles, ensuring a steady supply of hot water. Its compact design facilitates installation in tight spaces, making it a popular choice among enthusiasts and professionals alike.

Among its notable characteristics is an advanced control system that allows for easy adjustments, promoting user-friendly operation. The integration of innovative technology not only boosts efficiency but also minimizes energy consumption, contributing to a more sustainable usage model.

Maintenance is streamlined through accessible components, ensuring that users can perform routine checks with minimal effort. Regular upkeep enhances the longevity of the device, ensuring it operates at peak performance for years to come.

In conclusion, this equipment stands out for its reliable operation, energy efficiency, and user-oriented design, making it a valuable asset in any setting where hot water availability is essential.

Key Features and Specifications

This section outlines the essential characteristics and technical specifications of the unit, emphasizing its performance and functionality. Understanding these aspects is crucial for effective utilization and maintenance, ensuring optimal operation in various applications.

Core Characteristics

The appliance boasts a compact design, allowing for efficient installation in tight spaces. It features advanced temperature control, ensuring consistent heating performance. Additionally, its durable construction enhances longevity, making it suitable for demanding environments.

Technical Specifications

Equipped with a robust power source, the unit delivers reliable energy efficiency. The output capacity is optimized for both residential and commercial needs, while the intuitive interface allows for straightforward operation. Safety features, including overheat protection and automatic shut-off, further enhance user confidence.

Common Issues and Troubleshooting Tips

Understanding and addressing typical challenges can greatly enhance the functionality and lifespan of your heating system. By being aware of common faults and implementing effective solutions, you can ensure optimal performance and avoid costly repairs.

- Inconsistent Heating: If your unit is not providing even heat, check the thermostat settings and ensure that there are no obstructions around the vents. Consider inspecting the ductwork for leaks.

- Noisy Operation: Unusual sounds can indicate mechanical issues. Loose components or a malfunctioning fan might be the culprits. Tighten any loose parts and lubricate moving components as necessary.

- Excessive Fuel Consumption: If you notice a spike in energy usage, verify that the unit is properly calibrated. Regular maintenance, including cleaning filters, can improve efficiency.

- Flame Issues: A yellow or flickering flame can suggest incomplete combustion. Check the burner for dirt or debris and ensure the air intake is clear.

Implementing these troubleshooting tips can help maintain your heating system’s efficiency and reliability. Regular inspections and preventive care are essential in avoiding potential complications.

Essential Tools for Effective Repairs

Having the right equipment is crucial for ensuring successful maintenance and restoration tasks. The effectiveness of your work often hinges on the tools you choose, as they can significantly impact both the quality of repairs and the time spent on each project. Investing in a comprehensive toolkit not only enhances your efficiency but also helps prevent common pitfalls that can arise during the process.

Must-Have Equipment

Every toolkit should include a variety of basic instruments to tackle different challenges. Screwdrivers in various sizes and types are essential for loosening and tightening screws, while wrenches offer the flexibility to manage nuts and bolts. Additionally, pliers are indispensable for gripping, twisting, and cutting wires or small components. A sturdy hammer is also crucial for driving nails or breaking apart stubborn parts.

Specialized Instruments for Advanced Tasks

For more intricate repairs, consider adding multimeters to your collection. These devices allow for precise measurements of electrical values, which is particularly useful for troubleshooting. Additionally, tape measures and leveling tools ensure accuracy when aligning parts or making adjustments. Investing in quality equipment will not only make your tasks easier but also increase the longevity of your tools and the effectiveness of your work.

Step-by-Step Repair Procedures

This section provides a comprehensive guide to troubleshooting and fixing common issues with your heating system. By following the outlined steps, you can ensure efficient operation and longevity of the unit. Each procedure is designed to be straightforward, allowing for a systematic approach to problem-solving.

Begin by gathering all necessary tools and safety equipment before starting any work. Always disconnect the power source to prevent accidents. A clean workspace will also help maintain focus and organization throughout the process.

1. Initial Inspection: Start with a visual examination of the unit. Look for any obvious signs of wear, damage, or loose connections. Document any findings to keep track of potential issues.

2. Testing Components: Use a multimeter to check electrical components. Ensure that all connections are secure and free from corrosion. If a part appears faulty, it may need replacement.

3. Clearing Blockages: Examine the ventilation and exhaust systems for any obstructions. Remove any debris or buildup that may hinder airflow, as this can significantly affect performance.

4. Fluid Levels: Check the fluid levels in the system. Low levels can lead to overheating or operational failures. Top off any fluids according to the specifications provided by the manufacturer.

5. Functional Tests: After completing the inspections and adjustments, restore power and conduct a series of functional tests. Monitor the system for unusual sounds or irregular behavior, which may indicate further issues.

6. Final Review: Once all procedures are completed, conduct a final inspection to ensure everything is in order. Secure any panels or covers and clean the work area.

By meticulously following these steps, you can address common concerns effectively and maintain optimal functionality of your heating apparatus.

Maintenance Practices for Longevity

Ensuring the durability of your equipment involves implementing consistent upkeep strategies that prevent wear and tear. Regular attention to key components can significantly extend the lifespan and enhance performance.

Routine inspections should be conducted to identify any signs of damage or degradation. Check for leaks, corrosion, and loose connections, addressing issues promptly to avoid further complications. Maintaining cleanliness is essential; removing dirt and debris helps prevent operational hindrances.

Lubrication of moving parts is vital for reducing friction and wear. Follow manufacturer recommendations for appropriate lubricants, and apply them regularly to ensure smooth functionality. Proper storage conditions, away from extreme temperatures and humidity, also contribute to longevity.

Finally, familiarize yourself with the specific requirements of your equipment to optimize its operation. By taking these proactive measures, you can ensure your investment remains reliable for years to come.

