Effective upkeep of outdoor power equipment is essential for ensuring optimal performance and longevity. Understanding the intricacies of these machines allows users to tackle various challenges with confidence. This section aims to provide valuable insights and practical guidance tailored to enhance the experience of every operator.

From routine checks to addressing common issues, having a well-structured approach is crucial. By following the outlined strategies, users can easily navigate through potential obstacles, ensuring that their equipment operates smoothly. Emphasizing preventive measures will also help mitigate unexpected breakdowns, fostering a proactive mindset.

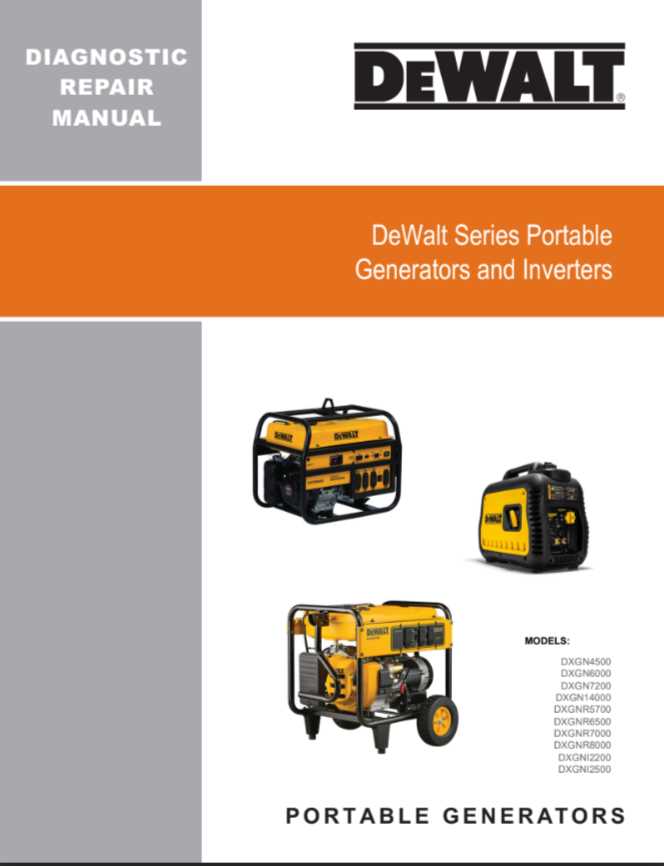

This section provides a comprehensive overview of a popular line of outdoor power equipment known for its durability and efficiency. Users will find that understanding the key features and specifications of this equipment is essential for optimal operation and maintenance.

Key Features

- Robust engine design for improved performance.

- Enhanced fuel efficiency for extended use.

- User-friendly interface for easy operation.

Specifications

- Available in various power outputs suitable for different applications.

- Equipped with advanced technology for reliability.

- Compact design facilitates easy storage and transport.

Understanding these aspects will aid users in maximizing the functionality and lifespan of their equipment.

Common Issues and Symptoms

When dealing with outdoor power equipment, various challenges can arise that may hinder performance. Recognizing these typical problems and their signs can greatly aid in effective troubleshooting and maintenance.

Engine Won’t Start: One of the most frustrating situations is when the engine fails to initiate. This may stem from issues such as a depleted battery, faulty ignition components, or fuel delivery problems. Observing the behavior of the starter can provide clues to the underlying issue.

Overheating: Excessive heat can lead to significant damage if not addressed. Common symptoms include unusual noises or a sudden loss of power. Ensuring proper ventilation and checking coolant levels can help mitigate this risk.

Uneven Performance: If the machinery operates inconsistently or displays a lack of power, it might indicate problems with the fuel mixture or air filters. Regularly inspecting these components can prevent further complications.

Excessive Vibration: Noticeable shaking during operation can signal loose parts or misalignment within the system. Tightening bolts and ensuring all components are secure can alleviate this issue.

Being aware of these common challenges allows for timely interventions, ensuring smooth and efficient operation of your equipment.

Essential Tools for Repairs

When undertaking maintenance tasks on outdoor power equipment, having the right set of tools is crucial for achieving optimal results. These instruments not only enhance efficiency but also ensure that the job is done correctly and safely. Below is a selection of vital items that every technician should consider having on hand.

Basic Tool Kit

- Wrenches: Adjustable and socket wrenches for loosening and tightening various components.

- Screwdrivers: A variety of flathead and Phillips screwdrivers for different fasteners.

- Pliers: Needle-nose and standard pliers for gripping and manipulating parts.

- Torque wrench: To ensure fasteners are tightened to the correct specifications.

Specialized Equipment

- Multimeter: Essential for diagnosing electrical issues and ensuring proper functionality.

- Fuel system cleaning kit: Helps maintain the fuel delivery system for optimal performance.

- Compression tester: Useful for assessing engine condition by measuring compression levels.

- Diagnostic tools: Specialized software or devices that can read error codes and system performance.

