In the world of coffee brewing, ensuring the optimal performance of your equipment is essential for achieving that perfect cup. Understanding the intricacies of your brewing apparatus can significantly enhance your experience, allowing for consistent results and the prevention of common issues.

Within this comprehensive guide, we will delve into essential techniques for maintaining your beloved beverage preparer. You will discover practical advice on identifying malfunctions, along with step-by-step procedures that will empower you to tackle challenges effectively.

Whether you’re a seasoned barista or an enthusiastic home user, having access to reliable information can make all the difference. Equip yourself with the knowledge needed to keep your device functioning at its best, ensuring that every brew is as delightful as the last.

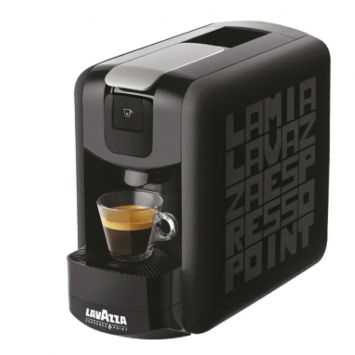

Understanding Lavazza Espresso Point Machines

This section aims to provide a comprehensive overview of a popular brewing system designed for high-quality coffee beverages. These devices are engineered to deliver consistency and convenience, making them a favored choice in various settings, from small cafes to large offices. Recognizing their key features and operational principles can significantly enhance user experience.

Key Features of the System

The brewing apparatus is equipped with several essential elements that contribute to its efficiency and effectiveness. Understanding these features will aid users in maximizing their investment.

| Feature | Description |

|---|---|

| Compact Design | Space-saving layout suitable for various environments. |

| Consistency | Delivers uniform results with every brew cycle. |

| Ease of Use | Simple interface allowing for quick operation. |

| Quality Control | Incorporates systems for optimal flavor extraction. |

Operational Principles

Understanding the workings of this brewing equipment is crucial for ensuring its longevity and performance. Familiarity with its operational principles allows users to troubleshoot common issues and maintain optimal functionality.

Common Issues with Espresso Machines

When it comes to brewing a perfect cup of coffee, various challenges can arise that affect performance and quality. Understanding these common problems can help users troubleshoot effectively and ensure a delightful coffee experience. Below are some frequent issues encountered with these brewing devices.

1. Inconsistent Brew Quality

One of the most frustrating challenges is the inconsistency in the flavor and strength of the coffee. This can stem from various factors, such as grind size, water temperature, or even the freshness of the coffee beans. Ensuring that each variable is monitored and adjusted can help achieve a more uniform result.

2. Leakage and Water Flow Issues

Another common problem is unexpected water leakage, which can disrupt the brewing process. This may be caused by worn seals, clogs in the water lines, or improper assembly. Regular maintenance and cleaning can often mitigate these issues, ensuring smooth operation.

Essential Tools for Repairs

Having the right equipment at hand is crucial for addressing issues effectively and ensuring longevity. Various instruments cater to different aspects of maintenance, making the process smoother and more efficient. Below is a compilation of indispensable items that can aid in troubleshooting and resolving complications.

1. Screwdrivers: A set of both flat-head and Phillips screwdrivers is vital. These tools allow for easy access to internal components, facilitating necessary adjustments or replacements.

2. Pliers: Needle-nose and standard pliers help grasp and manipulate small parts, which is often essential for tasks requiring precision.

3. Wrenches: Adjustable wrenches and socket sets are important for loosening or tightening nuts and bolts that secure various elements in place.

4. Multimeter: This device is essential for diagnosing electrical issues, measuring voltage, and ensuring components are functioning correctly.

5. Cleaning Supplies: Brushes, cloths, and appropriate solvents are necessary for maintaining hygiene and preventing the buildup of residues that can affect performance.

6. Safety Gear: Protective eyewear and gloves ensure safety while handling equipment, especially when working with sharp or potentially hazardous components.

Equipping oneself with these essential tools not only simplifies the process but also enhances the overall effectiveness of maintenance efforts.

Step-by-Step Troubleshooting Guide

This section provides a systematic approach to identifying and resolving common issues that may arise with your beverage preparation device. By following these steps, you can effectively diagnose problems and implement solutions to ensure optimal performance.

Identifying Common Issues

Begin by observing any irregularities during operation. Note any unusual sounds, error messages, or changes in beverage quality. This initial assessment is crucial for narrowing down potential causes and determining whether the issue is mechanical, electrical, or related to user input.