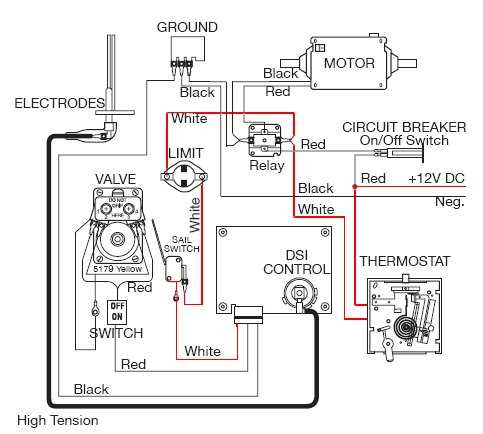

Understanding Electrical Components

Electrical systems consist of various elements that work together to ensure functionality and efficiency. Each component plays a crucial role in the overall operation, affecting performance and reliability. Gaining insight into these parts can help users troubleshoot issues and maintain optimal performance.

Power Sources serve as the backbone of any electrical setup. These sources provide the necessary energy to drive other components. Understanding the differences between batteries, generators, and other power supplies is essential for effective usage and maintenance.

Conductors facilitate the flow of electricity throughout the system. Wires and cables come in various types and sizes, each designed for specific applications. Knowledge of conductor materials and their properties helps in selecting the right type for different tasks.

Switches are pivotal for controlling the flow of current. They can turn circuits on or off, enabling users to manage power consumption efficiently. Familiarity with different switch types, such as toggle and push-button, is beneficial for both functionality and convenience.

Connectors are crucial for establishing secure electrical connections. Understanding the various connector types and their applications ensures reliable performance and safety. Proper use of connectors can prevent issues related to loose or corroded connections.

Fuses and Circuit Breakers act as protective devices within an electrical system. They safeguard against overcurrents, preventing damage to components. Knowing how these devices function can aid in selecting the appropriate protection for different applications.

By familiarizing oneself with these essential electrical components, individuals can enhance their understanding and ability to address various issues that may arise in electrical systems.

Hydraulic Systems Explained

Hydraulic systems utilize the principles of fluid mechanics to transmit power and control motion. They are widely employed in various industries due to their efficiency and capability to handle heavy loads with precision. Understanding the underlying concepts of these systems is essential for those involved in maintenance, operation, or design.

At the core of a hydraulic system is the hydraulic fluid, typically oil, which serves as the medium for energy transfer. When pressure is applied to the fluid in a confined space, it can generate force that acts on various components, such as pistons and cylinders. This force can then be harnessed to perform work, such as lifting, pushing, or rotating.

Components of a hydraulic system generally include a pump, actuators, valves, and a reservoir. The pump creates the flow of fluid, while actuators convert hydraulic energy into mechanical energy. Valves play a critical role in directing the fluid flow and regulating pressure, ensuring that the system operates smoothly and safely.

The advantages of hydraulic systems include their ability to produce high power-to-weight ratios, smooth and precise control, and adaptability to various applications. However, they also require regular maintenance to prevent leaks and ensure optimal performance, making knowledge of their operation and components crucial for any technician.

In summary, hydraulic systems are an essential part of modern machinery, providing reliable power and control through the effective use of fluid mechanics. A thorough understanding of their components and functionality is vital for anyone working within this field.

Safety Precautions During Repairs

When engaging in maintenance tasks, it is essential to prioritize safety to prevent accidents and ensure a smooth process. Proper precautions not only protect the individual performing the work but also safeguard the equipment and surrounding environment. Understanding and implementing safety measures can significantly reduce the risk of injuries and damage.

Personal Protective Equipment

Utilizing appropriate personal protective equipment (PPE) is crucial when undertaking any service activity. This includes safety goggles to shield the eyes from debris, gloves to protect the hands from sharp edges or chemicals, and sturdy footwear to prevent slips and injuries. Additionally, hearing protection may be necessary if tools generate significant noise.

Work Area Management

Maintaining a clean and organized workspace is vital for safe operations. Clear away any unnecessary items and ensure that tools are within reach to minimize the risk of accidents. Adequate lighting is also important to enhance visibility, allowing for precise handling and reducing the chance of mishaps. Always follow the recommended guidelines for proper ventilation if working with potentially harmful substances.

Resources for Further Learning

Exploring advanced techniques and maintenance practices can greatly enhance your understanding and skills in this field. Various materials and platforms are available to support your journey, whether you’re a beginner or looking to deepen your expertise.

- Online Courses: Platforms like Coursera and Udemy offer specialized courses that cover essential concepts and practical applications.

- YouTube Channels: Channels dedicated to repair techniques often provide step-by-step tutorials and visual demonstrations, making learning more accessible.

- Books and Guides: Comprehensive books are available that delve into theoretical foundations and hands-on strategies. Check local libraries or online bookstores.

- Forums and Communities: Engaging with online forums or social media groups can provide valuable insights, troubleshooting tips, and peer support.

- Workshops and Seminars: Attending hands-on workshops can help reinforce knowledge and offer practical experience in a collaborative environment.

Utilizing these resources can significantly expand your skill set and confidence in tackling various challenges in this domain.

Frequently Asked Questions

This section aims to address common inquiries related to maintenance and troubleshooting for various equipment. Whether you’re facing issues or looking for guidance on proper usage, the following information should help clarify your concerns.

Common Issues and Solutions

| Issue | Possible Solution |

|---|---|

| Device not starting | Check power source and connections. |

| Inconsistent performance | Inspect for blockages or debris. |

| Noisy operation | Examine for loose components or wear. |

Maintenance Tips

| Task | Frequency |

|---|---|

| Cleaning filters | Every month |

| Checking connections | Every three months |

| Inspecting hoses | Every six months |