Step-by-Step Maintenance Guide

Regular upkeep is essential to ensure optimal performance and longevity of your outdoor power equipment. Following a structured approach to maintenance can prevent potential issues and enhance the efficiency of your machine. This guide outlines essential tasks to keep your unit in peak condition.

Begin with Inspection: Start by visually examining your equipment for any signs of wear or damage. Look for loose connections, cracks, or corrosion. Addressing minor issues early can prevent more significant problems later.

Fluid Levels: Check all fluid levels, including oil, fuel, and coolant. Maintain appropriate levels as specified in your documentation. Replenishing fluids as needed is vital for proper operation.

Air Filter Maintenance: Inspect and clean or replace the air filter regularly. A clean filter ensures adequate airflow to the engine, promoting efficient combustion and performance.

Spark Plug Care: Examine the spark plug for signs of wear or buildup. Clean or replace it as necessary to ensure reliable ignition and smooth operation.

Blades and Belts: For equipment with blades or belts, inspect for wear and tear. Sharpen or replace blades to maintain cutting efficiency, and ensure belts are properly tensioned to avoid slippage.

Cleaning: Regularly clean the exterior of your unit to remove dirt and debris. This not only enhances appearance but also prevents the buildup of harmful materials that could impact performance.

Final Check: After performing these tasks, do a final inspection. Ensure all components are securely attached, and start the engine to listen for any unusual sounds. Address any concerns immediately to maintain optimal functionality.

Engine Troubleshooting Techniques

Identifying and resolving issues within an engine requires a systematic approach. By employing effective diagnostic methods, one can systematically uncover underlying problems, ensuring optimal performance and longevity. Understanding the symptoms and the possible causes is crucial in this process, enabling technicians to apply the right solutions.

Common Symptoms and Their Causes

Engines may exhibit various signs of distress, such as unusual noises, reduced power, or difficulty starting. Noises can indicate mechanical wear or misalignment, while poor power output may stem from fuel delivery issues or air filter blockages. Recognizing these symptoms early can prevent further damage and costly repairs.

Diagnostic Tools and Techniques

Utilizing diagnostic equipment is essential for effective troubleshooting. Tools such as multimeters, compression testers, and scan tools help gather vital data about engine performance. Additionally, conducting visual inspections can reveal leaks, worn components, or loose connections that may be contributing to the problem. Combining these techniques enables a comprehensive assessment and facilitates timely interventions.

Replacing Spark Plugs Effectively

Changing the ignition components in your engine is crucial for maintaining optimal performance. This process ensures that your machine runs smoothly and efficiently, improving fuel combustion and reducing emissions. Regular replacement of these components can prevent issues that lead to costly repairs.

Tools and Preparation

Before starting, gather the necessary tools to make the process efficient. You’ll need a spark plug socket, a ratchet, a torque wrench, and possibly a gap gauge. It’s also essential to refer to the manufacturer’s specifications for the correct type of plugs and gap settings.

Step-by-Step Process

Follow these steps for effective replacement:

| Step | Action |

|---|---|

| 1 | Ensure the engine is cool and disconnect the battery to prevent electrical shocks. |

| 2 | Remove the ignition coil or wire connected to the spark plug carefully. |

| 3 | Use the spark plug socket to unscrew the old plug from the engine. |

| 4 | Inspect the old plug for wear and compare it with the new one. |

| 5 | Install the new spark plug by hand to avoid cross-threading, then tighten it to the specified torque using a wrench. |

| 6 | Reconnect the ignition wire or coil and ensure everything is secured. |

Regular maintenance of these components not only enhances the efficiency of your engine but also prolongs its lifespan. Keep track of replacement intervals to ensure your equipment runs at its best.

Oil Change Process Explained

Regular maintenance of your engine includes an essential task: changing the lubricant. This procedure not only helps in extending the lifespan of the engine but also ensures optimal performance. Understanding the steps involved in this process is crucial for every operator.

Before starting, gather the necessary tools and materials:

- New lubricant

- Oil filter

- Wrench set

- Drain pan

- Funnel

- Shop rags

Follow these steps to successfully complete the task:

- Prepare the engine by running it for a few minutes to warm the lubricant, which helps it drain out smoothly.

- Turn off the engine and ensure it is cool enough to handle. Place the drain pan under the oil pan.

- Remove the drain plug and allow the old lubricant to fully drain into the pan.

- Replace the drain plug securely once all the old lubricant is removed.

- Remove the old filter using a wrench, then install the new filter according to the manufacturer’s instructions.

- Using a funnel, pour the new lubricant into the engine through the fill cap, ensuring you use the correct type and quantity.

- Start the engine and let it run for a few minutes. Check for leaks around the filter and drain plug.

- Turn off the engine and check the lubricant level using the dipstick, adding more if necessary.

Completing this procedure regularly will keep your engine running smoothly and efficiently. Make sure to dispose of the old lubricant and filter responsibly, following local regulations.

