Understanding the key aspects of keeping essential machinery in optimal working condition is vital for both performance and longevity. Regular upkeep helps prevent unexpected issues, ensuring continuous and reliable use. By following structured guidance, users can confidently address a range of operational needs, from daily upkeep to addressing more complex situations.

In this resource, you’ll find step-by-step insights for proper handling, from essential parts identification to functional tips that enhance productivity. Learning about the unique requirements of this equipment will not only extend its useful life but also improve efficiency during use. Each section is crafted to provide practical solutions, ensuring you can approach any maintenance task with clarity.

Following these recommendations and adapting them to specific situations allows users to prevent common issues, maintain high performance, and extend service life. With this complete guide, you’ll gain the knowledge and confidence to ensure equipment remains dependable and ready for every task.

Generac GP6500 Repair Manual Overview

This guide provides essential insights for understanding and maintaining a reliable power unit designed for a variety of energy needs. It covers the foundational aspects necessary for ensuring consistent operation and troubleshooting minor issues.

- Key Components Explanation: A detailed breakdown of critical parts, including the engine, fuel system, and control panel, is provided for easy identification and understanding.

- Startup and Shutdown Instructions: Step-by-step processes for safely beginning and ending use, helping to prevent common errors and extend equipment longevity.

- Regular Upkeep: An outline of routine checks and cleaning methods aimed at optimizing performance and identifying wear early.

- Troubleshooting Steps: Practical advice for resolving frequent issues, from basic adjustments to preventive measures, with minimal technical expertise required.

- Storage and Safety Tips: Guidance on proper storage practices to maintain functionality during long periods of inactivity, as well as safe handling instructions.

Each section of this guide equips users with the knowledge required for independent oversight, offering peace of mind through preventive care and simple solutions for maintaining reliable operation.

Basic Maintenance for Generating Equipment

To ensure reliable operation, regular upkeep of power equipment is essential. Routine maintenance not only extends the lifespan but also optimizes performance, preventing unexpected issues.

- Inspecting Components: Periodically check all visible parts for any signs of wear or damage. This includes cables, hoses, and connections to prevent issues from developing.

- Oil Replacement: Change the engine oil at recommended intervals to keep it running smoothly. Regular oil changes help avoid overheating and extend the life of the motor.

- Filter Cleaning: Clean or replace air filters to ensure optimal airflow. A clean filter prevents dust and debris from reaching the engine, maintaining efficiency.

- Fuel System Care: Drain any old fuel and replace it with fresh fuel if the equipment has been stored for a long period. This helps avoid clogging and ensures smooth startup.

- Battery Check: If the device includes a battery, inspect it regularly for charge level and connections. Ensure it’s securely in place and free of corrosion.

By following these steps, you can help your equipment operate reliably and efficiently, reducing the likelihood of costly repairs over time.

Starting System Troubleshooting Guide

In this section, we’ll explore common issues that can prevent an engine from starting, providing solutions to diagnose and resolve these problems effectively. This guide covers essential checks to ensure a reliable ignition process and avoid disruptions during use.

Inspecting the Battery and Connections

One of the first places to examine is the battery and its connections. Proper voltage and secure contacts are crucial for a stable starting system. Use the following steps to check the battery:

- Ensure the battery terminals are clean and free from corrosion.

- Verify that all connections are tight and secure.

- Use a multimeter to measure the battery voltage, ensuring it meets the necessary starting requirements.

Checking the Starter Motor and Solenoid

If the battery is functioning but the engine remains unresponsive, the starter motor or solenoid may require attention. Follow these steps to inspect these components:

- Listen for a clicking sound when attempting to start; a continuous click can indicate a weak solenoid.

- Test the starter motor by connecting it directly to a power source. A lack of response suggests a replacement might be necessary.

- Inspect wiring connections to the starter, ensuring they are intact and free from damage.

By systematically checking these starting components, you can identify and resolve common issues efficiently, enhancing the reliability of the ignition system and minimizing downtime.

Inspecting the Fuel System Components

Ensuring the fuel system is in optimal condition is essential for efficient equipment performance. Regular inspections can help identify potential issues early, improving both safety and longevity.

Fuel Tank Examination

Begin by visually assessing the fuel tank for signs of wear, such as rust, dents, or cracks. Ensure there are no fuel leaks by checking around the seams and connections. Internal residue or dirt in the tank can clog the fuel lines, so periodic cleaning is recommended to keep the system free of contaminants.

Fuel Line and Filter Check

Inspect the fuel lines for flexibility and integrity. Look for signs of damage like cracks or hardening, which can affect fuel flow. Replace any worn sections as needed. Don’t overlook the fuel filter; a clogged filter can restrict fuel supply, leading to operational issues. Clean or change the filter regularly to maintain a smooth flow of fuel.

Essential Safety Tips for Repairs

When performing maintenance on complex equipment, taking the right safety measures is crucial to prevent hazards. Observing best practices and understanding potential risks can significantly enhance both personal safety and the equipment’s longevity.