Systematic Troubleshooting Steps

Once you have identified the symptoms, proceed with the following steps: check power connections, inspect for blockages in water pathways, and assess the condition of essential components like the brewing unit and heating element. Refer to specific indicators, such as blinking lights or display messages, to guide your next actions. After addressing the immediate concerns, perform a test cycle to confirm that the problems have been resolved.

Replacing Key Components Safely

When it comes to maintaining equipment, ensuring the secure and correct replacement of essential parts is crucial. This process not only prolongs the lifespan of the device but also guarantees optimal performance. Understanding the necessary precautions and steps to follow can significantly reduce the risk of accidents and damage during this task.

Preparation Before Replacement

Before starting, it’s important to disconnect the power supply to the apparatus. Gather all necessary tools and replacement components in advance to streamline the process. Always consult the manufacturer’s guidelines to identify specific parts that may need attention, and familiarize yourself with the assembly of the unit to avoid confusion during the swap.

Step-by-Step Replacement Process

Begin by carefully removing the outer casing, taking note of any screws or clips that may be holding it in place. Once you have access to the internal components, proceed to detach the old part gently, ensuring not to damage surrounding areas. Install the new component, making sure it fits securely and is properly aligned. Finally, reassemble the unit with the casing and restore the power supply, performing a test to confirm that everything is functioning as expected.

Cleaning and Maintenance Tips

Regular upkeep is essential for ensuring optimal performance and longevity of your beverage preparation apparatus. Proper care not only enhances the taste of your drinks but also minimizes the likelihood of malfunctions. This section offers valuable suggestions for maintaining your equipment effectively.

Daily Cleaning Routine

Establishing a daily cleaning regimen is crucial. Start by removing any leftover grounds and rinsing the brewing unit. Wipe down the exterior surfaces with a damp cloth to eliminate dust and residues. It’s also beneficial to run a cleaning cycle with water to flush out any remnants inside the system. Regular attention to these details prevents buildup and promotes hygiene.

Periodic Maintenance Tasks

In addition to daily tasks, set aside time for more in-depth maintenance. Every month, inspect the water reservoir for mineral deposits and clean it thoroughly. Descaling every three to six months is recommended to prevent scaling issues. Check seals and gaskets for wear and replace them if necessary to maintain proper functionality. Keeping an eye on these components ensures the apparatus continues to operate smoothly.

Electrical Problems and Solutions

In the realm of coffee brewing devices, electrical issues can significantly impact performance and user experience. Understanding common faults and their resolutions is crucial for maintaining optimal functionality.

Common Electrical Issues

Devices may encounter various electrical anomalies, such as power failures, where the unit fails to turn on, or intermittent shutdowns, which can disrupt brewing cycles. Additionally, faulty wiring may lead to inconsistent heating or functionality, posing risks to both the equipment and user safety.

Troubleshooting Steps

To address these challenges, begin by checking the power source for any interruptions. Inspect cords and connections for signs of damage. If issues persist, consider testing internal components like the fuse or circuit board. Properly identifying the problem can facilitate effective repairs, ensuring a seamless coffee experience.

Steam Wand Repairs Explained

In any setup involving hot beverages, the functionality of the steaming apparatus is crucial for achieving the perfect texture and temperature. Over time, these components may encounter issues that hinder their performance, necessitating a thorough understanding of the potential problems and solutions. This section delves into common malfunctions, offering insights into diagnostics and fixes to restore optimal operation.

Identifying Common Issues

Steam wands can face several challenges, including inconsistent steam output, blockages, or leaks. The first step in addressing these concerns is to observe the performance during operation. Noticing irregularities such as sputtering or weak steam can indicate specific underlying problems that require attention.

Clearing Blockages

One of the most frequent issues involves clogs caused by milk residue or mineral buildup. Regular cleaning can prevent these blockages. If a blockage is suspected, dismantling the wand for a thorough cleaning with a suitable solution can restore function. A soft brush may also help in removing stubborn debris.

Fixing Leaks

Leaks can stem from worn seals or loose connections. Inspecting the fittings for any signs of wear and tightening connections can often resolve minor leaks. In cases where seals are compromised, replacing them is essential for maintaining proper steam pressure and functionality.