Fuel System Cleaning Procedures

Maintaining the cleanliness of the fuel system is essential for optimal engine performance. Regular cleaning helps prevent the buildup of deposits that can hinder fuel flow and reduce efficiency. This process involves several key steps to ensure that the components are free from contaminants and functioning properly.

Preparation for Cleaning

Before starting the cleaning process, it is crucial to gather all necessary tools and materials. This includes cleaning solutions specifically designed for fuel systems, brushes, and protective gear. Ensure that the work area is well-ventilated and that safety precautions are taken to handle any chemicals involved.

Step-by-Step Cleaning Process

Begin by disconnecting the fuel lines and removing any filters to access the system thoroughly. Apply the cleaning solution to the components, allowing it to soak for the recommended time to break down any stubborn deposits. Use brushes to scrub areas with heavy buildup, ensuring all surfaces are cleaned. Afterward, rinse thoroughly with clean fuel or a suitable solvent, then reassemble the system following the manufacturer’s specifications. Regular inspections and cleanings will prolong the life of the engine and enhance its performance.

Electrical System Diagnostics

Understanding the functionality of the electrical components within a machine is crucial for efficient operation. This section focuses on techniques to assess and troubleshoot the electrical framework, ensuring optimal performance and reliability. Proper diagnostics can prevent potential failures and prolong the lifespan of the equipment.

Begin by examining the battery condition and connections. A weak battery can lead to starting issues or intermittent performance. Use a multimeter to measure voltage levels, ensuring they align with the specified range. Check for corrosion on terminals and clean as necessary to maintain a solid connection.

Next, evaluate the ignition system. Inspect spark plugs and ignition coils for signs of wear or damage. Testing for spark can reveal if the ignition system is functioning correctly. If a weak or absent spark is detected, further investigation into wiring and components may be required.

Finally, analyze the wiring harness and connectors. Look for frayed wires, loose connections, or signs of electrical shorts. Utilize a wiring diagram for reference, ensuring each component is properly connected. Addressing any anomalies can enhance the overall efficiency and reliability of the machine’s electrical system.

Blade and Deck Maintenance Tips

Regular upkeep of cutting components and the underlying platform is essential for optimal performance and longevity of your lawn equipment. Proper attention to these areas not only ensures a clean cut but also enhances the efficiency of the machine, leading to a healthier lawn and reduced operational costs.

Cleaning and Inspection

After each use, it is advisable to remove any grass clippings, dirt, or debris from both the blade and deck. This helps prevent rust and buildup that can hinder performance. Inspect the blade for any signs of damage or wear, such as nicks or dullness. Sharpening the blade regularly maintains its cutting edge, while replacing it promptly when needed keeps your equipment running smoothly.

Deck Leveling and Alignment

Ensuring that the deck is level is crucial for achieving an even cut. Adjustments can be made to maintain proper height settings according to your lawn’s specific requirements. Additionally, check the alignment of the blade; misalignment can lead to uneven cutting and increased strain on the engine. Regular adjustments can significantly extend the lifespan of your equipment and improve its cutting performance.

Preventive Care and Best Practices

Regular maintenance is essential to ensure optimal performance and longevity of your equipment. Implementing a proactive approach helps to identify potential issues before they escalate, thereby reducing the likelihood of costly repairs and downtime.

Following a structured routine and adopting recommended practices can enhance efficiency and reliability. Below are key considerations for maintaining your machinery effectively:

| Task | Frequency | Notes |

|---|---|---|

| Oil Change | Every 50 hours | Use the recommended oil type for best performance. |

| Air Filter Inspection | Every 25 hours | Replace if dirty or damaged to ensure proper airflow. |

| Spark Plug Check | Every 100 hours | Clean or replace as necessary to ensure reliable starting. |

| Fuel System Maintenance | Every 30 hours | Inspect for leaks and ensure fuel is fresh. |

| Battery Maintenance | Monthly | Check connections and clean terminals. |

By adhering to these guidelines, you can ensure that your equipment remains in peak condition, minimizing the risk of unexpected failures and enhancing overall performance.

Where to Find Replacement Parts

Locating suitable components for maintenance or upgrades can be straightforward if you know where to look. Various resources are available for sourcing high-quality substitutes that meet your needs, whether for routine servicing or specific repairs.

Here are some reliable avenues to explore:

| Source | Description |

|---|---|

| Authorized Dealers | Visit certified retailers who specialize in parts for specific equipment. They often carry genuine components that ensure compatibility and reliability. |

| Online Marketplaces | Websites dedicated to parts sales provide a vast selection of options. Be sure to check customer reviews to verify the credibility of the sellers. |

| Manufacturer’s Website | Many manufacturers offer an online catalog where you can find original parts directly. This is often the best way to guarantee authenticity. |

| Local Hardware Stores | Check with nearby suppliers who may stock a variety of components, especially common items used in regular maintenance. |

| Forums and Online Communities | Join discussion groups or forums related to your equipment. Fellow users often share tips on where to find parts and may even offer links to reputable sources. |