- Disconnect Power Sources: Always ensure that power sources are fully disconnected before starting any task. This step reduces the risk of accidental shocks or other electrical hazards.

- Use Appropriate Tools: Rely on tools specifically designed for the task to avoid damage and ensure safe handling. Improper tools can lead to unexpected incidents and make repairs more difficult.

- Wear Protective Gear: Equip yourself with protective gloves, eyewear, and other gear as needed. This precaution helps shield you from potential harm during maintenance.

- Inspect for Potential Leaks: Carefully examine for any fluid or gas leaks before working on any part. Leaks can present serious hazards, especially in areas where combustible materials may be involved.

- Keep the Work Area Clear: Maintain a clean and organized workspace to avoid accidents and keep essential tools within easy reach.

- Follow Manufacturer Guidelines: Adhere closely to any maintenance instructions provided for your equipment. Guidelines are crafted to enhance safety and prolong functionality.

By following these precautions, you can foster a safe and efficient environment, reducing potential risks associated with complex maintenance tasks.

Step-by-Step Engine Diagnostics

Diagnosing engine issues is crucial for ensuring optimal performance and longevity. This process involves a systematic approach to identify and resolve any underlying problems. By following a structured method, users can effectively troubleshoot common symptoms and restore functionality.

Begin with the following steps:

- Visual Inspection:

- Check for any visible signs of damage, leaks, or wear.

- Inspect belts and hoses for cracks or fraying.

- Check Fuel Supply:

- Ensure there is sufficient fuel in the tank.

- Examine fuel lines for blockages or leaks.

- Assess Electrical Components:

- Inspect battery connections for corrosion or looseness.

- Test the ignition system, including spark plugs and wires.

- Examine Engine Compression:

- Use a compression gauge to check cylinder pressure.

- Identify discrepancies in readings between cylinders.

- Run Diagnostic Tests:

- Utilize diagnostic tools to read error codes.

- Analyze data to pinpoint issues related to sensors and systems.

By adhering to these steps, users can systematically diagnose engine problems and implement the necessary solutions to ensure proper operation.

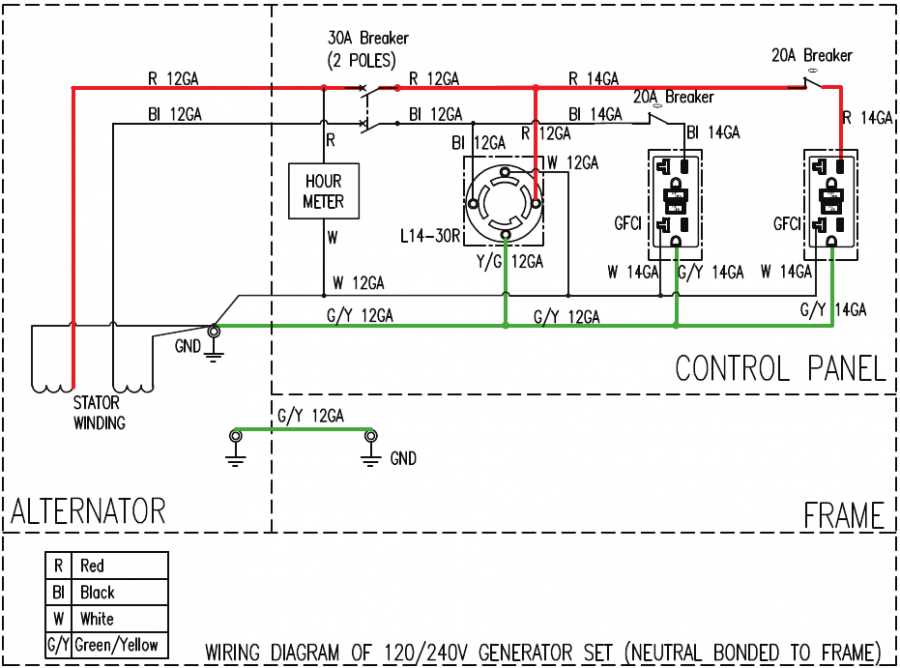

Electrical System Repair Techniques

The functionality of an electrical system is critical for optimal performance and safety. Understanding the underlying principles and common issues can greatly enhance the efficiency of maintenance tasks. This section outlines effective methods for troubleshooting and fixing electrical components.

Initial Diagnostics are essential for identifying faults within the system. Begin by inspecting connections, looking for loose wires or corrosion that may disrupt the flow of electricity. A multimeter can be utilized to measure voltage and continuity, helping to pinpoint problematic areas.

Component Replacement may be necessary when certain parts are found to be defective. It’s important to select compatible components to ensure seamless integration into the existing system. Always refer to the specifications provided by the manufacturer to avoid compatibility issues.

Regular Maintenance plays a key role in prolonging the lifespan of electrical systems. Schedule periodic inspections to check for wear and tear, ensuring that all connections remain secure and free of damage. Preventative measures can save time and resources in the long run.