Testing After Maintenance

Once any adjustments or cleanings have been made, it is important to test the steam output. A successful fix should result in a consistent and powerful steam flow, indicating that the apparatus is back to optimal performance. Regular maintenance checks can help prolong the life of this critical component.

Descaling Procedures for Optimal Performance

Regular maintenance is crucial for ensuring the longevity and efficiency of your brewing apparatus. One of the most significant aspects of upkeep is the descaling process, which removes mineral buildup and helps maintain optimal functionality. By following a systematic approach to descaling, you can enhance the quality of your beverages and prolong the lifespan of your equipment.

The descaling procedure should be performed periodically, depending on the hardness of your water and the frequency of use. Here’s a straightforward guide to help you through the process:

- Gather Necessary Supplies:

- Descaling solution recommended for your device

- Fresh water

- Container for collecting the liquid

- Prepare the Solution:

Mix the descaling agent with water as per the manufacturer’s instructions. Ensure the solution is well combined before use.

- Fill the Reservoir:

Pour the prepared solution into the water reservoir of your apparatus. Make sure not to exceed the maximum fill line.

- Run the Descaling Cycle:

Activate the descaling mode if available. If not, run a brew cycle without coffee, allowing the solution to flow through the system.

- Rinse Thoroughly:

After the descaling process, empty the reservoir and refill it with clean water. Run multiple cycles with fresh water to remove any residual descaling agent.

- Final Check:

Inspect the equipment for any remaining mineral deposits. If necessary, repeat the process to ensure complete removal.

Implementing these steps regularly will not only improve the performance of your apparatus but also enhance the flavor profile of your beverages. Adhering to a consistent descaling routine is key to achieving the best results.

Understanding Machine Error Codes

Deciphering error messages displayed on your brewing equipment is crucial for maintaining optimal performance. These codes serve as indicators of potential issues that require attention. Recognizing and addressing these alerts can prevent further complications and ensure a seamless coffee-making experience.

Common Error Indicators

Error messages can vary in meaning, but understanding the most frequent codes can help users troubleshoot effectively. Here are some common indicators:

| Error Code | Description | Recommended Action |

|---|---|---|

| E1 | Water reservoir is empty. | Refill the water tank. |

| E2 | Temperature issue detected. | Allow the unit to cool down, then restart. |

| E3 | Blocked brew path. | Clean the brew group and check for obstructions. |

| E4 | Faulty electrical connection. | Inspect power supply and connections. |

Interpreting Error Messages

Each error code provides specific guidance on the underlying problem. Users should document these occurrences for reference, as recurring issues may indicate a deeper malfunction that could necessitate professional servicing. Understanding these signals is essential for ensuring the longevity and efficiency of your brewing equipment.

When to Seek Professional Help

Understanding when to consult an expert is crucial for maintaining the longevity and efficiency of your equipment. Certain signs indicate that the problem may be beyond basic troubleshooting and requires specialized knowledge and skills.

| Indicator | Description |

|---|---|

| Persistent Malfunctions | If issues continue after following standard solutions, it’s time to seek assistance. |

| Unusual Noises | Strange sounds during operation may signal internal problems that need expert attention. |

| Leaking Fluid | Visible leaks can lead to more significant damage and should be addressed by a professional. |

| Electrical Problems | Flickering lights or failure to power on suggests electrical issues best handled by a specialist. |

| Loss of Performance | A noticeable decline in functionality often indicates the need for professional intervention. |

Addressing these signs promptly can prevent further complications and ensure optimal performance. Relying on professionals guarantees that your equipment receives the appropriate care it needs.

Resources for Further Assistance

If you encounter issues with your coffee brewing device, numerous resources are available to help you troubleshoot and resolve any problems. Whether you’re looking for online guides, community forums, or professional support, these tools can provide valuable insights and solutions tailored to your specific needs.

Here are some recommended sources for obtaining assistance:

| Resource Type | Description | Link |

|---|---|---|

| Official Website | The manufacturer’s official site often contains FAQs, troubleshooting tips, and downloadable documents. | Visit Site |

| User Forums | Online communities where users share experiences, solutions, and advice related to their brewing devices. | Join Forum |

| Video Tutorials | Visual guides on platforms like YouTube provide step-by-step instructions for common issues. | Watch Tutorials |

| Customer Support | Contact the support team directly for personalized assistance or to inquire about service options. | Get Support |