By implementing these techniques, users can effectively address and resolve electrical issues, ensuring reliable operation and safety of the overall system.

Replacing Filters and Essential Parts

Regular maintenance of your equipment is crucial for optimal performance and longevity. One of the key aspects of this upkeep involves the timely replacement of filters and critical components. Ensuring these parts are in good condition can prevent operational issues and enhance efficiency.

Types of Filters to Replace

- Air Filters: These should be checked regularly for dirt and debris. A clean air filter ensures proper airflow and can prevent engine overheating.

- Fuel Filters: Replacing the fuel filter helps maintain fuel quality and ensures that the engine receives clean fuel for optimal combustion.

- Oil Filters: Regularly changing the oil filter is essential for keeping the engine lubricated and running smoothly.

Steps for Replacing Parts

- Gather the necessary tools and replacement parts.

- Shut down the unit and disconnect it from the power source.

- Carefully remove the old filter or part, taking note of how it was installed.

- Install the new filter or component, ensuring it is secured properly.

- Reconnect the unit to the power source and perform a test run to verify proper functionality.

Regularly checking and replacing these components not only enhances performance but also extends the lifespan of the equipment. Make this maintenance a priority to ensure reliable operation.

Handling Generator Overload Issues

Generator overload occurs when the electrical demand exceeds the unit’s capacity, leading to performance problems and potential damage. Recognizing the signs of excessive load is crucial for maintaining optimal functionality and extending the lifespan of your equipment.

To address overload situations effectively, first identify the devices connected to the generator. Ensure that the total wattage of all appliances does not surpass the generator’s rated output. If necessary, prioritize the use of essential equipment and disconnect non-critical devices to alleviate the load.

Regular maintenance is vital in preventing overload scenarios. Inspect the generator for any signs of wear or malfunction, and ensure that it is running at peak efficiency. Additionally, consider using power management techniques, such as staggered start-up times for heavy equipment, to distribute the electrical load evenly.

Should an overload occur, it is essential to turn off all connected devices and allow the generator to cool down. Resetting the unit after resolving the issue will help restore normal operation. Implementing these strategies can significantly reduce the risk of generator overload and enhance overall performance.

Cold Weather Operating Tips

When temperatures drop, operating equipment efficiently requires special considerations to ensure optimal performance and longevity. Cold weather can affect both the fuel and the mechanical components, leading to potential issues if proper precautions are not taken. Below are some essential guidelines to follow during winter months.

Pre-Start Checks

Before starting any machinery in cold conditions, it’s crucial to conduct thorough pre-start checks. This includes examining fluid levels, ensuring the battery is fully charged, and checking for any signs of damage or wear. Proper maintenance can prevent failures during operation.

Fuel Considerations

Using appropriate fuel is vital for reliable performance in chilly environments. Consider switching to winter-grade fuel, which is formulated to resist gelling in low temperatures. Additionally, using fuel additives designed for cold weather can help improve flow and efficiency.

| Tip | Description |

|---|---|

| Warm-Up Time | Allow the engine to warm up for a few minutes before full operation to ensure proper lubrication. |

| Battery Maintenance | Keep the battery fully charged, as cold temperatures can reduce battery capacity significantly. |

| Regular Inspections | Check for fuel leaks and inspect hoses and belts for any signs of brittleness or damage due to cold. |

| Operating Hours | Limit prolonged usage in extremely low temperatures to prevent overheating and mechanical strain. |

Battery Care and Replacement

Proper maintenance and timely replacement of the power source are essential for ensuring optimal performance and longevity of your equipment. A well-cared battery can significantly enhance the reliability and efficiency of your device, preventing unexpected failures during critical operations.

Maintenance Tips

Regular checks on the battery’s fluid levels, connections, and overall condition are crucial. Keep the terminals clean and free from corrosion to promote efficient electrical flow. It’s advisable to charge the battery fully before extended periods of non-use to prevent deep discharge, which can damage the cells.

Replacement Guidelines

When it’s time to replace the power source, choose a compatible model that meets the specifications of your device. Ensure the replacement unit is properly installed, with secure connections and appropriate settings for charging. Dispose of the old battery responsibly, following local regulations for hazardous materials.

Professional Support and Service Options

Accessing expert assistance and service alternatives is essential for maintaining the efficiency and longevity of your power generation equipment. Understanding the available support avenues can significantly enhance your experience, ensuring that your device operates optimally and meets your specific needs.

Expert Consultation Services

Engaging with professionals who specialize in equipment maintenance can provide valuable insights and solutions. These consultants offer tailored advice based on the unique characteristics of your generator, helping to identify potential issues before they escalate. Utilizing such services can lead to more informed decisions regarding care and upkeep.

Authorized Service Centers

Utilizing certified service locations guarantees that your equipment is in capable hands. Technicians at these centers possess in-depth knowledge and access to original components, ensuring repairs are carried out to the highest standards. Regular maintenance through authorized providers not only prolongs the life of your unit but also enhances performance and reliability.